Bicomponent microfibers

A microfiber, dispersed technology, applied in textiles, bandages, transportation and packaging, etc., can solve the problems of high cost and high processing costs, and achieve the effect of easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0110] A nonwoven web of multiple layers of microfibers was produced as follows:

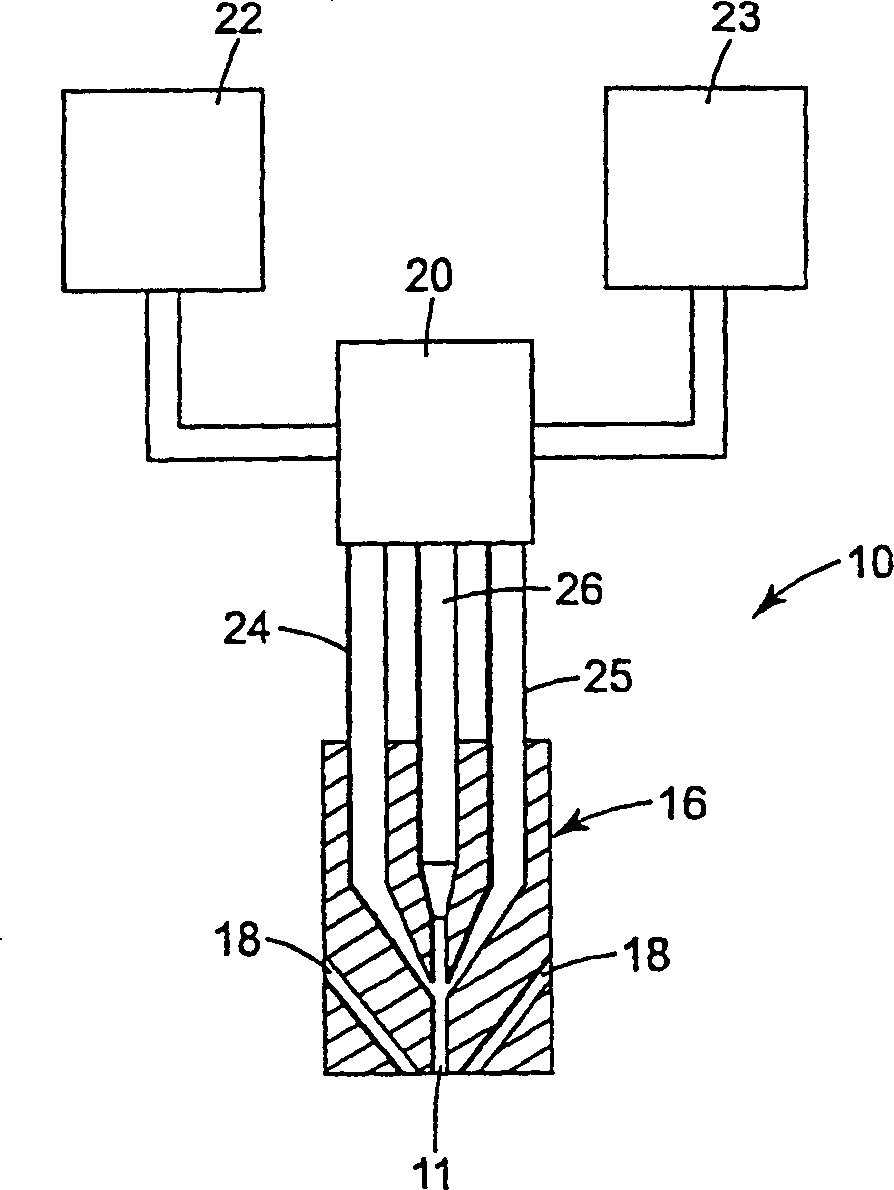

[0111] The multilayer sprayed microfibrous webs of the present invention were made using the meltblowing process described in US Patent 5,207,970 (Joseph et al.). The method uses a meltblown die with round smooth surfaced holes (10 / cm) with a length / diameter ratio of 5 / 1.

[0112] Examples 1-29 and Comparative Examples C1-C8 were prepared with different formulations as listed in Table 1 below. The examples were prepared using two extruders at different temperatures and with die bodies at different temperatures, under certain conditions of air temperature, gap and collector distance. The temperature of each extruder, die body and air in °C and the gap and collector distance in centimeters for each example and comparative example are listed in Table 2 below.

[0113] The first extruder, having sections with temperatures listed in Table 2, fed the melt stream of Resin 1 for each Example listed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com