Formwork device for constructing inclined shaft working surface in coal mine

A technology for working face and inclined shaft, which is applied to shaft equipment, shaft lining, mining equipment, etc., can solve the problems of poor appearance of shaft wall, high labor intensity, frequent movement of vertical arches, etc. Low labor intensity and the effect of reducing operation links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

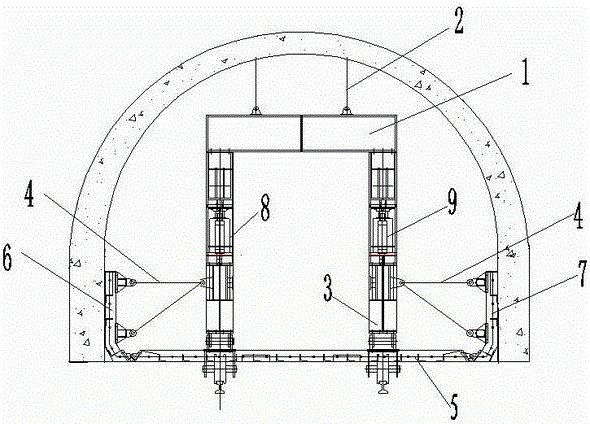

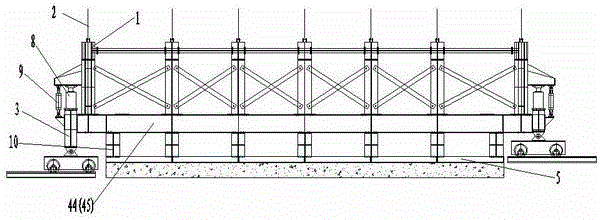

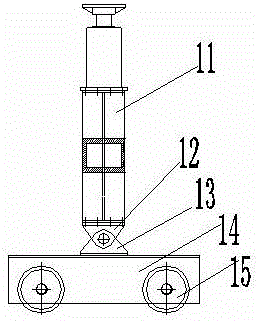

[0049] figure 1 , figure 2 Among them, the construction formwork device of the coal mine inclined shaft working face is mainly composed of a door frame 1, a fixed oil cylinder 2, a traveling mechanism 3, a mold closing cylinder 4, a bottom formwork 5, a left formwork 6, a right formwork 7, a main lift cylinder 8, and a main lift cylinder. Lowering oil cylinder 9, formwork fixing seat 10, mast bottom longitudinal beam I44 and mast bottom longitudinal beam II45, the two ends of the mast bottom longitudinal beam I44 and mast bottom longitudinal beam II45 are respectively provided with square holes, and the door The bottom longitudinal beam I44 of the mast and the bottom longitudinal beam II45 of the mast are arranged side by side, and the four traveling mechanisms 3 are arranged at the lower parts of the two ends of the bottom longitudinal beam I44 of the mast and the bottom longitudinal beam II45 of the mast. The lifting cylinder column 11 on the traveling mechanism 3 Go throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com