Robot assembling section for box body and cross beam of disinfection cabinet production line

A production line and robot technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of low production efficiency and low degree of automation of manual screwing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

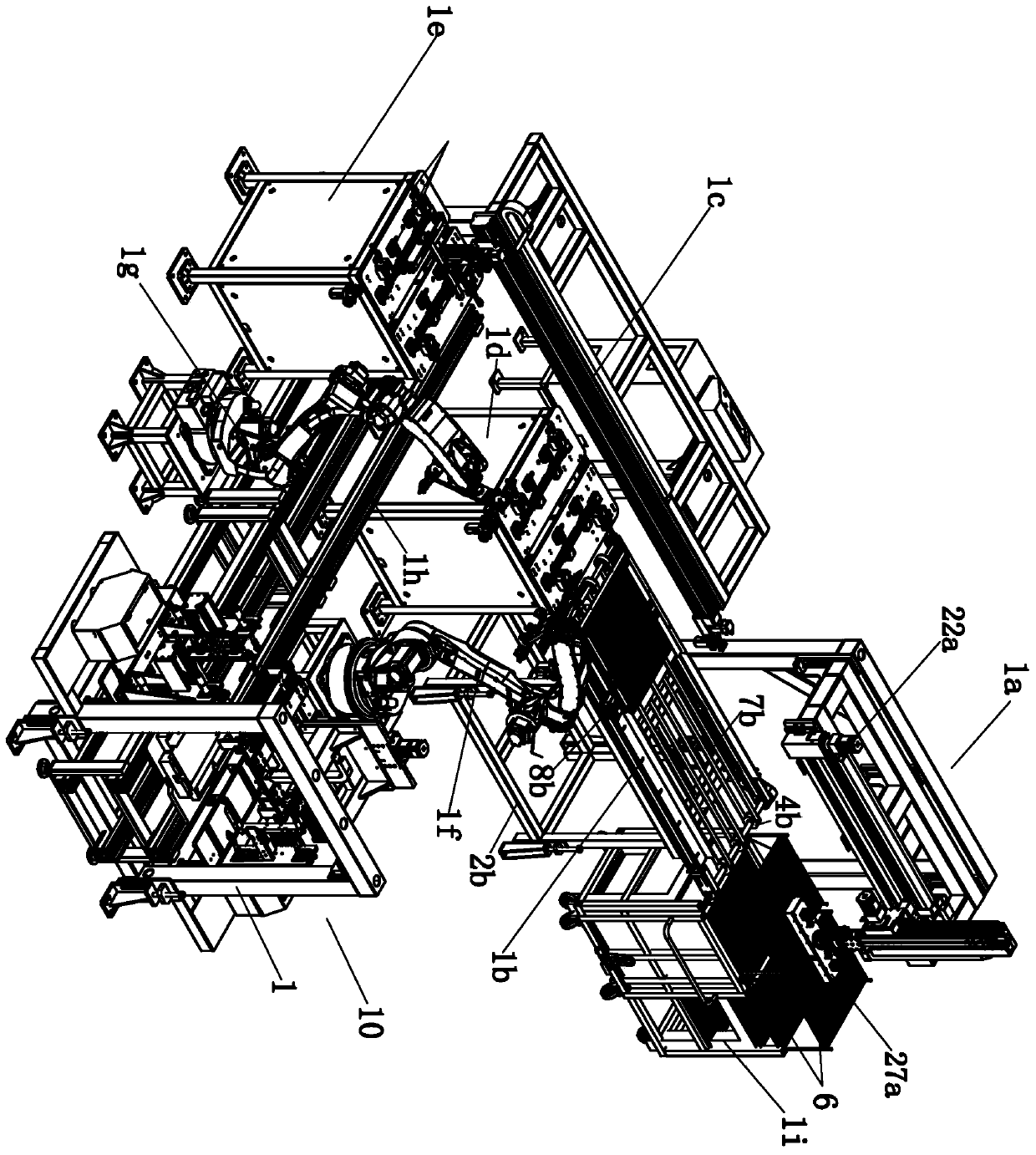

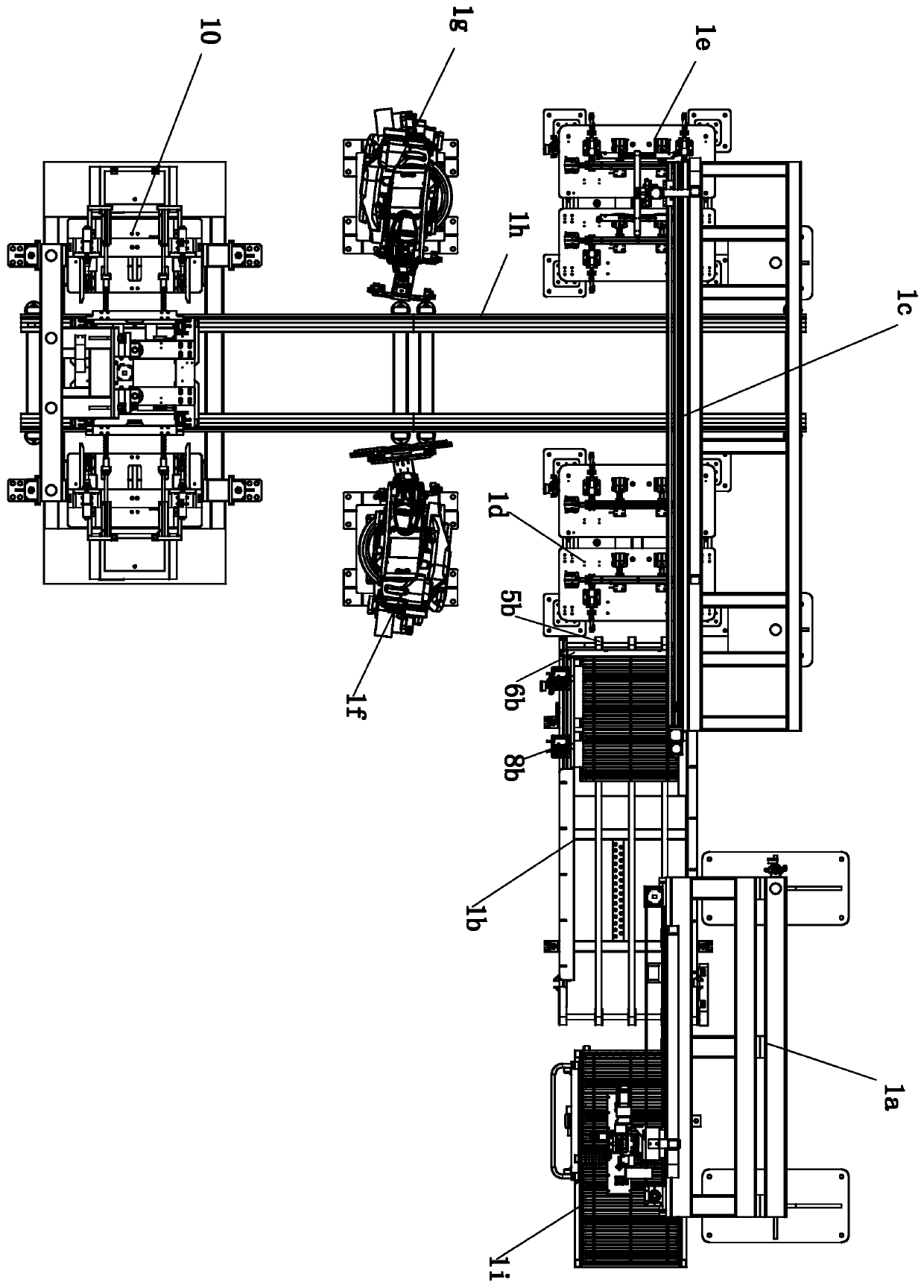

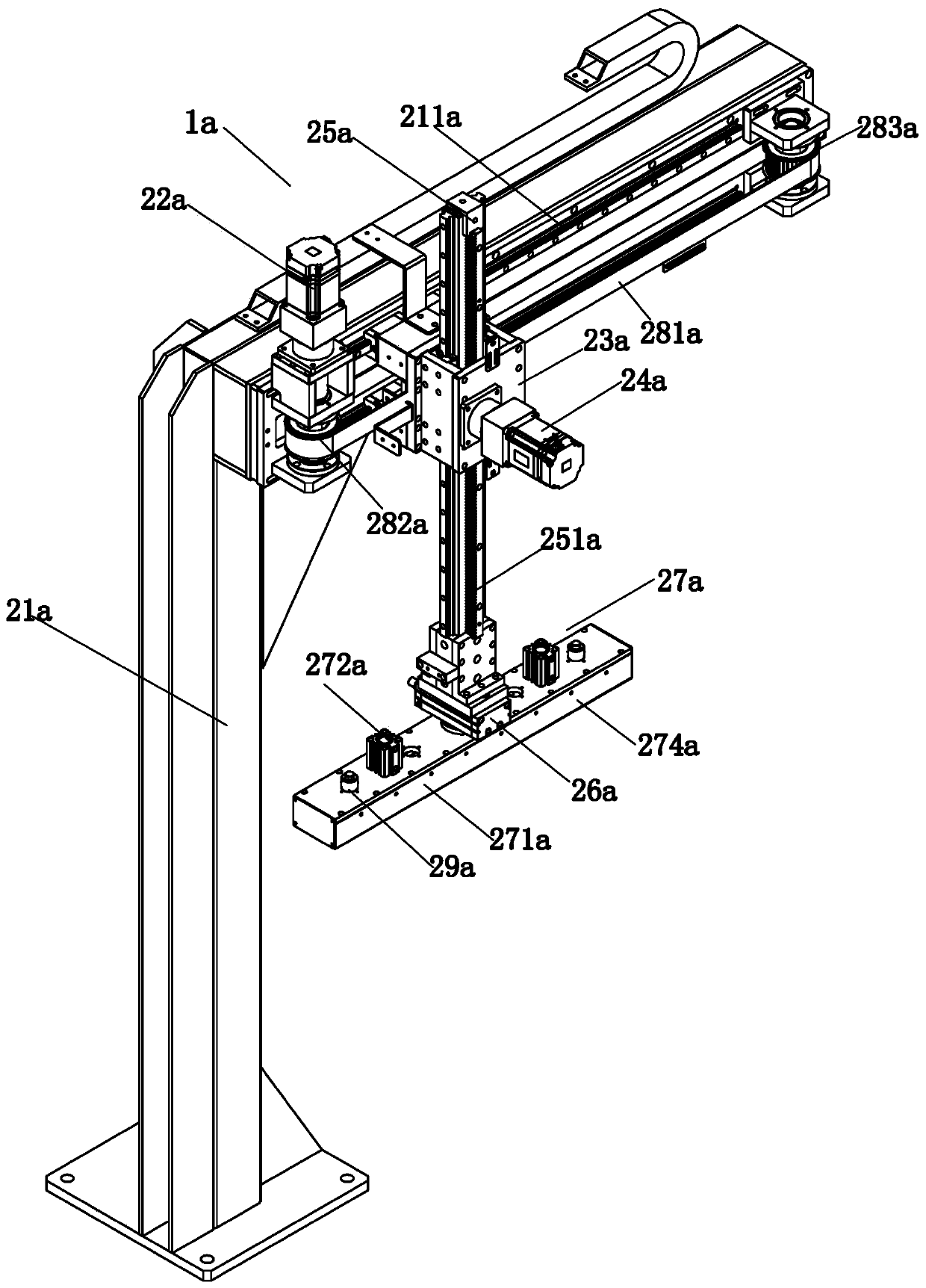

[0055] Embodiment one, such as Figure 1 to Figure 17 As shown, a robot assembly section of the box body and the beam of a disinfection cabinet production line includes a beam tooling vehicle 1i, a feeding manipulator 1a, a positioning conveyor line 1b, two secondary positioning platforms 1d, 1e, a feeding manipulator 1c, two Beam feeding robots 1g, 1f, box assembly line 1h and beam screwing machine 10.

[0056] The crossbeam tooling vehicle 1i is used for arranging and placing a plurality of crossbeams 6 .

[0057] The feeding manipulator 1a is used to grab the arranged beams 6 on the beam tooling vehicle 1i onto the positioning conveying line 1b.

[0058] The positioning conveying line 1b is used to position the multiple rows of beams 6 grabbed by the feeding manipulator 1a.

[0059] The feeding manipulator 1c is used to grab the two beams 6 positioned on the positioning conveying line 1b to the secondary positioning platforms 1d and 1e.

[0060] The tops of the secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com