Patents

Literature

41results about How to "Enough traction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

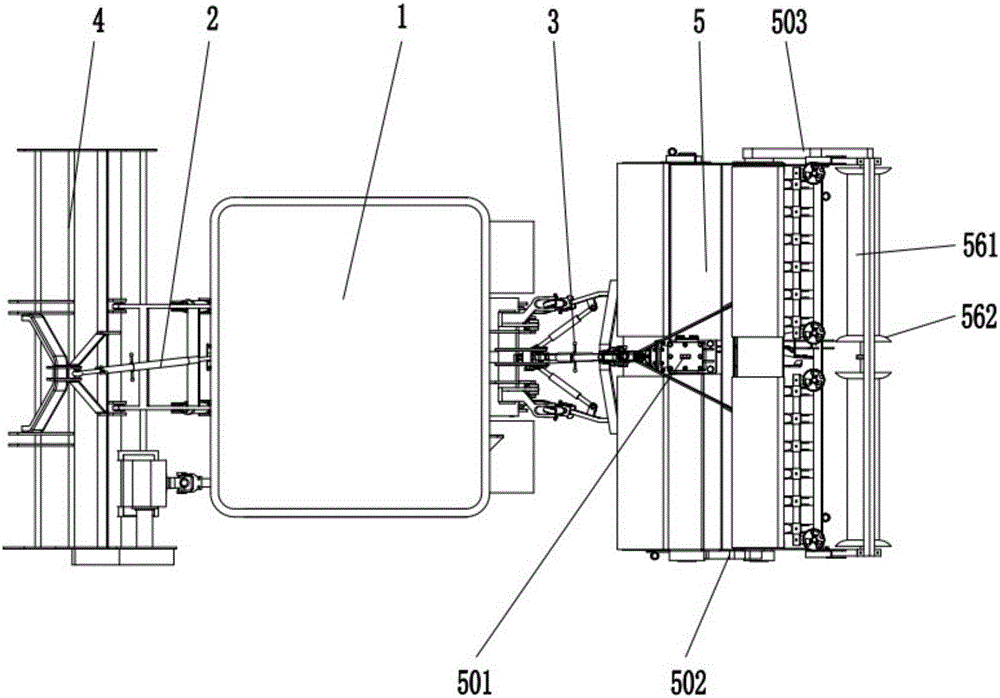

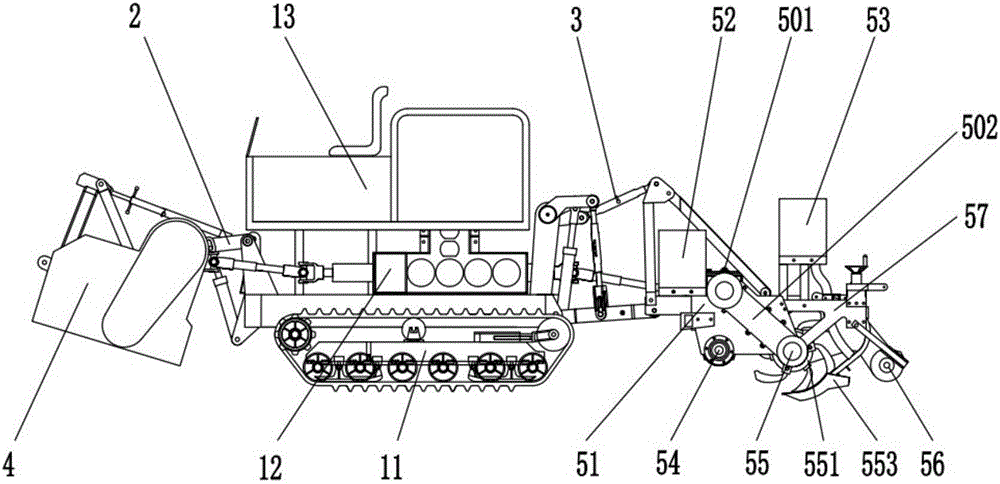

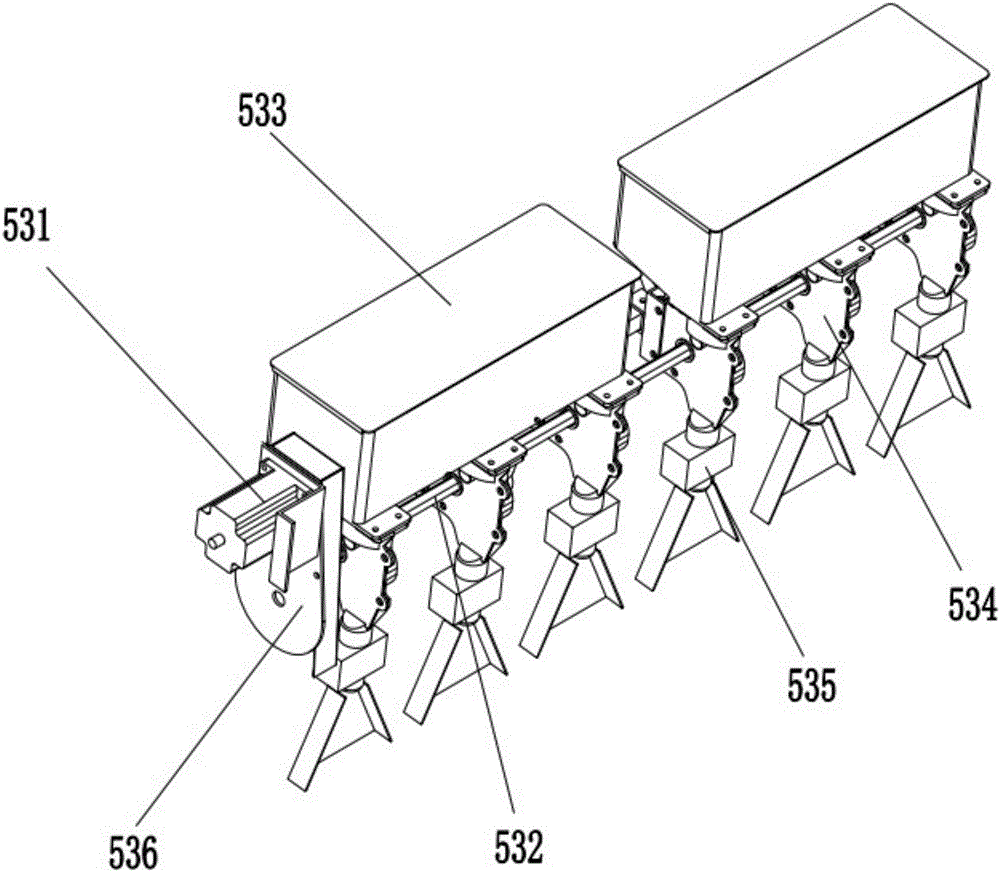

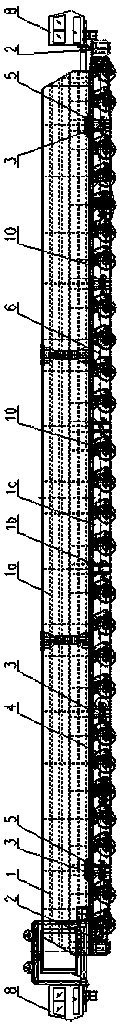

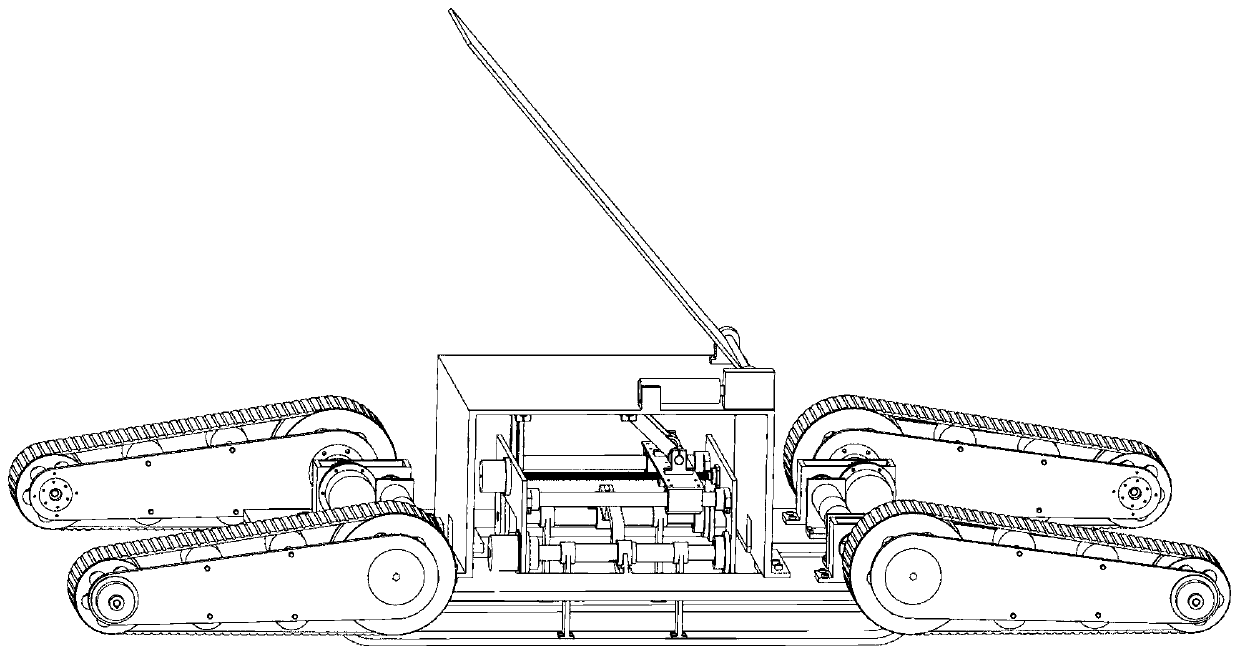

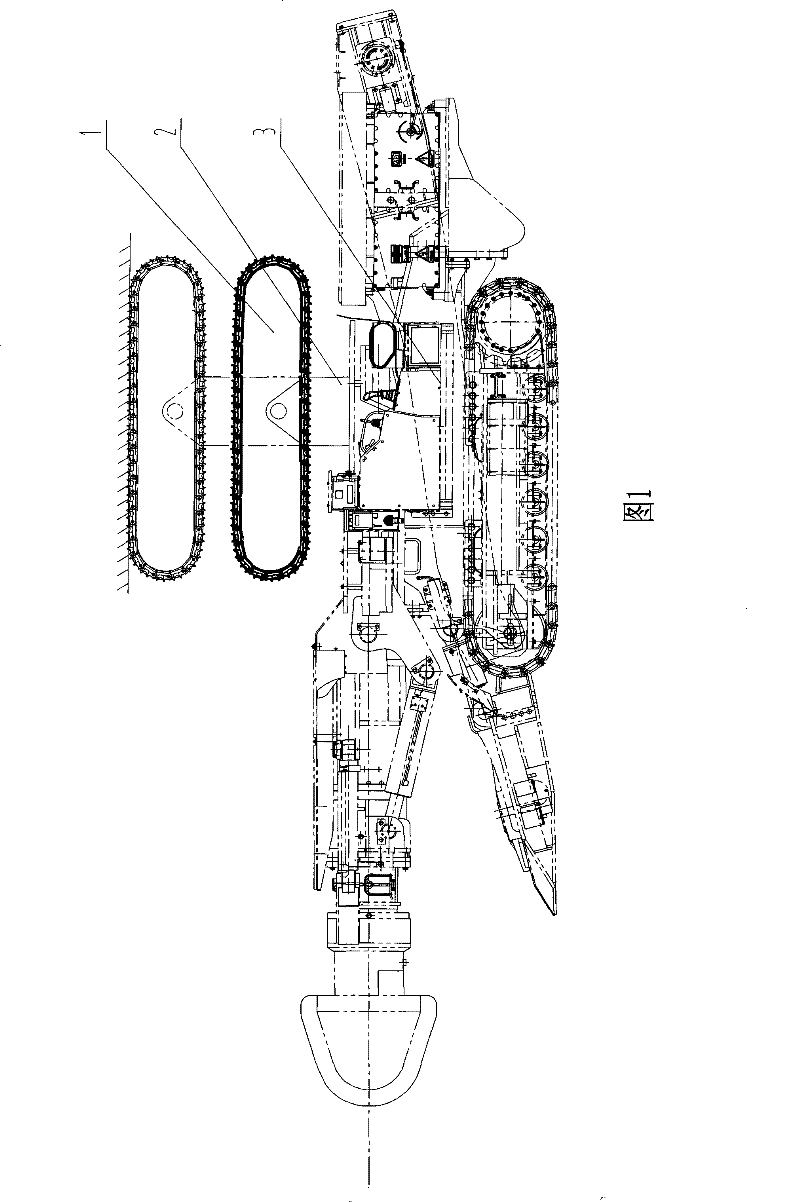

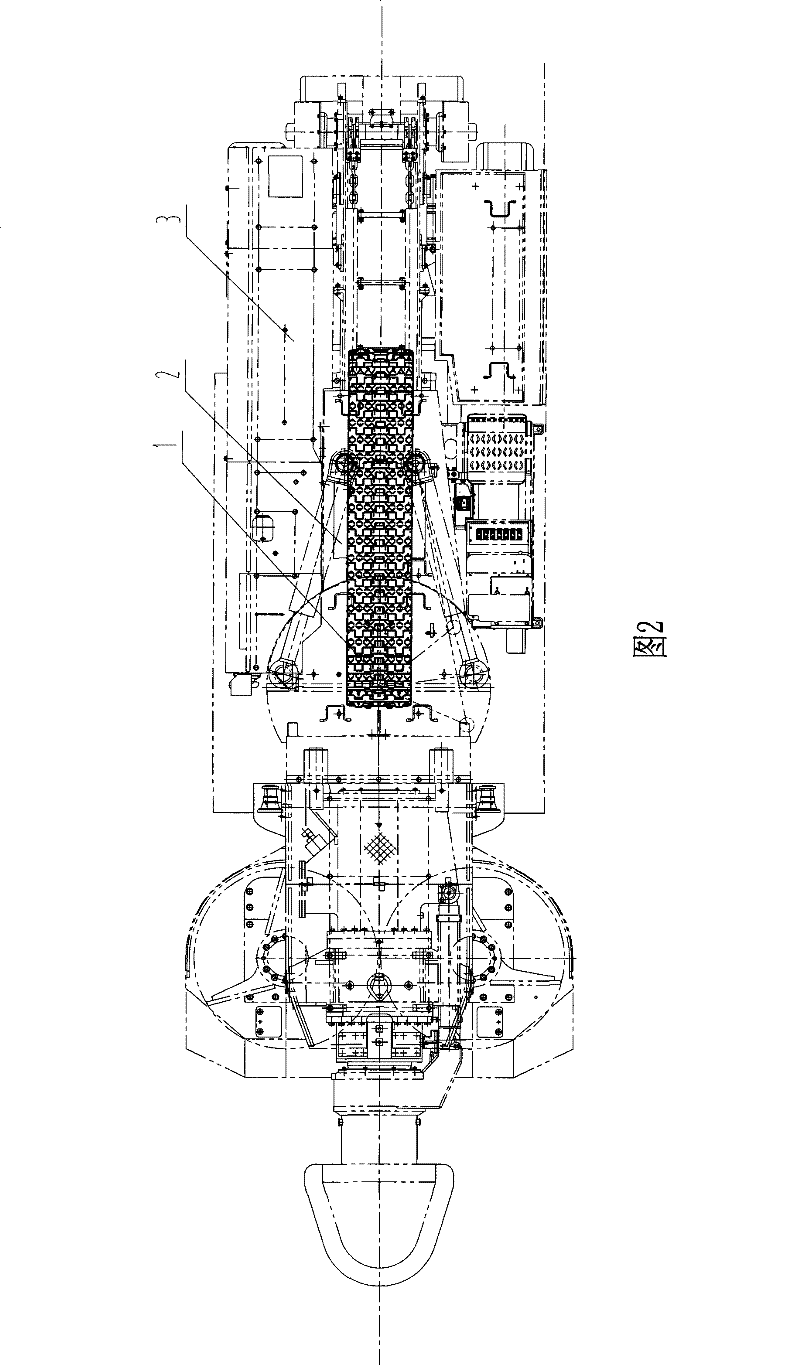

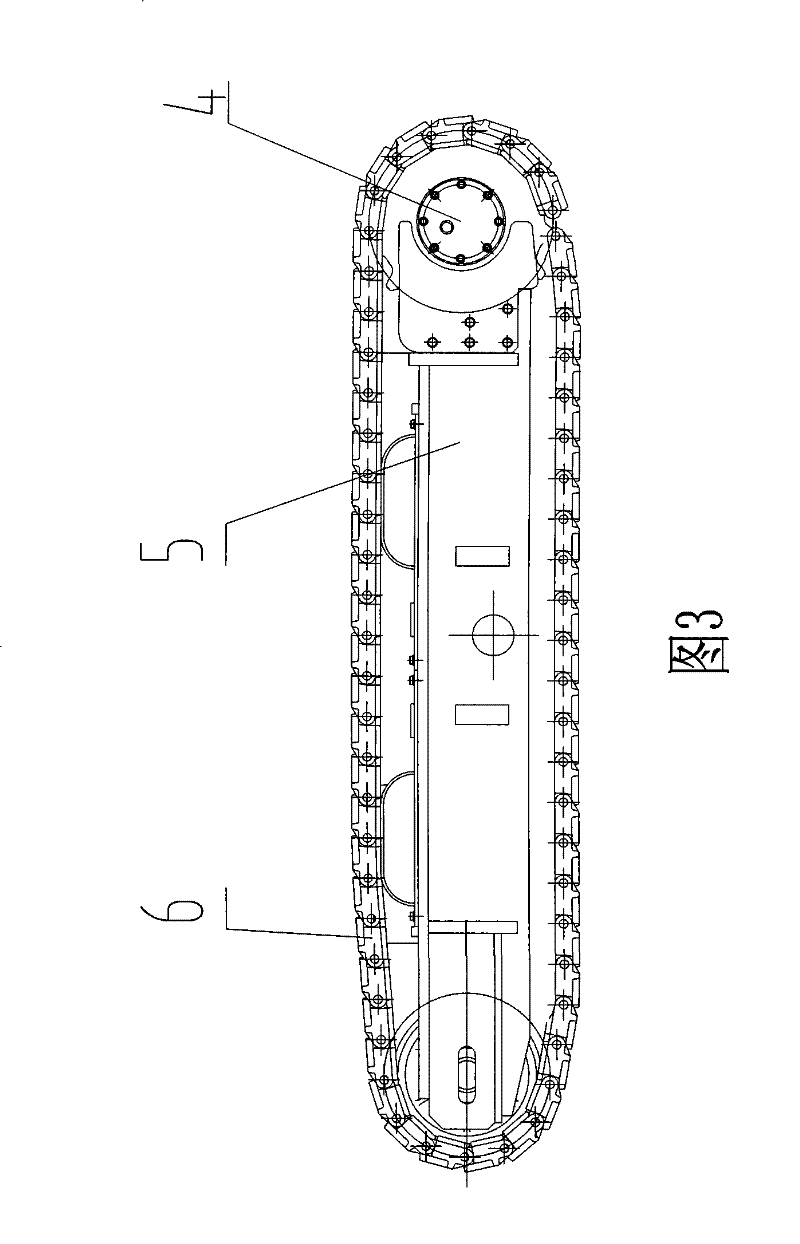

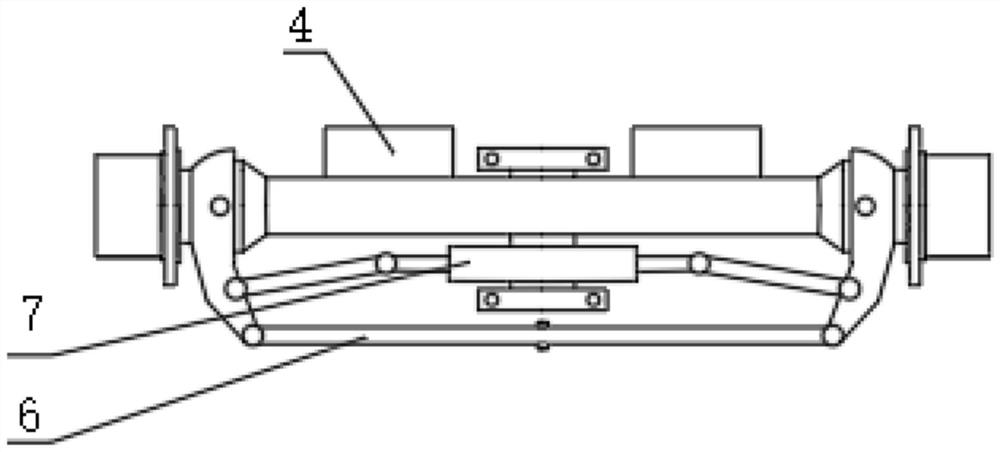

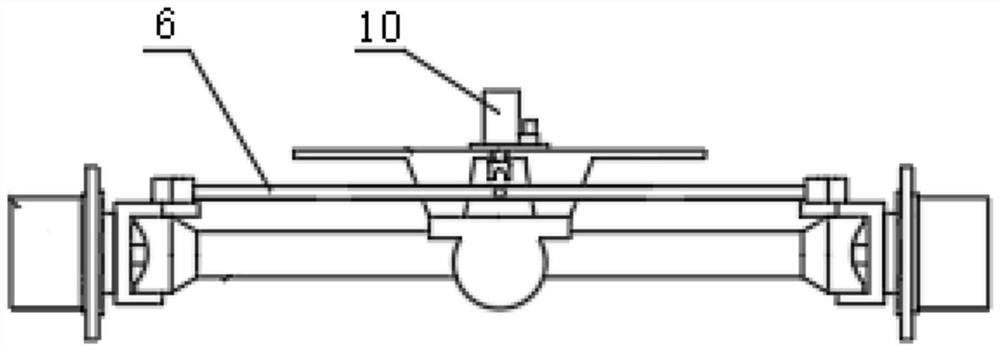

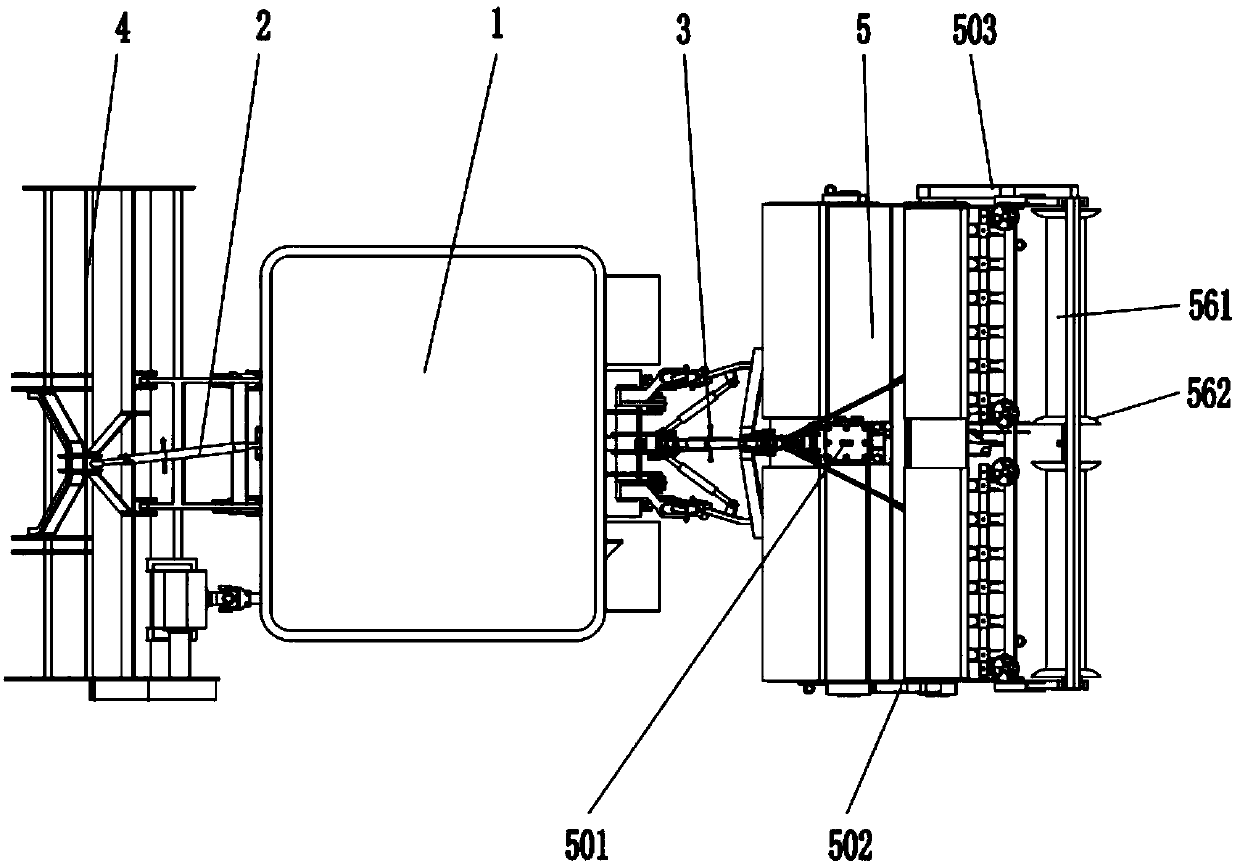

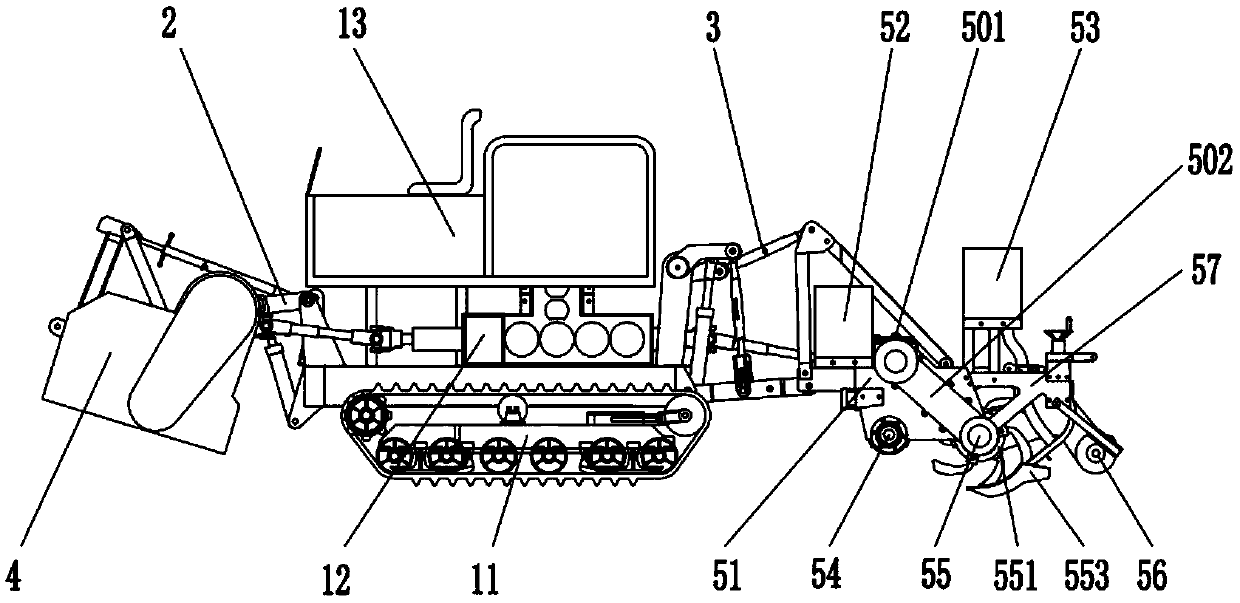

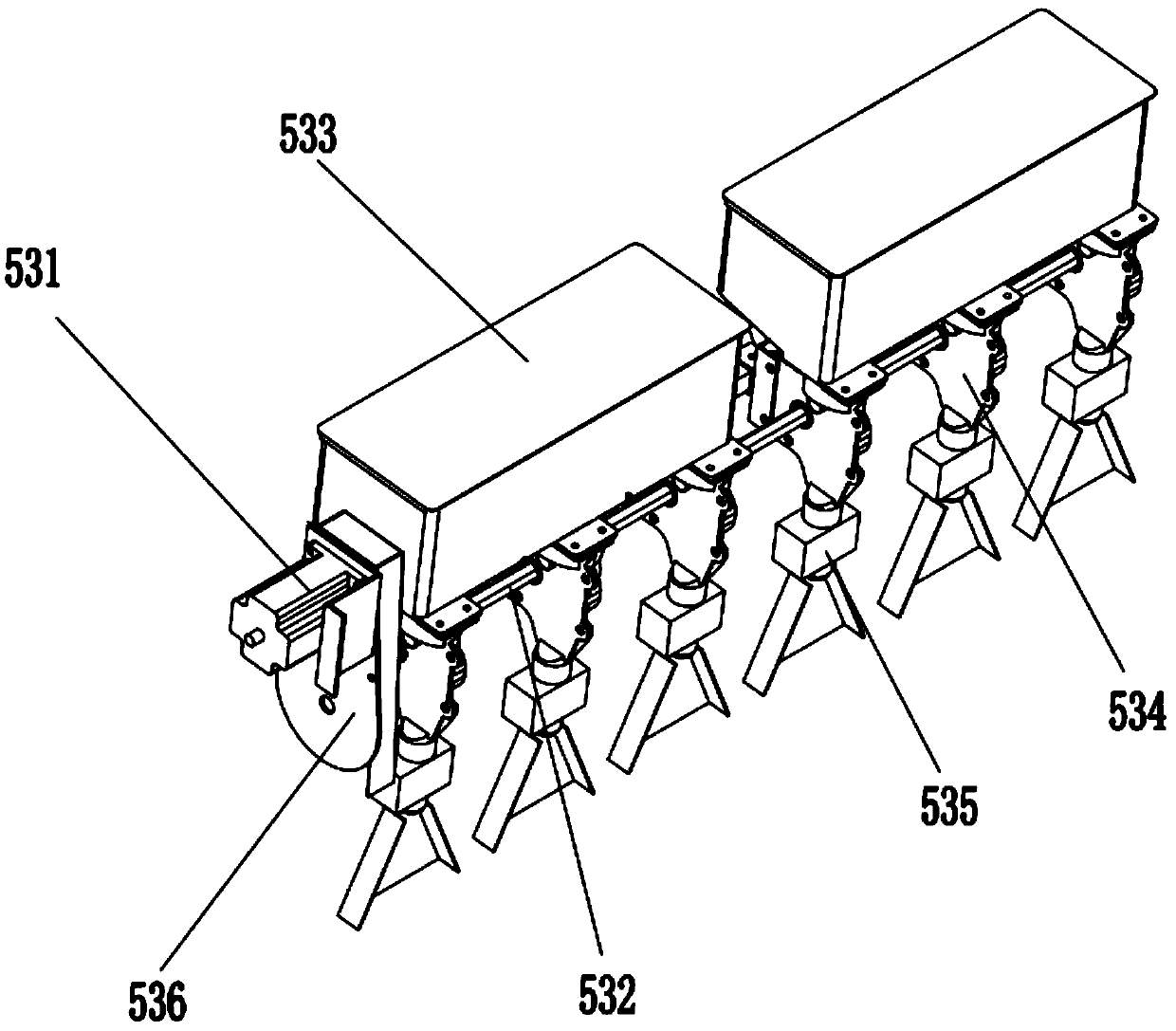

Self-propelled prepositive-straw-smashing postpositive-rotary tillage ditching, fertilizing and seeding combined operation equipment

