Intelligent inspection robot

An intelligent inspection and robot technology, applied in the field of robots, can solve the problems of reducing work efficiency, alarm, and unclear equipment in the screen cabinet, and achieve the effect of monitoring temperature changes and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

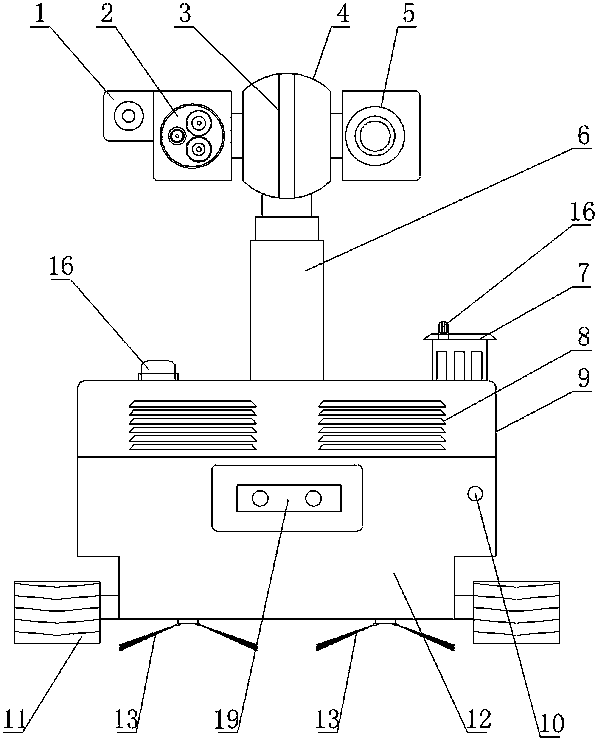

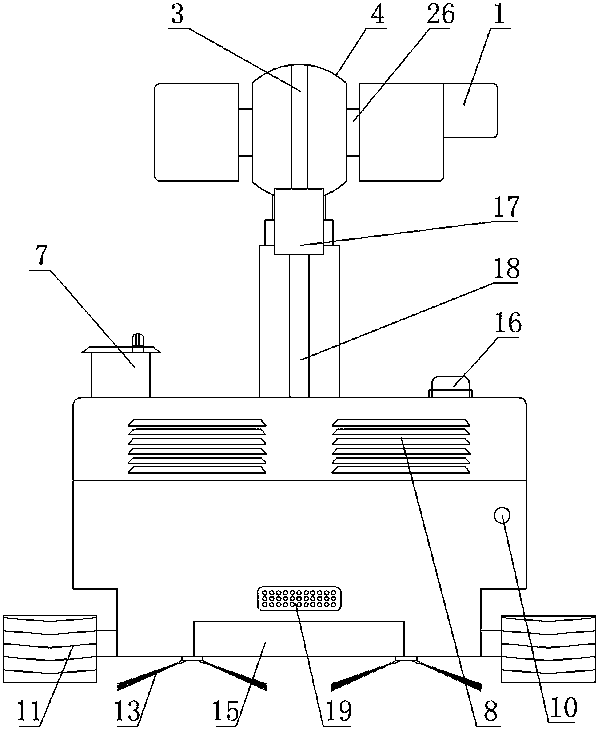

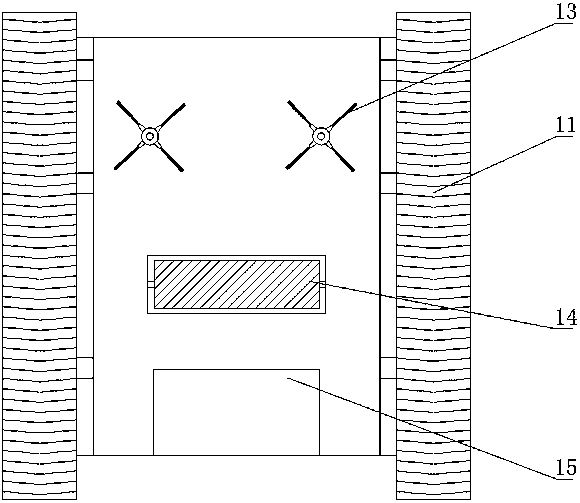

[0025] Such as Figure 1-8As shown, the intelligent inspection robot includes a main body 12, crawler belts 11 are provided on both sides of the lower side of the main body 12, a charging port 19 is provided on the rear side of the main body 12, and the four sides of the main body 12 are respectively provided with There is an infrared ranging sensor 10, the upper side of the main body 12 is provided with a main box 9, the front and rear sides of the main box 9 are respectively provided with cooling holes 8, and the middle part of the main box 9 is provided with a first Electric telescopic rod 6, the upper side of described first electric telescopic rod 6 is provided with ball type rotary joint 4, and the right side of described ball type rotary line joint 4 is connected with infrared thermal imager 5, and described ball The left side of the type rotary joint 4 is connected with a camera 2, the left side of the camera 2 is provided with an illuminating lamp 1, and the upper rig...

Embodiment 2

[0028] Such as Figure 1-8 As shown, the intelligent inspection robot includes a main body 12, crawler belts 11 are provided on both sides of the lower side of the main body 12, a charging port 19 is provided on the rear side of the main body 12, and the four sides of the main body 12 Infrared ranging sensors 10 are respectively provided, the upper side of the main body 12 is provided with a main box 9, the front and rear sides of the main box 9 are respectively provided with cooling holes 8, and the middle part of the main box 9 is provided with The first electric telescopic rod 6, the upper side of the first electric telescopic rod 6 is provided with a spherical rotary joint 4, and the right side of the spherical rotary joint 4 is connected with an infrared thermal imager 5, the said The left side of the spherical rotary joint 4 is connected with a camera 2, the left side of the camera 2 is provided with an illuminating lamp 1, and the upper right side of the main chassis 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com