Garlic conveying device and sowing machine

A conveying device and seeder technology, applied in potato planters, planting methods, applications, etc., can solve the problems of reducing artificial planting, achieve weight saving, avoid inconsistent garlic back orientation, and reduce length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

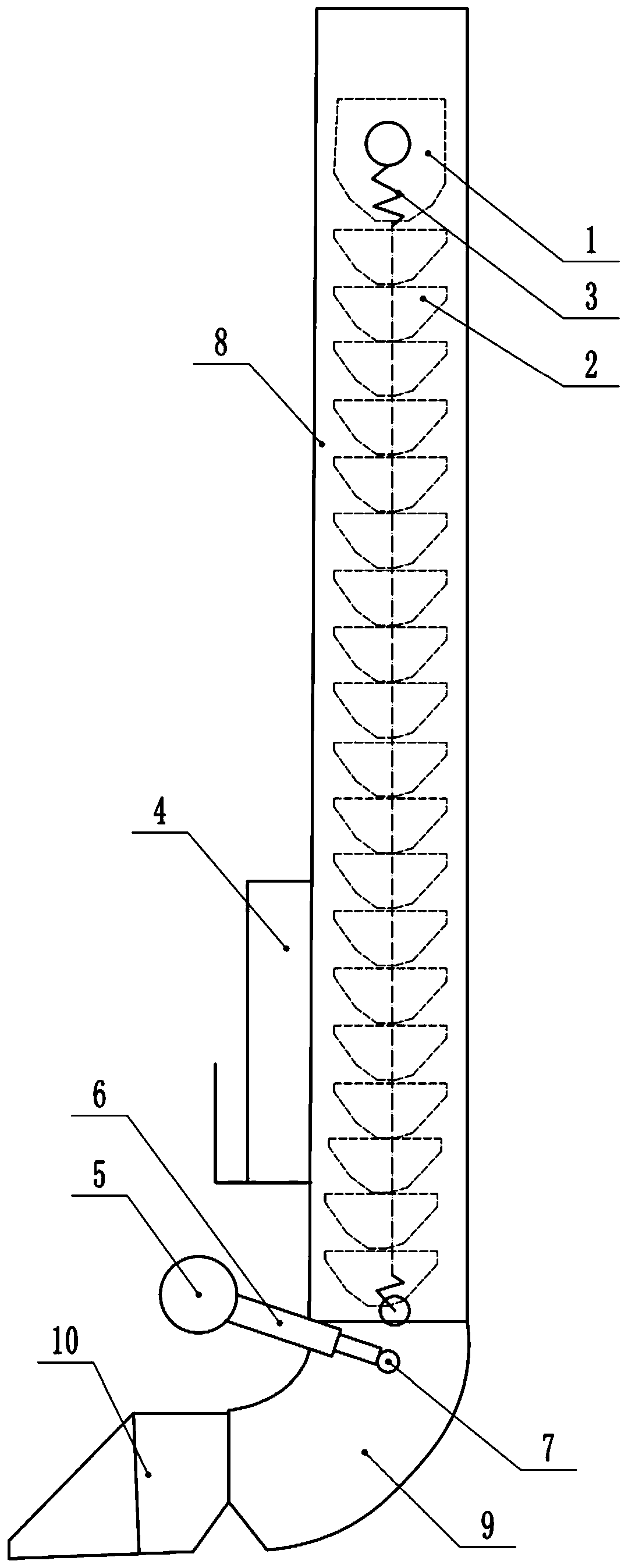

[0047] In a typical implementation of the present application, such as Figure 1-Figure 10 As shown, a conveying device for assisting garlic planting is proposed.