ActiveCN106134553AWalking smoothlyReduce compactionSpadesPlantingAgricultural engineeringTurning frames

The invention discloses self-propelled prepositive-straw-smashing postpositive-rotary tillage ditching, fertilizing and seeding combined operation equipment and belongs to the field of agricultural machinery. The combined equipment comprises a power chassis assembly, a front suspension, a rear suspension, a straw smashing device and a finishing device, the straw smashing device is arranged in front of the power chassis assembly through the front suspension, and the finishing device is arranged in rear of the power chassis assembly; the power chassis assembly comprises a frame and crawler-type walking device, a transmission box and a driving cab assembly, the transmission box and the driving cab assembly are arranged on the frame and crawler-type walking device, and the finishing device comprises a fertilizing device, a seeding device, a rotary tillage device, a ditching device and a compacting device which are integrally mounted. The self-propelled prepositive-straw-smashing postpositive-rotary tillage ditching, fertilizing and seeding combined operation equipment integrally realizes various agricultural operations like returning smashed straw into fields, rotary tillage, fertilizing, ditching and seeding, so that working efficiency is improved greatly, and precision intelligent seeding is realized; straw is smashed and returned into the fields, so that resources are recycled, straw burning is avoided, environment is protected, and soil is improved.

Owner:TAICANG XIANGSHI AGRI MACHINE

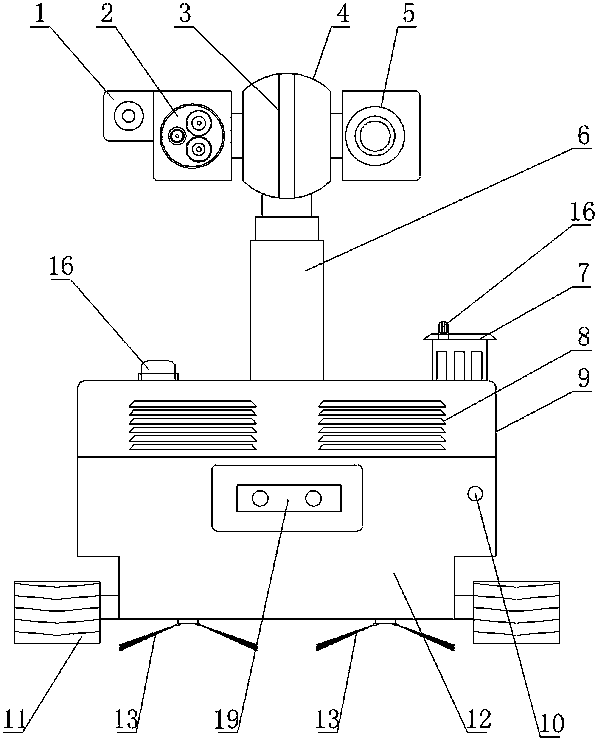

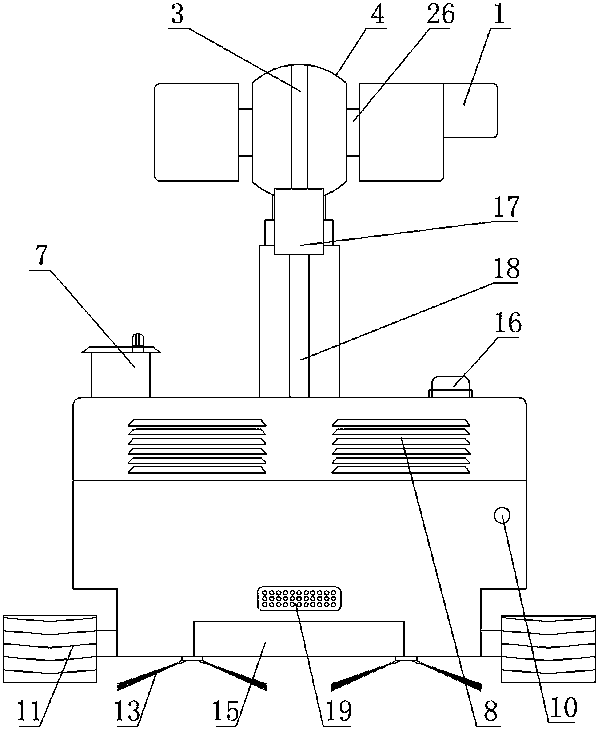

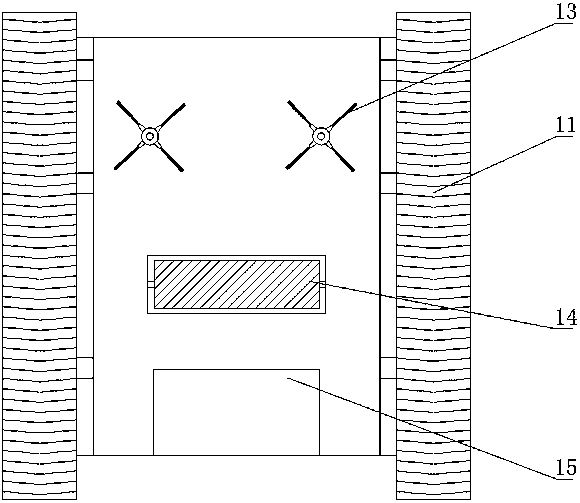

Intelligent inspection robot

PendingCN111061264AReduce noiseEnough tractionMeasurement devicesEndless track vehiclesThermographic cameraEngineering

The invention relates to an intelligent inspection robot which comprises a body. A charging connector is arranged on the front side of the body. Infrared distance measuring sensors are arranged on thefour faces of the body respectively. A host box is arranged on the upper side of the body. Heat dissipation holes are formed in the front side and the rear side of the mainframe box respectively. A first electric telescopic rod is arranged in the middle of the mainframe box. A spherical rotary joint is arranged on the upper side of the first electric telescopic rod. The right side of the spherical rotating wire joint is connected with an infrared thermal imager. The left side of the spherical rotary joint is connected with a camera. An illuminating lamp is arranged on the left side of the camera. A temperature and humidity sensor is arranged on the upper side of the right portion of a host. A sound sensor is arranged on the upper side of the temperature and humidity sensor. Crawler beltsare arranged on the two sides of the lower side of the body. Dusting brushes are arranged on the lower side of the body. A dust suction hole is formed in the rear side of the dusting brushes. A dust collection box is arranged on the rear side of the dust suction hole. The system has the advantages of being long in endurance time, high in intelligence, comprehensive in inspection, diversified in function and comprehensive in detection.

Owner:STATE GRID CORP OF CHINA +1

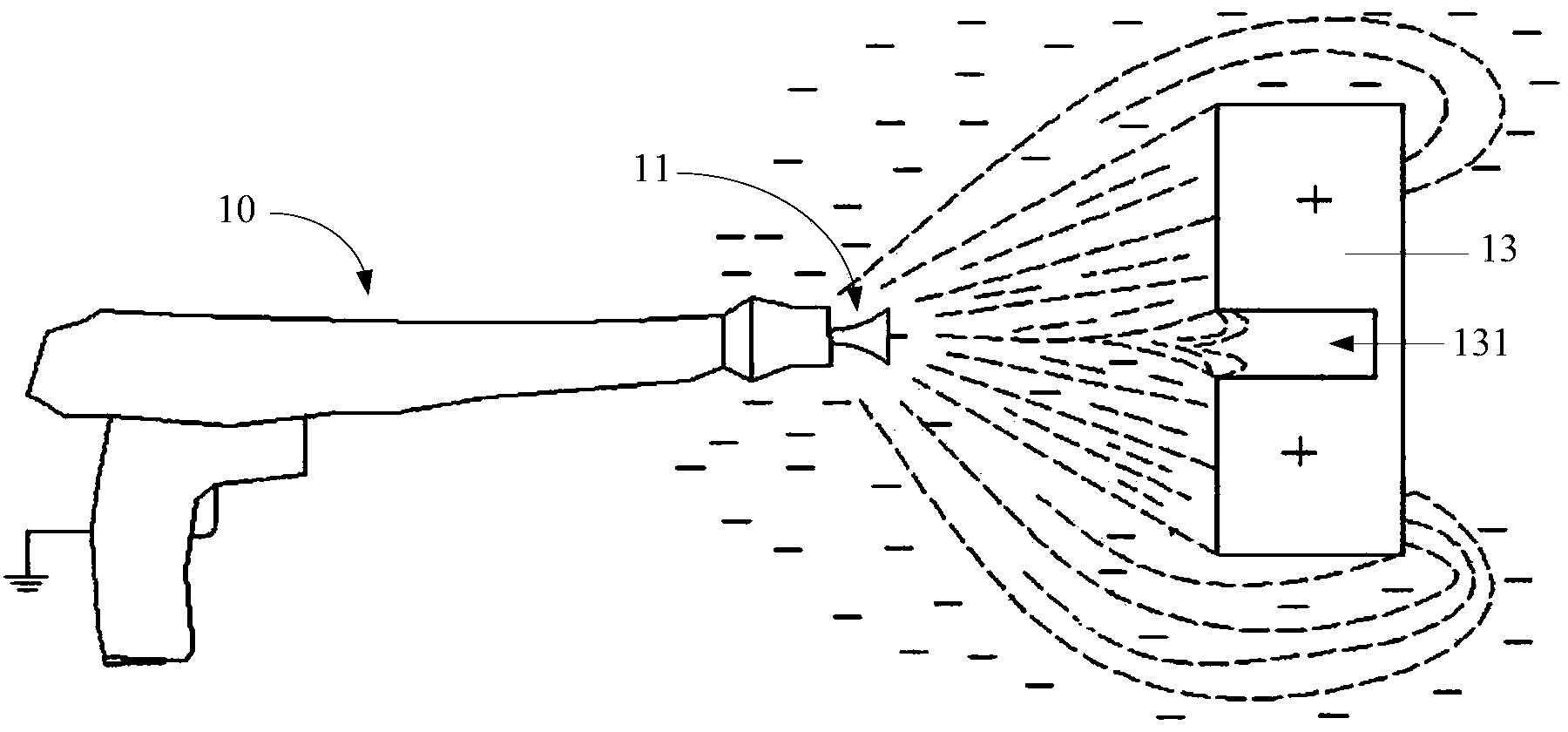

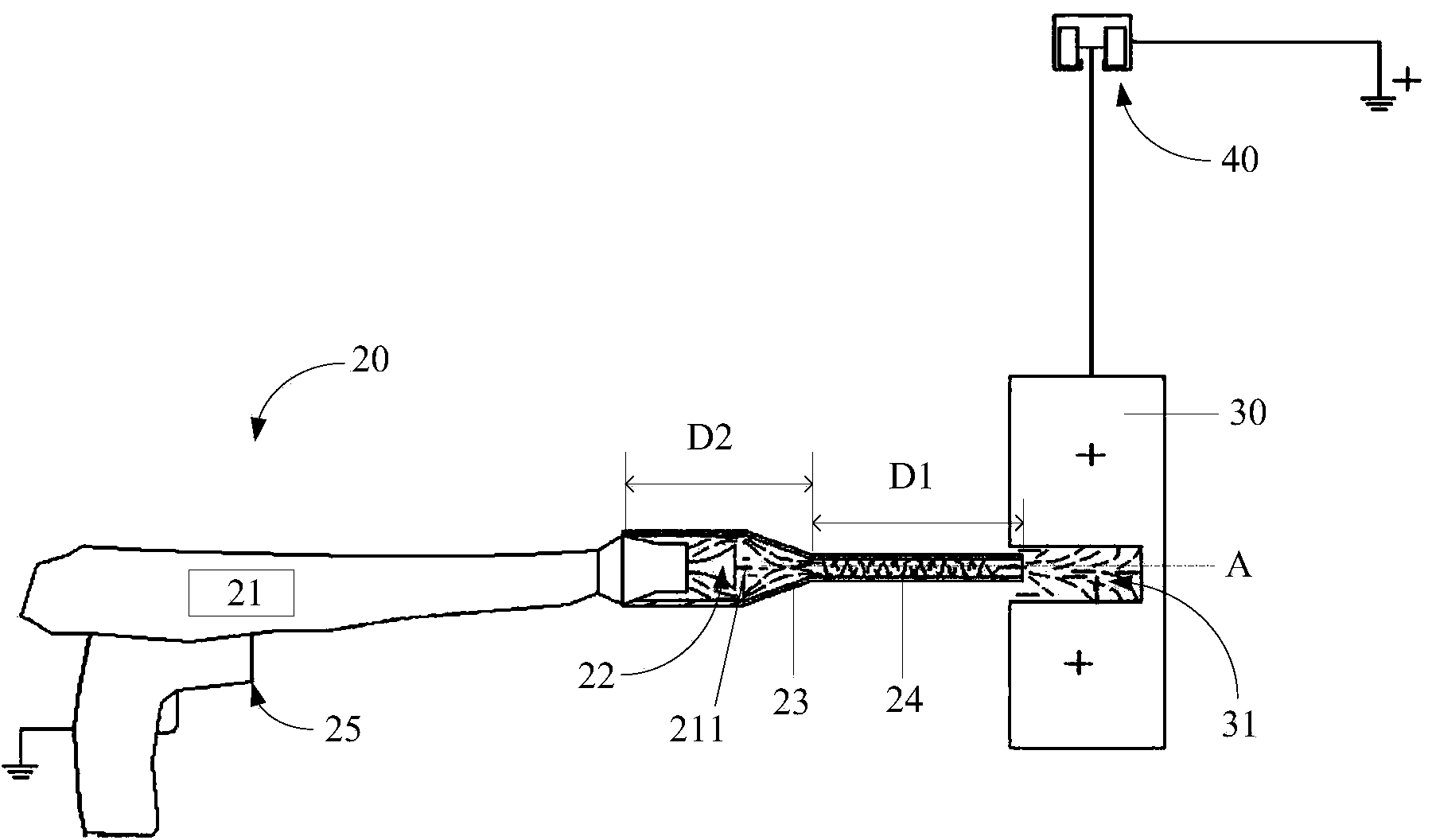

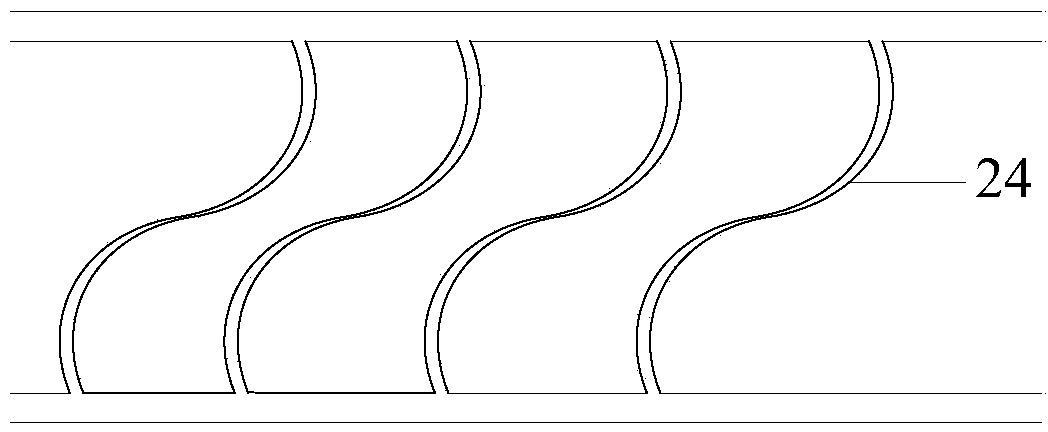

Electrostatic powder spraying device and spraying method thereof

ActiveCN104162492AReduce electrostatic force fieldIncrease the powder depthLiquid spraying plantsLiquid surface applicatorsEngineeringPowder Spray

The invention provides an electrostatic powder spraying device and a spraying method of the electrostatic powder spraying device. The electrostatic powder spraying device comprises a jet airflow generating element, an electric field generating element and an electric field shaping element, wherein the jet airflow generating element is used for generating jet airflow carrying electrified powder particles, the electric field generating element is used for generating an electrostatic force field for guiding the electrified powder particles between the electric field generating element and an element to be sprayed, and the electric field shaping element is used for shaping the electrostatic force field so as to reduce the Faraday cage electrostatic shielding effect of electrostatic force around a concave area of the element to be sprayed. Due to the mode, the problem that no power can be applied to the concave area of the element to be sprayed because of the Faraday cage electrostatic shielding effect can be solved, and the powder applying depth in the concave area is increased.

Owner:ANHUI TATFOOK TECH CO LTD

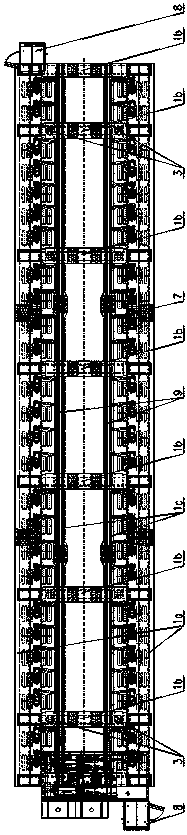

Low-level girder transporting vehicle and bridge erection and installation method

PendingCN109610319ALower the altitudeReduce wearVehicle to carry long loadsBridge erection/assemblyTraction systemBuilding construction

The invention, which belongs to the technical field of bridge construction machinery and methods, is named as a low-level girder transporting vehicle and a bridge erection and installation method. Theinvention mainly provides a low-level transporting girder vehicle comprising a vehicle body, telescopic support legs, a box beam jacking cylinder, a suspension running assembly, a truss mechanism, atruss mechanism traction system, a steering cylinder and driver cabs. The telescopic support legs and the box beam jacking cylinder are arranged at the vehicle body respectively; the driver cabs are arranged at the front end and the rear end of the vehicle body; and a rotating mechanism is arranged between the driver cabs and the vehicle body. The vehicle body has a U-shaped structure and is provided with a track. The truss mechanism is arranged on the track and is connected with the truss mechanism traction system. The suspension running assembly and the steering cylinder are arranged below the vehicle body; and the steering cylinder is connected to the vehicle body and the suspension running assembly. The low-level transporting girder vehicle can be applied to transportation of different-span box beams for tunneling and bridge erection construction.

Owner:HAN JIANG HEAVY IND CO LTD 11TH BUREAU GRP CRCC +1

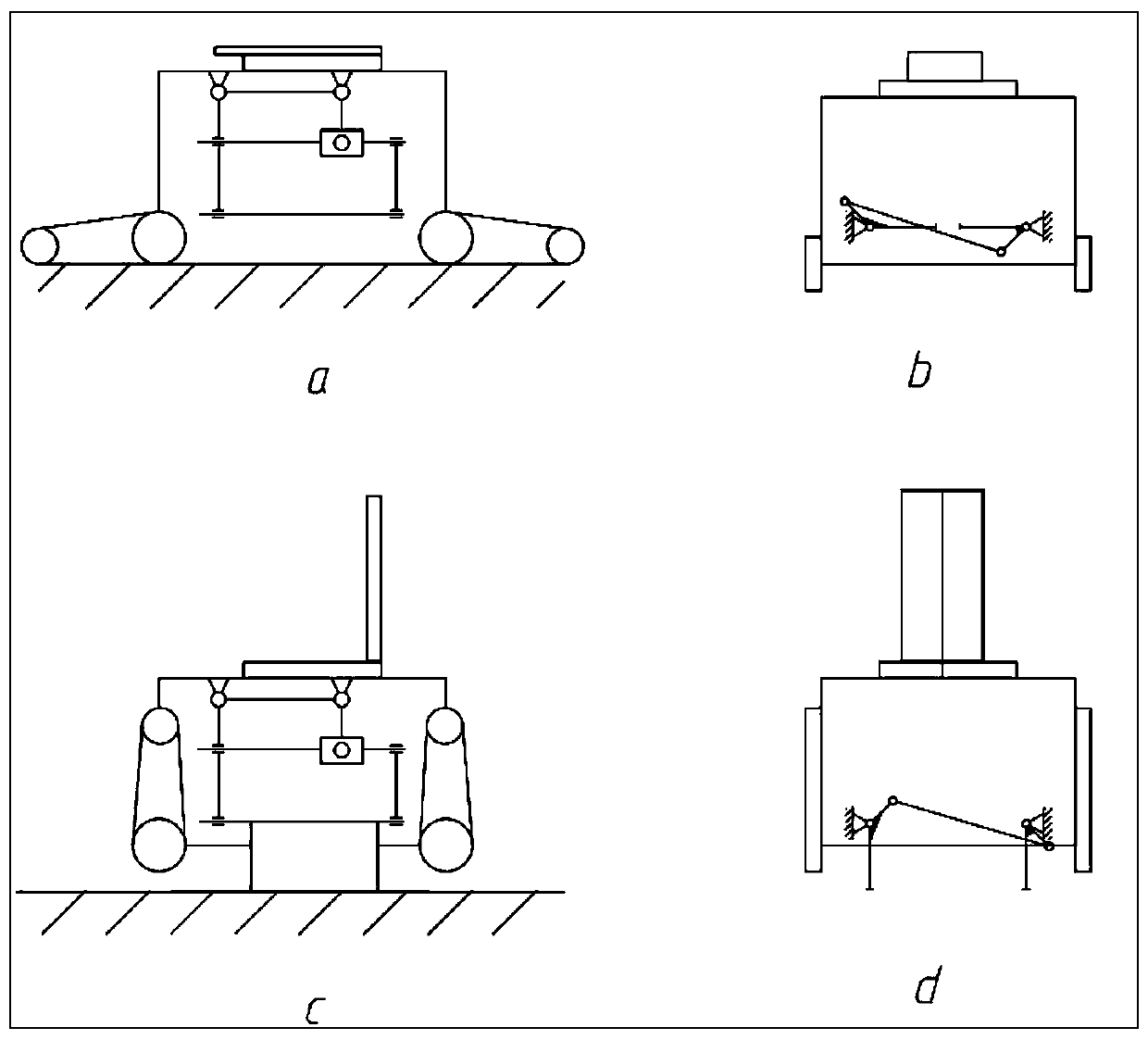

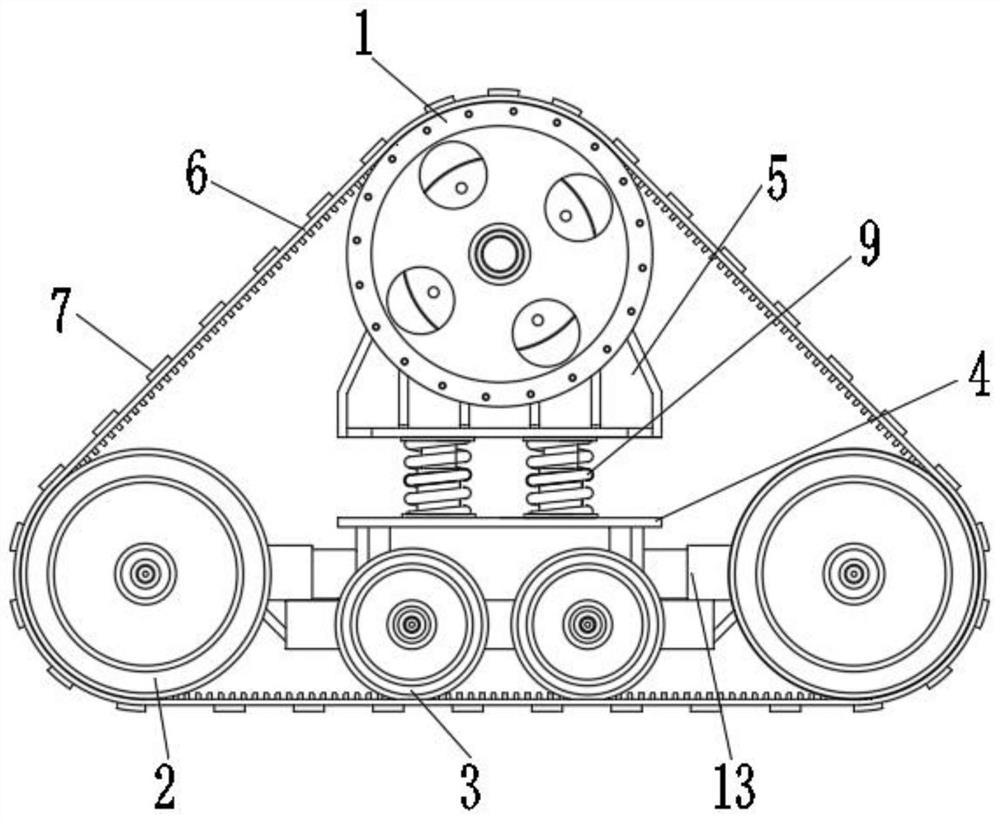

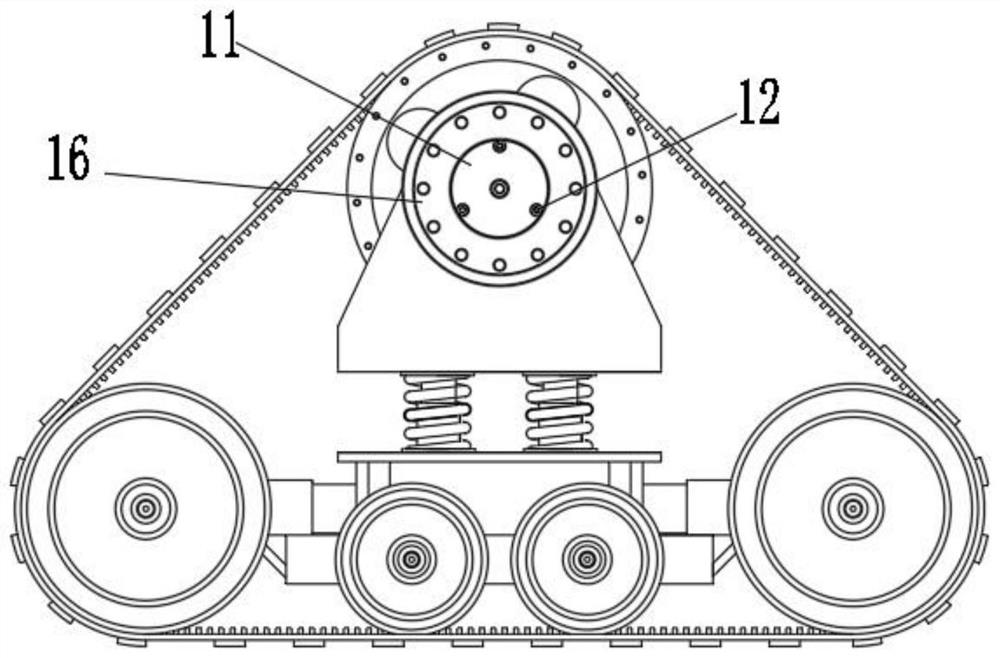

Crawler-type sleigh composite walking polar region robot

ActiveCN110481667AIncrease the polar outdoor exploration distanceImprove usage characteristicsSledgesDrive wheelReducer

The invention provides a crawler-type sleigh composite walking polar region robot. A position-changing crawler walking mechanism comprises four independent walking crawlers and a crawler rocker arm support. The walking crawler comprises a crawler belt body, driving wheels, supporting wheels and guide wheels. The crawler belt surrounds the driving wheels, the supporting wheels and the guide wheels,the driving wheel rotates in the mode that a hollow shaft is connected with a speed reducer shaft, the crawler rocker arm support rotates in the mode that a solid shaft located in the hollow shaft rotates, and different crawler advancing movement modes are achieved by controlling locking of a front guide wheel shaft and a rocker arm shaft. A sail sleigh mechanism comprises a sail at the top of arobot body and a sleigh at the bottom and capable of ascending and descending freely. The sail at the top can ascend and descend through a gear motor, the sleigh at the bottom can pop up from the bottom of the vehicle body, the angle of the sleigh is adjusted, and the pitching degree of the robot is further adjusted; the vehicle body can still be kept horizontal when the robot runs on an inclinedroad surface, and therefore it is guaranteed that instruments in the vehicle body can normally run.

