Spray nozzle capable of automatically controlling flow distribution

A technology of flow distribution and nozzles, which is applied in liquid/gas jet drilling, wellbore/well parts, earthwork drilling and production, etc. It can solve problems such as increasing drilling distance, drilling resistance, and weakening the adaptability of dense formations. Achieve the effect of reducing processing cost and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

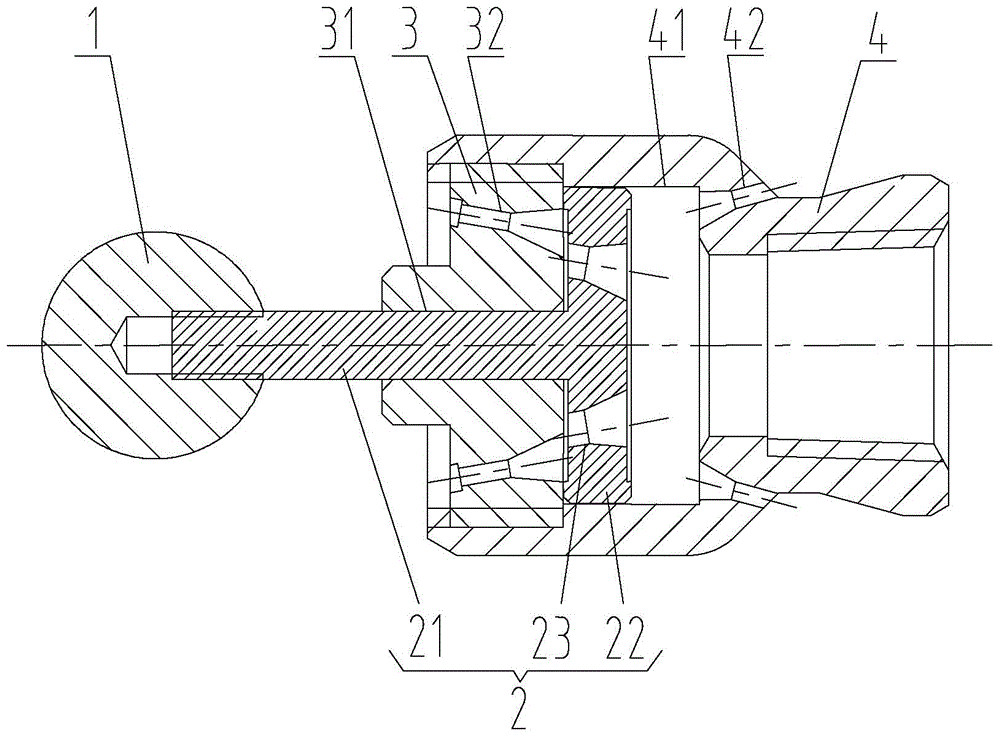

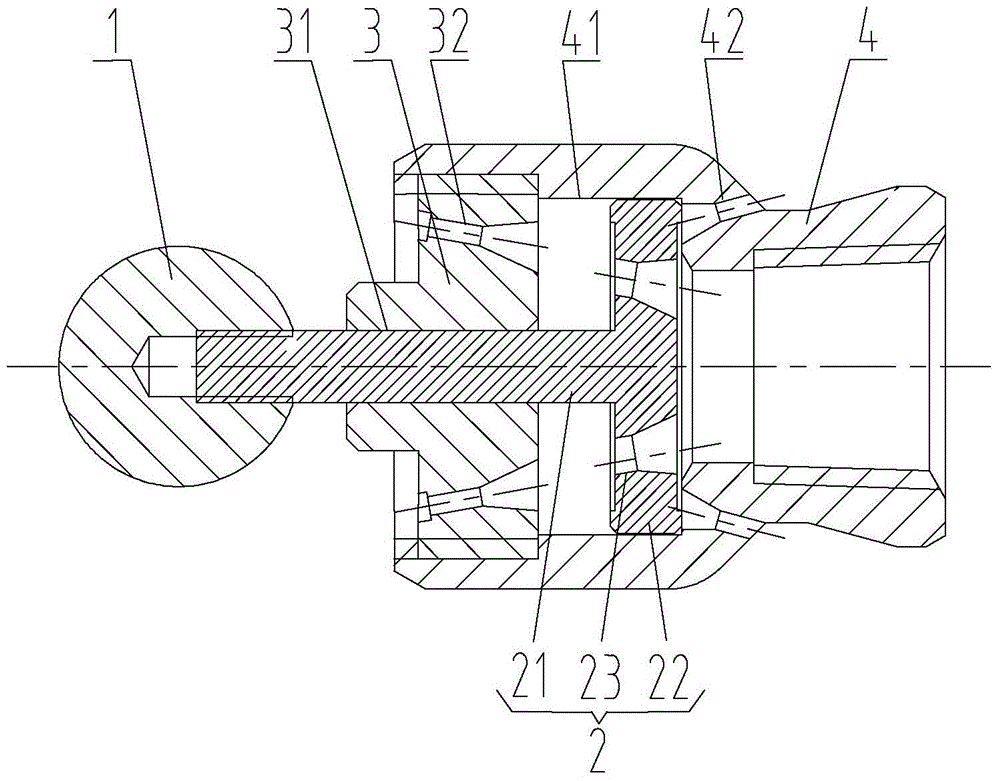

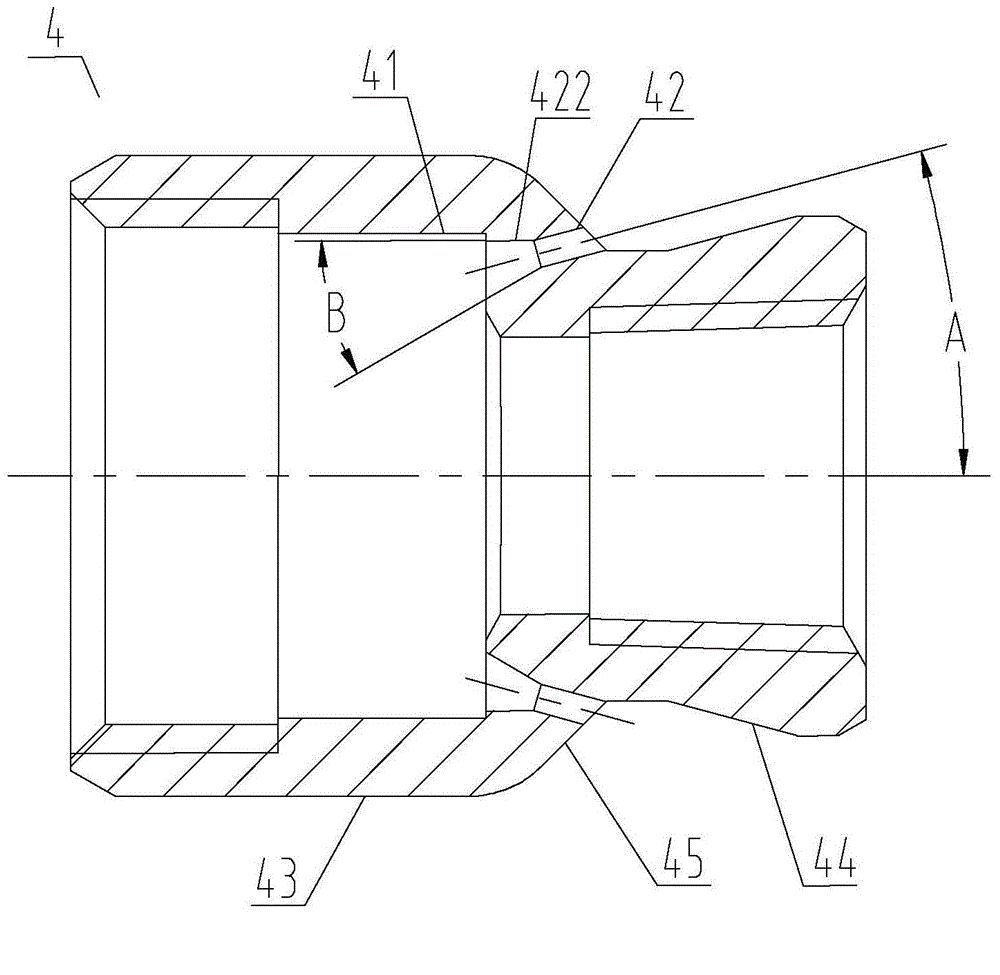

[0046] see figure 1 and figure 2 As shown, a nozzle for automatically controlling flow distribution of the present invention includes a probe 1, a reversing control rod 2, a forward nozzle 3 with a through hole and a backward nozzle 4 with a through hole. see image 3 As shown, the backward nozzle 4 includes an accommodating portion 43 and a connecting portion 44 sequentially connected along the axial direction of the through hole, and the front portion of the accommodating portion 43 is connected to the forward nozzle 3 .

[0047] recombine figure 1 and figure 2 As shown, the reversing control rod 2 includes a sliding part 22 that slides in the inner cavity of the receiving part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com