Welding airtightness detecting device and detecting method of battery box

A technology of air tightness detection and battery box, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement, and by measuring the acceleration and deceleration rate of fluid, etc. Accurate and rapid detection of tightness and double air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

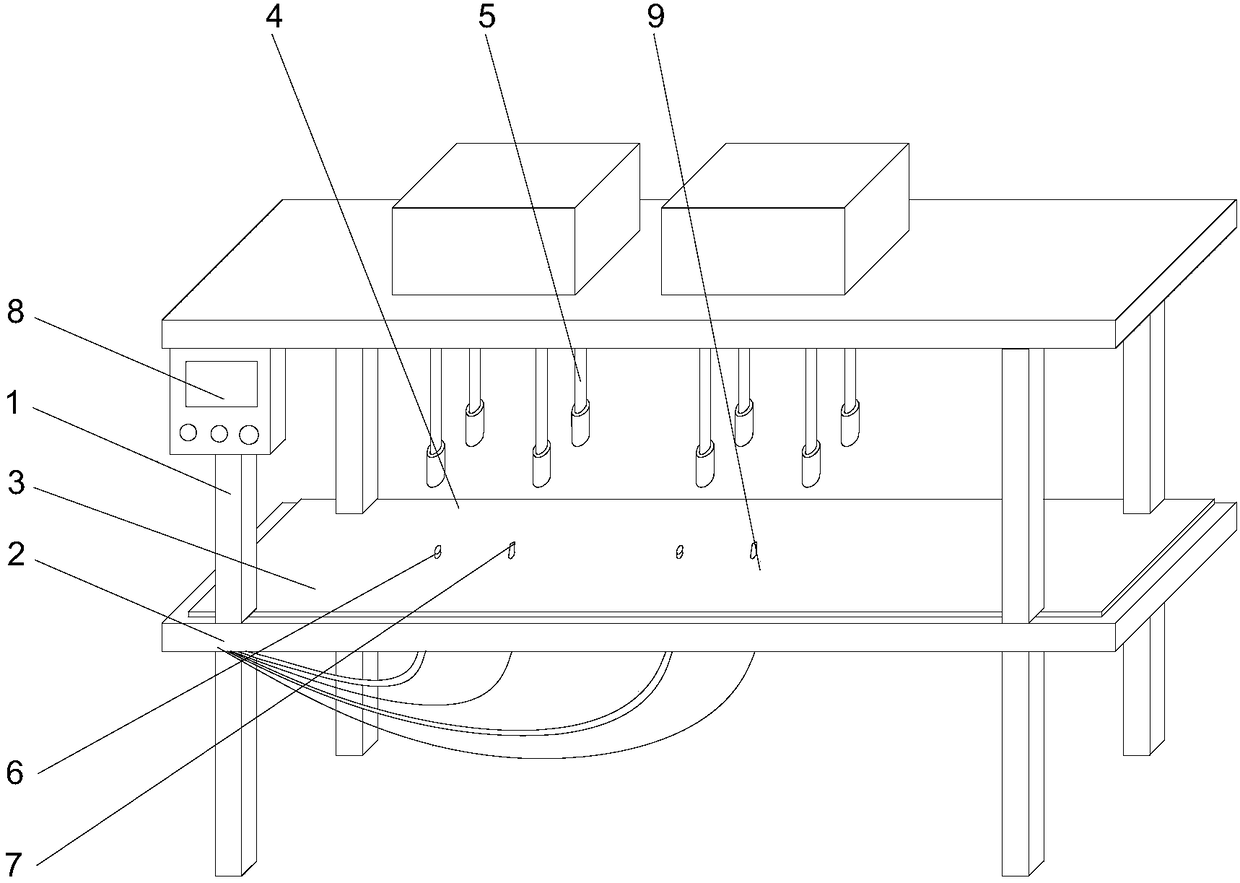

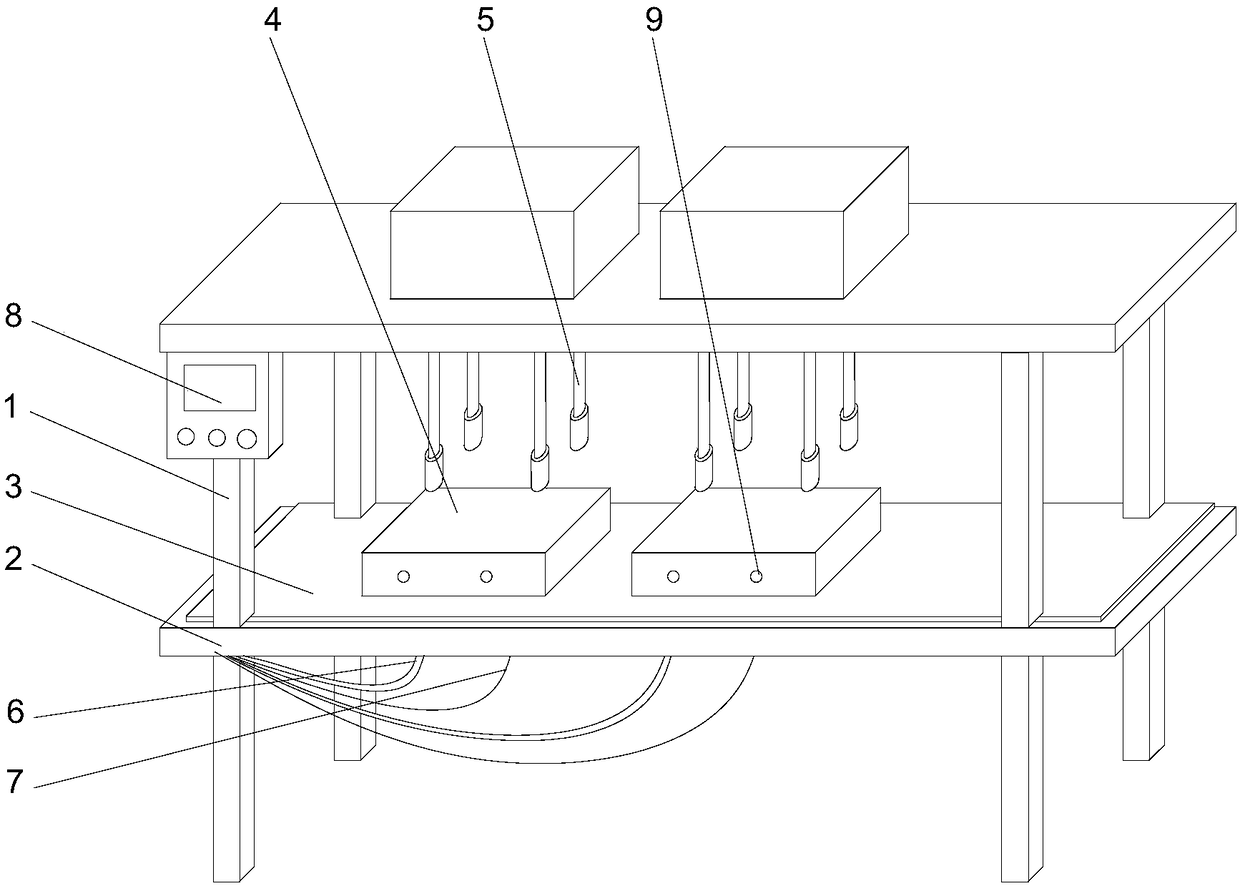

[0022] Such as figure 1 Or as shown in one of 2, the invention discloses a battery box welding air tightness detection device, which includes a detection platform 2 arranged on a frame 1, a plurality of detection stations are arranged on the detection platform 2, and the surface of the detection platform 2 An elastic backing plate 3 is provided, and the battery box 4 is placed on the elastic backing plate 3 corresponding to the detection station. A stamping cylinder 5 is arranged above each testing station, and the battery box 4 is airtightly buckled when the stamping cylinder 5 is pressed down. Closed on the elastic backing plate 3, the elastic backing plate 3 of each detection station is provided with a pressurized air pipe 6 and a pressure sensor 7 leading into the inner cavity of the battery box 4, and the pressurized air pipe 6 is used to pass through the battery box 4. The pressure sensor 7 is used to detect the air pressure in the inner cavity of the battery box 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com