Method for encapsulating CaO-Y2O3-Al2O3-SiO2 glass at port of SiCf/SiC core cladding tube

A glass encapsulation and cladding tube technology, applied in nuclear power generation, climate sustainability, fuel elements, etc., can solve problems such as loss of mechanical properties, exposed core, hydrogen explosion, etc., to ensure stable microstructure and nuclear irradiation. Small decay rate, small effect of nuclear radiation decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

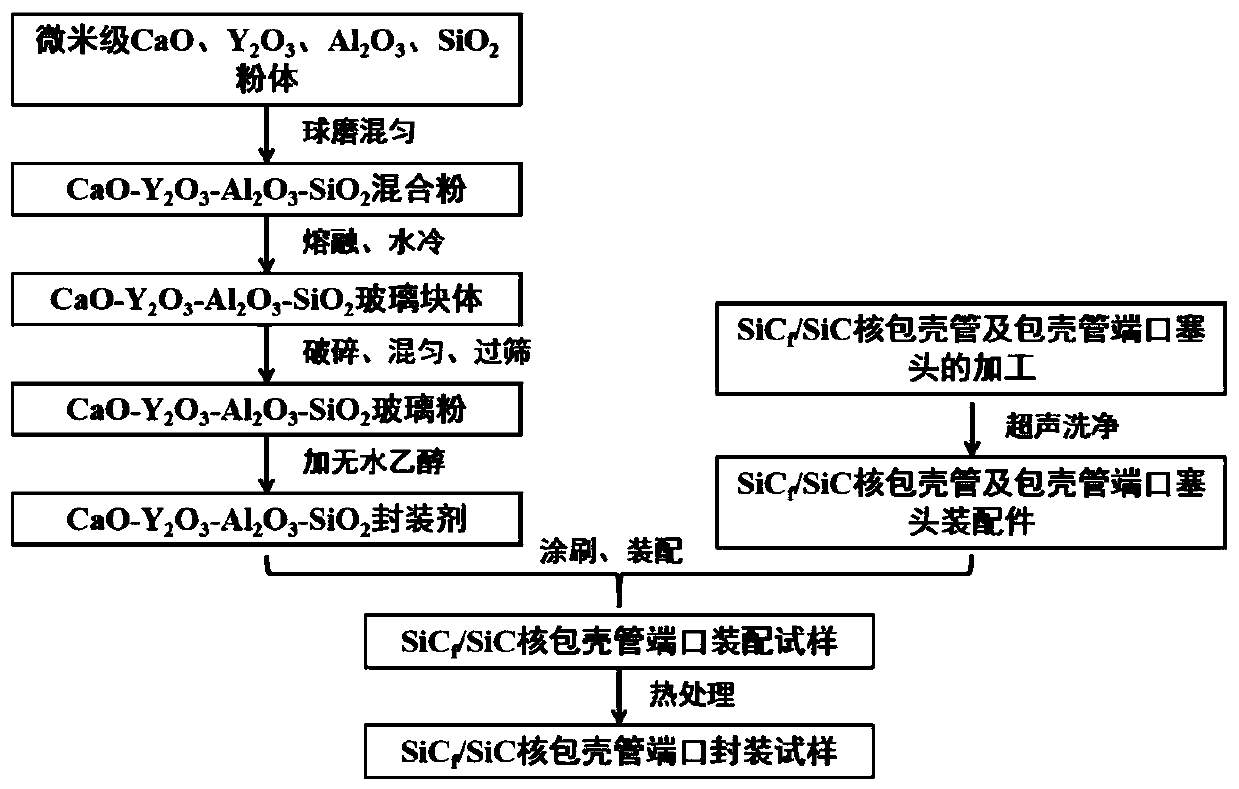

Embodiment 1

[0049] Use CaO and Y with a particle size of ~1μm 2 o 3 、Al 2 o 3 , SiO 2 Powder, its mass ratio is: 9.0% CaO, 18.2% Y 2 o 3 , 27.3% Al 2 o 3 , 45.5% SiO 2 , put the four kinds of powders into a ball mill jar and mill them at a speed of 300r / min for 12 hours, put the mixed powders after ball milling in an alumina crucible, and perform heat treatment in an air atmosphere. The heat treatment temperature is 1650°C, and the holding time is 2 Hours, after heat treatment, place it directly in cold water for rapid cooling to form a CYAS glass block. The glass block is crushed and ball-milled, and sieved through a 150-mesh sieve to obtain CYAS glass powder. Alcohol is added to the glass powder to form an encapsulating agent, and the mass fraction of the added alcohol is 90%. Coat the encapsulant on the inner wall of the cladding tube and the surface of the cladding tube plug to be sealed, press the glass powder into a sheet with a thickness of 3mm and place it on the claddin...

Embodiment 2

[0051] Use CaO and Y with a particle size of ~1μm 2 o 3 、Al 2 o 3 , SiO 2 Powder, its mass ratio is: 4.8% CaO, 19.0% Y 2 o 3 , 28.6% Al 2 o 3 , 47.6% SiO 2 , put the four kinds of powders into the ball milling jar and mill them at a speed of 300r / min for 12 hours, put the mixed powders after ball milling in an alumina crucible, and carry out heat treatment in an air atmosphere. The heat treatment temperature is 1600°C, and the holding time is 2 Hours, after heat treatment, place it directly in cold water for rapid cooling to form a CYAS glass block. The glass block is crushed and ball-milled, and sieved through a 150-mesh sieve to obtain CYAS glass powder. Alcohol is added to the glass powder to form an encapsulating agent, and the mass fraction of the added alcohol is 70%. Coat the encapsulant on the inner wall of the cladding tube and the surface of the cladding tube plug to be sealed, press the glass powder into a sheet with a thickness of 3mm and place it on the ...

Embodiment 3

[0053] Use CaO and Y with a particle size of ~1μm 2 o 3 、Al 2 o 3 , SiO 2 Powder, its proportioning mass ratio is: 20% Y 2 o 3 , 30% Al 2 o 3 , 50% SiO 2 , Put the four kinds of powders into the ball milling tank and mill them at a speed of 300r / min for 12 hours, put the mixed powders after ball milling in an alumina crucible, and perform heat treatment in an air atmosphere. The heat treatment temperature is 1650°C, and the holding time is 3 Hours, after heat treatment, place it directly in cold water for rapid cooling to form a YAS glass block. The glass blocks are crushed and ball-milled, and sieved through a 150-mesh sieve to obtain YAS glass powder. Alcohol is added to the glass powder to form an encapsulating agent, and the mass fraction of the added alcohol is 70%. Coat the encapsulant on the inner wall of the cladding tube and the surface of the cladding tube plug to be sealed, press the glass powder into a sheet with a thickness of 3mm and place it on the cla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com