Natural plant deodorant and preparation process thereof

A natural plant and deodorant technology, applied in deodorization, disinfection, etc., can solve the problems of high equipment investment, low purity, and small processing gas volume, and achieve the effect of maintaining the air environment, simple processing technology, and eliminating odors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Fruit Extracts: 15%

[0030] Plant extracts: 28%

[0031] Non-ionic surfactant: 7%

[0032] Cationic surfactant: 5%

[0033] Purified water: 45%.

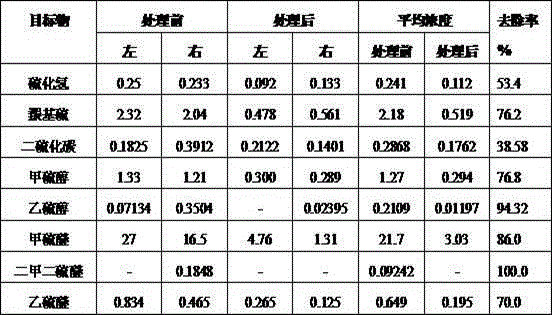

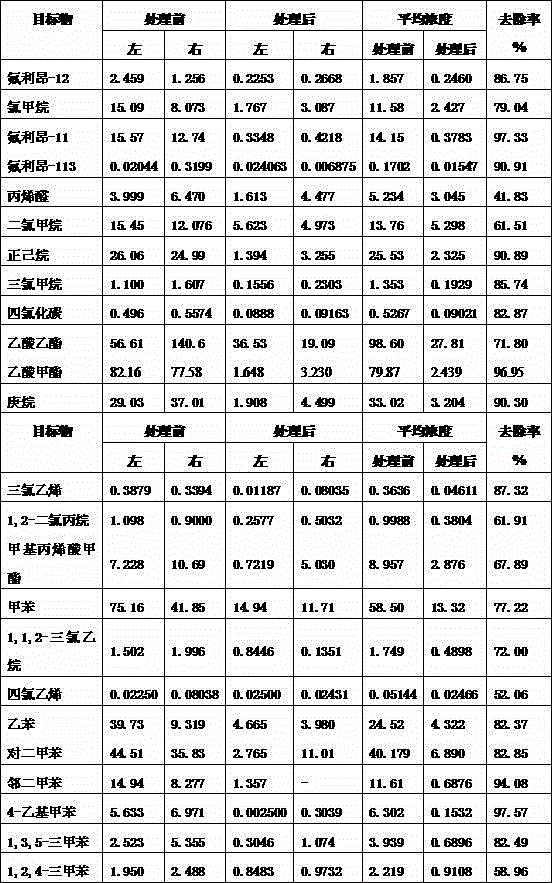

[0034] The fruit extracts mentioned in the above formula are extracted from one or more kinds of fruits such as pineapple, grapefruit, orange, etc. Specifically, whether to use one or a mixture of multiple types should be selected according to actual needs , For example: Garbage deodorization technology, as we all know, domestic garbage has complex components, resulting in complex harmful gas components (volatile harmful gases such as: Freon, toluene, xylene, acrolein, tetrachloroethylene, etc.; sulfide harmful gases such as: sulfide Hydrogen, carbon disulfide, methyl sulfide, methyl mercaptan, etc.) For these harmful substances, we selected active substances extracted from bananas, pineapple, orange pomelo, added active substances extracted from orange leaves, and then blended with polymer surfactants. It can quickly re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com