Device and method for fast positioning and pasting of fiber grating sensor

A fiber grating and sticking device technology, which is applied in the direction of coating liquid on the surface, connecting components, coatings, etc., can solve the problems affecting the use of fiber grating strain/stress sensors, poor positioning accuracy, slow sticking speed, etc. Improve the paste precision and paste quality, easy operation, reliable work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

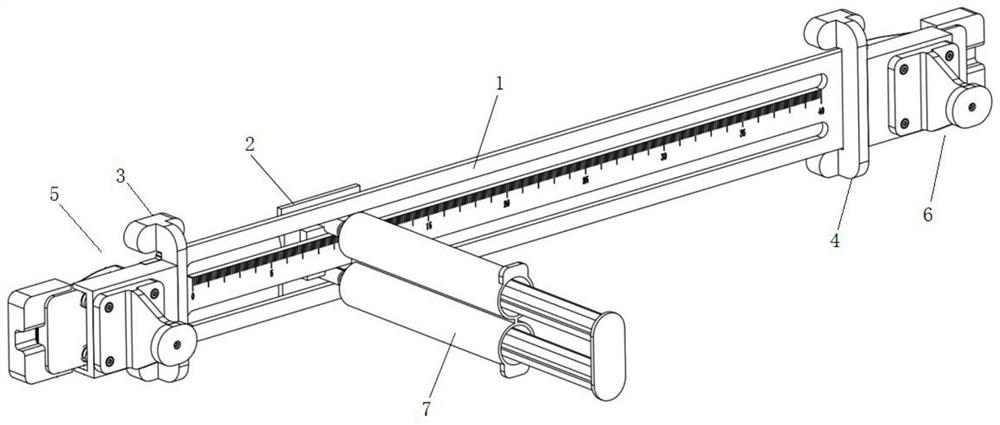

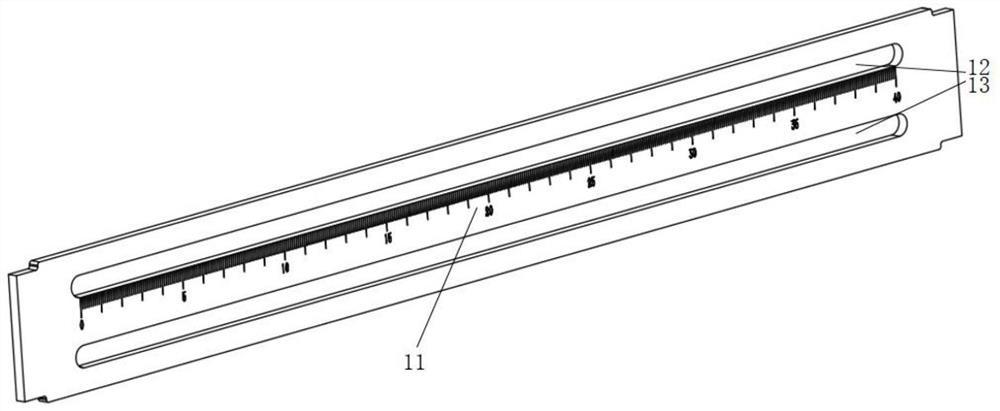

[0050] This embodiment provides a fiber grating sensor fast positioning paste device, such as figure 1 As shown, it includes: a guide scale 1, a moving glue head 2, a first fixing buckle 3, a second fixing buckle 4, a first support member 5 and a second support member 6;

[0051] The guide scale 1 includes a scale line, which is used to locate the sticking position of the fiber grating sensor;

[0052] The mobile gluing head 2 is movably connected with the guide scale 1, and is used to move along the scale line so that the adhesive material is coated on the sticking position on the fiber grating sensor, so that the fiber grating sensor is pasted to the surface of the measured structure;

[0053] The first fixing buckle 3 and the second fixing buckle 4 are buckled on the two side surfaces of the guide scale 1 respectively, and are used to fix the guide scale 1 to the surface of the structure to be measured;

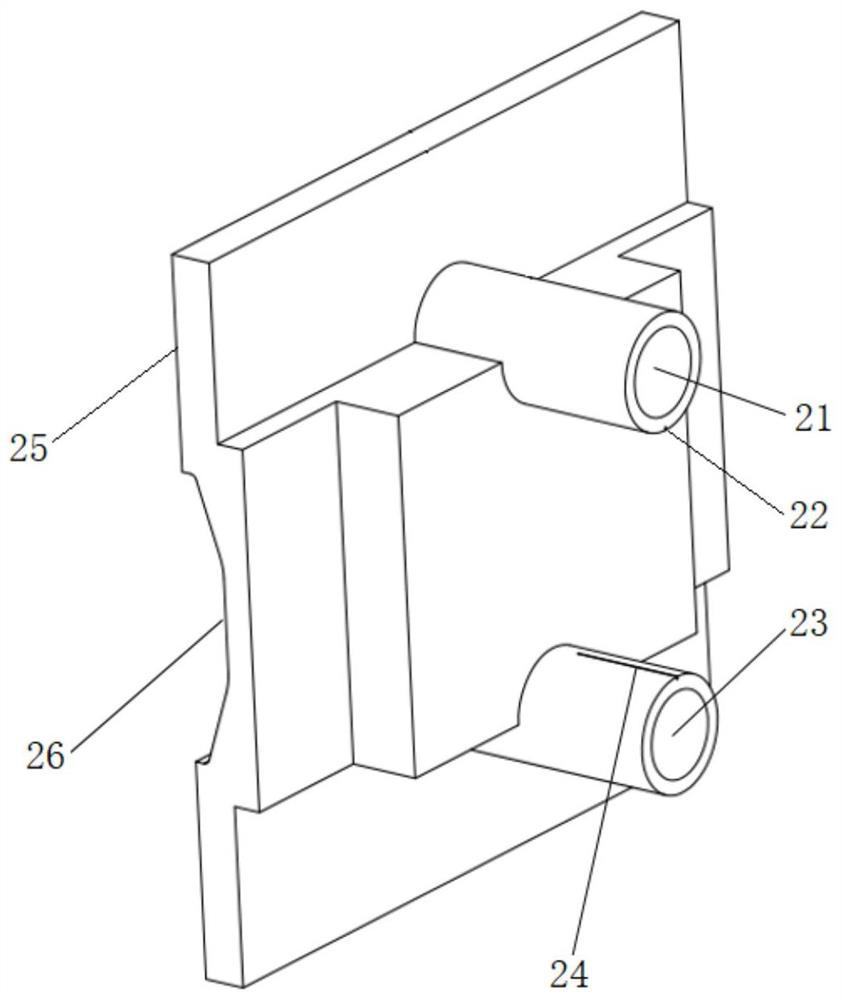

[0054] The first supporting part 5 and the second supporting part 6 ...

Embodiment 2

[0077] This embodiment provides a fast positioning and pasting method for a fiber grating sensor, which can be applied to the fast positioning and pasting device for a fiber grating sensor in embodiment 1, such as Figure 10 As shown, the method includes the following steps:

[0078] S1. Fix the fast positioning and sticking device of the fiber grating sensor to the surface of the structure under test through the first fixing buckle and the second fixing buckle, so that the mobile glue applicator is placed near the position to be pasted;

[0079] S2. Pull the lifting handles of the first supporting part and the second supporting part, and lift the outer pressing parts of the two;

[0080] S3. Pass the fiber grating sensor through the gap between the inner pressing piece and the outer pressing piece respectively, so that the position to be pasted of the fiber grating sensor is aligned with the position to be pasted on the surface of the measured structure;

[0081] S4. Loosen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com