A new battery manufacturing method

A manufacturing method and storage battery technology, applied to lead-acid batteries, lead-acid battery construction, lead-acid battery electrodes, etc., can solve problems such as overcharging and over-discharging of independent unit batteries, failure of combined power supply, and decline in battery life, and achieve improved High rate charge and discharge performance, increased electrochemical reaction activity, and improved battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

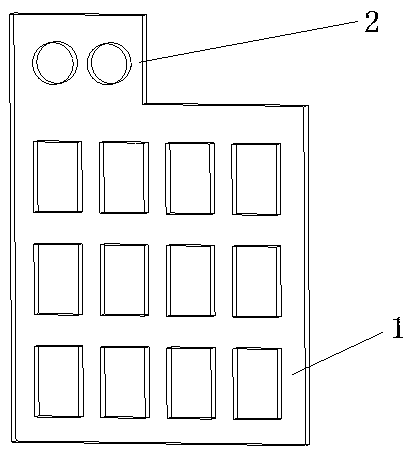

Image

Examples

Embodiment 1

[0069] (1) Preparation of porous carbon material preparation raw material powder

[0070] In parts by weight, 23 parts of wood chips, 40 parts of coconut shells, 30 parts of walnut shells, 3.5 parts of graphite, and 3.5 parts of low-melting pitch are mixed together, and the porous carbon material is prepared after crushing and finely grinding the raw material powder, wherein The particle size of the raw material powder prepared from the porous carbon material is 20-300 μm.

[0071] (2) Preparation of positive electrode plate

[0072] In parts by weight, 100 parts of porous carbon materials are used to prepare raw material powder, 9 parts of PbSO 4 , 1.5 parts of Pb 3 o 4 , 0.05 parts of SnO 2 , 0.05 Bi 2 o 3 Mix well, among them, PbSO 4 , Pb 3 o 4 , SnO 2 and Bi 2 o 3 The size of the particles is 20nm to 1000nm; then, add 4 parts of coal tar, 2 parts of polyvinyl alcohol, and a certain amount of deionized water to the mixed powder material in order to make a paste;...

Embodiment 2

[0084] (1) Preparation of porous carbon material preparation raw material powder

[0085] In parts by weight, 10 parts of charcoal, 10 parts of rice husk, 31 parts of coconut shell, 30 parts of walnut shell, 8.5 parts of graphite, and 10.5 parts of low-melting pitch are mixed together, crushed and ground to make a porous carbon material The raw material powder is prepared, and the particle size of the raw material powder prepared by the porous carbon material is 20-300 μm.

[0086] (2) Preparation of positive electrode plate

[0087] In parts by weight, 100 parts of porous carbon materials are used to prepare raw material powder, 18 parts of Pb(OH) 2 , 1.5 parts of PbO, 0.18 parts of SnO 2 , 0.19 Bi 2 o 3 Mix well, among them, Pb(OH) 2 , PbO, SnO 2 and Bi 2 o 3 The particle size of the mixture is 20nm to 1000 nm; then, add 2 parts of coal tar, 4 parts of polyvinyl alcohol, and a certain amount of deionized water to the mixed powder material in order to make a paste; T...

Embodiment 3

[0099] (1) Preparation of porous carbon materials Preparation of materials

[0100] In parts by weight, 10 parts of sawdust, 10 parts of rice husk, 30 parts of coconut shell, 25 parts of walnut shell, 12 parts of carbon fiber material, 6 parts of graphite, and 7 parts of low-melting pitch are mixed together, crushed and ground The raw material powder is prepared from the porous carbon material, and the particle size of the raw material powder prepared from the porous carbon material is 20-300 μm.

[0101] (2) Preparation of positive electrode plate

[0102] In parts by weight, 100 parts of porous carbon materials are used to prepare raw material powder, 15 parts of PbCO 3 , 0.115 parts of SnO 2 , 0.115 Bi 2 o 3 Mix well, among them, PbCO 3 , SnO 2 and Bi 2 o 3 The particle size of the mixture is 20nm to 1000 nm; then, add 3 parts of coal tar, 3 parts of polyvinyl alcohol, and a certain amount of deionized water to the mixed powder material to make a paste; Coated in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com