Owner:HARBIN ENG UNIV

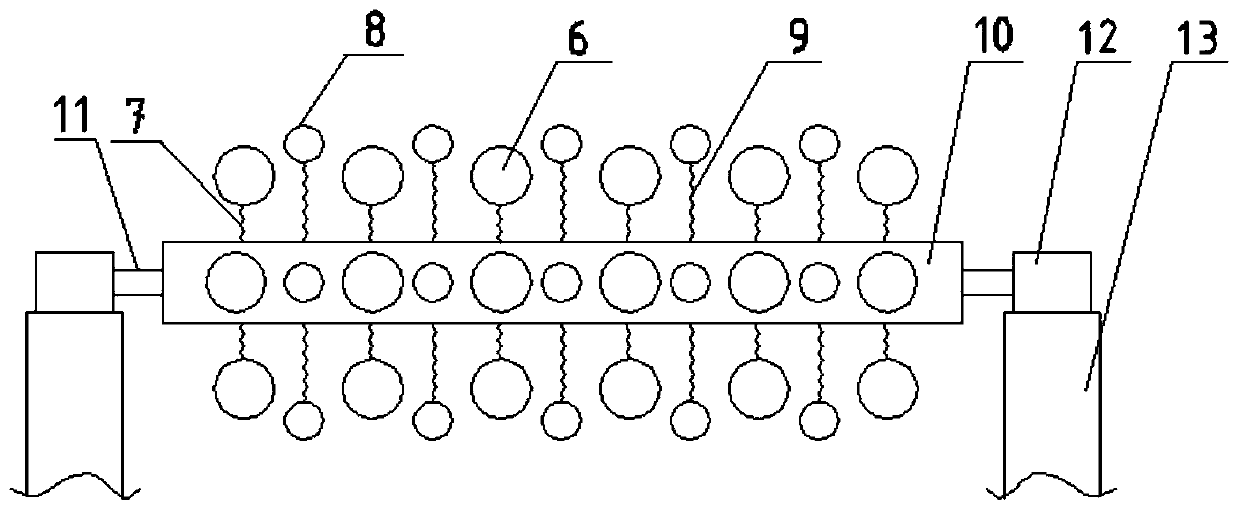

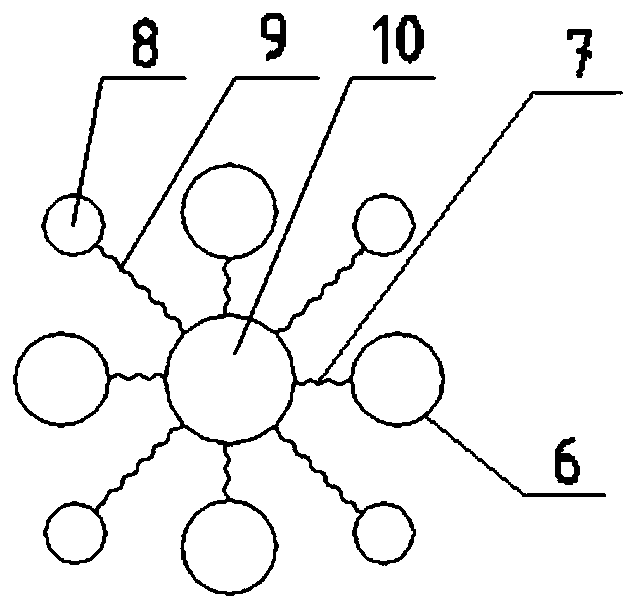

Unpowered rolling beating sweeping device and method

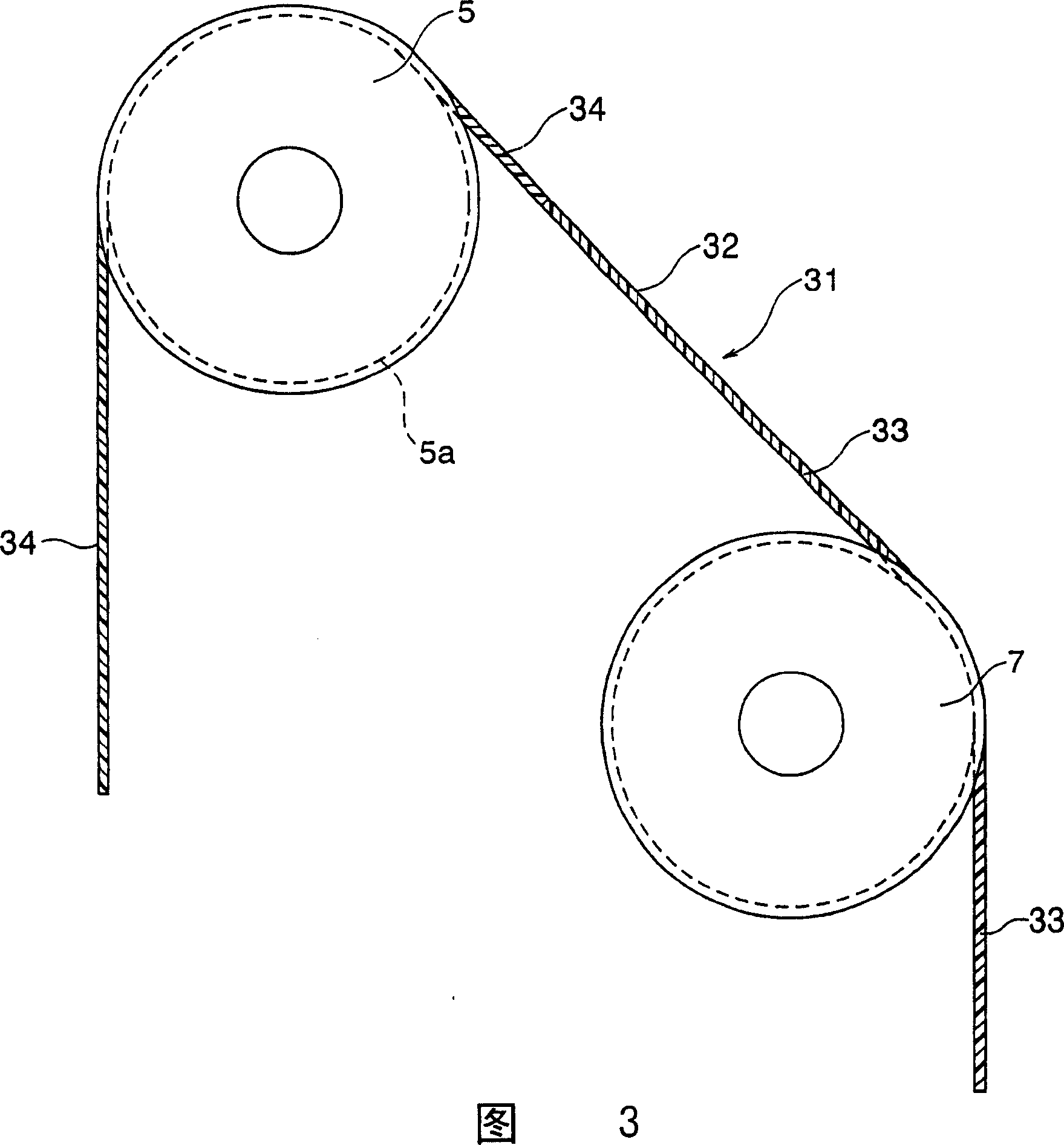

ActiveCN109761018AAvoid dust and spillage of materialsImprove the site environmentCleaningLeather beltEngineering

The invention discloses an unpowered rolling beating sweeping device and method. The device comprises a belt surface, a head transmission roller, a head hopper, an unpowered rolling beating sweeper and a support, wherein the belt surface is tightly attached to the head transmission roller to rotate, the head hopper is arranged outside the head transmission roller and the unpowered rolling beatingsweeper, the unpowered rolling beating sweeper is arranged on the inner surface of the belt surface in the return direction, and the belt surface is arranged between the wall surface of the head hopper and the unpowered rolling beating sweeper; and the unpowered rolling beating sweeper comprises a hammer I, a spring I, a hammer II, a spring II, a rolling bearing, a sweeper center shaft and a rolling bearing block, wherein the hammer I, the spring I, the hammer II and the spring II are arranged on the rolling bearing. According to the device and method, adhesive material on a material conveyingsurface of a belt conveyor can be effectively removed, so that friction between a belt and an equipment support caused by long-term and frequent deviation is reduced, and the normal service life of the belt on the belt conveyor is prolonged.

Owner:马钢集团设计研究院有限责任公司

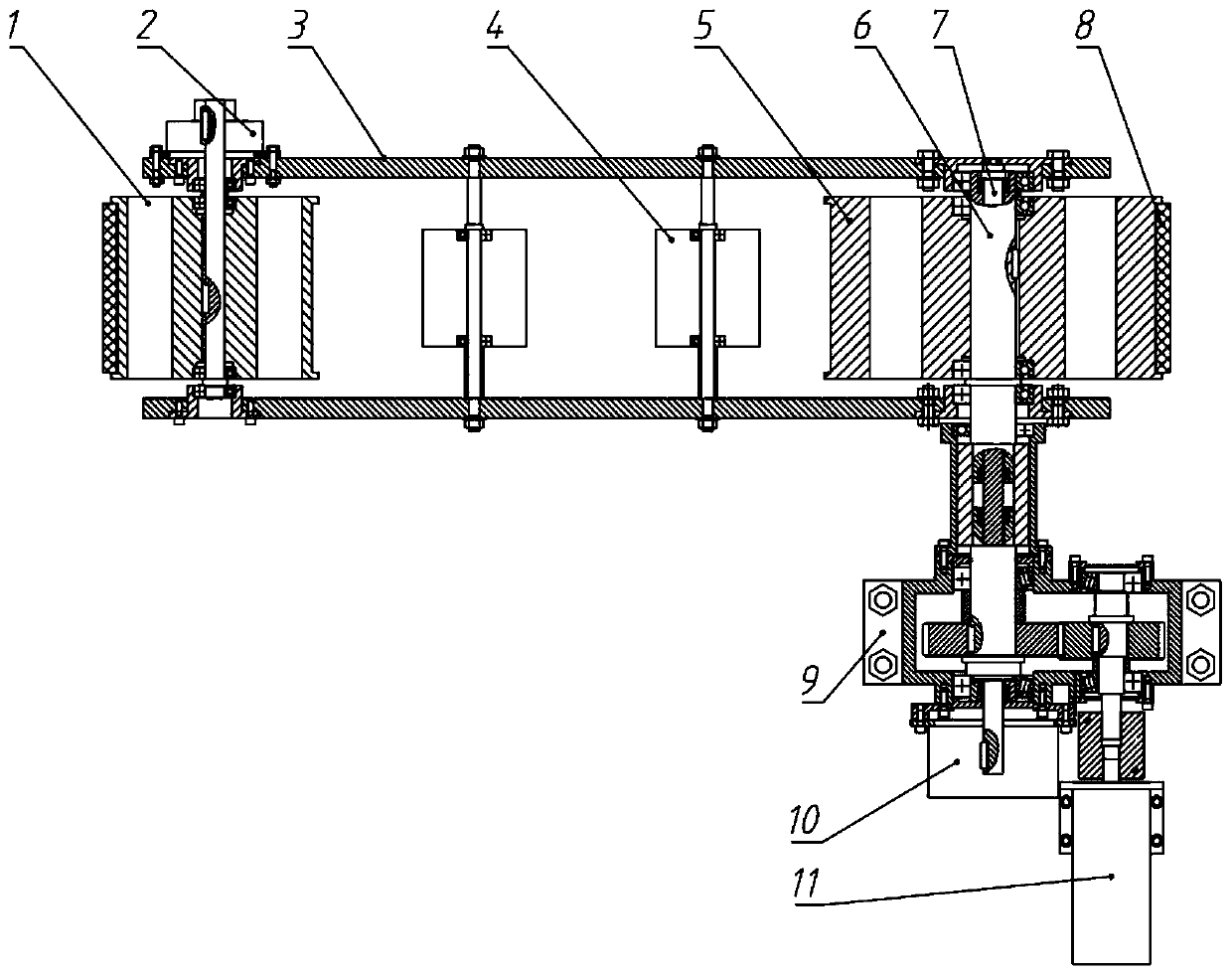

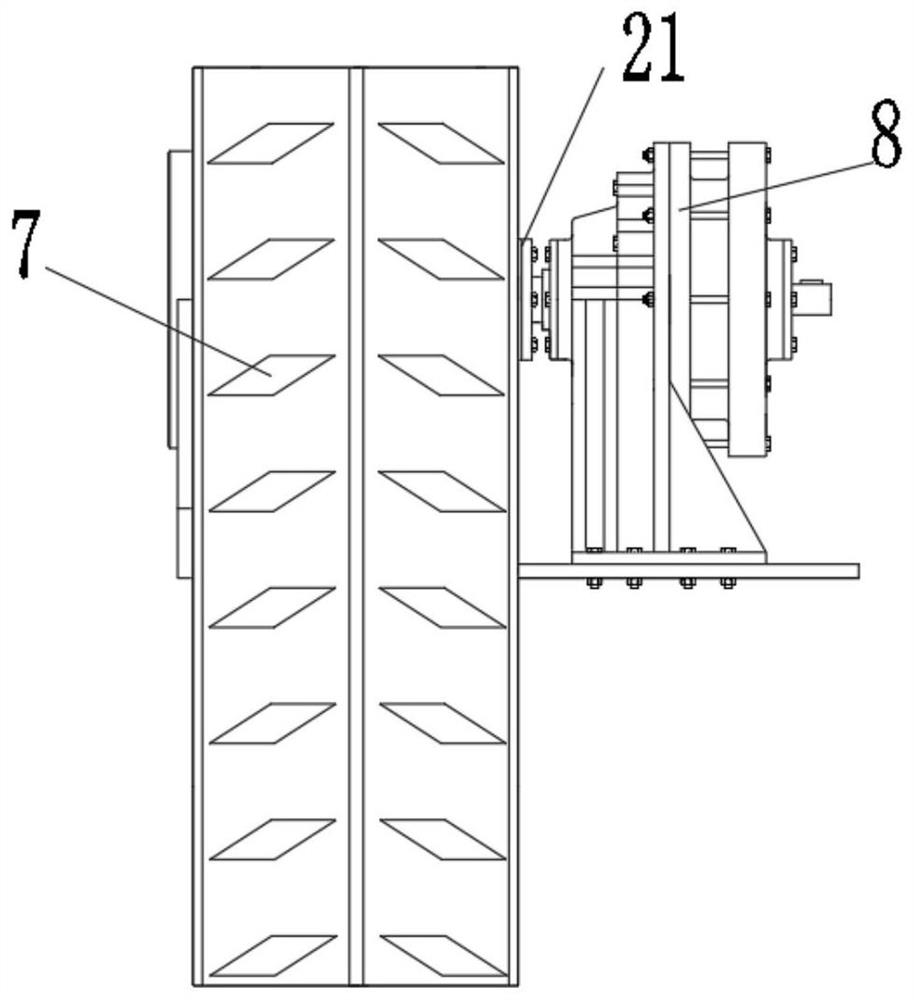

Hose pulling device

ActiveCN107825686AGuaranteed not to deformGuaranteed not to slipTubular articlesPull forceGear wheel

The invention discloses a hose pulling device. The hose pulling device comprises a mounting base plate, a first pulling mechanism, a second pulling mechanism and a precision positioning sleeve. The first pulling mechanism and the second pulling mechanism each comprise a transmission chain, a driving sprocket, a moving sprocket, a transmission gear and multiple pipe-holding Huff sleeves. Each driving sprocket and the corresponding moving sprocket are in transmission connection with the interior of an inner ring of the corresponding transmission chain to form a rotating transmission structure. Each transmission gear is in transmission connection with the corresponding driving sprocket. The pipe-holding Huff sleeves are uniformly arranged on the corresponding transmission chains in the lengthdirection of the transmission chains. Hose channels for limiting hoses are formed between the pipe-holding Huff sleeves of the adjacent transmission chains of the first pulling mechanism and the second pulling mechanism. A positioning channel and a chain channel are arranged on the precision positioning sleeve. According to the hose pulling device, the outer surfaces of the hoses are held by thesymmetrical pipe-holding Huff sleeves and are pulled, it is guaranteed that the hoses do not deform and pulling can be conducted through whole ring holding of the outer surfaces of the hoses, the enough pulling force is provided, and it is guaranteed that the hoses do not slide in the pulling process.

Owner:南通市通州区三槐机械制造有限公司

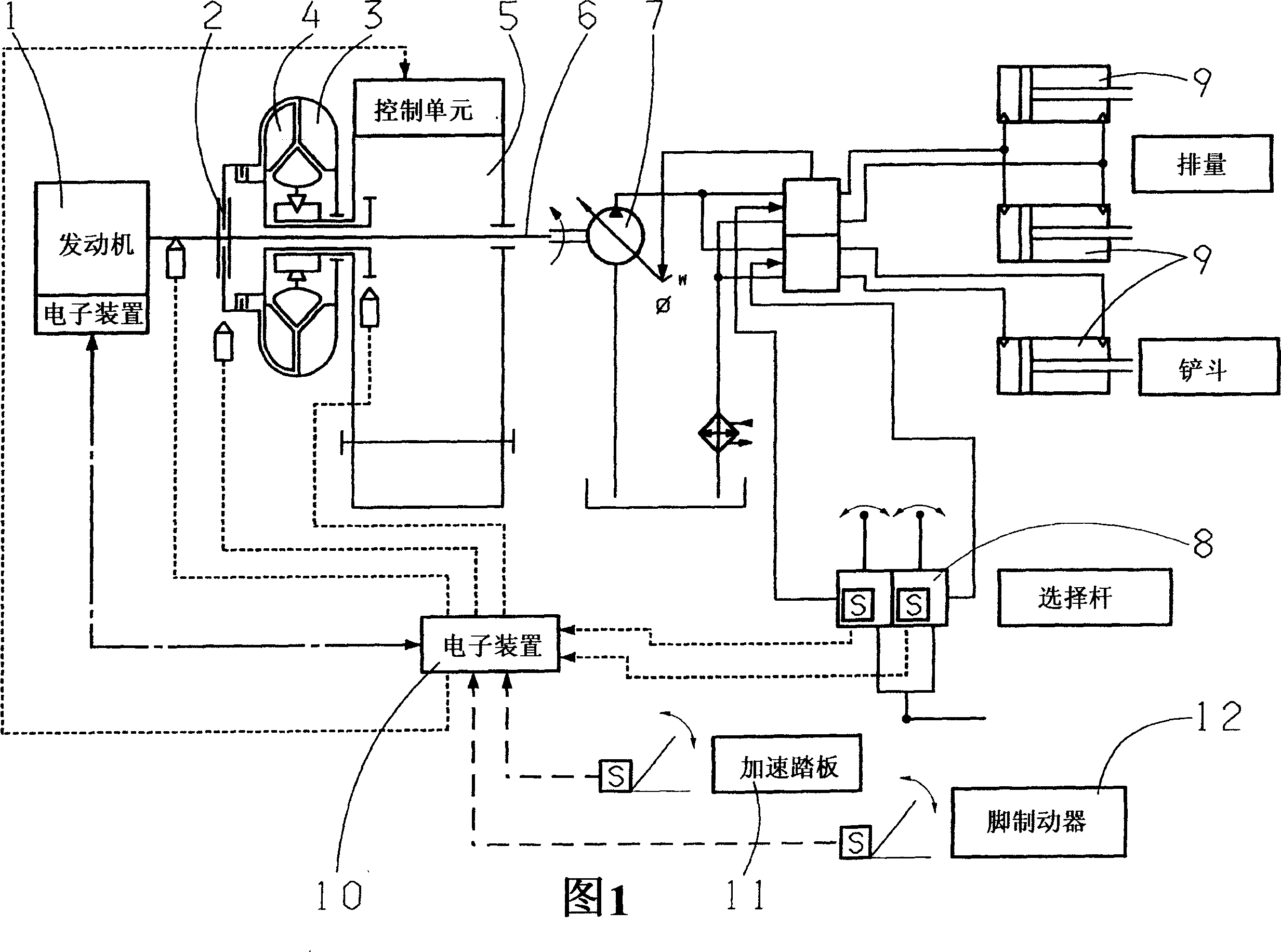

Drive train for a mobile vehicle and method for controlling said drive train

InactiveCN1768185AReduce the burden onLarge transmission ratioAuxillary drivesHand manipulated computer devicesImpellerMobile vehicle

In a drive train for a working machine, in particular, a wheel loader, the driving speed is preselected via a driving pedal ( 11 ) and the working hydraulic system is actuated via a selector lever ( 8 ), whose signals are fed to an electronic control unit ( 10 ) which regulates a drive engine ( 1 ) and a clutch ( 2 ) arranged between the drive engine ( 1 ) and a pump impeller ( 3 ) of a hydrodynamic torque converter in such a manner that an auxiliary drive ( 6 ) for a pump ( 7 ) of the working hydraulic system is operated at a sufficient speed, while the preselected driving speed is not exceeded.

