Model core conveying trolley

A technology for conveying trolleys and conveying tables, which is applied to tires, other household appliances, household appliances, etc., can solve problems such as freedom degree restriction, track forming curved parts, discontinuous parts, and complicated operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

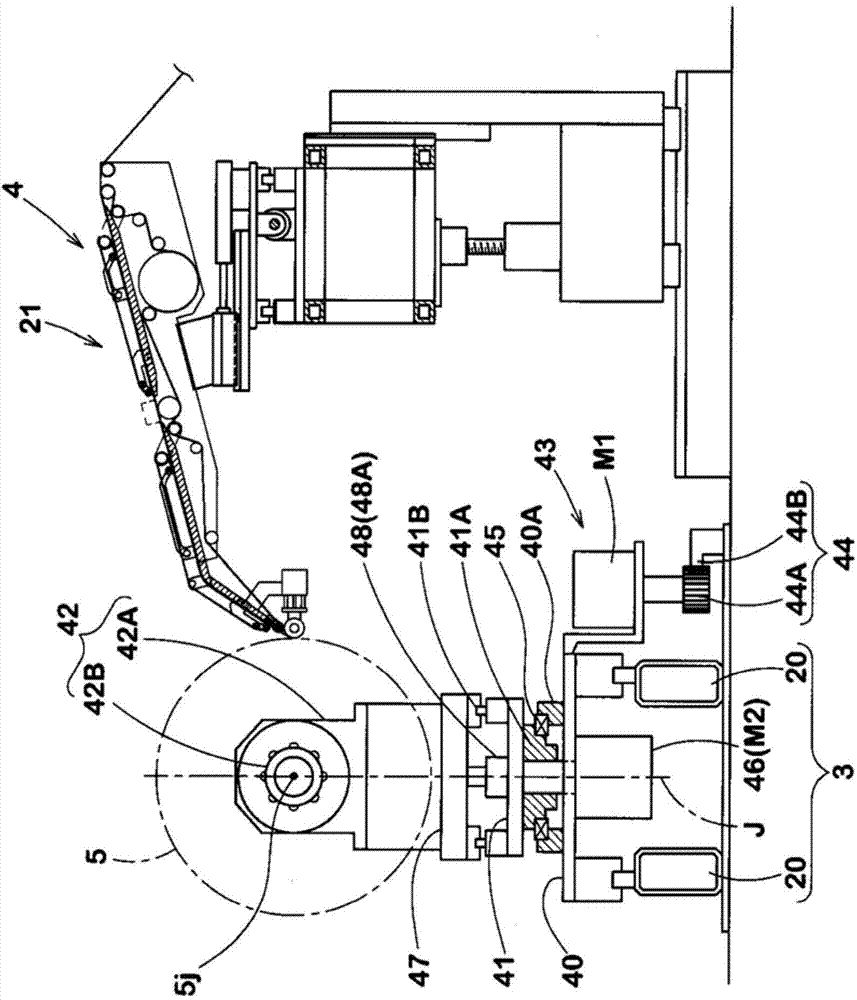

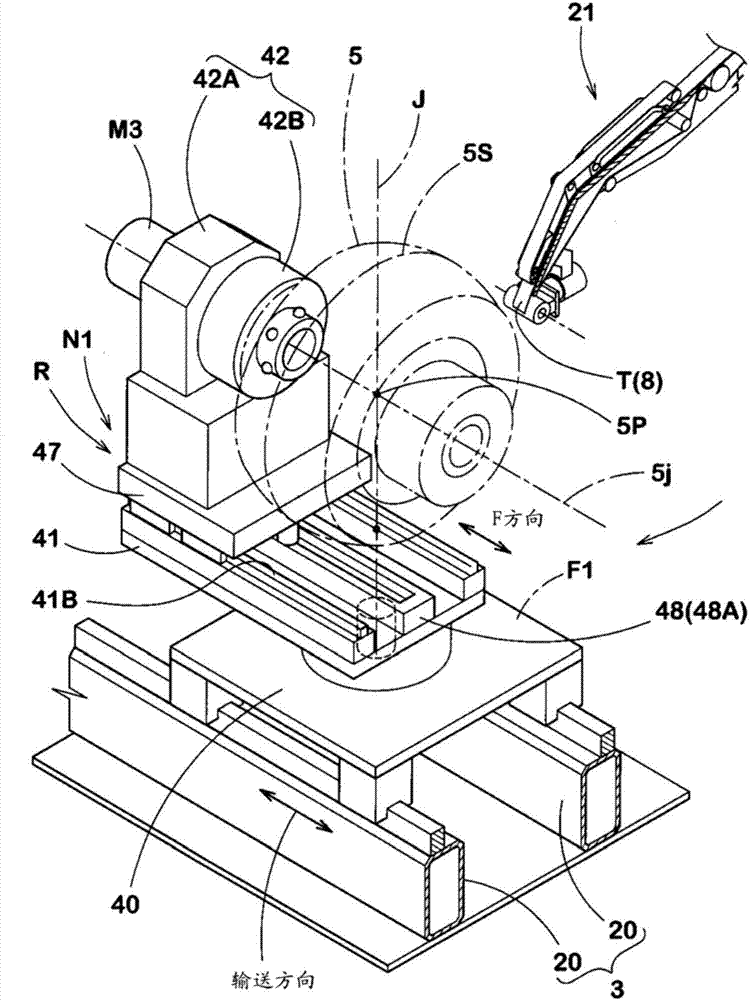

[0041] Hereinafter, embodiments of the present invention will be described in detail.

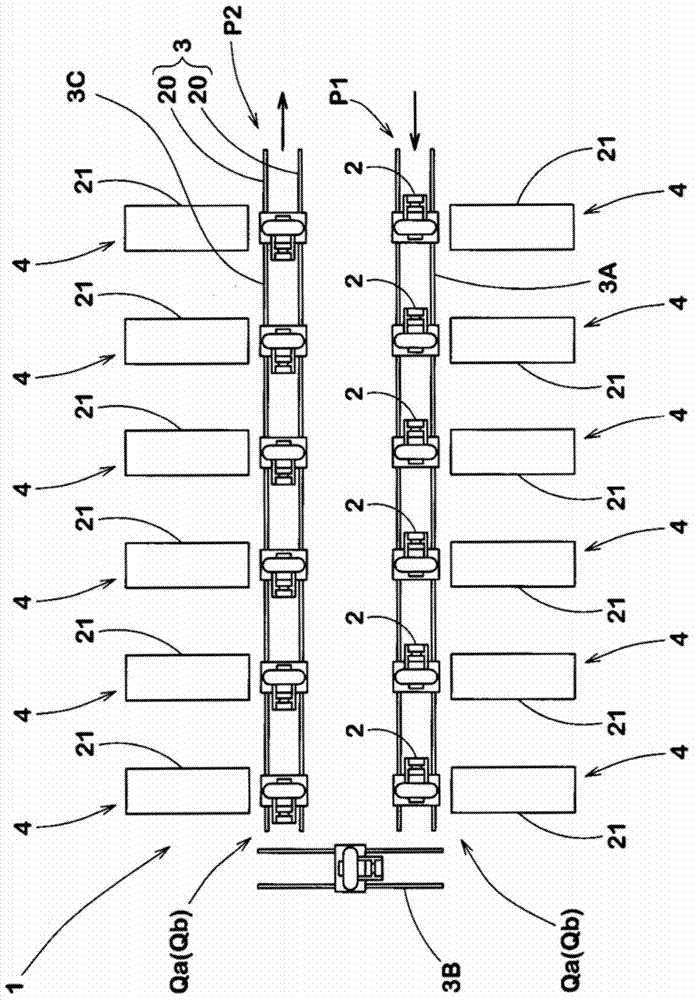

[0042] figure 1An embodiment of a green tire production line 1 using the core conveying trolley 2 of the present invention is schematically shown in . The raw tire production line 1 has a rail 3 on which a core transport trolley 2 runs; and a plurality of work stations 4 arranged along the rail 3 . Then, each work station 4 sticks the tire components T on the outer surface of the rigid core 5 moving on the rail 3 according to the order of the arrangement described above, thereby forming the green tire 6 .

[0043] Figure 8 An example of a green tire 6 formed on the manufacturing line 1 described above is shown in FIG. In this example, the green tire 6 is formed to include:

[0044] (a) a carcass T1 extending from the tread portion 6a to the bead portion 6c via the sidewall portion 6b;

[0045] (b) a belt layer T2 arranged radially outside the carcass T1 and inside the tread portion 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com