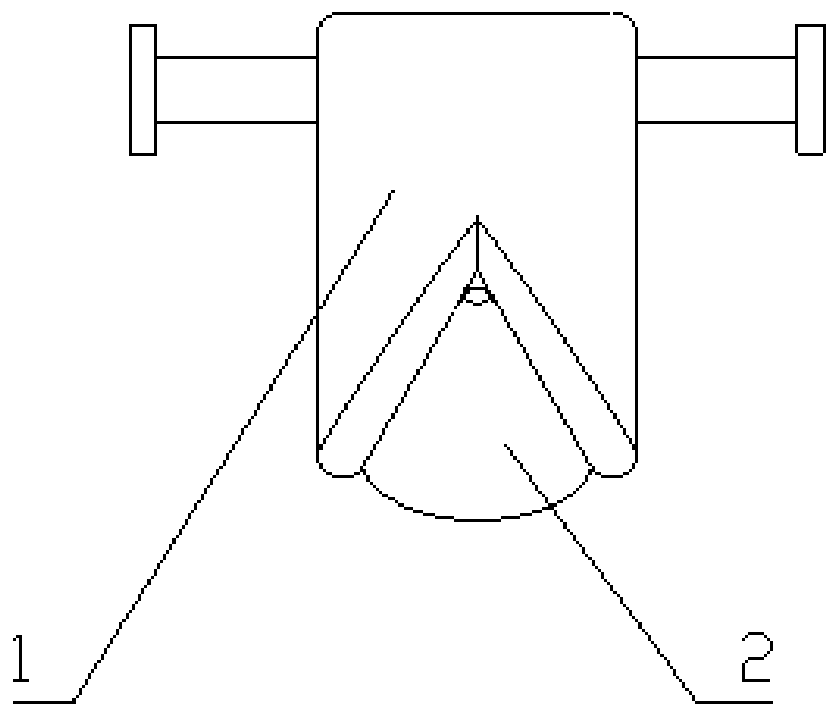

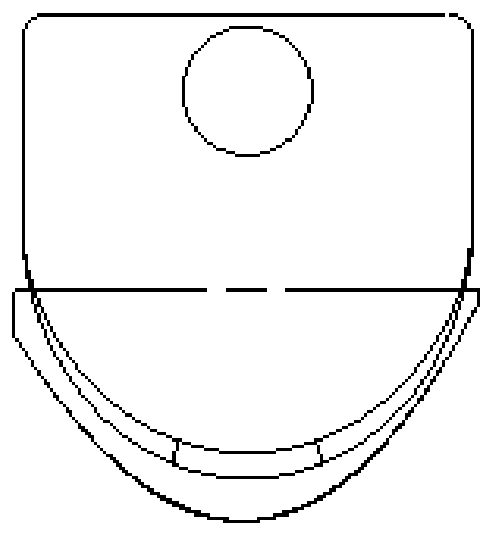

[0048] A garlic conveying device, comprising a vertical section 8, an arc section 9 and a horizontal section 10 connected in sequence, the vertical section includes a conveying cylinder with an elliptical cross-section, and a pressing block 1 is fitted in the conveying cylinder, The seed pressing block is equipped with a tension spring, and the seed pressing block is used to push the garlic seeds 2 in the delivery tube to the arc section under the action of the extension spring 3, and the end of the horizontal section near the arc section is provided with a The seed-throwing port, the arc-shaped section is equipped with a seed-taking claw, and the seed-taking claw is used to transport the garlic seeds in the delivery cylinder to the seed-throwing port;

[0049] One end of the conveying cylinder connected to the ar...

Embodiment 2

[0071] In another typical embodiment of the present application, such as Figure 11-13 Shown, propose a kind of garlic planter that utilizes embodiment 1 garlic delivery device.

[0072] A kind of garlic seeder, comprises frame 12, controller, ground wheel 13 and above-mentioned garlic delivery device, described garlic delivery device is fixed on the frame, and described controller and driving mechanism, opening and closing mechanism, telescopic link are respectively Electric connection, the ground wheel is installed on the frame through bearings, and a plurality of pressure hole cones are arranged on the outer peripheral surface of the ground wheel, and the pressure hole cones are used to penetrate the ground to form a seed hole for containing garlic seeds, and the control system is used to control the opening and closing mechanism to release the garlic seeds into the seed hole;

[0073] Preferably, the pressure hole cone is a frustum-shaped structure with sharp thorns on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com