Owner:ZF FRIEDRICHSHAFEN AG

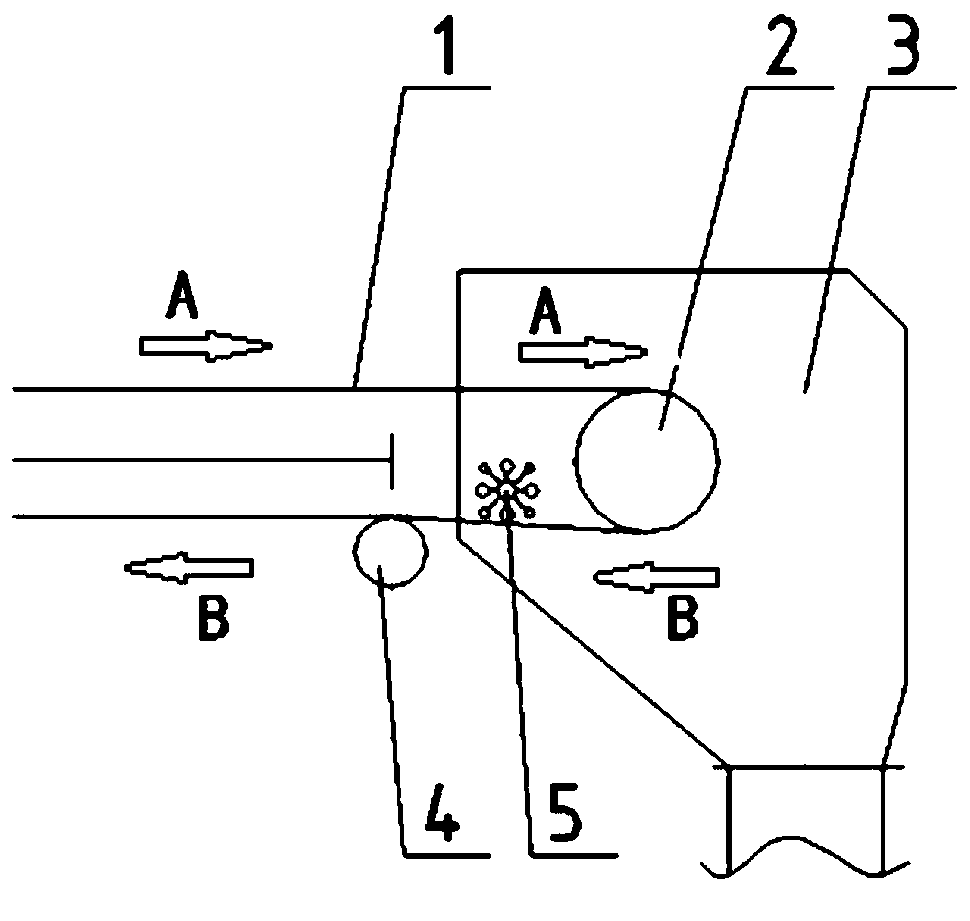

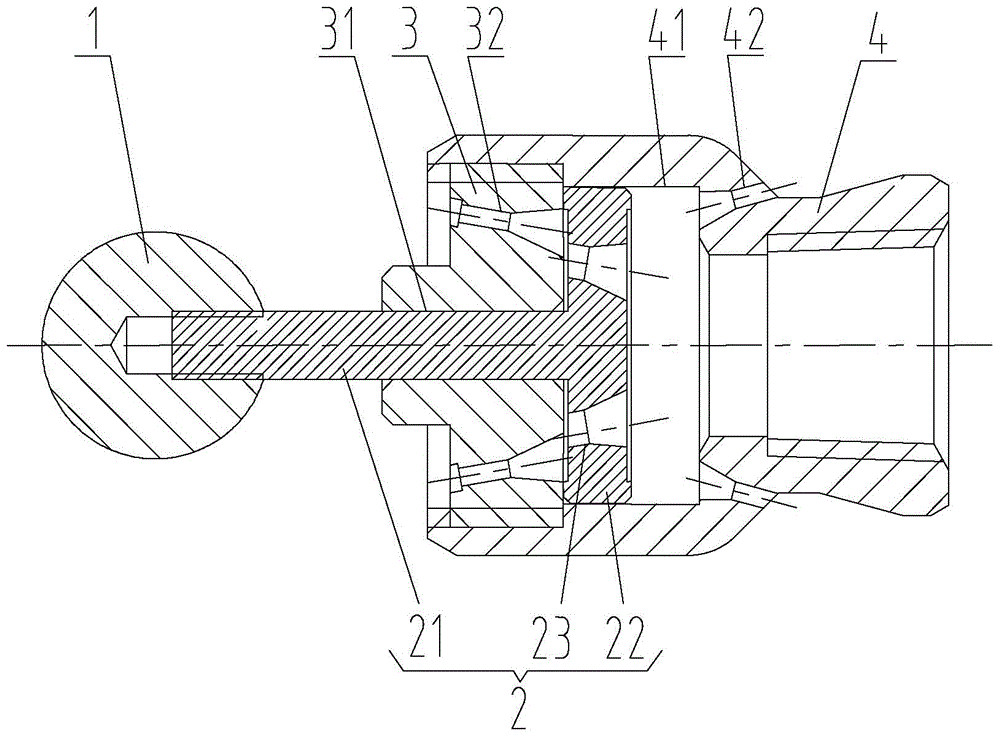

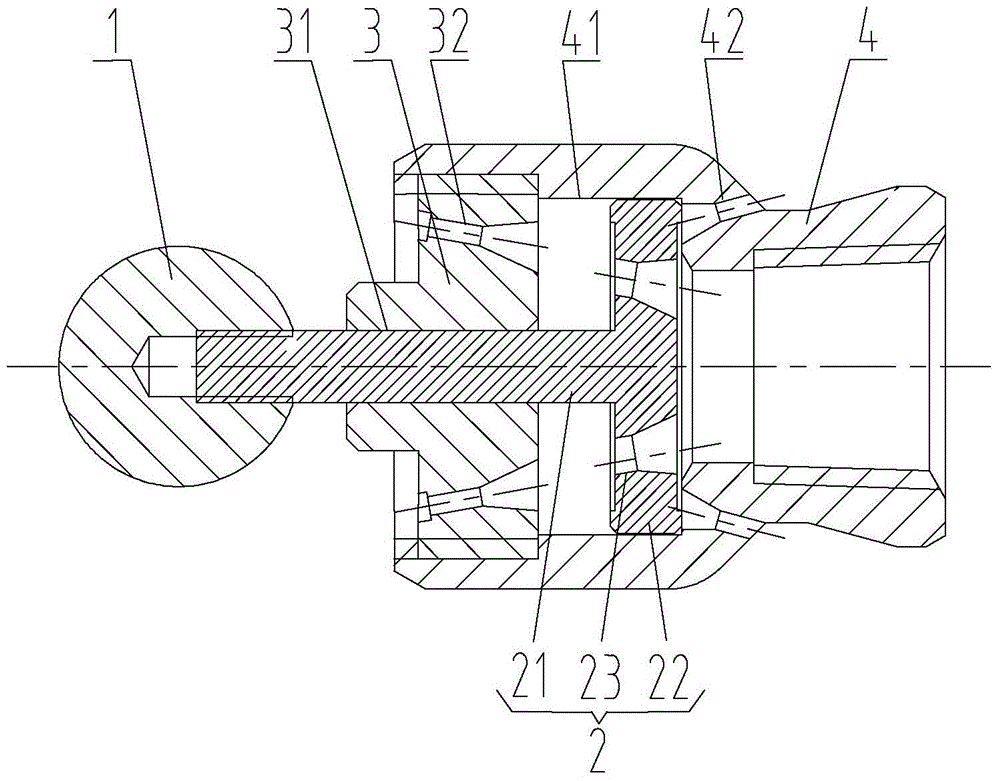

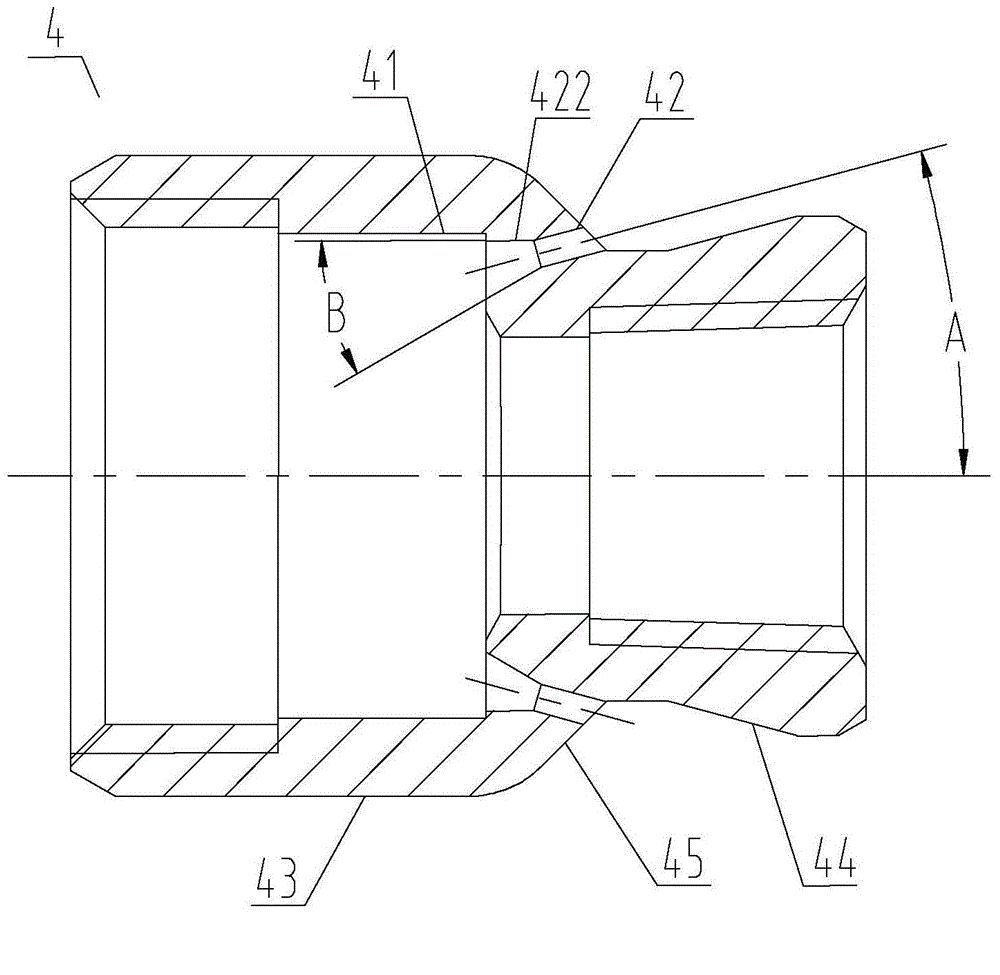

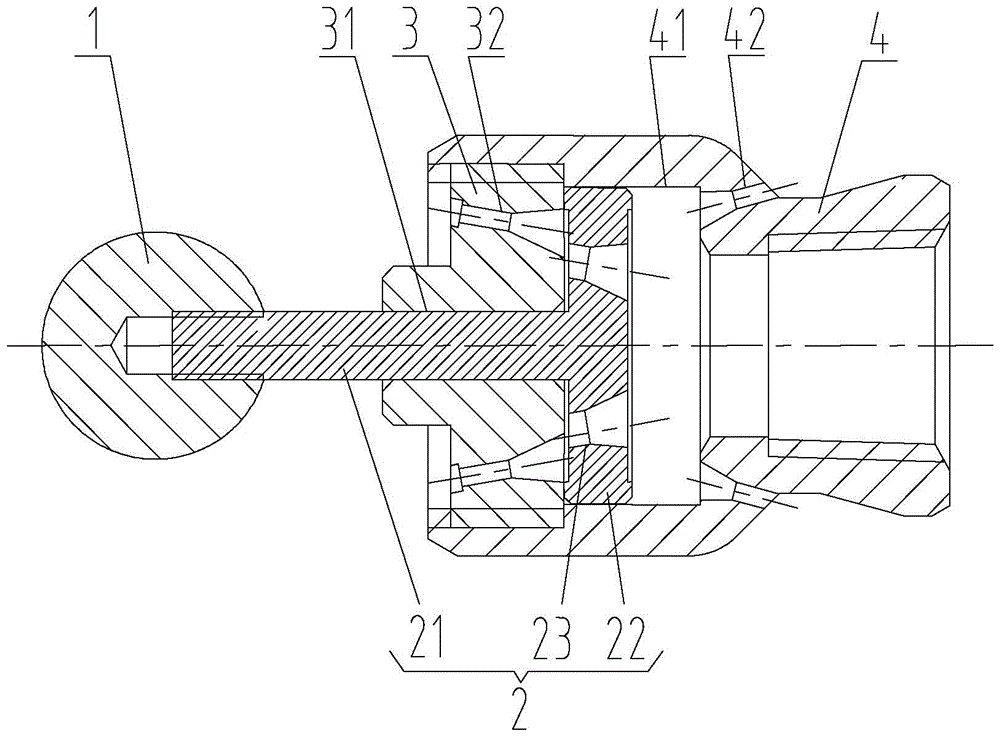

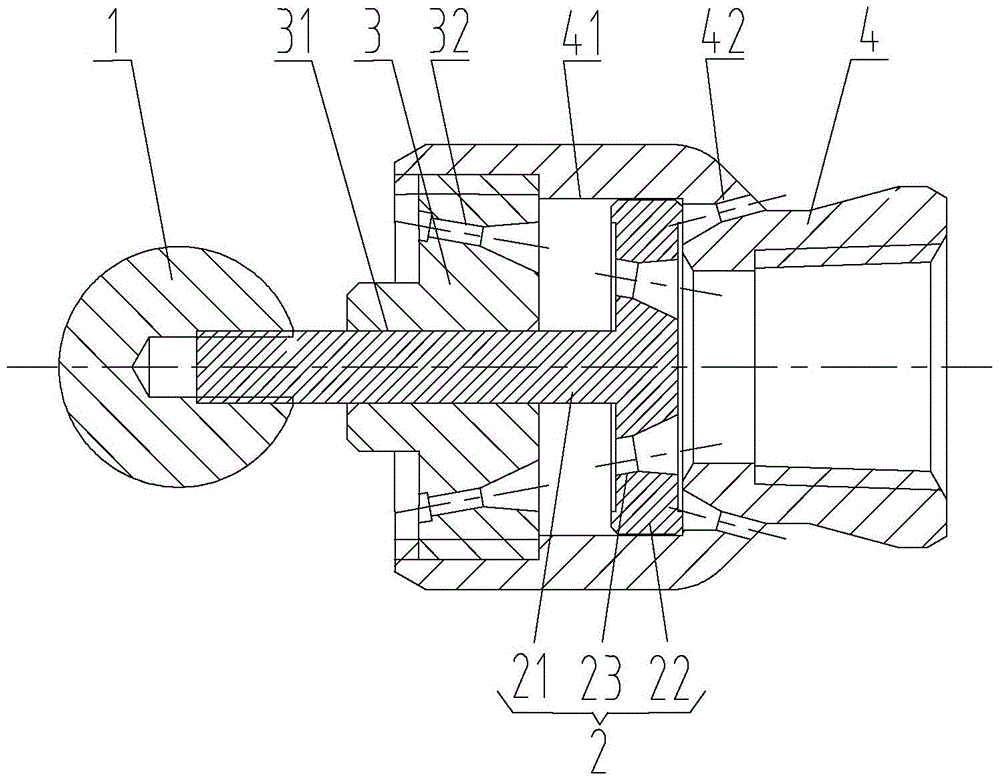

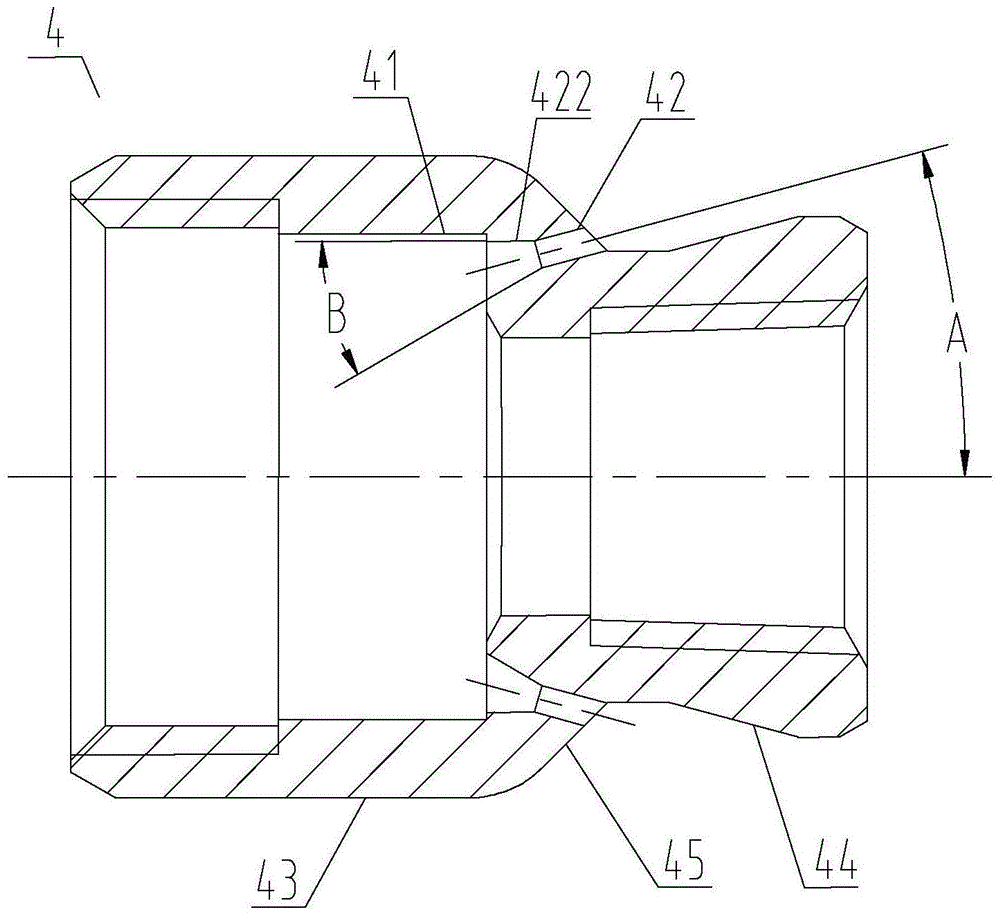

Spray nozzle capable of automatically controlling flow distribution

ActiveCN104453715ASufficient drilling capacityEnough tractionLiquid/gas jet drillingBorehole/well accessoriesControl flowAutomatic control

The invention provides a spray nozzle capable of automatically controlling flow distribution. The spray nozzle comprises a probe, a forward nozzle body, a backward nozzle body and a steering control rod. The backward nozzle body comprises a containing part and a connecting part which are axially and sequentially connected with each other along a through hole of the backward nozzle body. The front portion of the containing part is connected with the forward nozzle body. The steering control rod comprises a slide part sliding in an inner cavity of the containing part, and a rod part in sliding fit with a through hole of the forward nozzle body. The rod part extends out of the forward nozzle body, and the extension end of the rod part is connected with the probe. A forward spray hole and a backward spray hole which are communicated with the inner cavity of the containing part are formed in the forward nozzle body and the backward nozzle body respectively. A through flow passing hole is formed in the slide part. When the slide part slides to be tightly attached to the forward nozzle body, at least part of the section of the flow passing hole is communicated with the forward spray hole; when the slide part slides to be tightly attached to the connecting part, the slide part shields the backward spray hole; thus, distribution of forward flow and backward flow is achieved, sufficient traction is ensured during normal drilling, and meanwhile the sufficient rock break-off capacity is achieved when the spray nozzle encounters an obstacle.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

