Working process of retractable and foldable buried garbage storage

A technology of workflow and garbage storage, which is applied in the field of workflow of compressible and foldable underground garbage storage, which can solve the problems of increased difficulty in collection, transportation and sorting, increased safety hazards, and increased costs, so as to reduce repeated cleaning of garbage The workload, the reduction of heavy physical labor, and the effect of reducing the cost of land use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in combination with specific embodiments.

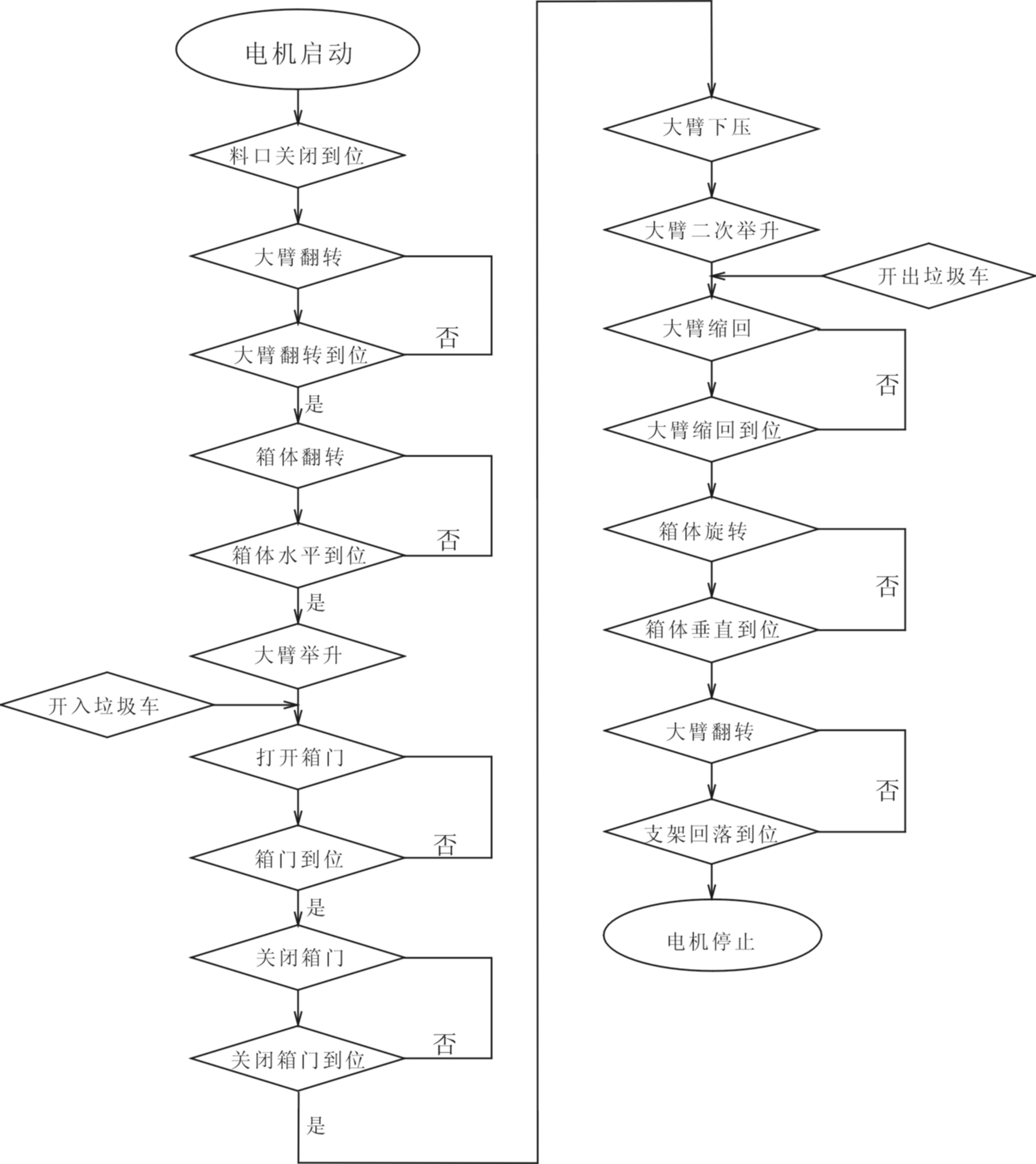

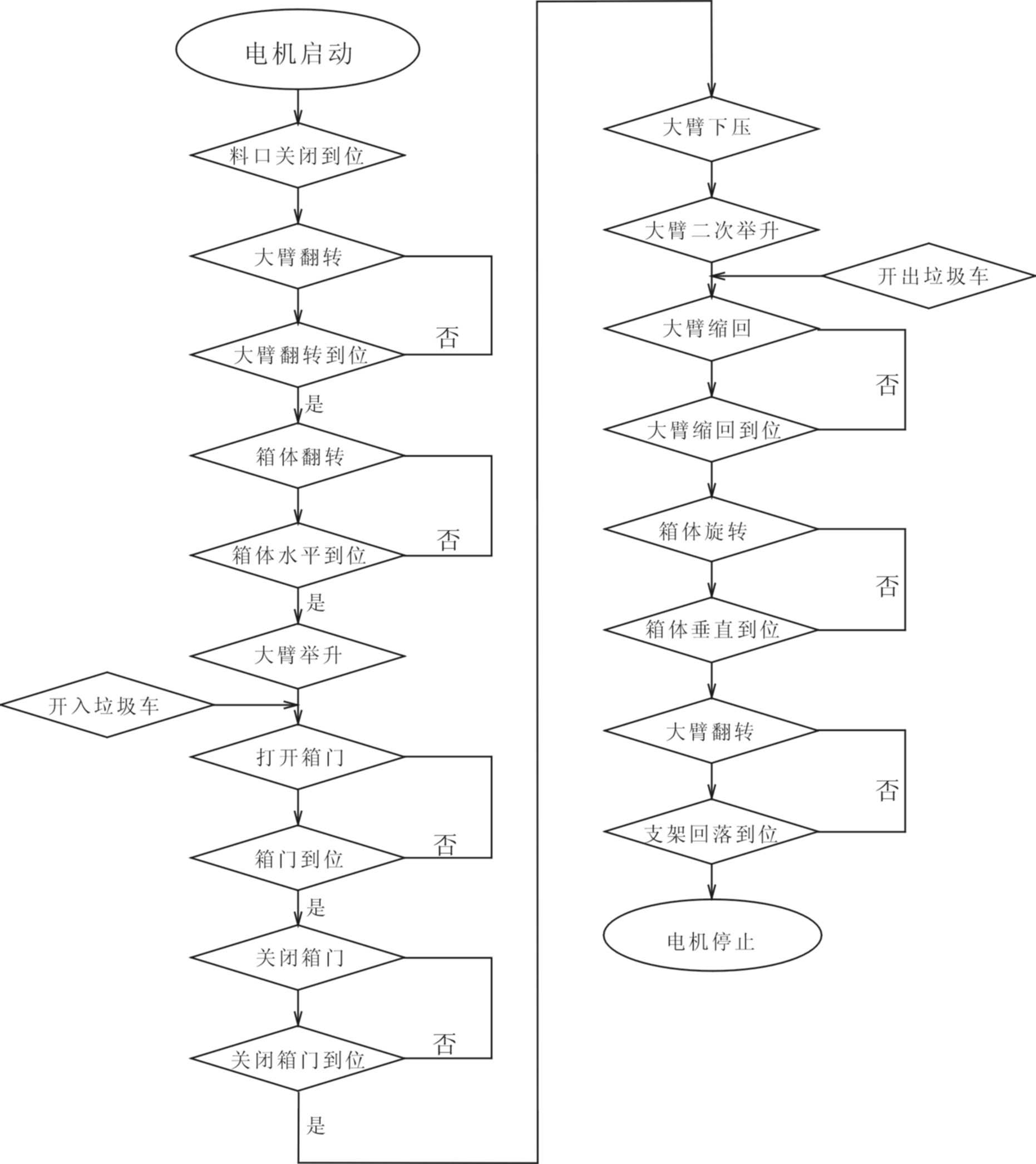

[0019] The working process of the compressible and foldable underground garbage store is characterized in that the process mainly includes the following procedures:

[0020] The first action is to move out of the garbage bin, extend the boom flip cylinder, and swing the boom lifting cylinder to lift the garbage bin out of the pit synchronously and slowly, perpendicular to the ground, and stop;

[0021] In the second action, the garbage bin is turned over, and the oil cylinder for turning over the bin is stretched out, and the bin is swung to make the lower door vertically downward and stop;

[0022] The third action lifts the garbage bin, the boom lift cylinder extends, slowly lifts the garbage bin to a height of 5 meters, and stops. The garbage truck then slowly poured into the marked parking space on the ground level and stopped;

[0023] The fourth action is garbage lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com