Equipment for auxiliary loading of sheet metal cutting machines

A metal plate and cutting machine technology, applied in the field of mechanical processing, can solve problems such as difficulty in feeding materials, and achieve the effects of reasonable structural design, improved convenience, and strong grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to further understand the content, features, and effects of the present invention, the following examples are given to illustrate in detail as follows:

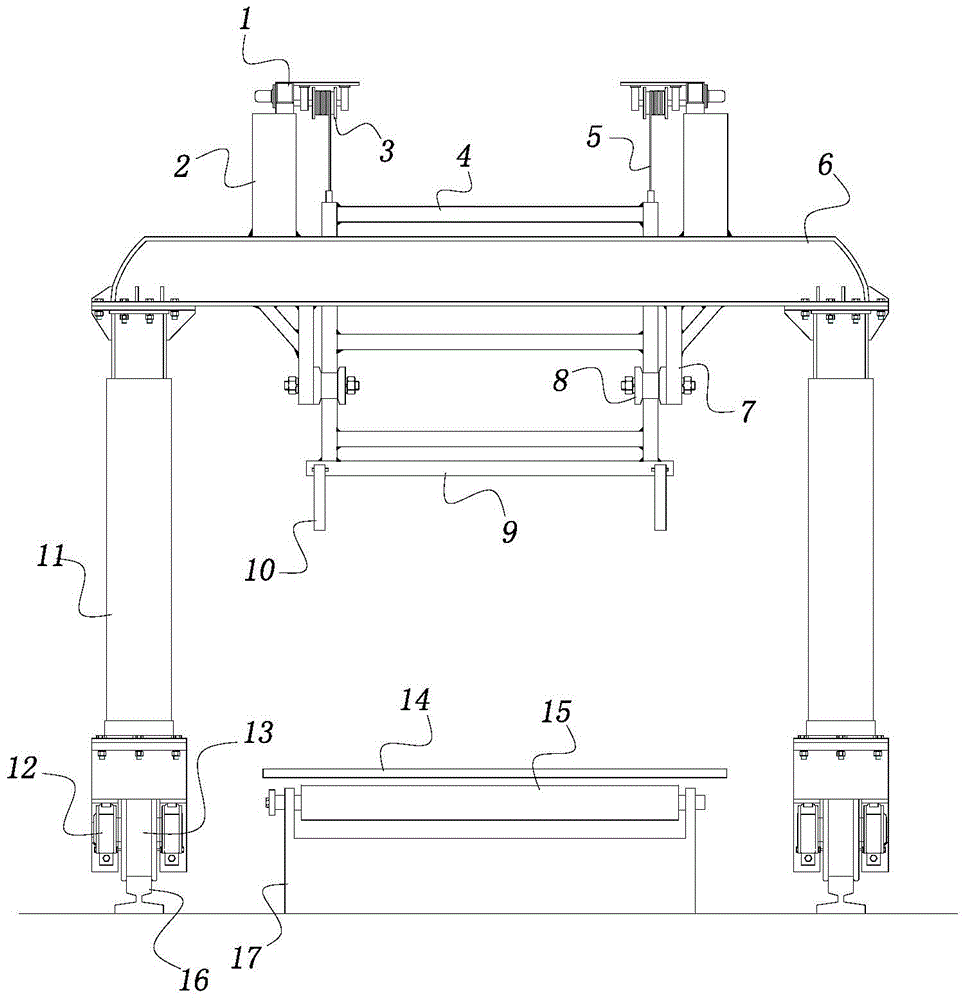

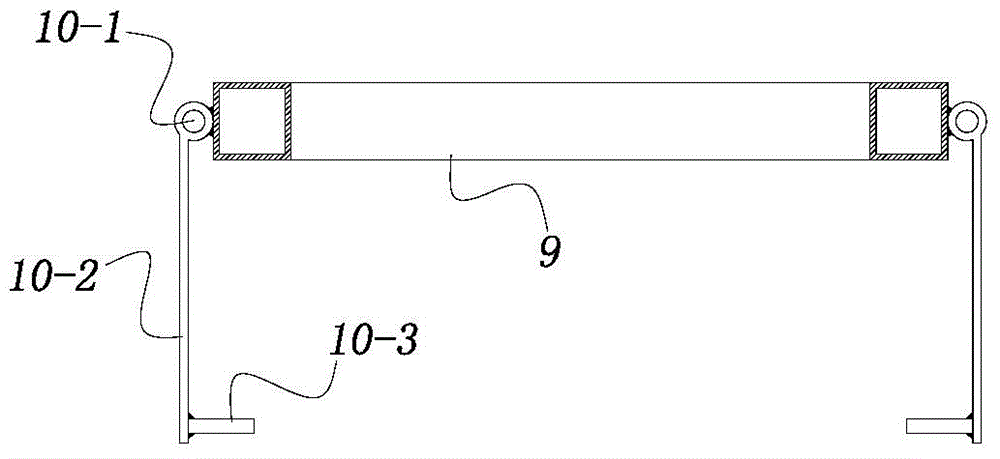

[0011] See figure 1 The present invention includes a floor rail 16 and a frame 17 located between the floor rails 16 and arranged along the length direction. A plurality of supporting shaft rollers 15 of equal height are installed side by side on the top of the frame 17. The metal plate 14 is placed on each supporting shaft roller 15, and the supporting shaft roller 15 rotates under the drive of external force to transport the metal plate 14 forward to a suitable position.

[0012] It also includes four uprights 11 with a driver 12 and a roller 13 installed at the bottom, and the roller 13 is located on the ground rail 16. A crossbeam 6 is installed between the tops of two adjacent uprights 11, four rectangularly distributed bases 2 are fixedly installed on the crossbeam 6, and a reducer 1 is installed on the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com