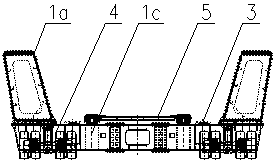

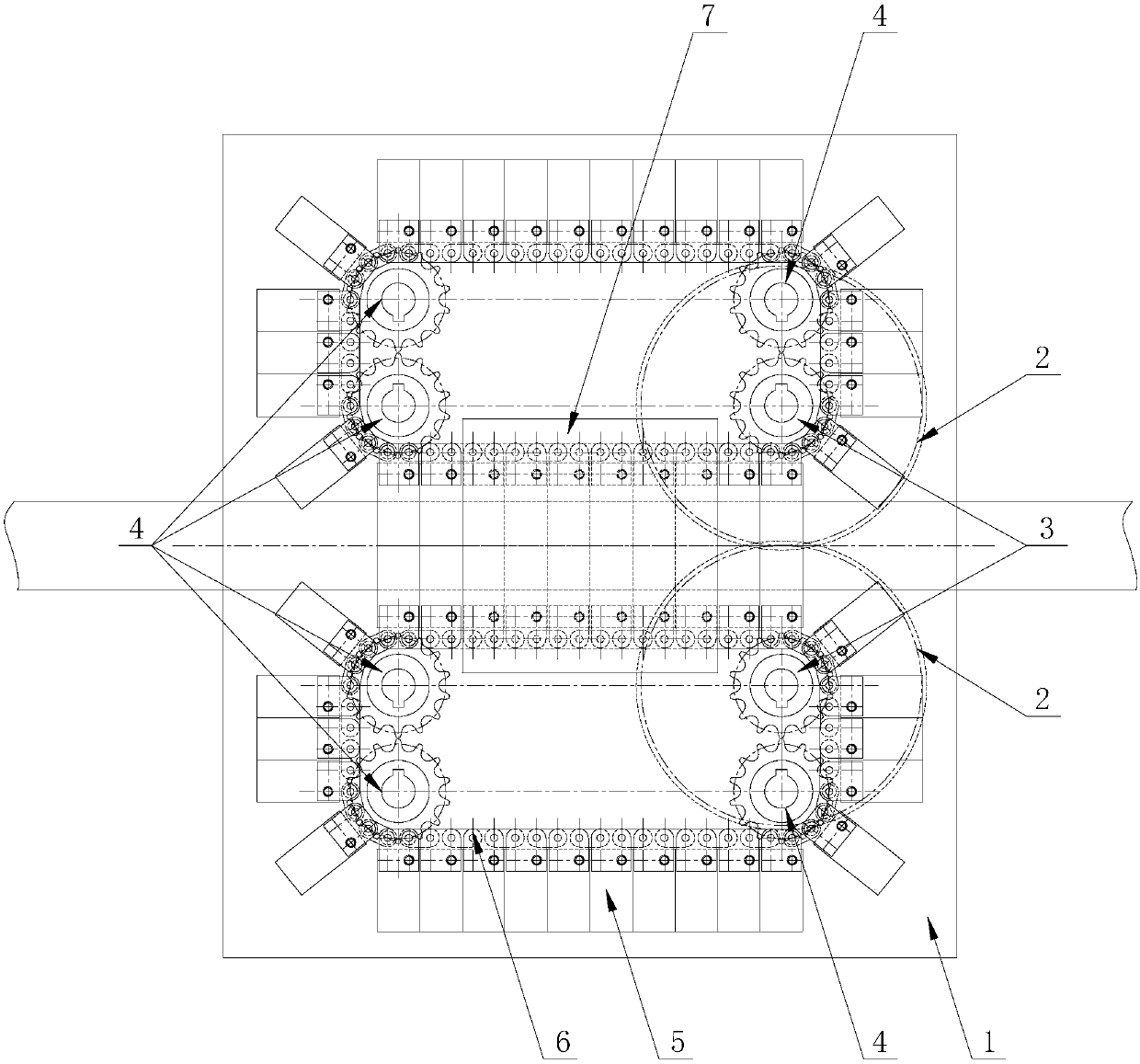

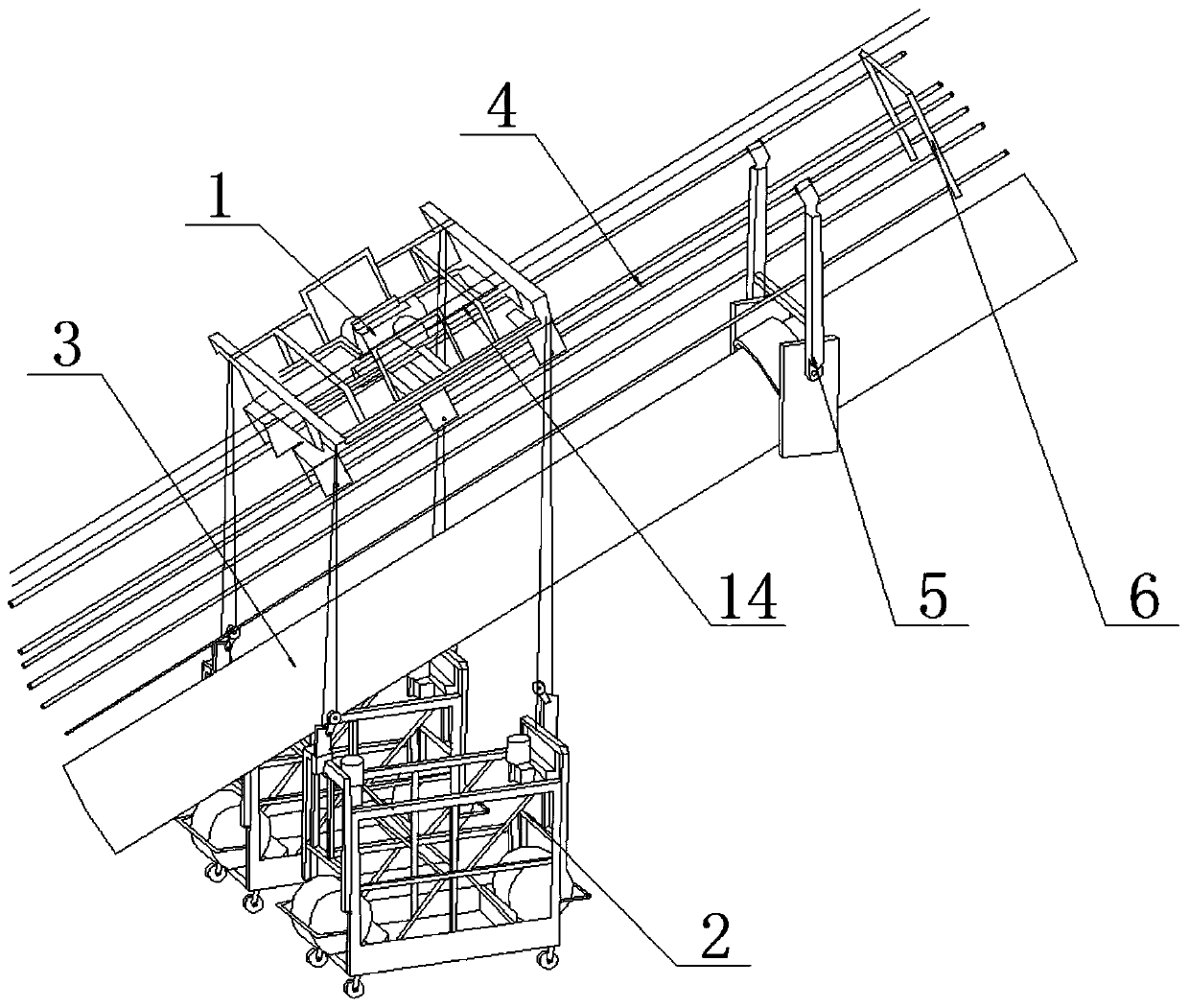

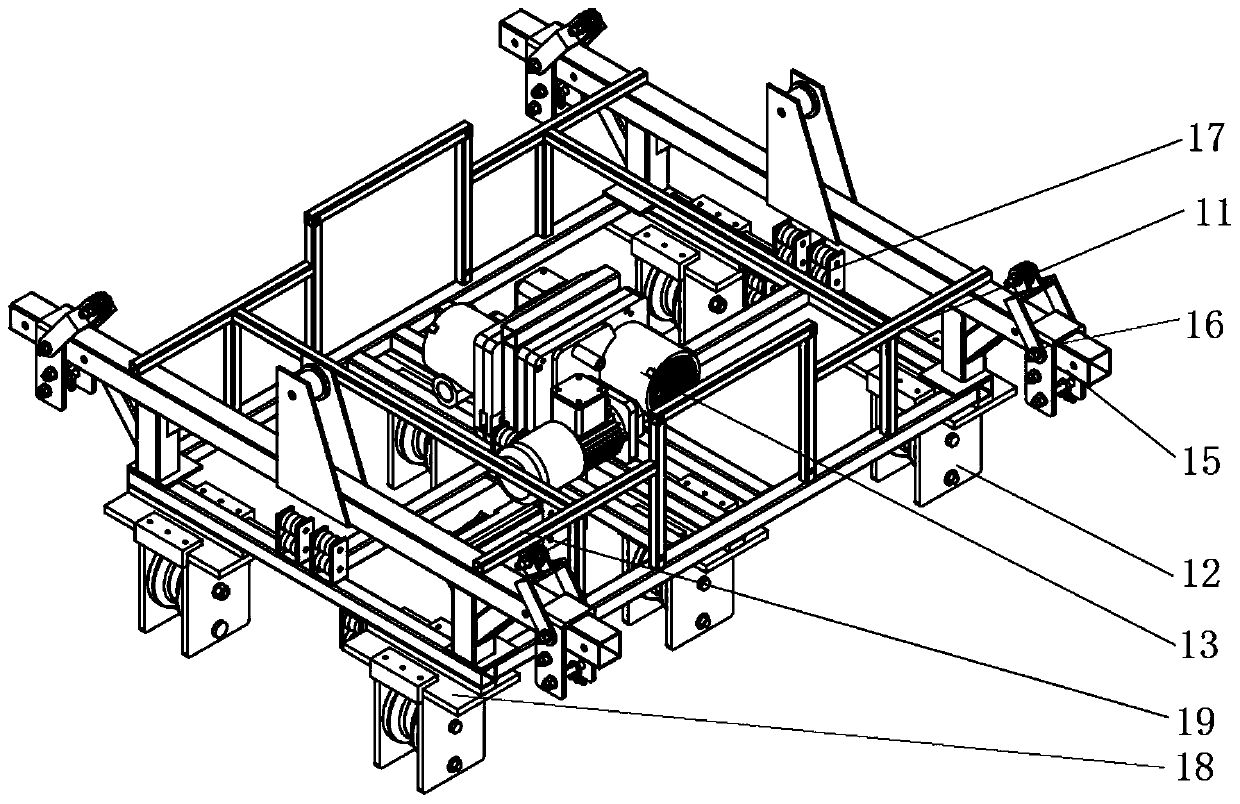

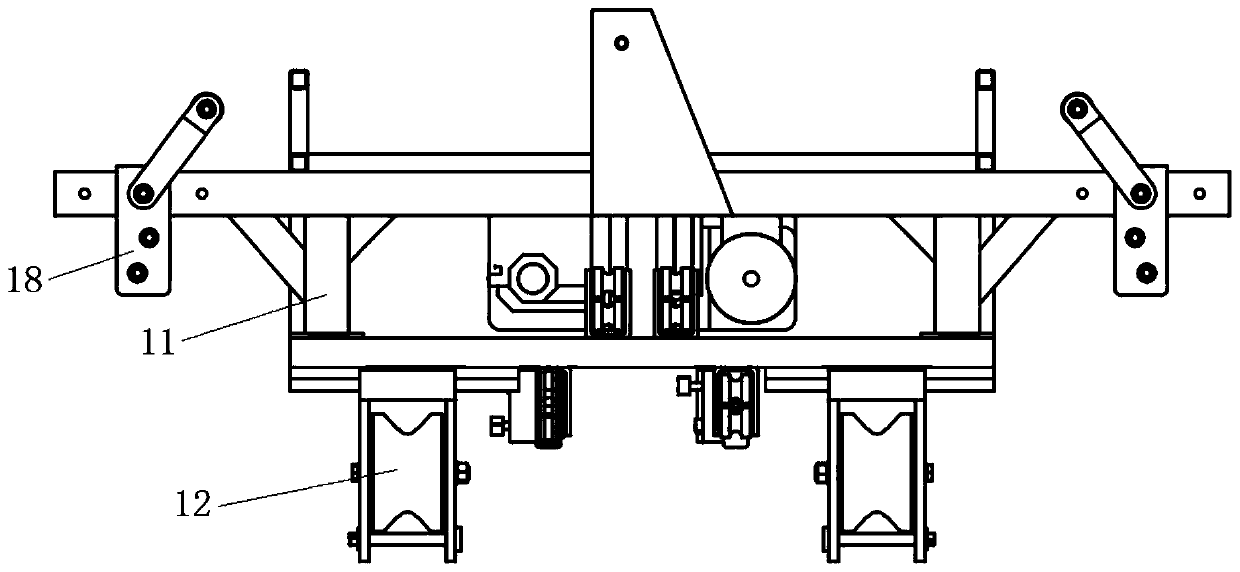

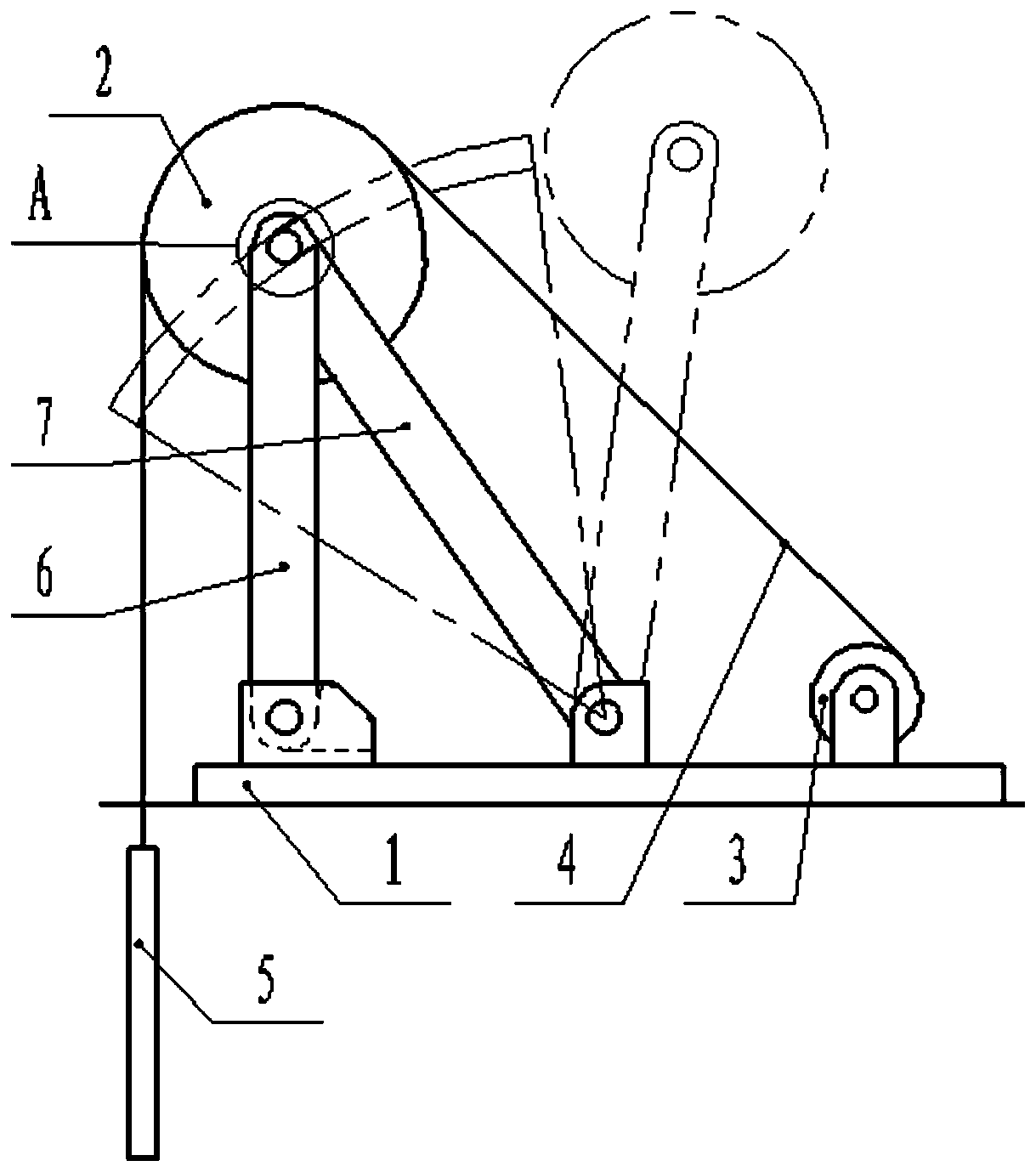

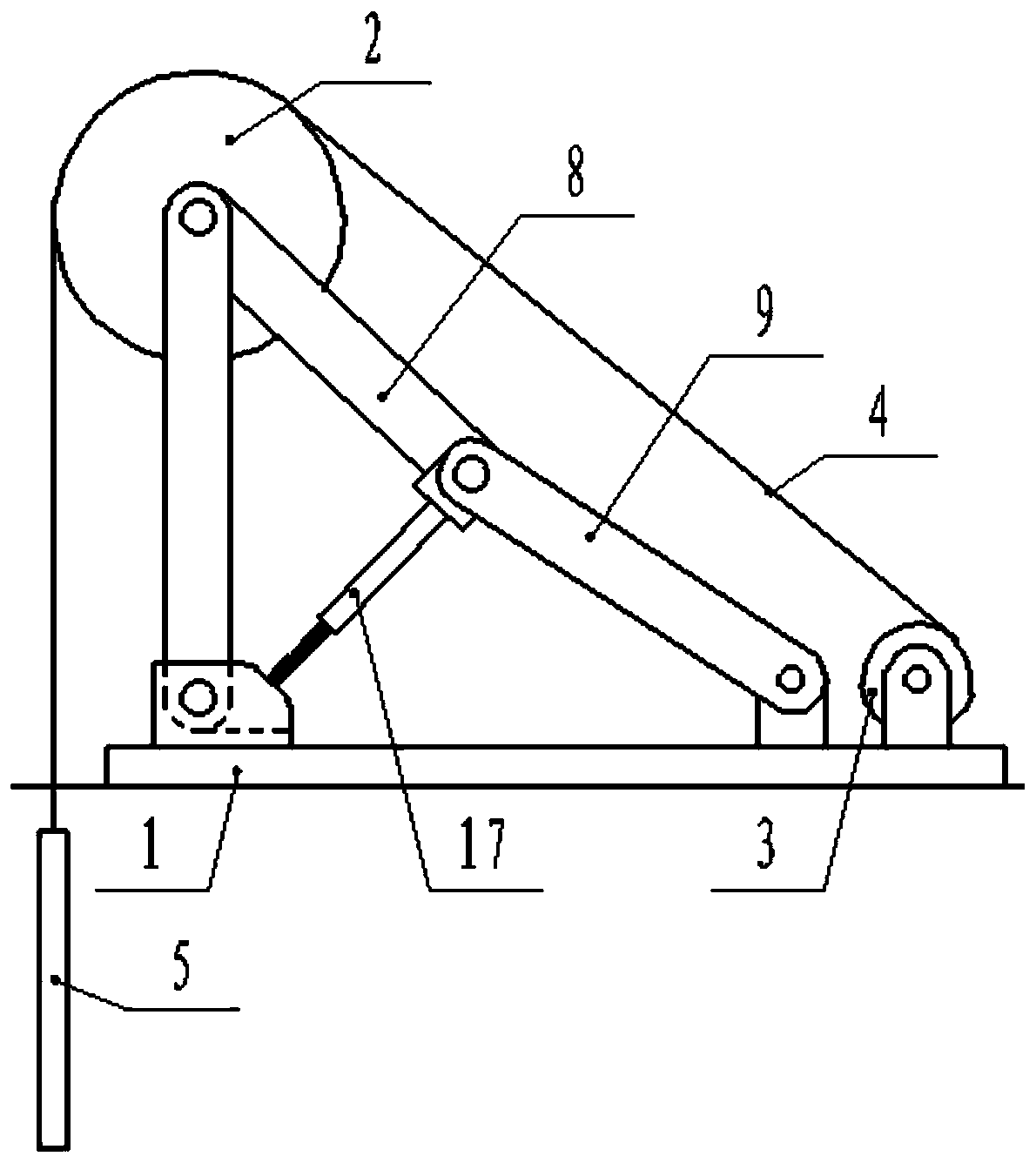

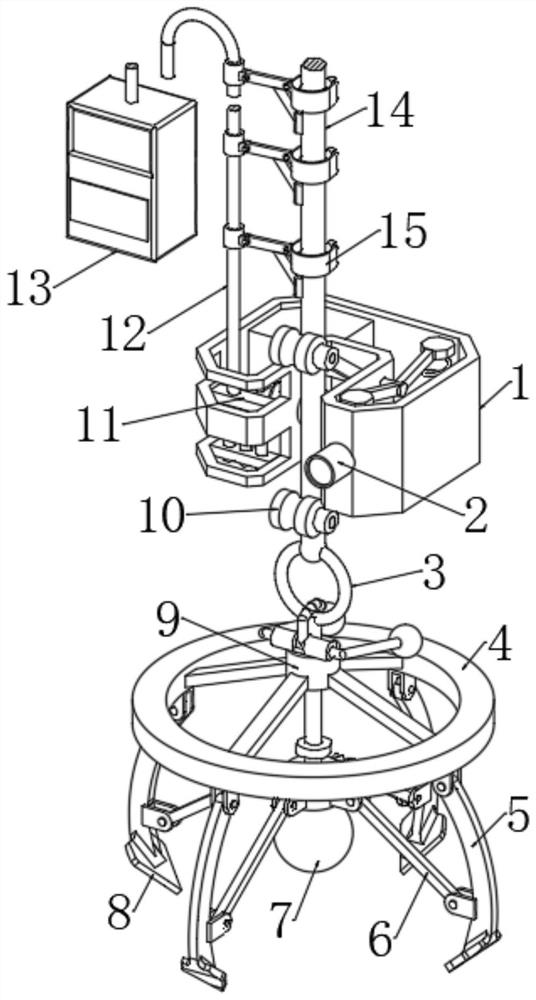

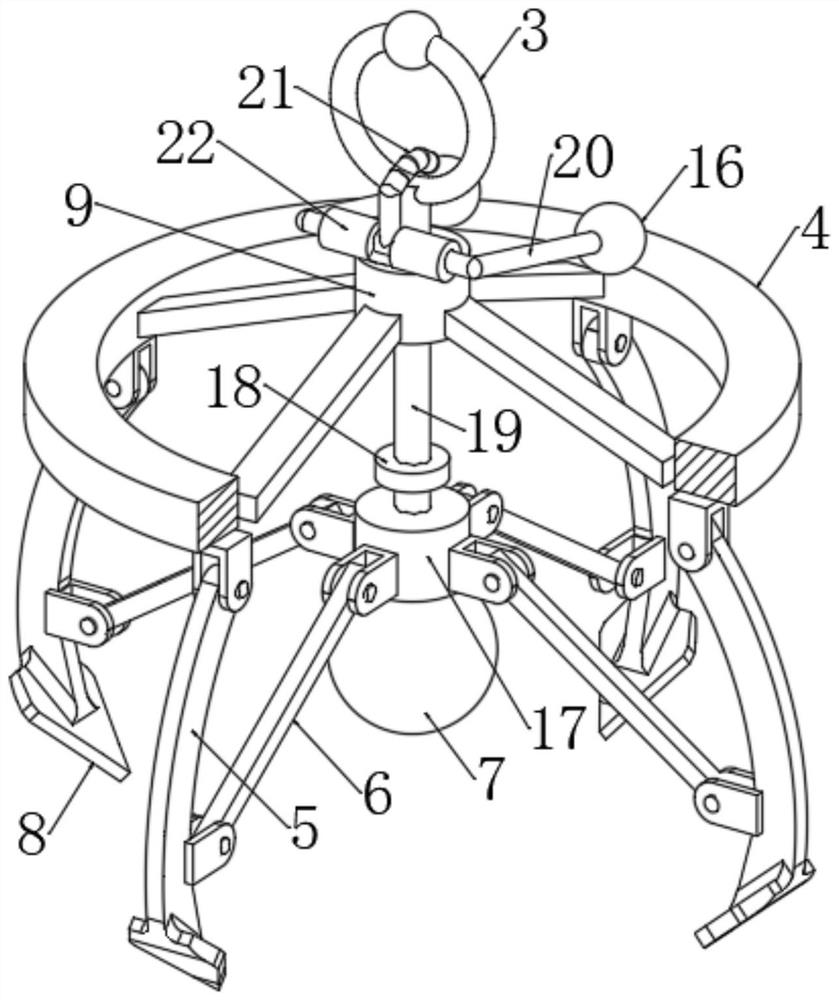

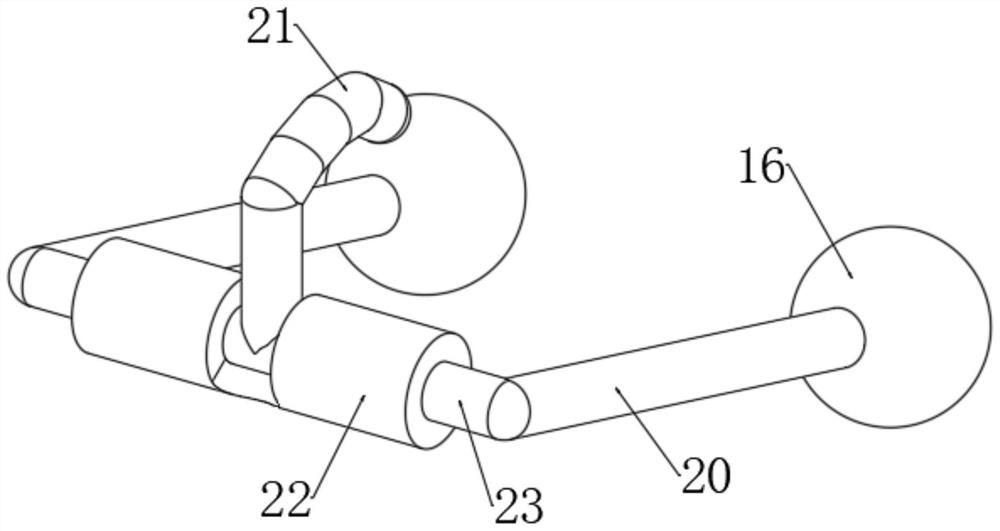

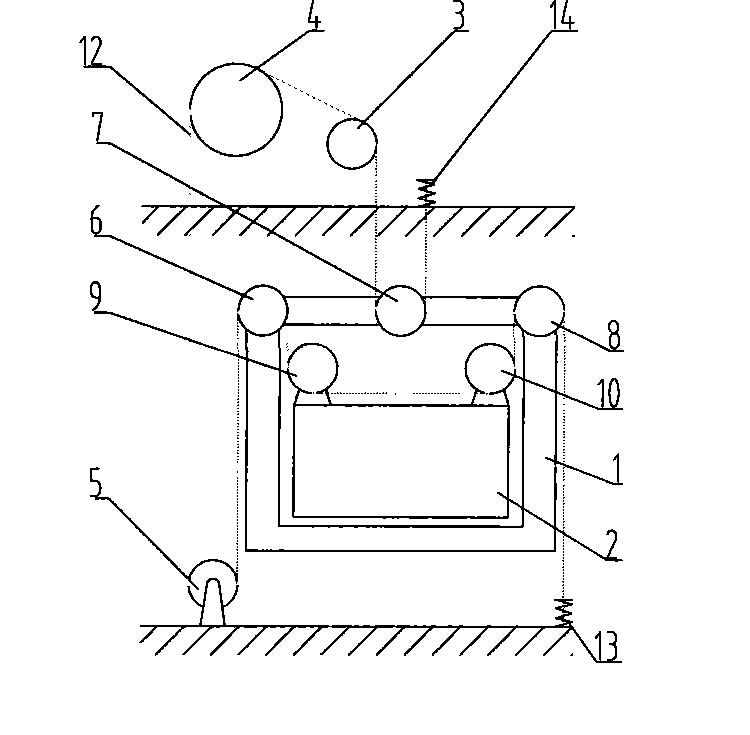

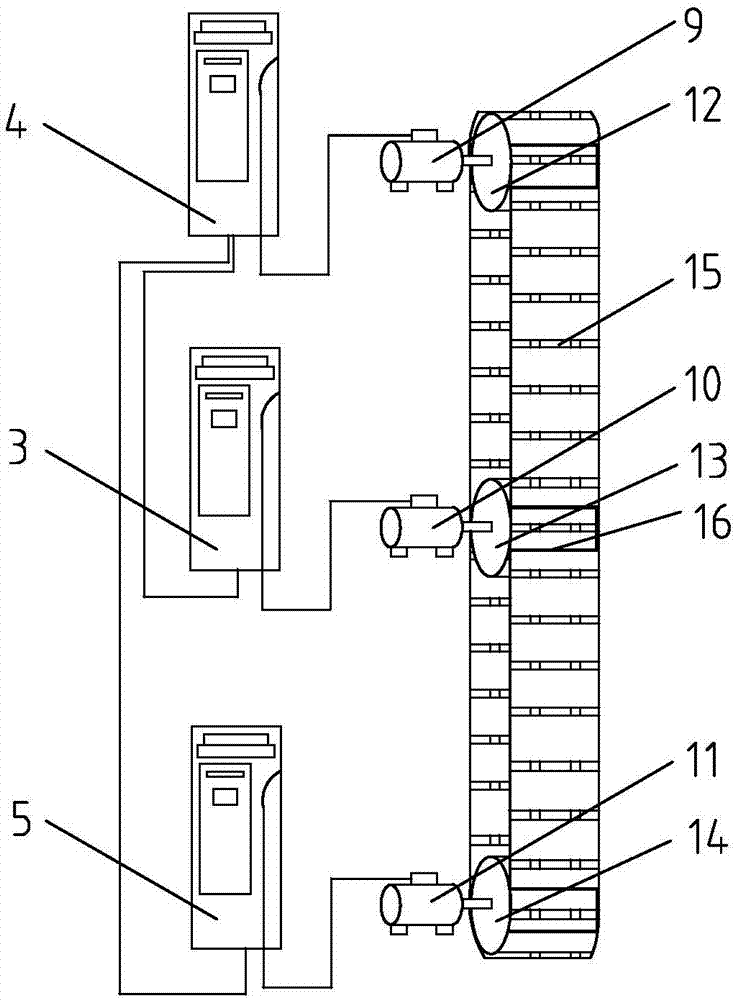

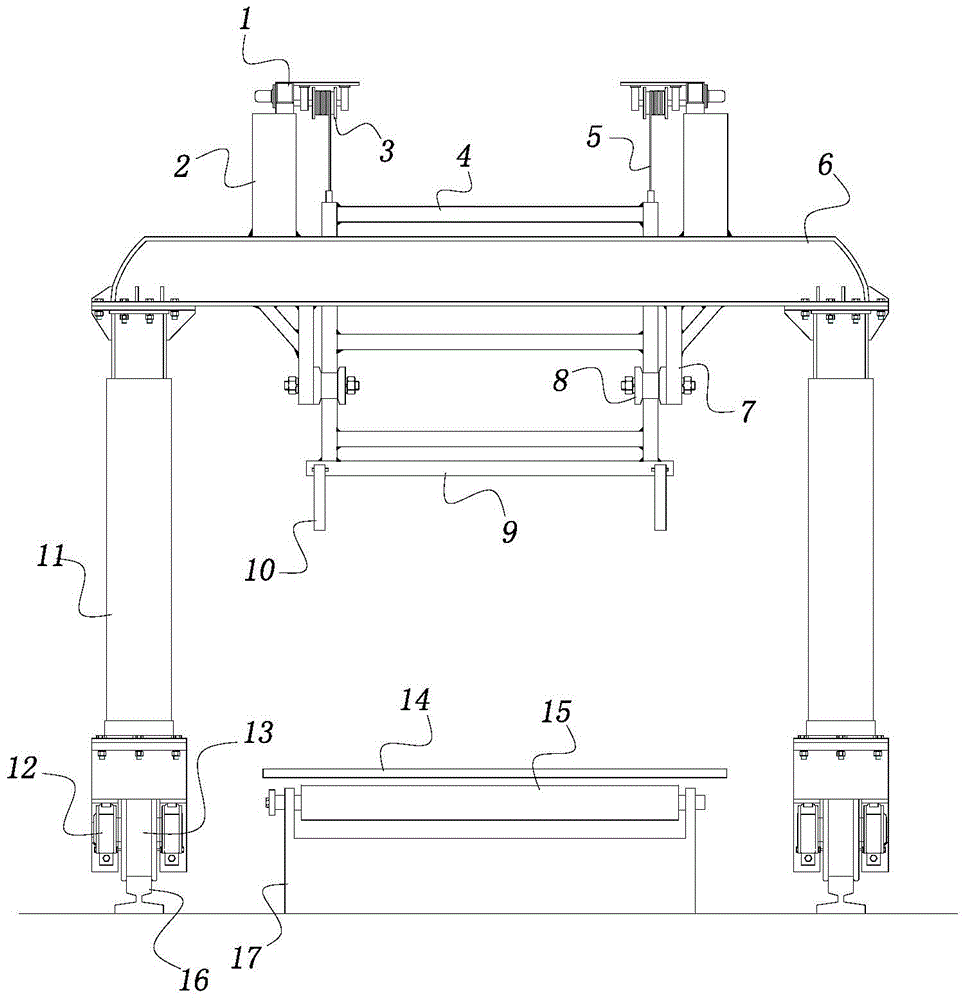

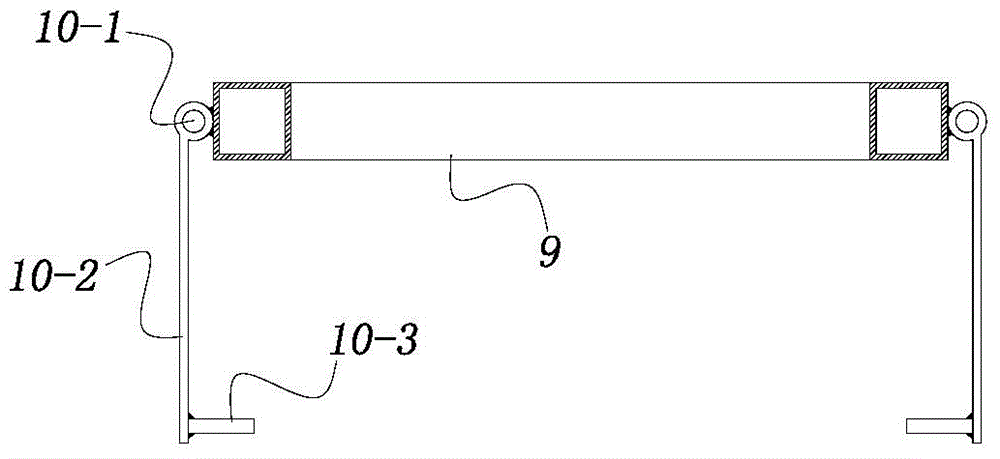

Planetary walking trolley for detecting and maintaining main cable and sling of suspension bridge

PendingCN111549662AEnough tractionAvoid the risk of falling off the handrailBridge structural detailsVehicle frameClassical mechanics

The invention relates to a planetary walking trolley for detecting and maintaining a main cable and a sling of a suspension bridge, which comprises a traction trolley (1) and a hanging basket (2), andthe hanging basket (2) is hung below the traction trolley (1); wherein the traction trolley (1) comprises a frame (11); left and right groups of travelling wheels (12) are arranged at the bottom of the frame (1), an elevator (13) is arranged in the middle of the frame (11), a traction steel wire rope (14) is arranged on the elevator (13), two lifting point cross beams (15) are arranged on the frame (11) in parallel front and back, and left and right lifting appliances (16) are arranged on the lifting point cross beams (15). The traction trolley walks along the main cable handrail steel wire rope, the hanging basket ascends and descends below the traction trolley, and theoretically, the hanging basket can reach any position of a suspension bridge main cable and sling system through combination of different moving tracks of the two systems.

Owner:无锡金诚工程技术服务有限公司

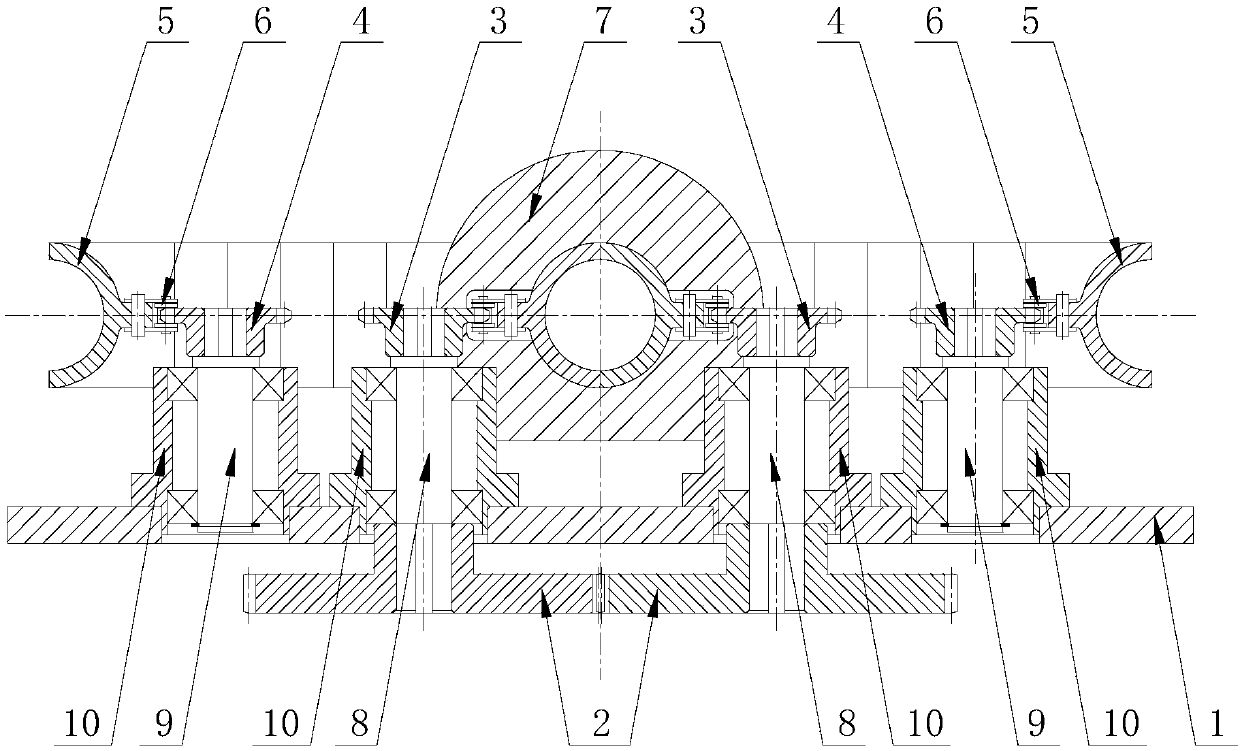

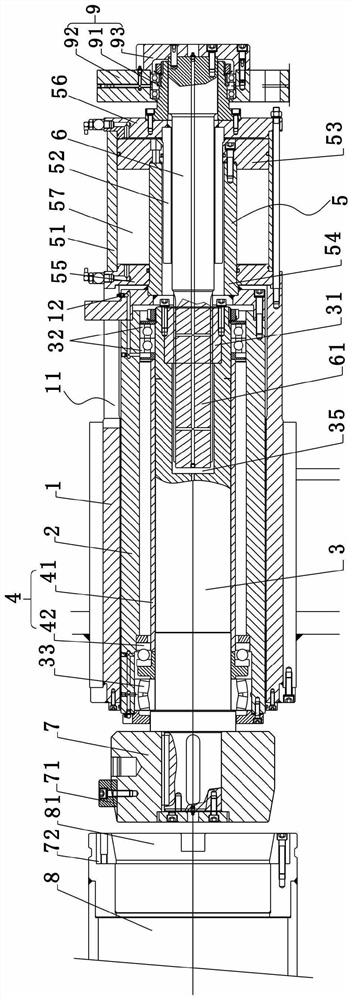

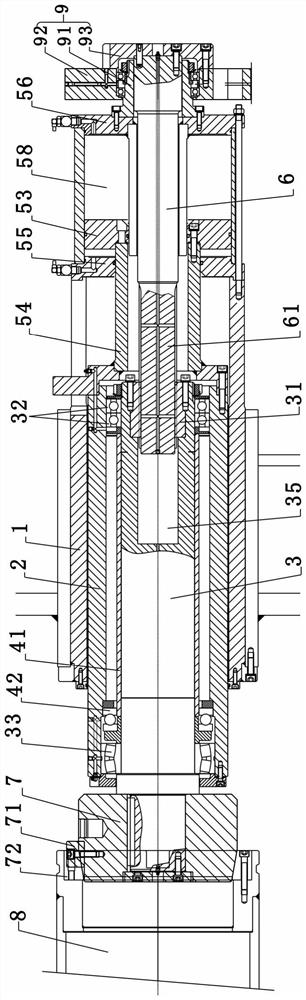

Track driving wheel with adjustable grounding specific pressure

PendingCN112389554AWide range adjustment of ground specific pressureHas the ability to absorb shockEndless track vehiclesDrive wheelReduction drive

The invention discloses a track driving wheel with adjustable grounding specific pressure, which comprises a lower support frame provided with a plurality of loading wheels at the bottom, the lower support frame is fixedly connected with an upper support frame through a plurality of mechanical fluid double damping devices, and two ends of the support frame 5 are respectively and fixedly provided with a mounting seat and a small-tooth-difference planet gear speed reducer. An output shaft of the small-tooth-difference planet gear speed reducer is connected with a middle shaft, the middle shaft is rotationally connected with a driving wheel and a flange plate, the flange plate is fixed to the mounting base, two telescopic mechanisms are arranged at the two ends of the lower support frame andconnected with inducer rotating shafts, the two inducers are in transmission connection with the driving wheel through tracks, and loading wheels and the bottom faces of the inducers are horizontallyarranged. According to the device, the problems of high ground pressure, low road holding force and limited road condition adaptation when the conventional engineering machinery vehicle works are solved, and the large-range adjustment of the grounding specific pressure of the track driving wheels during working can be realized so as to adapt to different road conditions.

