Glass magnetic force piston-type pump

A piston pump and glass technology, applied in pumps, liquid displacement machines, machines/engines, etc., can solve problems such as unsuitable pressure conditions, poor air tightness of the system, poor corrosion resistance, etc., to achieve safety, gas Excellent tightness and improved utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

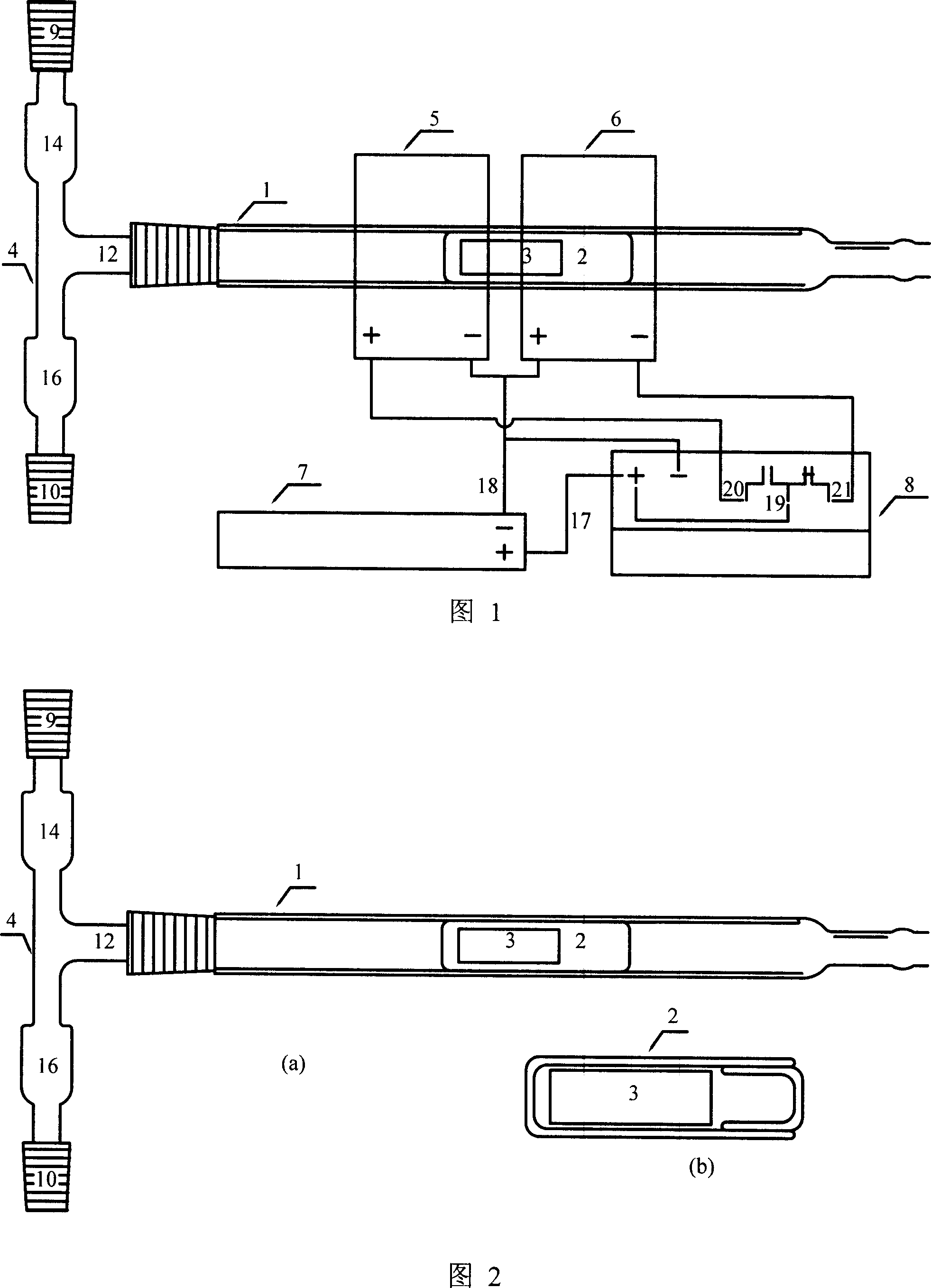

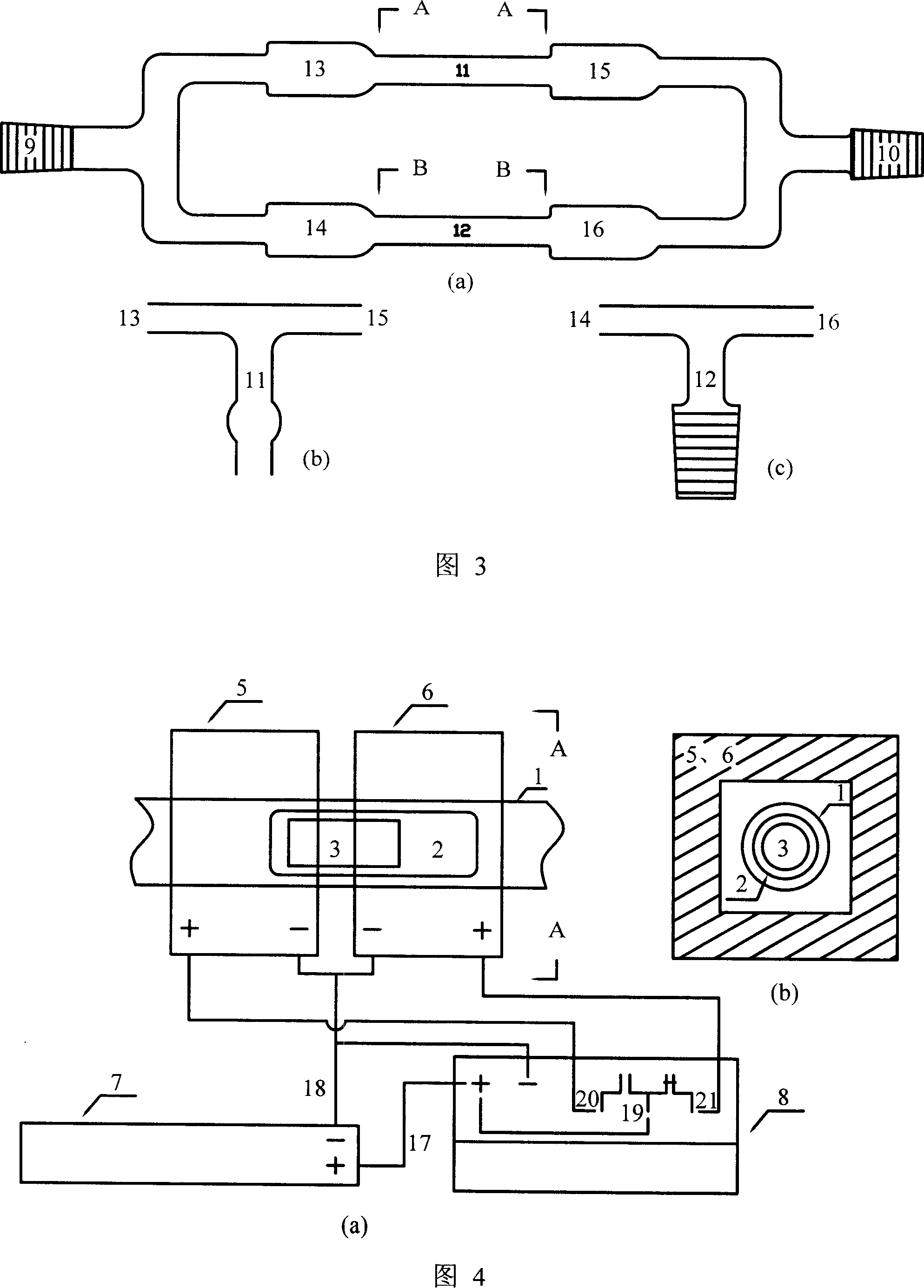

[0034] The glass part is carried out as shown in Figure 2 and 3, and is fired with Pyrex (PYREX) glass, in which the following conditions are mainly guaranteed:

[0035] 1. The magnetic core 3 can be loaded into the glass piston 2

[0036] 2. The glass piston 2 can be loaded into the glass pump body 1 from the left end of the glass pump body 1

[0037] 3. The glass piston 2 and the glass pump body 1 are in contact with each other, with good air tightness and easy movement

[0038] 4. Each glass automatic piston in the glass combination check valve 4 moves freely, and has good ventilation and airtightness

[0039] 5. Keep the verticality of the first glass grinding port 9, the second glass grinding port 10, and the level of the third glass grinding port 12

[0040] Glass part connection: where the glass is combined with a one-way valve 4, so that the first glass grinding port 9 is on the top and the second glass grinding port 10 is on the bottom, and it is placed vertically t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com