High bending fatigue strength ceramic package outer lead and preparation method

A technology of bending fatigue strength and external lead installation. It is used in semiconductor/solid-state device manufacturing, electrical components, and electrical solid-state devices. It can solve problems such as bending and shedding, and achieve good electrical conductivity, high mechanical strength, and controllable grain size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] A method for preparing outer leads of ceramic packages with high bending fatigue strength, especially a method for preparing outer leads of digital, microwave, power electronics, optoelectronic devices and other ceramic packages with outer leads, comprising the following process steps:

[0017] a) Choose a material with good electrical conductivity and a thermal expansion coefficient (TEC) of 4.1 to 13×10 -6 K -1 , Metals or alloys with a thickness of 0.05 mm to 1.0 mm, such as copper, iron, nickel, iron-nickel, iron-cobalt-nickel metals or alloys;

[0018] b) According to the design requirements, use etching, cutting or punching to process the required shape;

[0019] c) Use N 2 , H 2 Or its mixed atmosphere protection, 300 ℃ ~ 1100 ℃ programmed temperature control heat treatment to remove material surface defects, and control the internal grain size at 1 ~ 80 μm;

[0020] d) Deposit metal or alloy on the surface by sputtering or plating process, such as zinc, chro...

Embodiment 1

[0025] a) Select the coefficient of thermal expansion to be 5.8×10 -6 K -1 , 0.3mm thick iron-nickel alloy sheet;

[0026] b) Process the required shape by chemical etching;

[0027] c) Clean with acetone and alcohol, and then 2 、H 2 Under protective atmosphere conditions, 1050°C, heat preservation for 30Min, eliminate pollution, oxide layer and internal stress generated during processing, and control the internal grain size at 30-80μm;

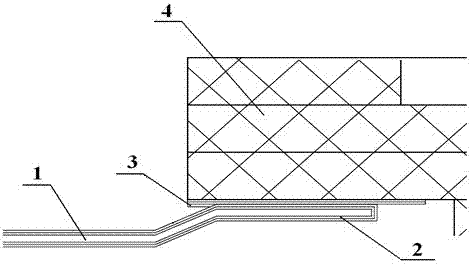

[0028] d) Assemble together according to the design requirements, such as figure 1 shown, using the N 2 , H 2 Mixed atmosphere protection, the temperature is 920 ℃ in the program temperature control furnace to complete the welding;

[0029] e) Post-soldering treatment, 10 minutes in an alkaline solution with a pH value of 10 to 12, 5 minutes in an acidic solution with a pH value of 2 to 4, and 5 minutes in a plasma surface cleaning device to remove the oxide layer or pollutants on the surface of the lead wire ;

[0030] f) Functional...

Embodiment 2

[0032] a) Select the coefficient of thermal expansion to be 5.8×10 -6 K -1 , 0.05mm thick iron-nickel alloy sheet;

[0033] b) Process the required shape by mechanical stamping, such as die stamping;

[0034] c) Clean with acetone and alcohol, and then 2 、H 2 Under protective atmosphere conditions, 1050°C, heat preservation for 30Min, eliminate pollution, oxide layer and internal stress generated during processing, and control the internal grain size at 30-80μm;

[0035] d) Assemble together according to the design requirements, such as figure 1 shown, using the N 2 , H 2 Mixed atmosphere protection, the temperature is 920 ℃ in the program temperature control furnace to complete the welding;

[0036] e) Post-soldering treatment, 10 minutes in an alkaline solution with a pH value of 10 to 12, 1 minute in an acidic solution with a pH value of 2 to 4, and 9 minutes in a plasma surface cleaning equipment to remove the oxide layer or pollutants on the surface of the lead wir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com