Owner:徐州博汇世通重工机械有限责任公司 +1

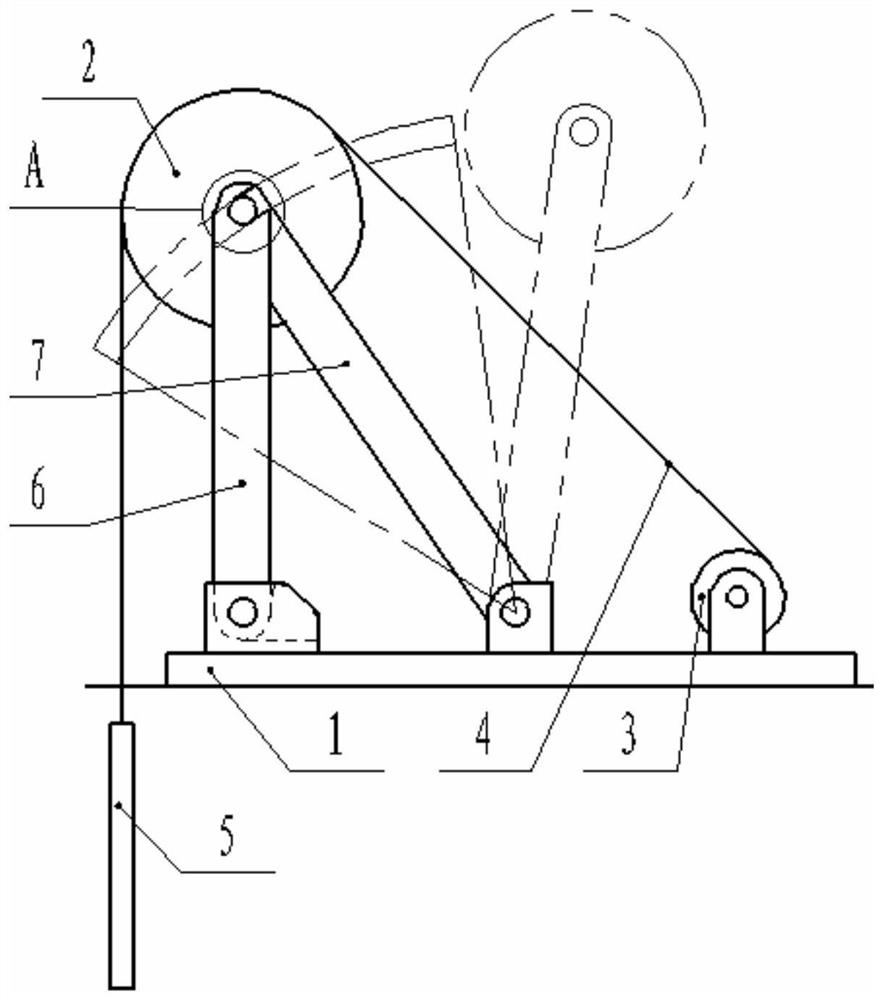

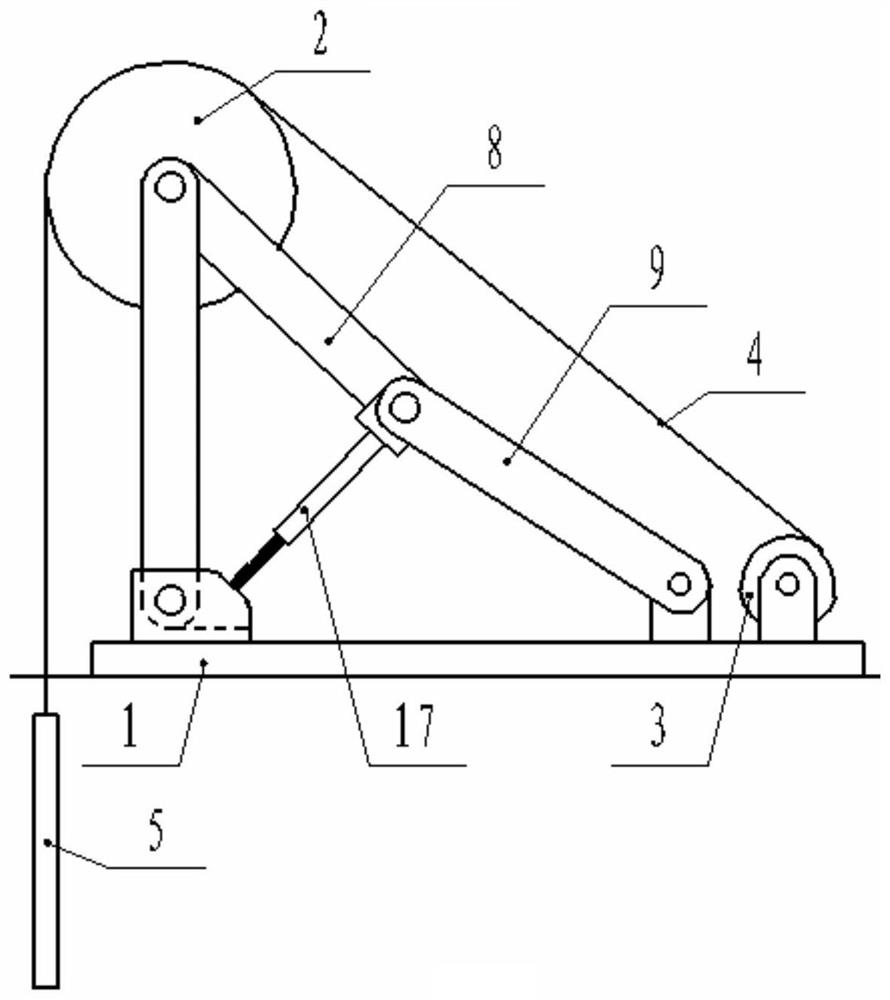

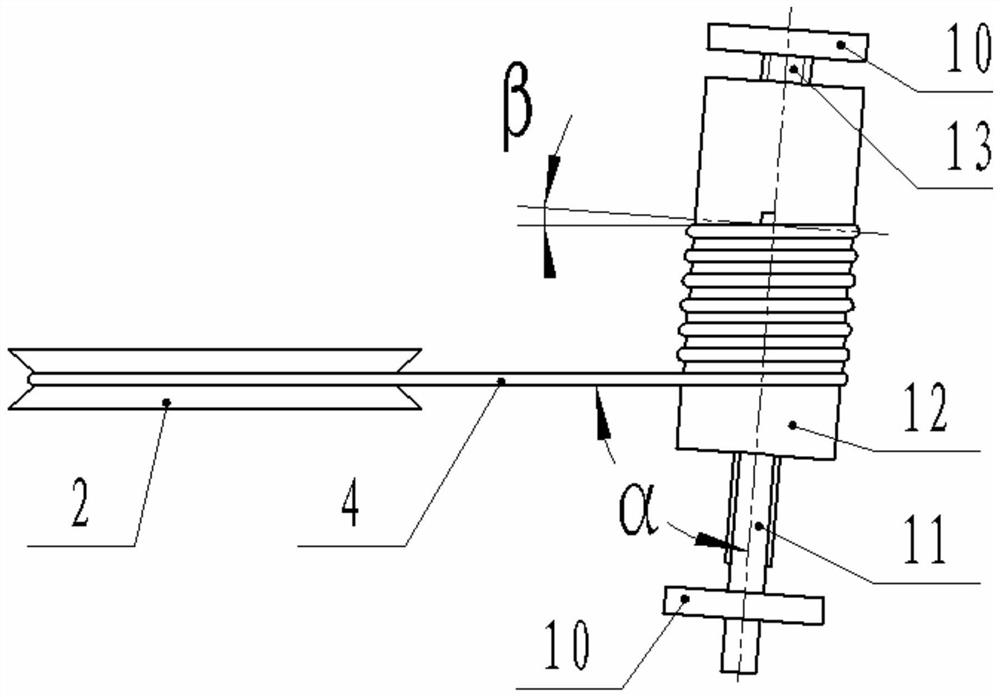

Intelligent oil sucking machine

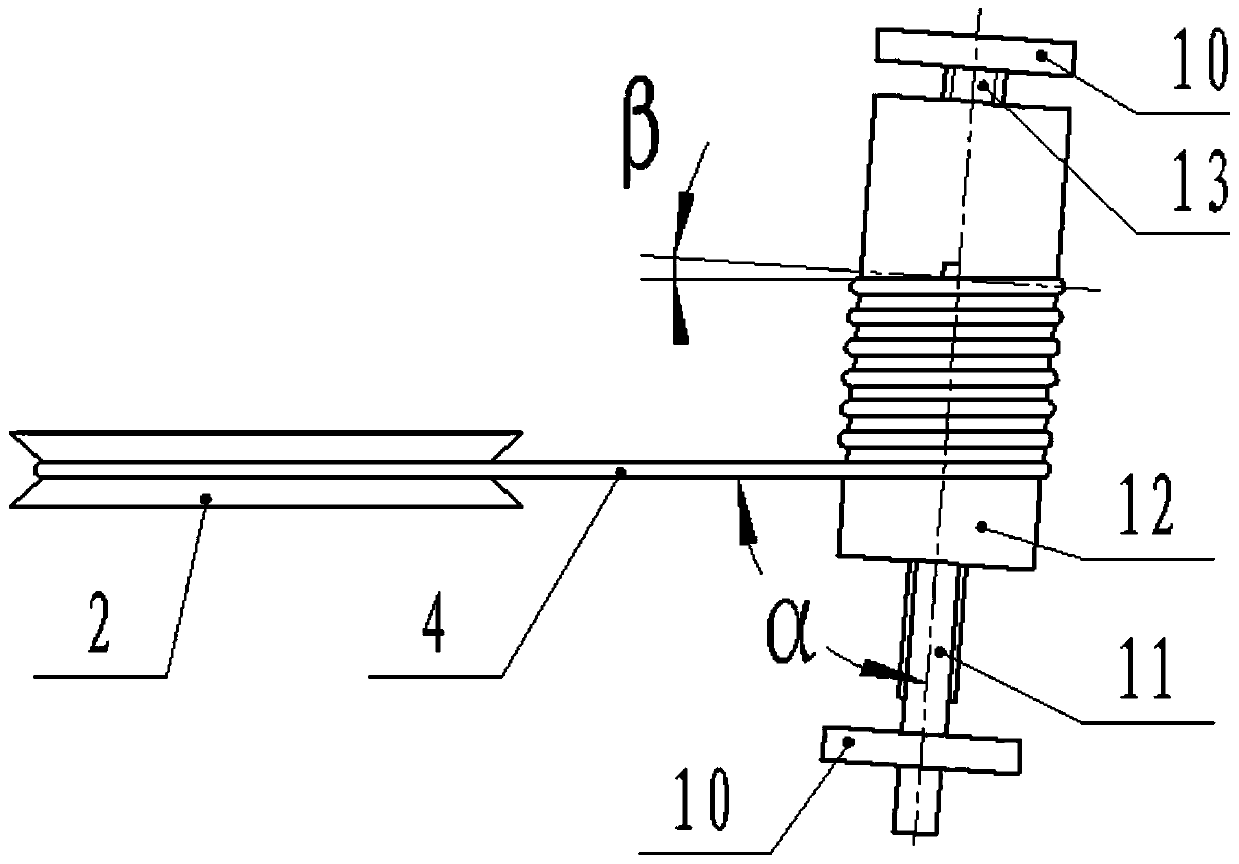

ActiveCN111173478AReduce wearImprove convenienceFlexible member pumpsFluid removalDrive shaftAcute angle

The invention belongs to the technical field of oil extraction devices for an oil field, and particularly relates to an intelligent oil sucking machine. The intelligent oil sucking machine comprises abase, a support frame, a guide wheel, a winding drum, a steel wire rope, an oil sucking pump and a motor, wherein a spiral groove for accommodating the steel wire rope is formed in the outer wall ofthe winding drum; the winding drum is in inclined arrangement; an included acute angle alpha formed between the axial line of the winding drum and the steel wire rope and the helix angle beta of the spiral groove meet a relationship that alpha=90 degree - beta; the winding drum structurally comprises a drum body, a driving shaft, a threaded support shaft and a shaft support frame; one end of the drum body is connected with a driving shaft through a spline; and the other end of the drum body is connected with the threaded support shaft through transmission screw threads. The intelligent oil sucking machine has the advantages that through the arrangement of the spiral groove with great thread pitches, the steel wire rope to be wound on the winding drum can be effectively prevented from beingin contact with the steel wire rope wound on the winding drum, so that the abrasion of the steel wire rope is reduced.

Owner:华运隆腾机械制造有限公司

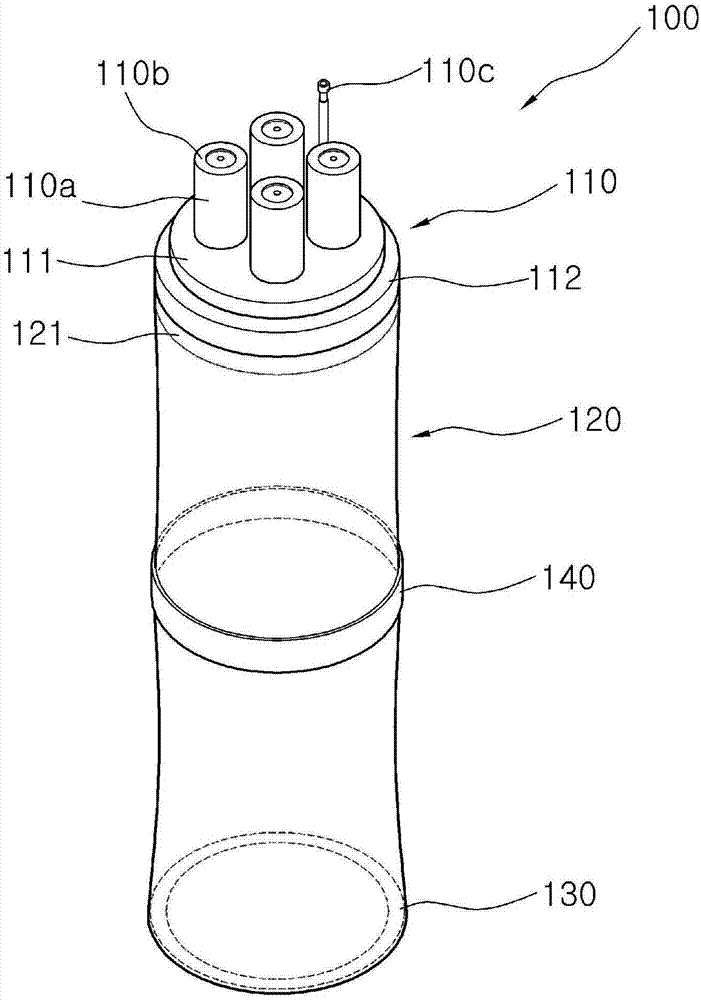

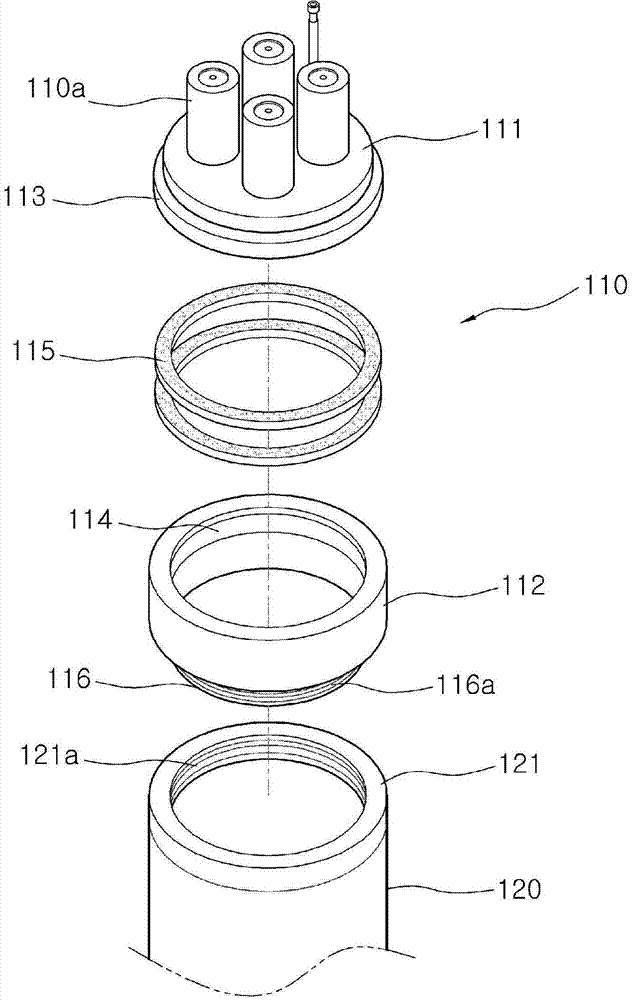

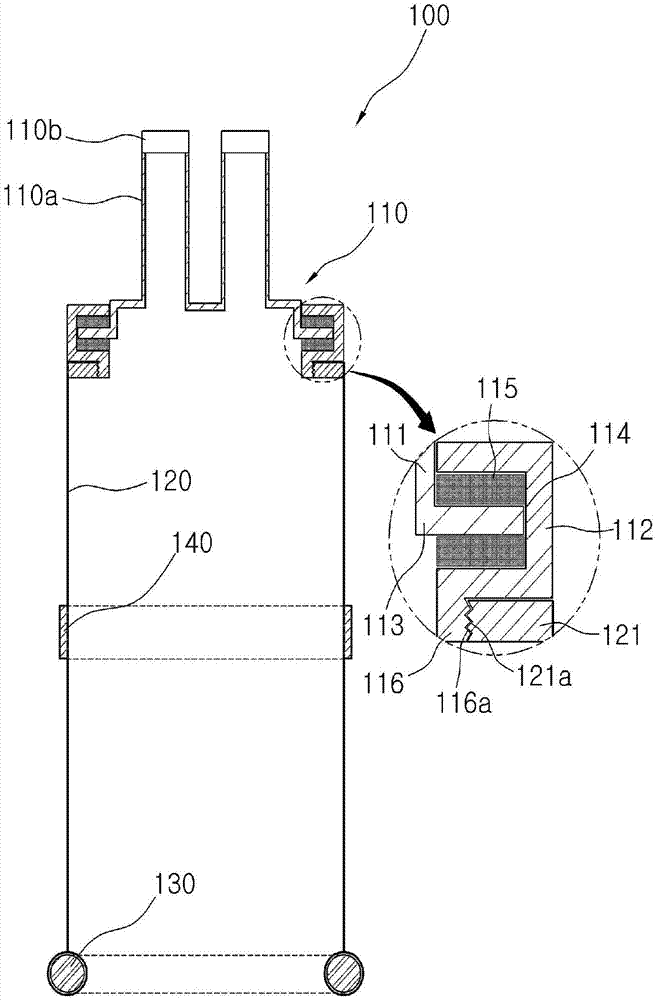

Endoscopy instrument guider port

InactiveCN103200880AEnough tractionAppropriate surgical managementSuture equipmentsInternal osteosythesisSurgical delayFlexible endoscope

The present invention relates to an endoscopy instrument guider port, comprising a main body member where at least one surgical instrument entrance part is disposed at an upper surface, a protective tube extending downwards by a predetermined distance from the main body member, a retaining ring body fixed to a lower end portion of the protective tube, the retaining ring body being freely deformed and restored, and a control ring body disposed at a predetermined position along a length direction of the protective tube to be coiled around the protective tube through a folding motion and control a length of the protective tube.; According to the present invention, the control ring body disposed at the protective tube facilitates length adjustment and traction generation of the protective tube, appropriate handling of surgical situations is possible because an upper body may be turned and separated, and surgical delays may be prevented while endoscopy operations may be made easier.

Owner:徐午男

Portable underground water level automatic measuring and recording device

InactiveCN114543929AAffect measurement accuracyEasy accessMachines/enginesWater resource assessmentLocking mechanismWater level

The invention relates to the technical field of underground water measurement, and discloses a portable underground water level automatic measuring and recording device which comprises a shell, a measurement recorder, a sensor, a steel rope, a balance weight ring and a cable, one end of the cable is connected with the sensor, the other end of the cable is connected with the measurement recorder, the sensor is installed in the shell, and the balance weight ring is installed in the shell. The lower end of the steel cable is connected with the counterweight ring, a protective cover is fixedly connected in the shell, a climbing mechanism is connected in the protective cover, the shell is connected with the steel cable through the climbing mechanism, the side wall of the cable is connected with a plurality of locking mechanisms, and the cable is connected with the steel cable through the locking mechanisms. According to the portable underground water level automatic measuring and recording device, the detection probe cannot be damaged during installation, the device does not make contact with the well wall during measurement, normal measurement of the water level measuring device is guaranteed, and meanwhile the signal transmission cable is not prone to deformation and damage during use.

