Hot-melting pressure sensitive adhesive and preparation method thereof

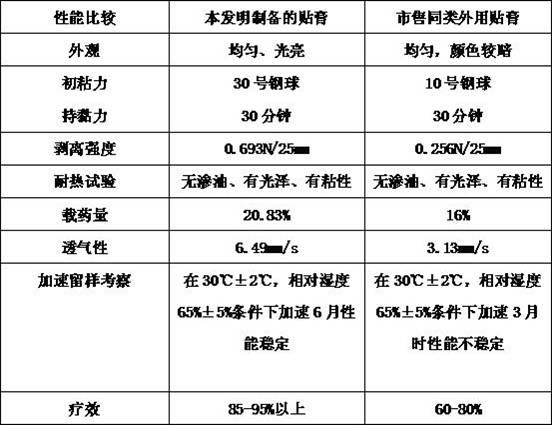

A technology of hot-melt pressure-sensitive adhesive and molten state, which is applied in the fields of cosmetics, medical equipment, medicine, and health care, and can solve the problems of poor compatibility, poor air permeability, and easy oxidation of pressure-sensitive adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1 (preparation of hot-melt pressure-sensitive adhesive)

[0017] The present invention is made by weight: styrene-isoprene-styrene 380g, liquid paraffin 260g, rosin glyceride 270g, zinc oxide 50g and BHT1010 10g are made as raw material, and its preparation method is: first 380g styrene- Isoprene-styrene, 260g of liquid paraffin and 2.5g of BHT1010 are placed in a kneader, at 120°C, mixed and stirred for 1 hour to a molten state, then 270g of rosin glyceride and 2.5g of BHT1010 are added, at 120°C, After mixing and stirring for 20 minutes to a molten state, add 50 g of zinc oxide and 5 g of BHT1010, and mix and stir for 20 minutes at 110° C. to a molten state to obtain the product.

Embodiment 2

[0018] Embodiment 2 (preparation of hot-melt pressure-sensitive adhesive)

[0019] The present invention is by weight: 360g of styrene-isoprene-styrene, 200g of liquid paraffin, 60g of rosin glyceride, 80g of C5 hydrogenated petroleum resin, 150g of terpene resin, 60g of light powder and 2,6-ditertiary 30g of butyl-p-cresol is made from 30g of butyl-p-cresol. The preparation method is as follows: first knead 360g of styrene-isoprene-styrene, 200g of liquid paraffin and 7.5g of 2,6-di-tert-butyl-p-cresol In the machine, at 130°C, mix and stir for 1 hour to a molten state, then add 60g rosin glyceride, 80g C5 hydrogenated petroleum resin, 150g terpene resin and 7.5g 2,6-di-tert-butyl p-cresol, in After mixing and stirring at 130°C for 20 minutes to a molten state, add 60g of light powder and 15g of 2,6-di-tert-butyl-p-cresol, and mix and stir at 120°C for 20 minutes to a molten state.

Embodiment 3

[0020] Embodiment 3 (preparation of hot-melt pressure-sensitive adhesive)

[0021] The present invention is by weight: styrene-isoprene-styrene 340g, liquid paraffin 170g, rosin glyceride 100g, C5 hydrogenated petroleum resin 70g, terpene resin 110g, zinc oxide 70g, light powder 20g and BHT1010 50g It is made of raw materials, and its preparation method is: firstly put 340g of styrene-isoprene-styrene, 170g of liquid paraffin and 12.5g of BHT1010 in a kneader, mix and stir for 1 hour at 125°C until it melts, and then Add 100g rosin glyceride, 70g C5 hydrogenated petroleum resin, 110g terpene resin and 12.5g BHT1010, at 125°C, mix and stir for 20 minutes to melt, then add 70g zinc oxide, 20g light powder and 25g BHT1010, at 125°C , Mix and stir for 20 minutes until molten state, that is, too.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com