Multi-connection-flange tester and using method thereof

A tester and multi-connection technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc., to achieve the effect of simple and fast operation, ensuring air tightness requirements, and meeting production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

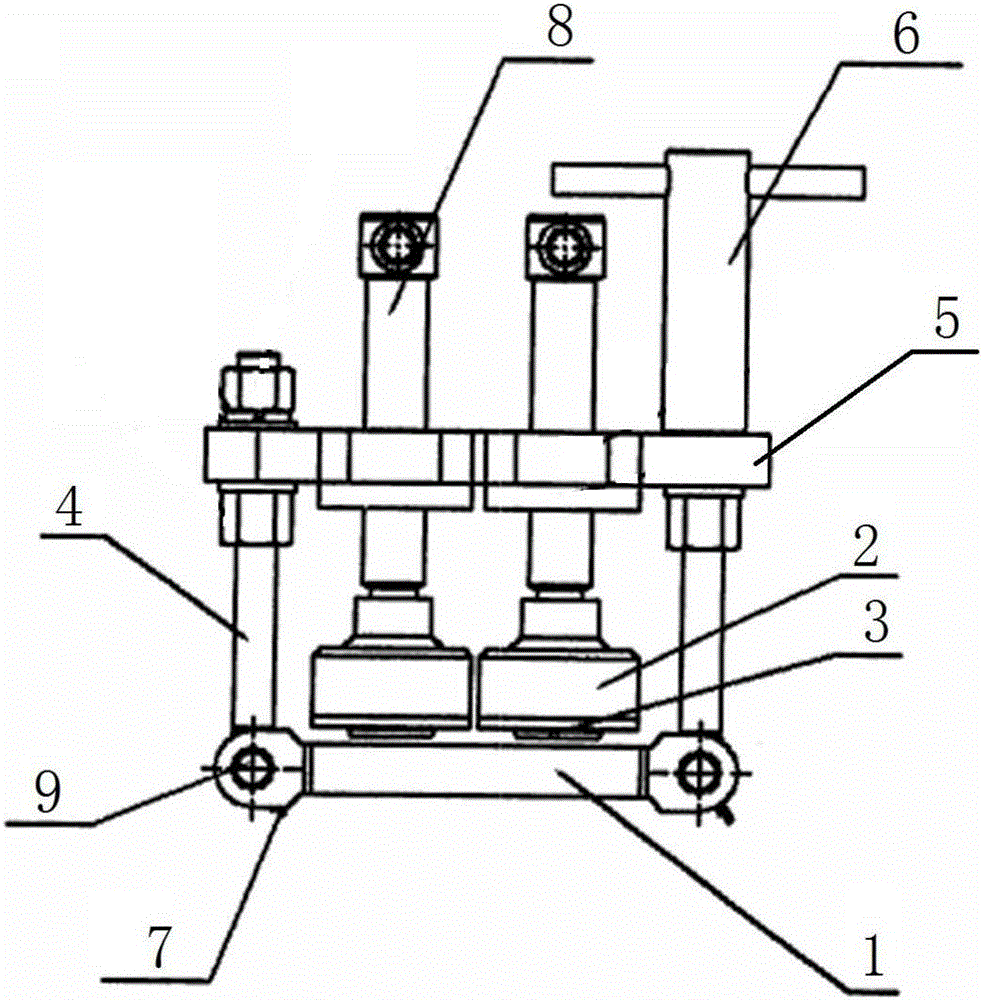

[0011] Such as figure 1 As shown, a multi-connection flange tester, a beam 5 is arranged above the base plate 1, and the base plate 1 and the beam 5 are connected by bolts 4, and a compactor 2 is provided between the base plate 1 and the beam 5, and the compactor 2 The upper end surface is provided with a screw 8, the screw 8 runs through the beam 5, the upper end surface of the beam 5 is provided with a handle 6, and the handle 6 corresponds to the position of the bolt 4 on one side.

[0012] Both ends of the base plate 1 are provided with cotter pins 7 , and the lower ends of the bolts 4 are connected with the cotter pins 7 through pin shafts 9 .

[0013] The lower end surface of the compactor 2 is provided with a rubber pad 3 .

[0014] There are two compactors 2 .

[0015] A method of using a multi-connection flange tester: adjust the handle 6, increase the distance between the compactor 2 and the bottom plate 1, place the flange parts that need to be tested for air tigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com