Universal tool for pasting reinforcing sheets and using method and application thereof

A technology of reinforcing sheets and tooling, applied in the preparation of test samples, etc., can solve the problems of difficulty in mold cleaning, lack of positioning benchmarks, and limitations on the number and size of prepared samples, so as to improve the preparation accuracy and efficiency, and improve the processing dimensional accuracy. , the effect of improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

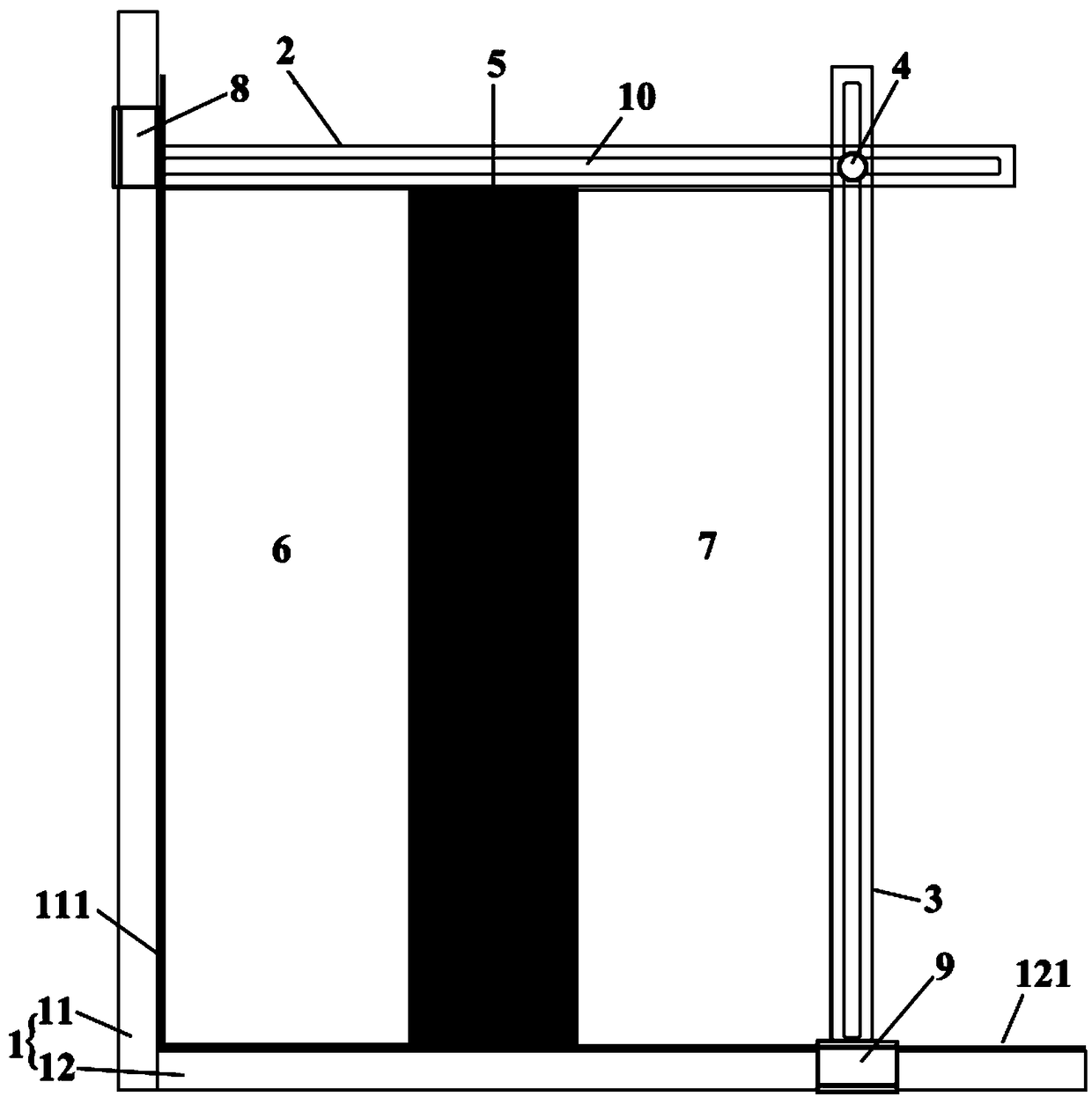

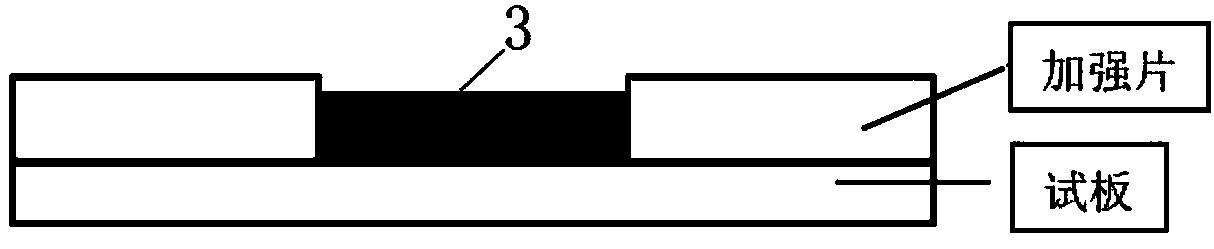

[0054] This embodiment proposes a general-purpose tooling for pasting reinforcement sheets, and the general-purpose tooling includes:

[0055] An L-shaped right-angle main positioning arm 1;

[0056] A first sliding arm 2, the first sliding arm 2 is perpendicular to one side of the right-angle main positioning arm 1;

[0057] A second sliding arm 3, the second sliding arm 3 is perpendicular to the other side of the right-angle main positioning arm 1;

[0058] A positioning slider 4, the positioning slider 4 connects the first sliding arm 2 and the second sliding arm 3;

[0059] A limit block 5, said limit block 5 is used for the positioning of the reinforcement sheet and ensures the gauge length of the test piece;

[0060] The limiting block 5 is arranged in a rectangle formed by the right-angle main positioning arm 1 , the first sliding arm 2 and the second sliding arm 3 .

[0061] The right-angle main positioning arm 1 includes a first positioning arm 11 and a second posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com