Labyrinth sealing structure of industrial labyrinth compressor

A labyrinth seal, compressor technology, applied in mechanical equipment, machines/engines, liquid variable-capacity machinery, etc., can solve the problem of increasing compressor maintenance workload and operating costs, environmental pollution of separation and drainage, and large consumption of lubricating oil. and other problems, to achieve the effect of reducing unplanned downtime, reducing maintenance workload, and reducing the number of spare parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

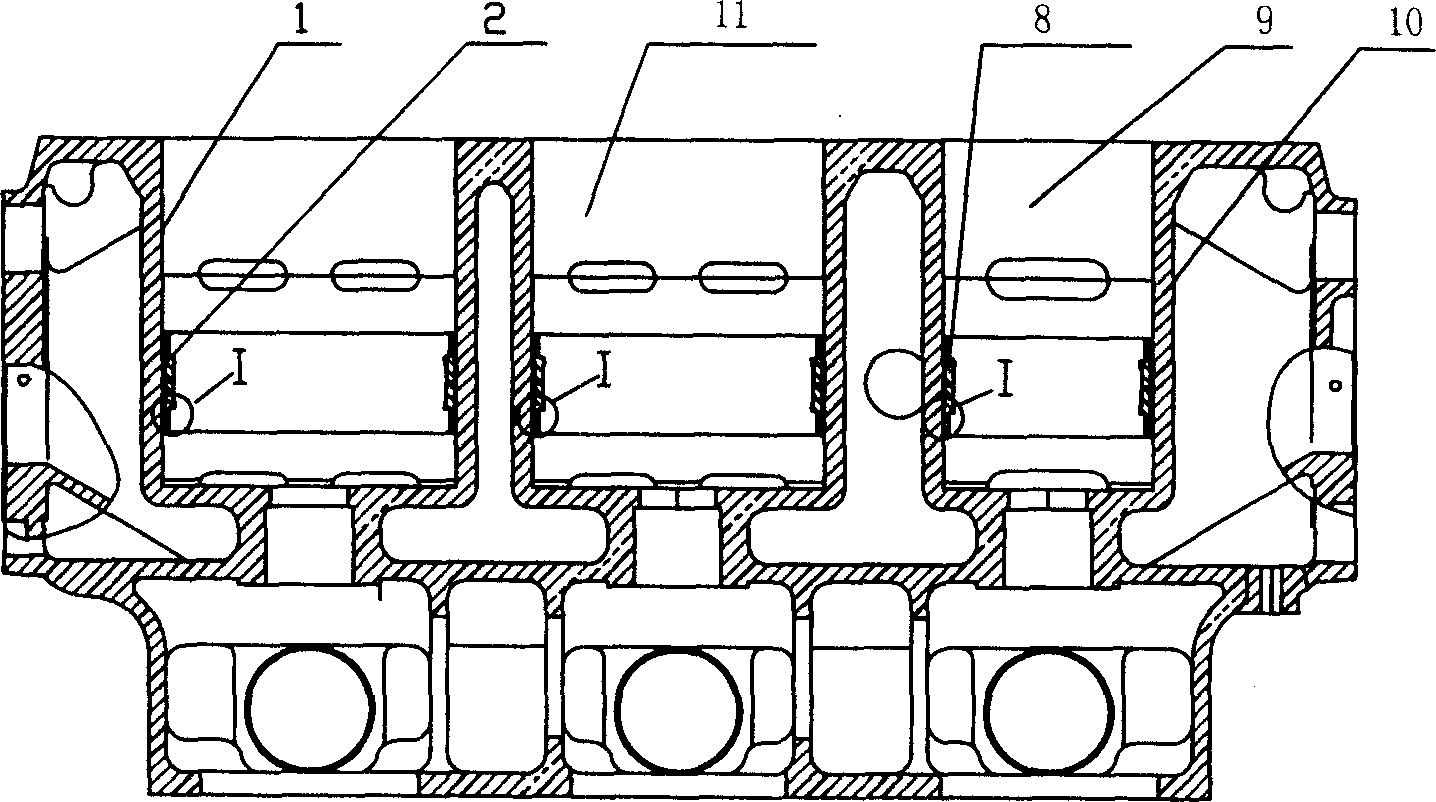

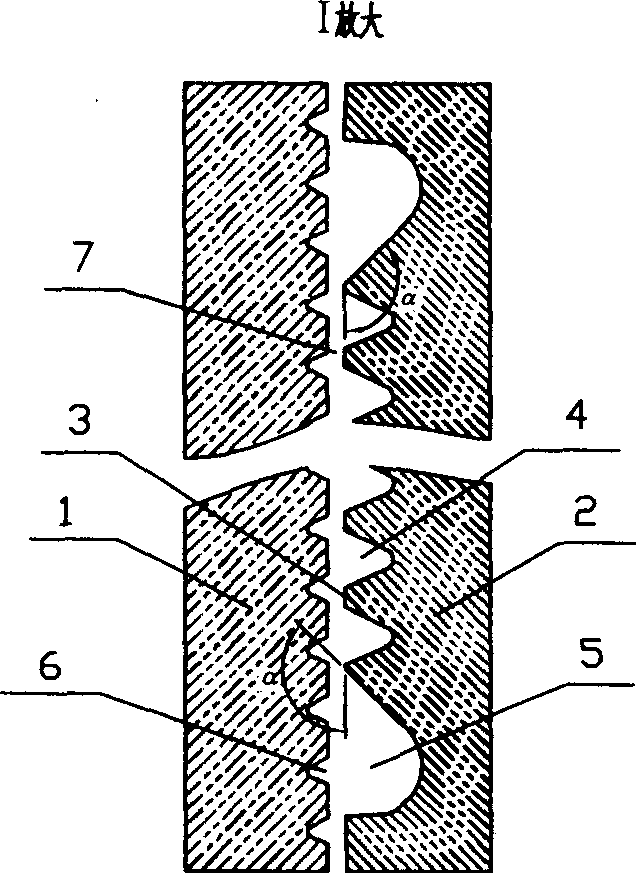

[0011] combine figure 1 , figure 2 , the present invention comprises a cylinder block, in which a cylinder chamber and a piston jacket 2 are arranged, and cylinder walls 1 are formed on both sides of the cylinder chamber 11, a labyrinth groove volume chamber is arranged on the cylinder wall 1, and a throttling point 3 is arranged on the piston jacket 2 , the volume chamber 4, the piston jacket 2 is separated from the cylinder wall 1 to form a small gap 7, the large three-row two-stage compression labyrinth compressor consists of two primary cylinder chambers 11 and a secondary cylinder chamber 9, when the primary piston When moving downward, the volume of the first-stage cylinder becomes larger, the first-stage intake valve opens, and the compressed gas enters the cylinder. When the piston moves upward, the piston works, the volume of the cylinder becomes s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com