Screwdriver cap over-molding device

A technology of secondary injection molding and screwdriver, applied in household components, household appliances, other household appliances, etc., can solve problems such as difficulty in meeting the demand for mass production of screwdriver caps, damage to production personnel and equipment, and low production efficiency. The effect of reducing manual participation, reducing labor costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

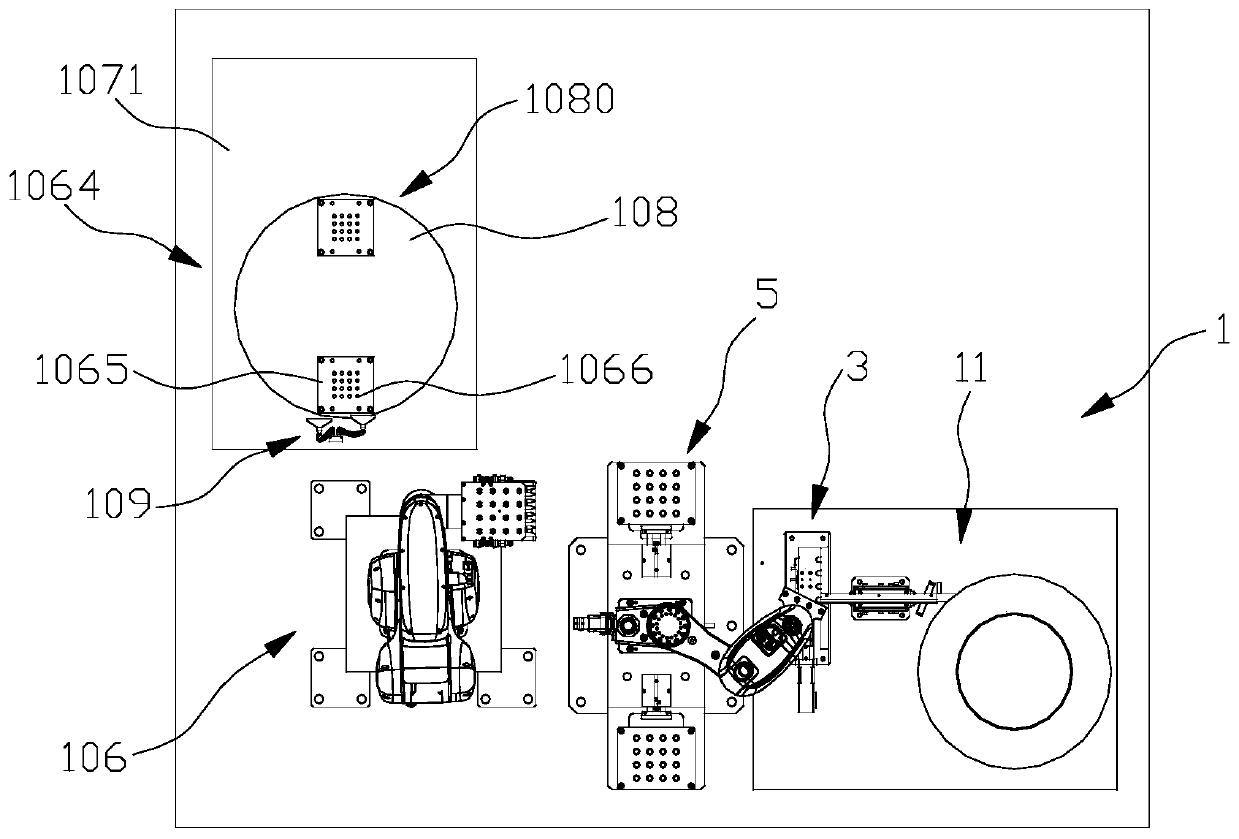

[0060] see figure 1 , Figure 19 to Figure 20 , The secondary injection molding equipment for screwdriver caps in this embodiment includes a screwdriver cap conveying device 1 , a screwdriver cap arrangement and positioning device 5 , a material transfer device 106 and an injection molding device 1064 .