Owner:冯起才

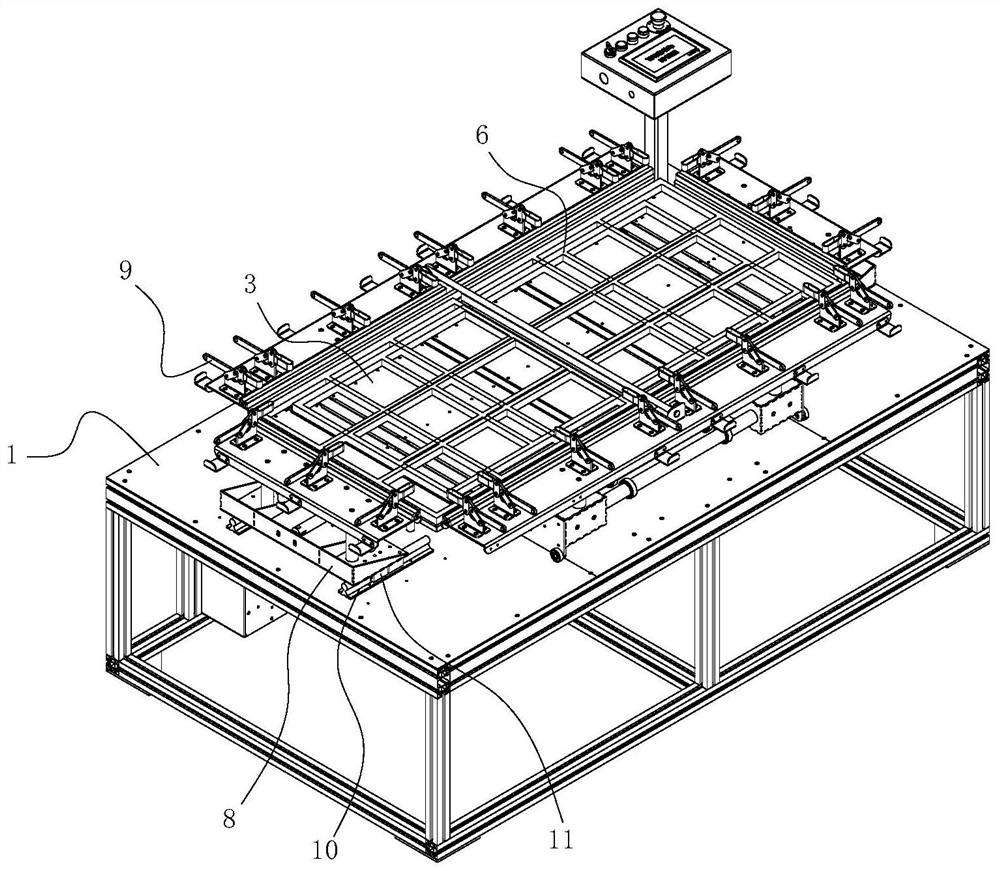

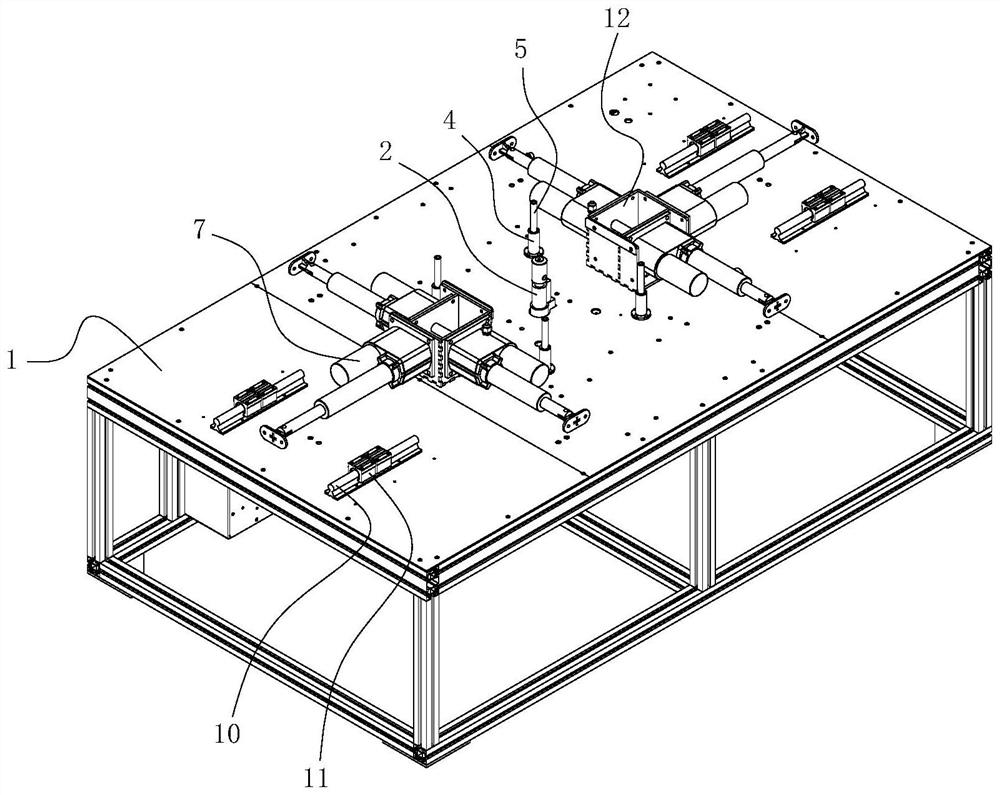

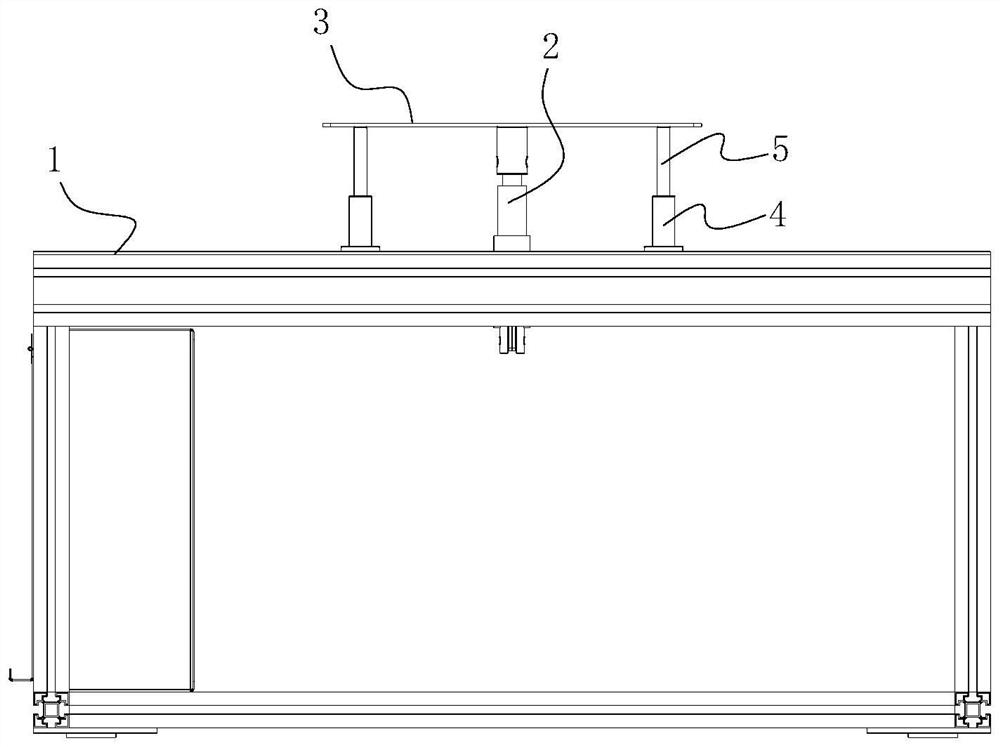

Electric tightening machine

An electric tightening machine comprises a working platform, a lifting electric push rod arranged in the vertical direction is installed in the middle of the working platform, the lifting electric push rod is provided with a vertical ejector rod vertically extending upwards, and a lifting flat plate is installed at the upper end of the vertical ejector rod; horizontal electric push rods are arranged on the working platform and located on the periphery of the lifting electric push rod, the horizontal electric push rods are provided with transverse ejector rods extending towards the four sides of the lifting flat plate, the transverse ejector rods are provided with horizontal movable frames, and the horizontal movable frames are provided with a plurality of clamps. And the clamps are uniformly distributed along a straight line parallel to the corresponding side edge of the lifting flat plate. The tightening machine can be suitable for manufacturing more screens of different sizes and models, and the occupied space of a component system is small.

Owner:LIAOYUAN RUIYI GRAIN MACHINERY MFG +1

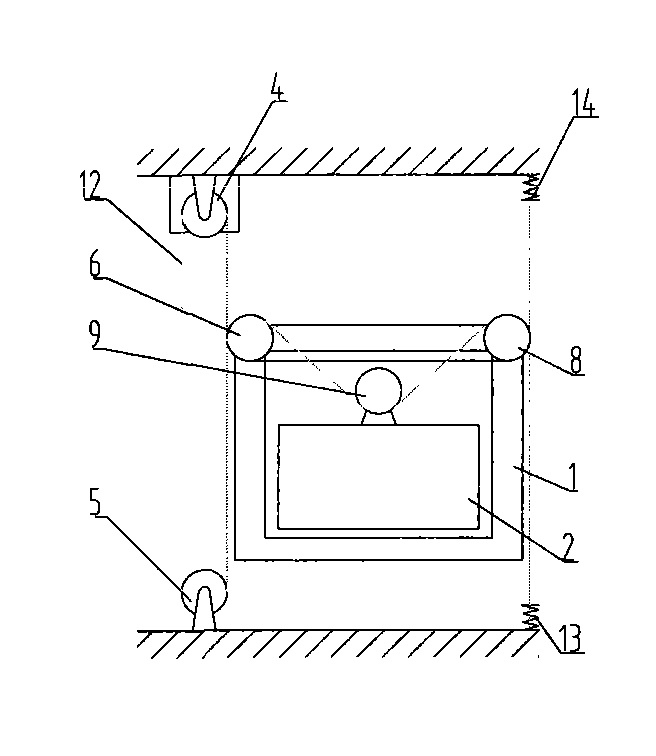

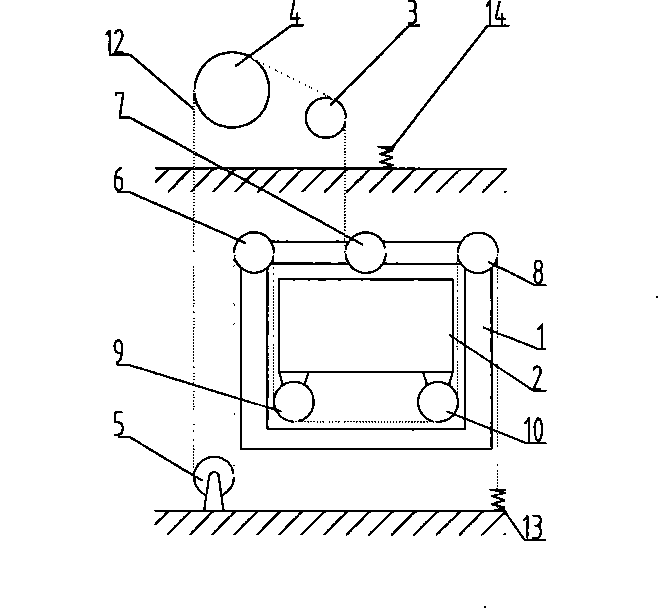

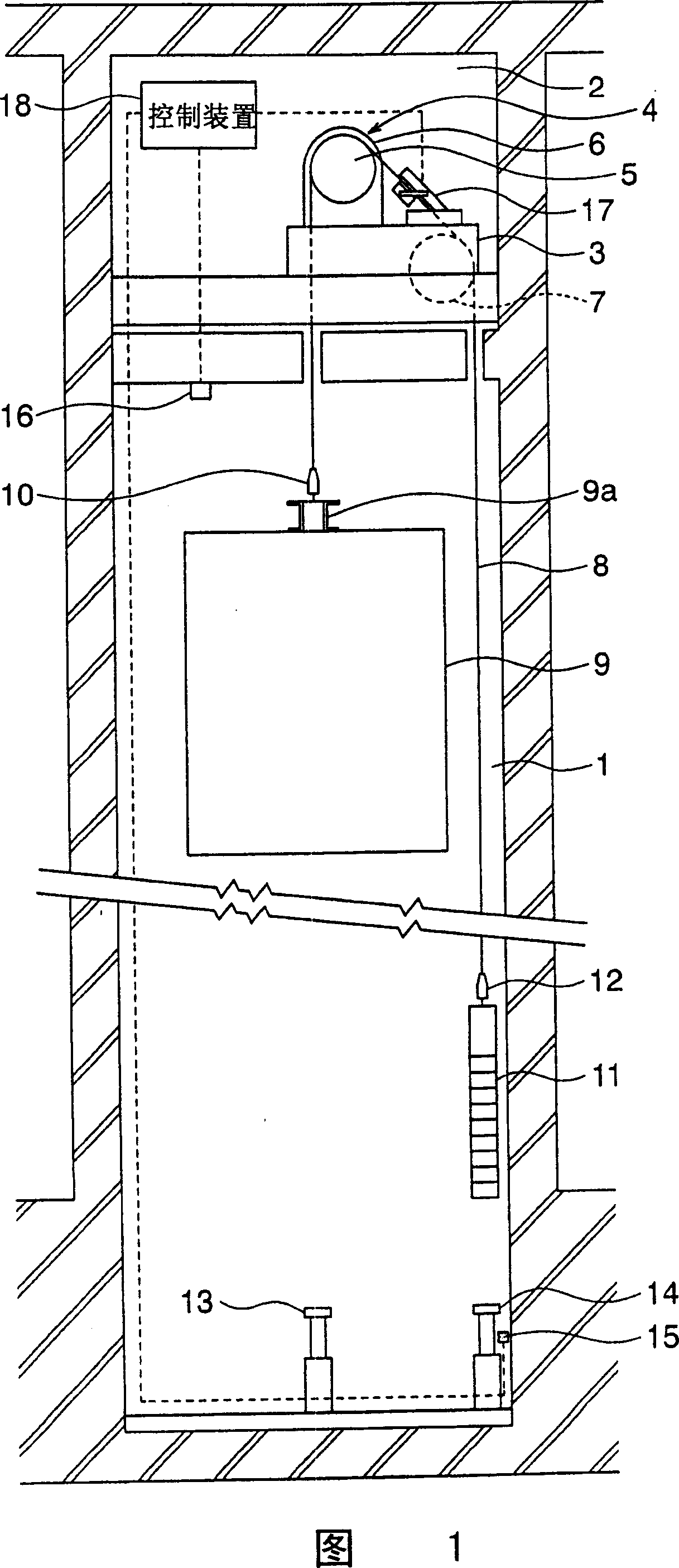

Non-counterweight elevator system

Owner:XIZI OTIS ELEVATOR

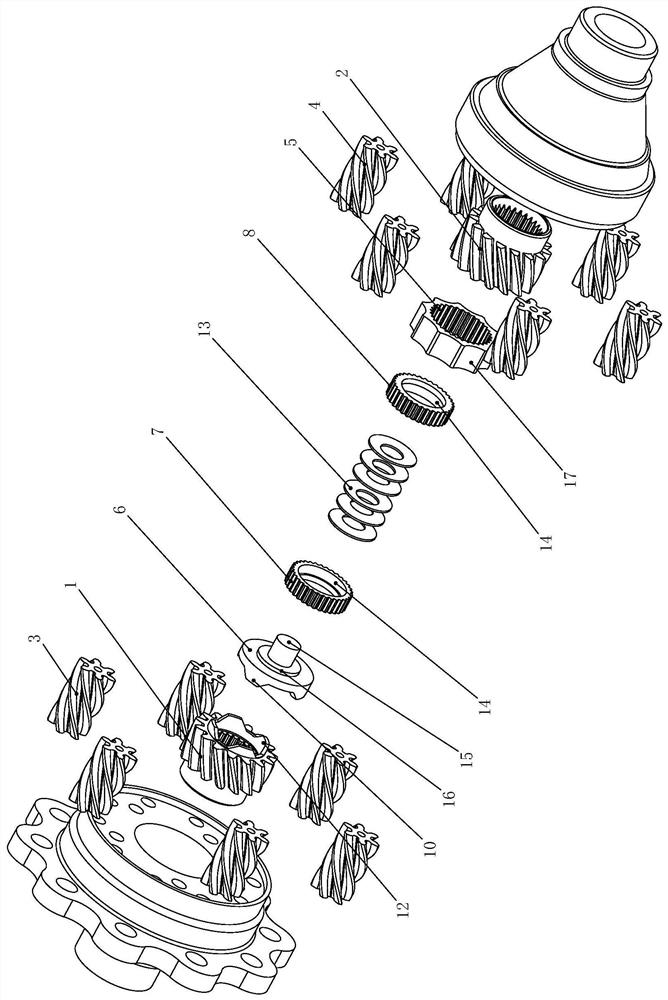

Locking differential mechanism

PendingCN113551018AHigh lockup rateEnough tractionDifferential gearingsAutomotive engineeringControl theory

The invention belongs to the technical field of differential mechanisms, and particularly relates to a locking differential mechanism. The locking differential mechanism comprises a shell, left half shaft spiral teeth, right half shaft spiral teeth, a left planetary gear and a right planetary gear are rotationally connected in the shell, a middle check ring is arranged in the shell, a driving seat is arranged between the middle check ring and the left half shaft spiral teeth, the driving seat is in circumferential linkage with the left half shaft spiral teeth through the circumferential driving surface, and when the left half shaft spiral teeth rotate relative to the driving seat in the circumferential direction, the left half shaft spiral teeth can drive the driving seat to move in the axial direction through the circumferential driving surface and push the middle check ring to abut against the right half shaft spiral teeth. When an automobile idles or slips, the left half shaft spiral teeth and the driving seat can rotate relatively, the driving seat pushes the middle check ring to abut against the right half shaft spiral teeth in the axial direction of the driving seat under the guidance of the circumferential driving surface, thus the middle check ring and the driving seat are tightly attached together to form approximately-rigid fixed connection, and enough traction force is provided for the automobile.

Owner:台州市阿瑞诗汽车配件有限公司

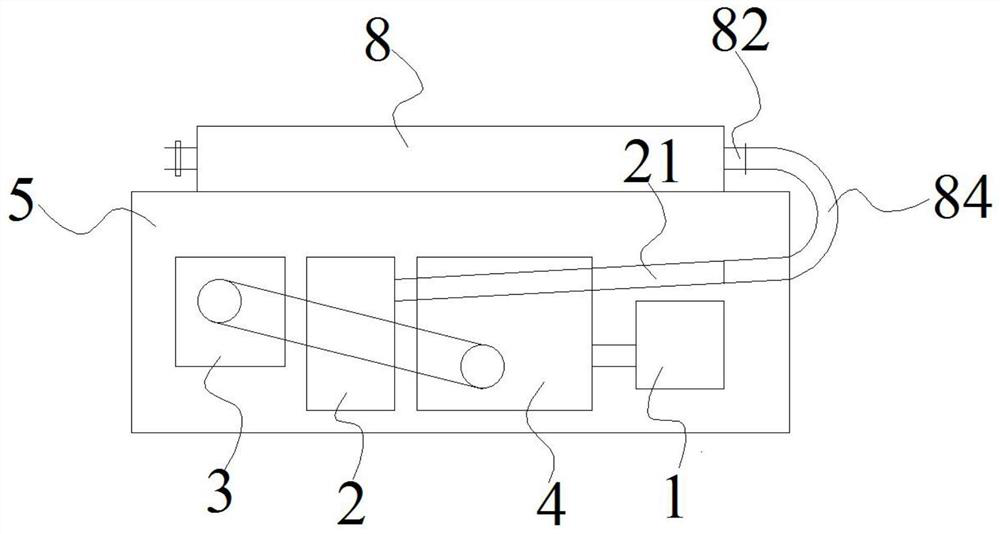

Tightening head device of two-way stretching film winding machine

PendingCN112027733ACompact structureSufficient space for installationWebs handlingWinding machineCylinder block

The invention discloses a tightening head device of a two-way stretching film winding machine. The tightening head device comprises a fixing sleeve, a sliding sleeve, a sliding shaft, a transverse moving bearing assembly and an air cylinder, and a rotating shaft axially penetrates through the air cylinder; a transmission assembly used for driving the rotating shaft to rotate is arranged on a cylinder body of the air cylinder, the air cylinder is used for driving the sliding sleeve and the sliding shaft to jointly move transversely, one end of the sliding shaft is in transmission connection with the rotating shaft, and the other end of the sliding shaft extends out of the sliding sleeve and is provided with a chuck. According to the tightening head device, the air cylinder is arranged at the rear end of the fixing sleeve and connected with the fixing sleeve into a whole through screws, limitation of the side portion of the fixing sleeve on the cylinder diameter of the air cylinder is eliminated, on the one hand, the air cylinder has sufficient installation space, the cylinder diameter of the air cylinder can be set to be proper, and enough traction force is provided for the chuck.

Owner:GUANGDONG SHICHENG PLASTIC MACHINERY

An intelligent pumping unit

ActiveCN111173478BCaused by wear and tearAvoid contactFlexible member pumpsFluid removalAcute angleDrive shaft

The invention belongs to the technical field of oil extraction devices for an oil field, and particularly relates to an intelligent oil sucking machine. The intelligent oil sucking machine comprises abase, a support frame, a guide wheel, a winding drum, a steel wire rope, an oil sucking pump and a motor, wherein a spiral groove for accommodating the steel wire rope is formed in the outer wall ofthe winding drum; the winding drum is in inclined arrangement; an included acute angle alpha formed between the axial line of the winding drum and the steel wire rope and the helix angle beta of the spiral groove meet a relationship that alpha=90 degree - beta; the winding drum structurally comprises a drum body, a driving shaft, a threaded support shaft and a shaft support frame; one end of the drum body is connected with a driving shaft through a spline; and the other end of the drum body is connected with the threaded support shaft through transmission screw threads. The intelligent oil sucking machine has the advantages that through the arrangement of the spiral groove with great thread pitches, the steel wire rope to be wound on the winding drum can be effectively prevented from beingin contact with the steel wire rope wound on the winding drum, so that the abrasion of the steel wire rope is reduced.

Owner:华运隆腾机械制造有限公司

Auxiliary top traveling mechanism of tunneling machine

Owner:SANY HEAVY EQUIP

Nozzles with automatic control of flow distribution

ActiveCN104453715BSufficient drilling capacityEnough tractionLiquid/gas jet drillingBorehole/well accessoriesControl flowAutomatic train control

The invention provides a spray nozzle capable of automatically controlling flow distribution. The spray nozzle comprises a probe, a forward nozzle body, a backward nozzle body and a steering control rod. The backward nozzle body comprises a containing part and a connecting part which are axially and sequentially connected with each other along a through hole of the backward nozzle body. The front portion of the containing part is connected with the forward nozzle body. The steering control rod comprises a slide part sliding in an inner cavity of the containing part, and a rod part in sliding fit with a through hole of the forward nozzle body. The rod part extends out of the forward nozzle body, and the extension end of the rod part is connected with the probe. A forward spray hole and a backward spray hole which are communicated with the inner cavity of the containing part are formed in the forward nozzle body and the backward nozzle body respectively. A through flow passing hole is formed in the slide part. When the slide part slides to be tightly attached to the forward nozzle body, at least part of the section of the flow passing hole is communicated with the forward spray hole; when the slide part slides to be tightly attached to the connecting part, the slide part shields the backward spray hole; thus, distribution of forward flow and backward flow is achieved, sufficient traction is ensured during normal drilling, and meanwhile the sufficient rock break-off capacity is achieved when the spray nozzle encounters an obstacle.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

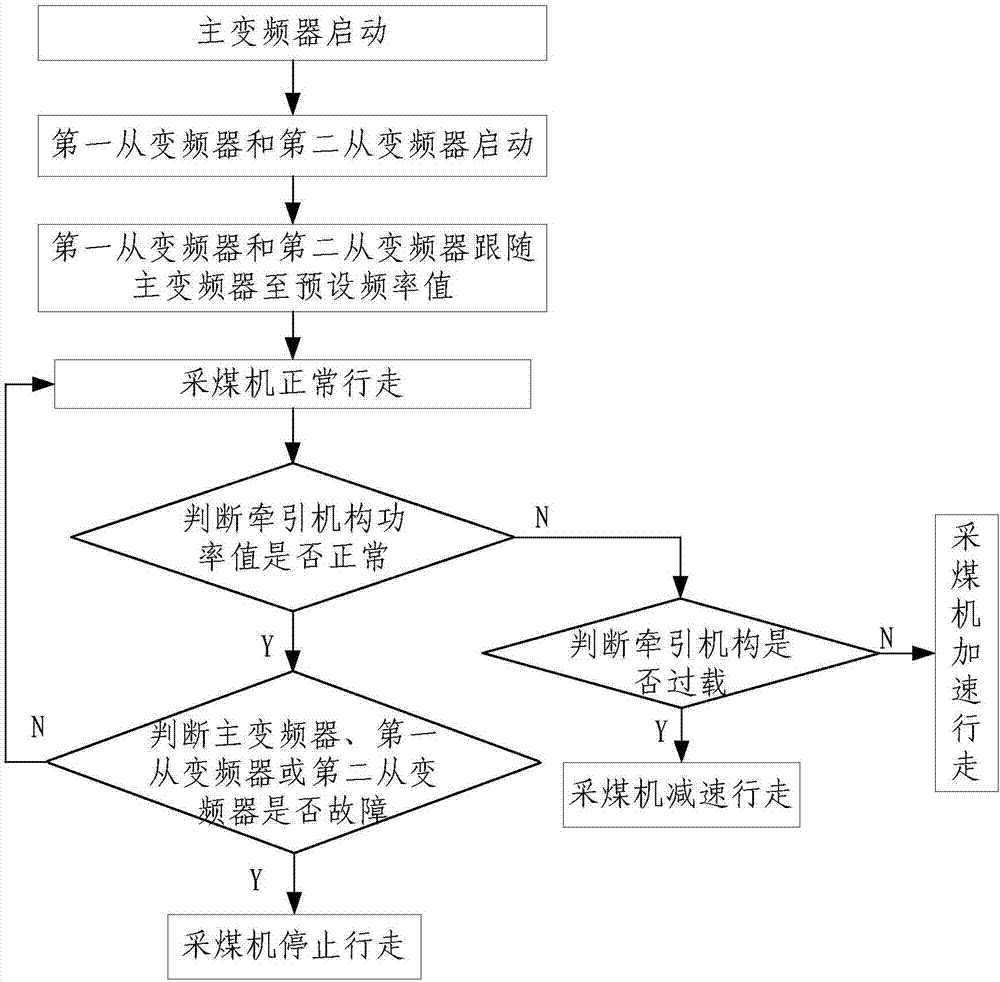

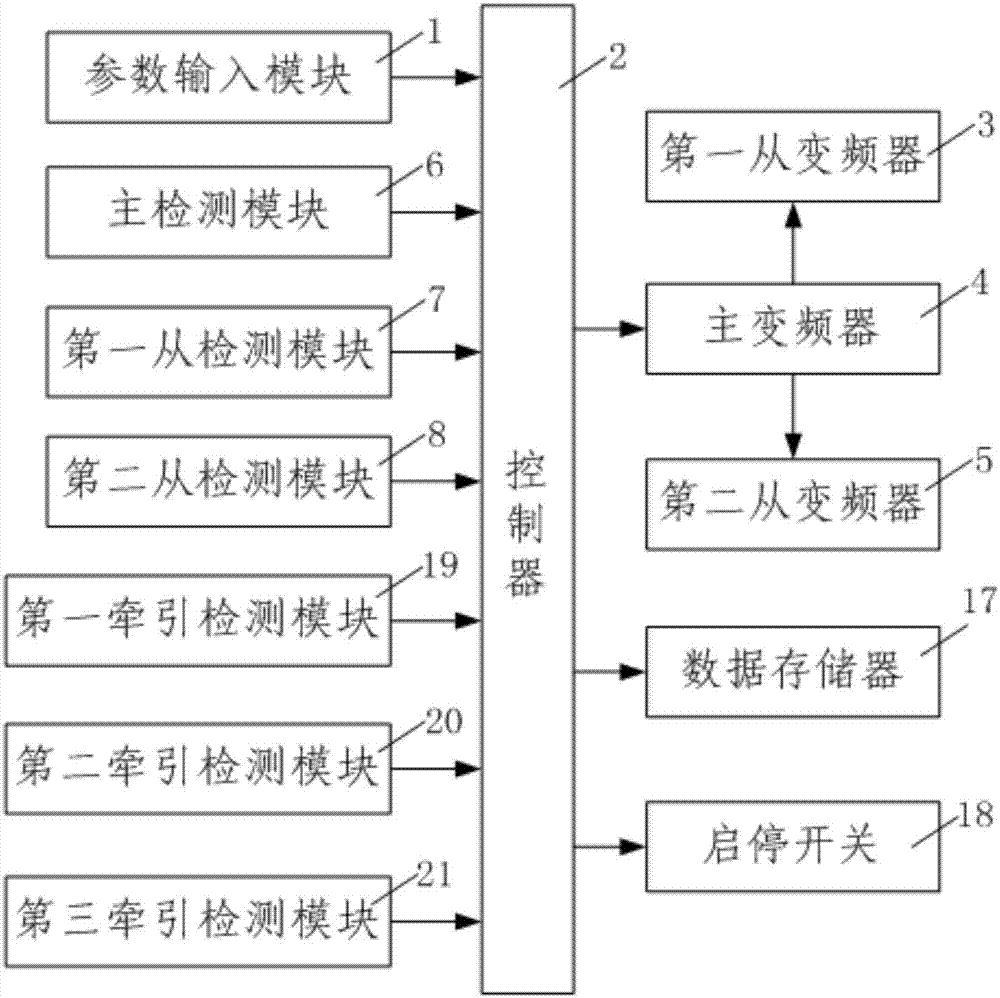

Large-inclined-angle coal cutter dragging control device and control method

The invention discloses a large-inclined-angle coal cutter dragging control device and control method. The large-inclined-angle coal cutter dragging control device comprises a walking mechanism, a traction mechanism and an electrical control mechanism. The electrical control mechanism comprises a controller, a main frequency changer, a first auxiliary frequency changer and a second auxiliary frequency changer, wherein the first auxiliary frequency changer and the second auxiliary frequency changer are in communication with the main frequency changer. The invention simultaneously discloses a large-inclined-angle coal cutter dragging control method. The method comprises the following steps that 1, walking of a coal cutter is controlled; 2, it is detected that whether traction motors overload or underload; and 3, it is detected that whether the frequency changers fail or not. According to the large-inclined-angle coal cutter dragging control device and control method, the three frequency changers adopt the control way of one main and two auxiliaries, the traction mechanism overload or underload detecting function is achieved, the frequency changer failure detecting function is achieved, on the basis of maintaining the first traction motor, the second traction motor and the third traction motor be at synchronous operation, the traction motors are prevented from overloading or underloading, any one of the frequency changers fails, the coal cutter stops working, failure expansion is avoided, and damages of equipment of the coal cutter are reduced.

