Infant diaper and preparation method thereof

A technology for diapers and infants, applied in the field of hygiene care products, can solve problems such as ineffective skin protection, toxins in urine, poor air permeability, etc., to achieve the effect of rejecting bacterial pollution, inhibiting bacteria, and keeping dry and comfortable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

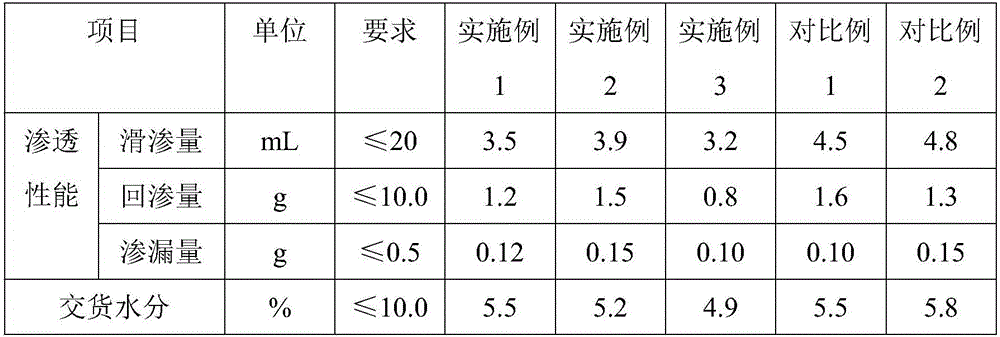

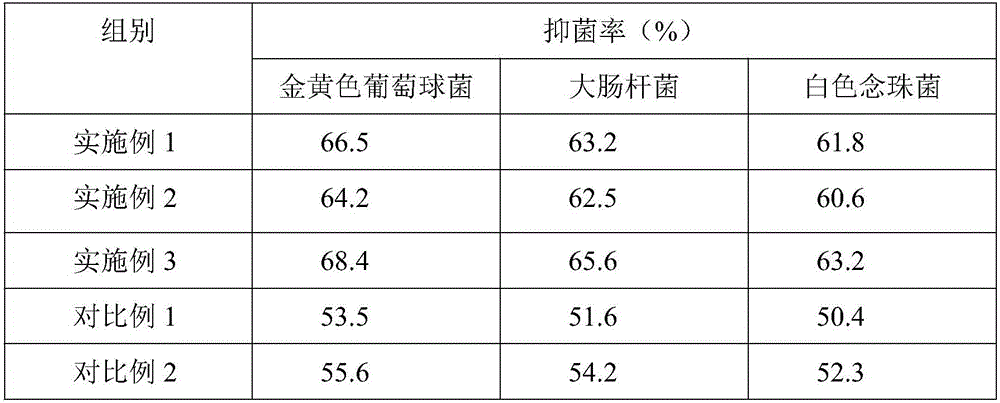

Examples

Embodiment 1

[0039] Embodiment 1, a kind of baby diaper

[0040] The baby diapers include a diaper body, and the diaper body is respectively provided with a surface layer, a diversion layer, an absorbent core layer and a back layer from top to bottom, and the surface layer is made of moxa, Lyocell fiber and ES fiber ; The diversion layer is obtained by reinforcing ES fibers with a thickness of 6D through hot air; the absorbent core layer includes composite fibers, superabsorbent resin and fluff pulp, and the weight ratio of the composite fibers, superabsorbent resin and fluff pulp is 3:10:13; the back layer is a breathable microporous film.

[0041] The composite fiber is made of the following raw materials in weight ratio: carboxymethyl chitosan 3, aloe polysaccharide 0.1, tea polyphenol 0.05 and water 55.

[0042] The preparation method of described composite fiber is:

[0043] (1) Get carboxymethyl chitosan, add water, stir until completely dissolving, put into vacuum oven for defoami...

Embodiment 2

[0052] Embodiment 2, a kind of baby diaper

[0053] The baby diapers include a diaper body, and the diaper body is respectively provided with a surface layer, a diversion layer, an absorbent core layer and a back layer from top to bottom, and the surface layer is made of moxa, Lyocell fiber and ES fiber ; The diversion layer is obtained by reinforcing ES fibers with a thickness of 6D through hot air; the absorbent core layer includes composite fibers, superabsorbent resin and fluff pulp, and the weight ratio of the composite fibers, superabsorbent resin and fluff pulp is 5:6:8; the back layer is a breathable microporous film.

[0054] The composite fiber is made of the following raw materials in weight ratio: carboxymethyl chitosan 5, aloe polysaccharide 0.2, tea polyphenol 0.08 and water 70.

[0055] The preparation method of described composite fiber is:

[0056] (1) Get carboxymethyl chitosan, add water, stir until completely dissolving, put into vacuum oven for defoaming...

Embodiment 3

[0065] Embodiment 3, a kind of baby diaper

[0066] The baby diapers include a diaper body, and the diaper body is respectively provided with a surface layer, a diversion layer, an absorbent core layer and a back layer from top to bottom, and the surface layer is made of moxa, Lyocell fiber and ES fiber ; The diversion layer is obtained by reinforcing ES fibers with a thickness of 6D through hot air; the absorbent core layer includes composite fibers, superabsorbent resin and fluff pulp, and the weight ratio of the composite fibers, superabsorbent resin and fluff pulp is 4:8:11; the back layer is a breathable microporous film.

[0067] The composite fiber is made of the following raw materials in weight ratio: carboxymethyl chitosan 4, aloe polysaccharide 0.15, tea polyphenol 0.06 and water 60.

[0068] The preparation method of described composite fiber is:

[0069] (1) Get carboxymethyl chitosan, add water, stir until completely dissolving, put into vacuum oven for defoami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com