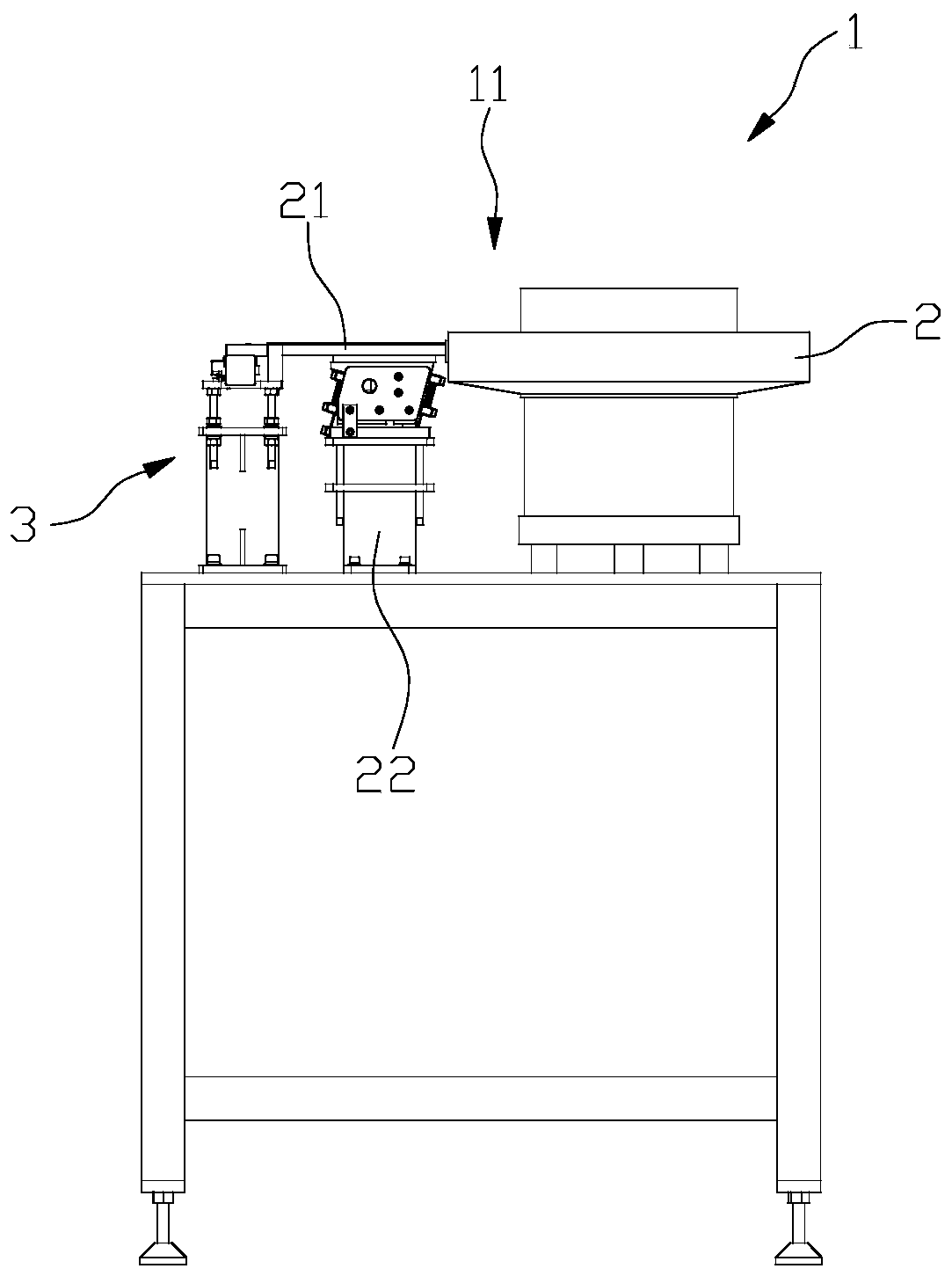

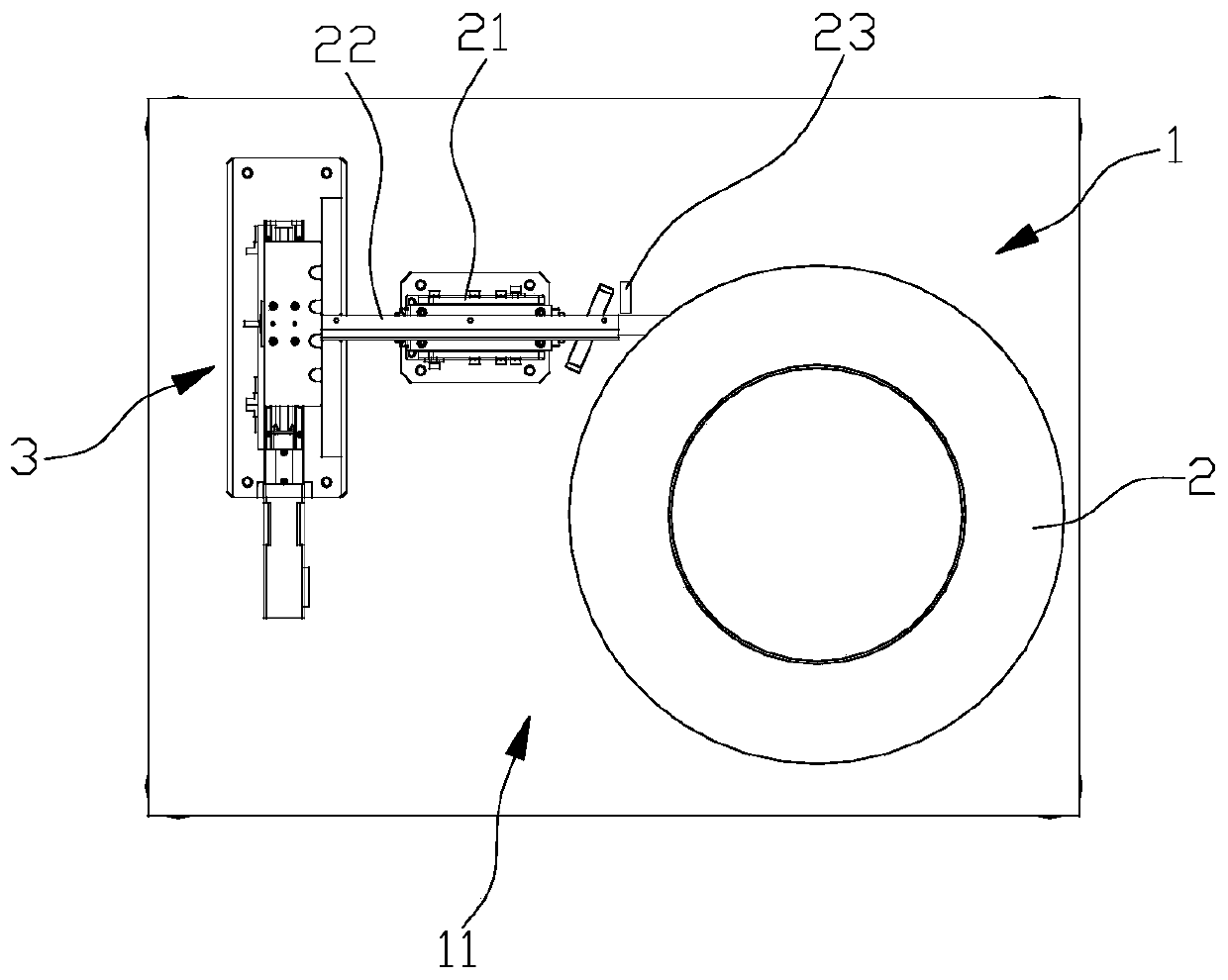

[0061] see Figure 2 to Figure 3 , the screwdriver cap arrangement positioning device 5 is used to arrange several workpieces into an array, the screwdriver cap conveying device 1 includes a vibrating plate 11 and a positioning device 3; the vibrating plate 11 includes a circular vibrating plate 2 and a feeding track 21, the described The head end of the feeding track 21 is connected to the discharge end of the circular vibrating plate 2; the positioning device 3 includes a limiting member 4, a positioning member 37 and a positioning drive device 371, and the limiting member 4 is vertically arranged on the feeding track 21 end, the stopper 4 is provided with a material pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com