Owner:XIAN COAL MINING MACHINERY

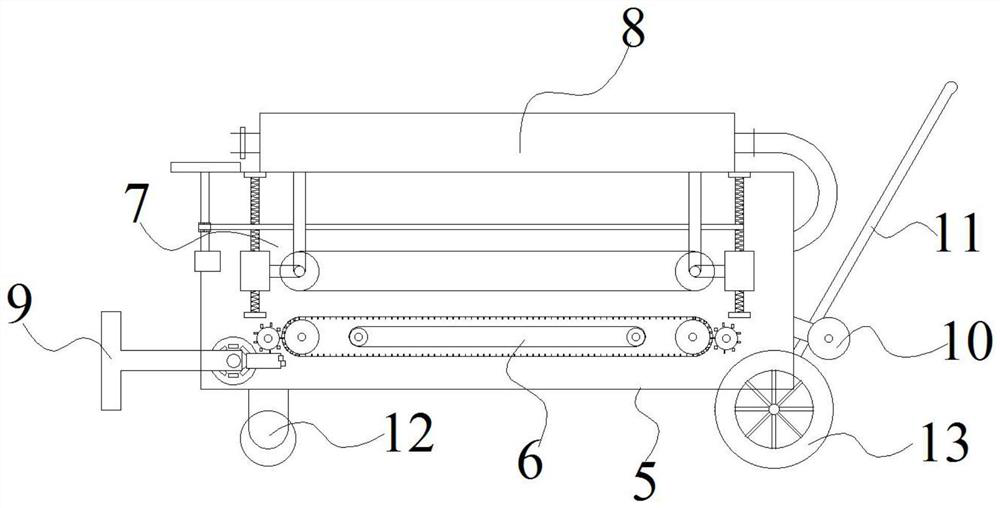

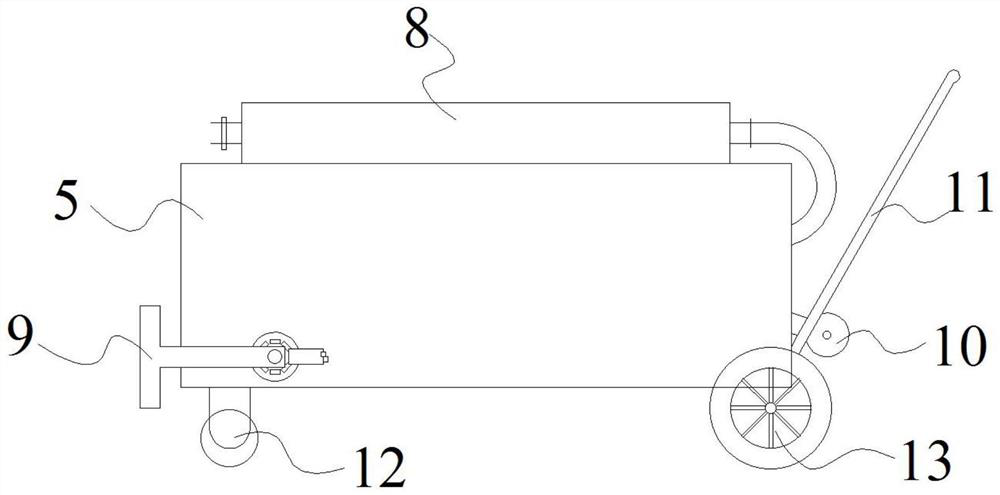

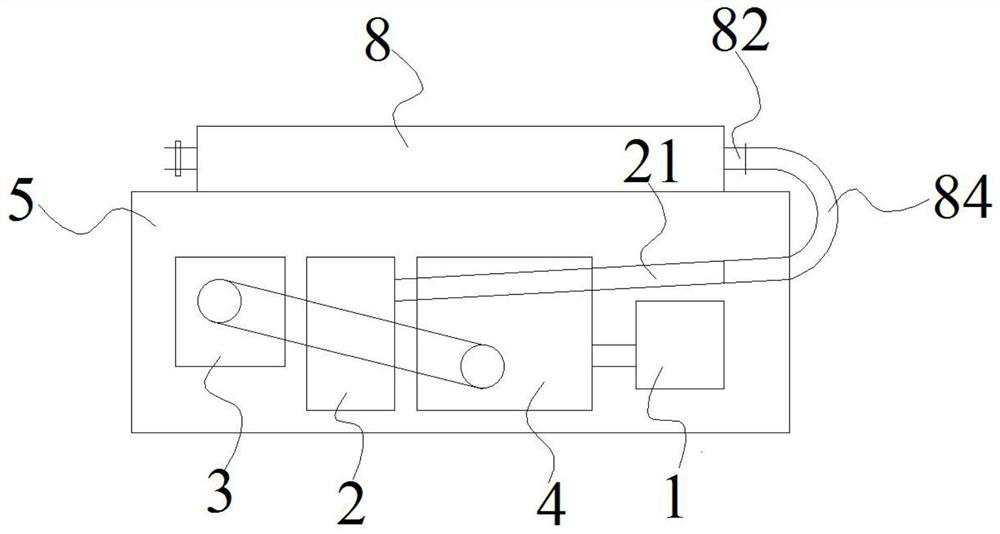

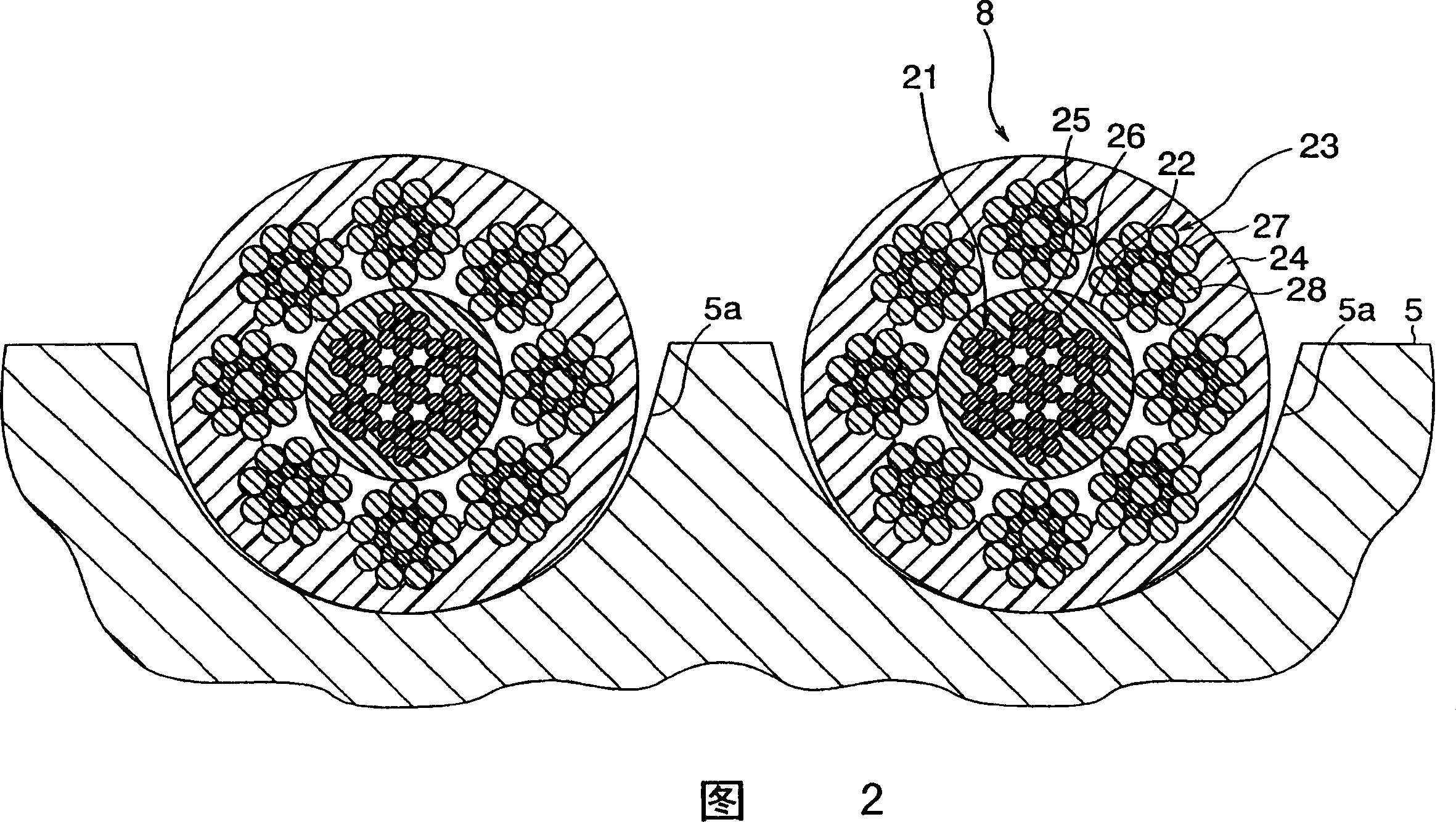

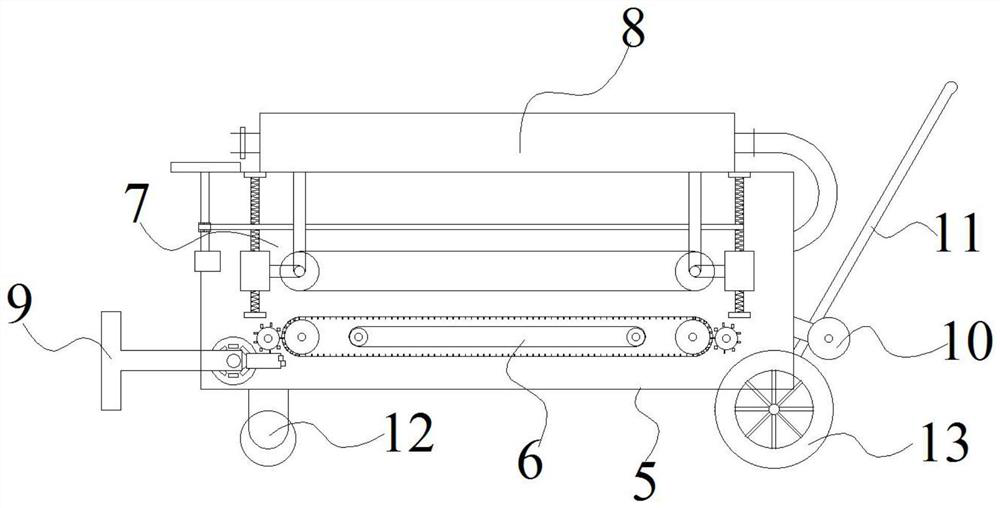

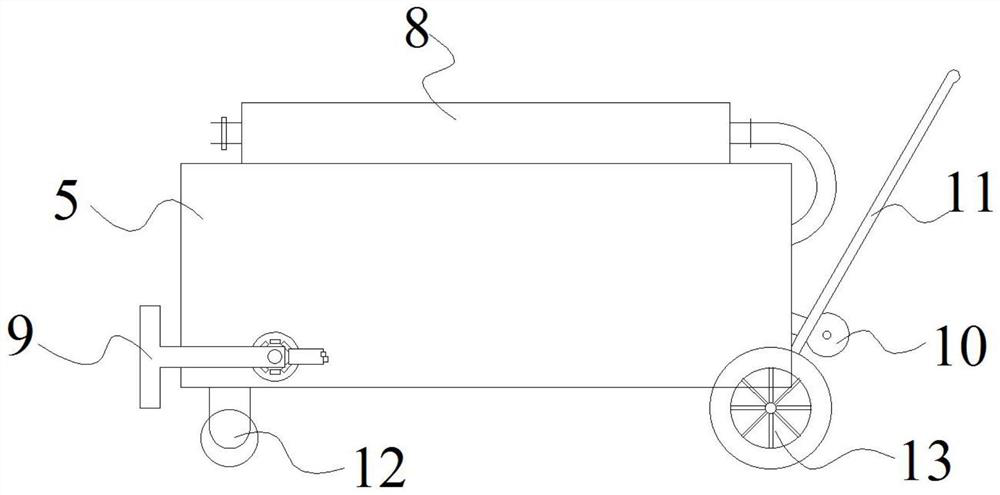

Anti-compression and tensile-loss-resistant optical cable traction machine

ActiveCN113721338AGreat tractionImprove traction efficiencyOptical fibre/cable installationAir filterMachine

The invention relates to an anti-compression and tensile-loss-resistant optical cable traction machine. An oil tank, an air filter, a gearbox and an engine are arranged in the optical cable traction machine; the optical cable traction machine comprises a machine frame, a conveying traction mechanism, a pressing transmission mechanism, an emergency braking mechanism, supporting frames, a wire guide wheel, a handle, universal wheels and wheels; and the conveying traction mechanism is arranged at the lower end of the machine frame in the horizontal direction, the pressing transmission mechanism is arranged above the conveying traction mechanism in parallel, the conveying traction mechanism and the pressing transmission mechanism are in transmission connection with the gearbox, the emergency braking mechanism is arranged at the upper end of the machine frame, the lower end of the machine frame is connected with the pressing transmission mechanism, an exhaust pipe is arranged on one side of the air filter, one end of the emergency braking mechanism is connected with the exhaust pipe, the supporting frames are movably connected with the two sides of the machine frame respectively, the wire guide wheel is connected to the machine frame and located on the side, away from the supporting frames, of the conveying traction mechanism, the handle is obliquely arranged on the side, away from the supporting frames, of the machine frame, and the universal wheels and the wheels are connected to the bottom end of the machine frame.

Owner:SHANGHAI YUANWEI CONSTR ENG CO LTD

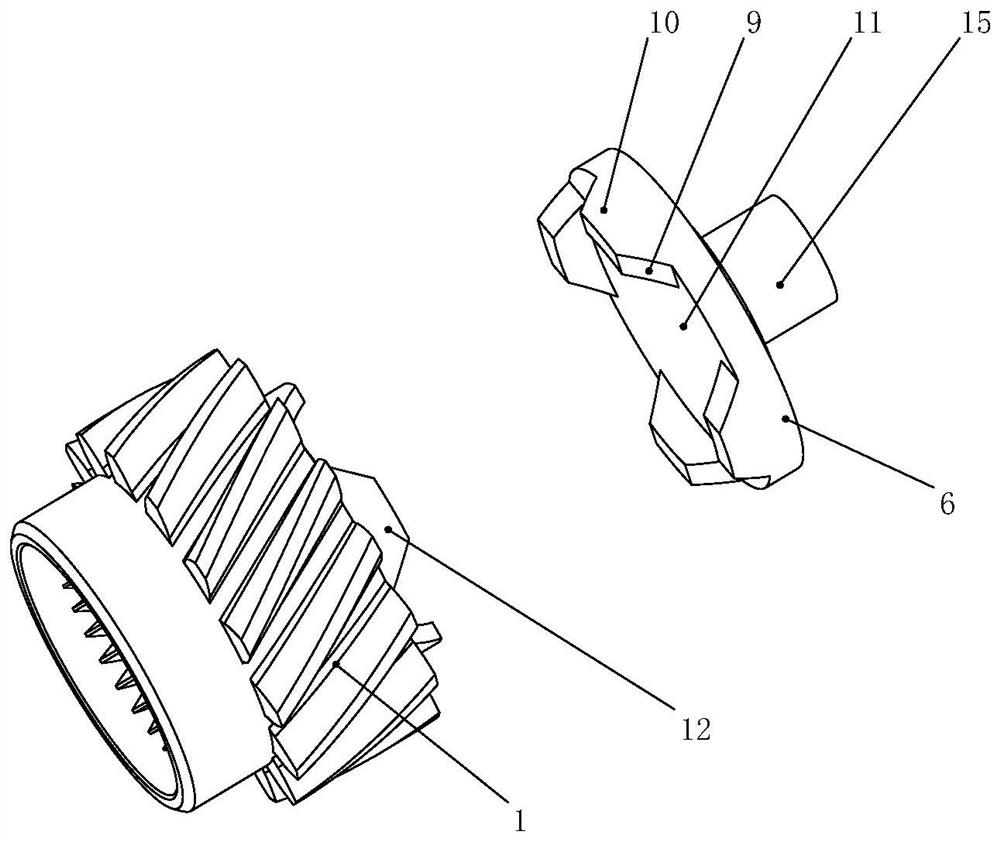

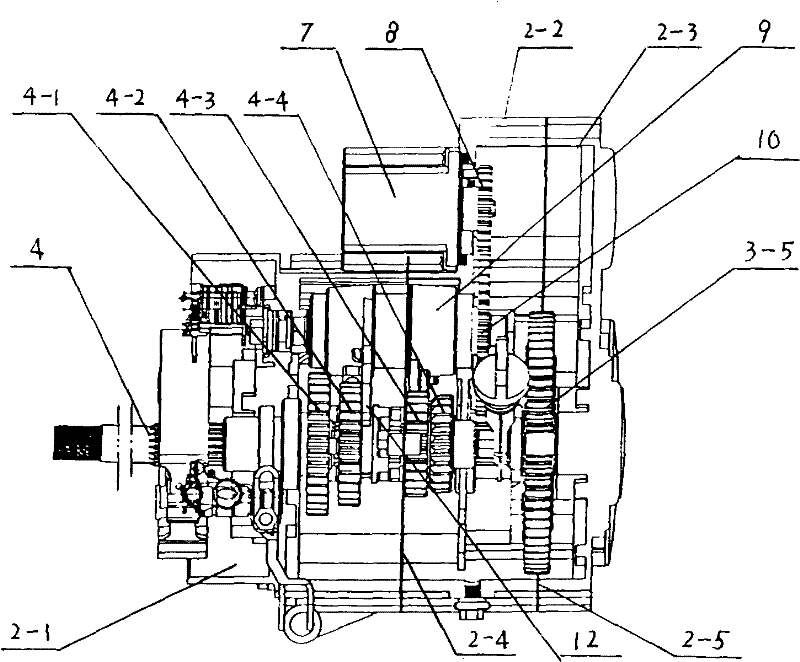

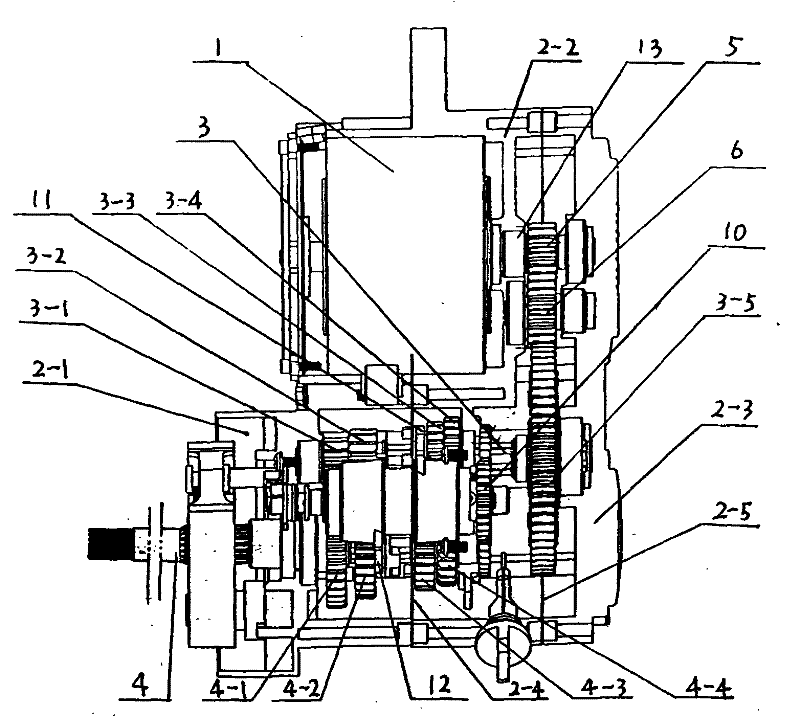

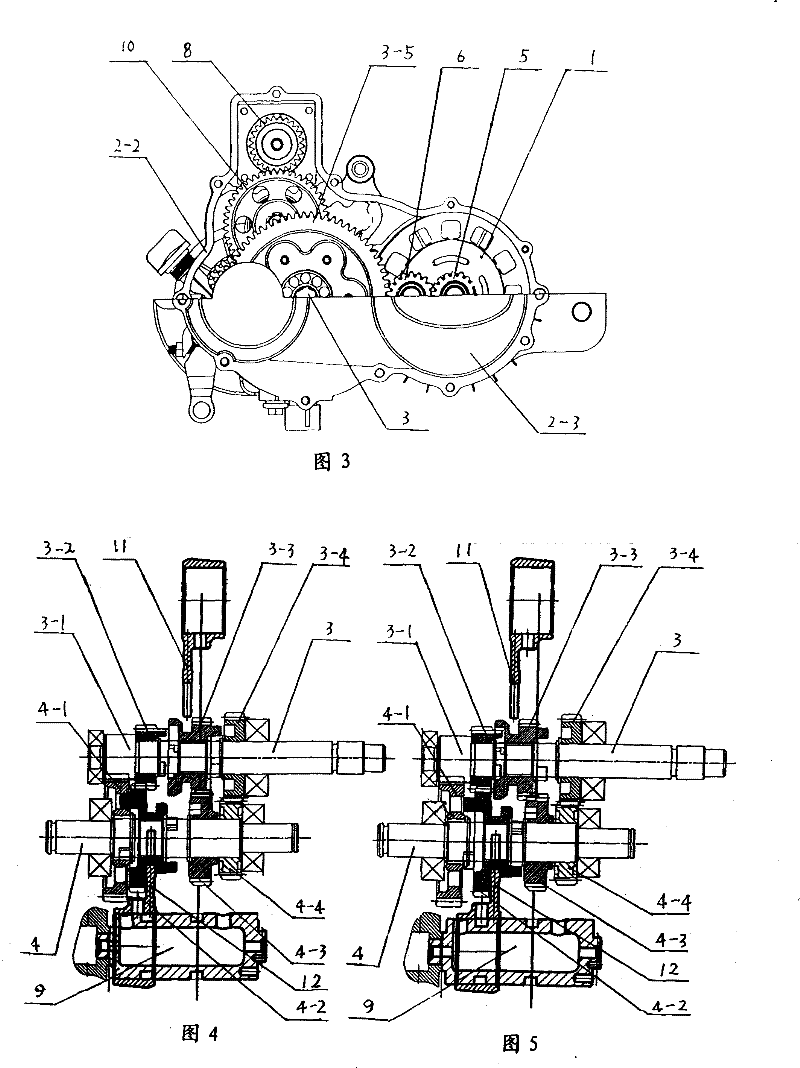

Integrated multi-shift speed changing power mechanism of electric motorcycle

InactiveCN101486372BImprove cooling conditionsEnough tractionWheel based transmissionElectric propulsion mountingDrive shaftDirect current

The invention relates to an integrated electric motorcycle multi-stage variable-speed power plant, which comprises a direct-current motor, a gearbox and an electric shifting mechanism, and is characterized in that a main driving shaft in the gearbox is sequentially provided with a first-stage driving gear, a second-stage driving gear, a third-stage driving gear, a fourth-stage driving gear and a reduction gear; a driven shaft is provided with a first-stage driven gear, a second-stage driven gear, a third-stage driven gear and a fourth-stage driven gear, and directly connected with a wheel hubin a matching way; and a shell of the direct-current motor and a box body of the gearbox are integrated into a whole, a gear at the end of a rotating shaft is meshed with an intermediate gear which is meshed with the reduction gear on the main driving shaft, and the motor is connected with a controller, a power supply and a starting switch by a lead. The power plant not only has compact structureand strong integrity, but also leads the radiating condition of the direct-current motor to be improved significantly; and the speed is adjusted by driving a variable-speed drum through a stepping motor, thus leading the motorcycle to have enough traction when driving on an upslope, and be speeded up when driving on a level road.

Owner:重庆百年上邦实业(集团)有限公司

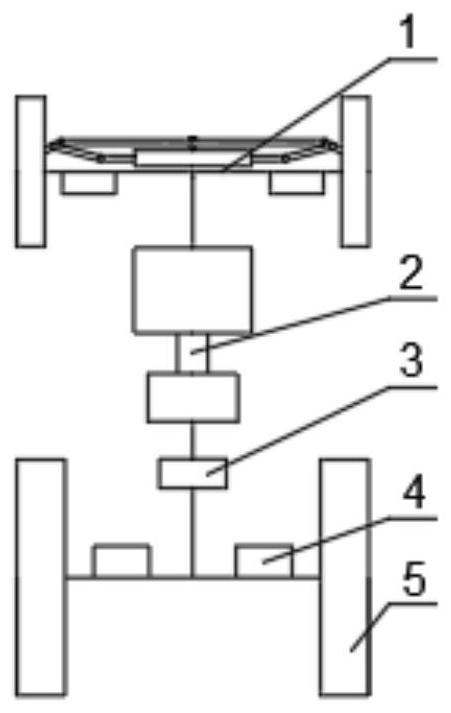

Novel walking chassis

PendingCN113120082ALow costEnough tractionElectric propulsion mountingUnderstructuresSteering wheelDrive motor

The invention discloses a novel walking chassis which comprises a chassis main body, a front axle driving mechanism, a chassis power device, a chassis system control unit, a plurality of groups of independent driving motors and a plurality of groups of wheels are arranged on the chassis main body, and the chassis system control unit is connected with the front axle driving mechanism, the chassis power device and the independent driving motors. According to the novel walking chassis, enough traction force can be guaranteed; the novel walking chassis has high fault tolerance, after a fault occurs, a vehicle can limp and get out of trouble as long as two driving energy work devices exist, variable steering can be achieved, normal driving comfort is guaranteed, meanwhile, the vehicle can turn in situ, steering wheels are rigidly connected in the in-situ turning process, the wheels on the two sides rotate reversely to achieve in-situ turning in a mode similar to track turning, the design cost can be reduced, machine types can be diversified, large traction force and good control passing performance can be provided for a non-bearing type vehicle body, and better use prospects are achieved.

Owner:HENAN RICHUANG GENERAL MACHINERY MFR

Elevator equipment

InactiveCN100372753CEnough tractionReduce tractionElevatorsHoisting equipmentsLower limitEngineering

Elevator equipment, wherein a main rope is wounded on the drive sheave of a drive device, a car and a counterbalance weight are suspended by the main rope, and a rope brake device stopping the rise of the car by the drive device by holding the main rope when the counterbalance weight is moved downward beyond the lower limit of a normal lifting stroke is installed on the counterbalance weight side of the drive sheave.

Owner:MITSUBISHI ELECTRIC CORP

An anti-compression and anti-stretch optical cable pulling machine

ActiveCN112255749BGreat tractionImprove traction efficiencyOptical fibre/cable installationAir filterWire wheel

Owner:苏州维斯勒姆智能科技有限公司

CVT

ActiveCN105697702BSmall rotational lossLarge rotation lossGearboxesFriction gearingsRadial positionMechanical engineering

A continuously variable transmission, comprising: a first shaft, carrying a first disc to rotate together; a second shaft, carrying a pair of second discs to rotate together, and the second discs are arranged at intervals along the second shaft , the first axis and the second axis are such that the first disc is located between and overlaps with the second disc, the opposite surfaces of the first disc and the second disc Inclined; a pair of driving rings, both located between the first disc and the second disc on opposite sides of the first disc, the end surface of the driving ring is in contact with the first disc contacting an opposing surface of the second disc to transmit power between the first shaft and the second shaft; and a control mechanism that drives the drive ring relative to the first disc and the second disc move, thereby changing the mutual radial position, thereby changing the speed of the continuously variable transmission.

Owner:SAIC MOTOR

Equipment for auxiliary loading of sheet metal cutting machines

The invention belongs to the technical field of mechanical processing and particularly relates to equipment for auxiliary loading of a metal plate cutter. The equipment comprises ground rails and a rack which is positioned between the ground rails and arranged in a length direction, and further comprises four stand columns with drivers and roller wheels on bottoms, and a lifting framework, wherein a plurality of equal-height supporting roller shafts are mounted on the top of the rack in parallel; the roller wheels are positioned on the ground rails; a transverse beam is mounted between tops of the adjacent two stand columns; four bases which are distributed in the form of a rectangle are fixedly connected and mounted on the transverse beams; a speed reducer and a steel cable reel driven by the speed reducer are mounted on the top of each base, and a steel cable is wound on each steel cable reel; the lower end of each steel cable is fixedly connected with the lifting framework; a horizontal bottom framework is fixedly connected and mounted at the bottom end of the lifting framework; a plurality of hangers for hanging a metal plate are arranged on the edge of the bottom framework; left and right groups of wheel racks with limiting roller wheels at bottom ends are fixedly connected on the bottoms of the transverse beams; the edges at the two sides of the lifting framework are blocked between the limiting roller wheels.

Owner:TIANJIN WUQING DISTRICT JINGCHENG METAL PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com