Patents

Literature

126results about How to "Improve traction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic wheel

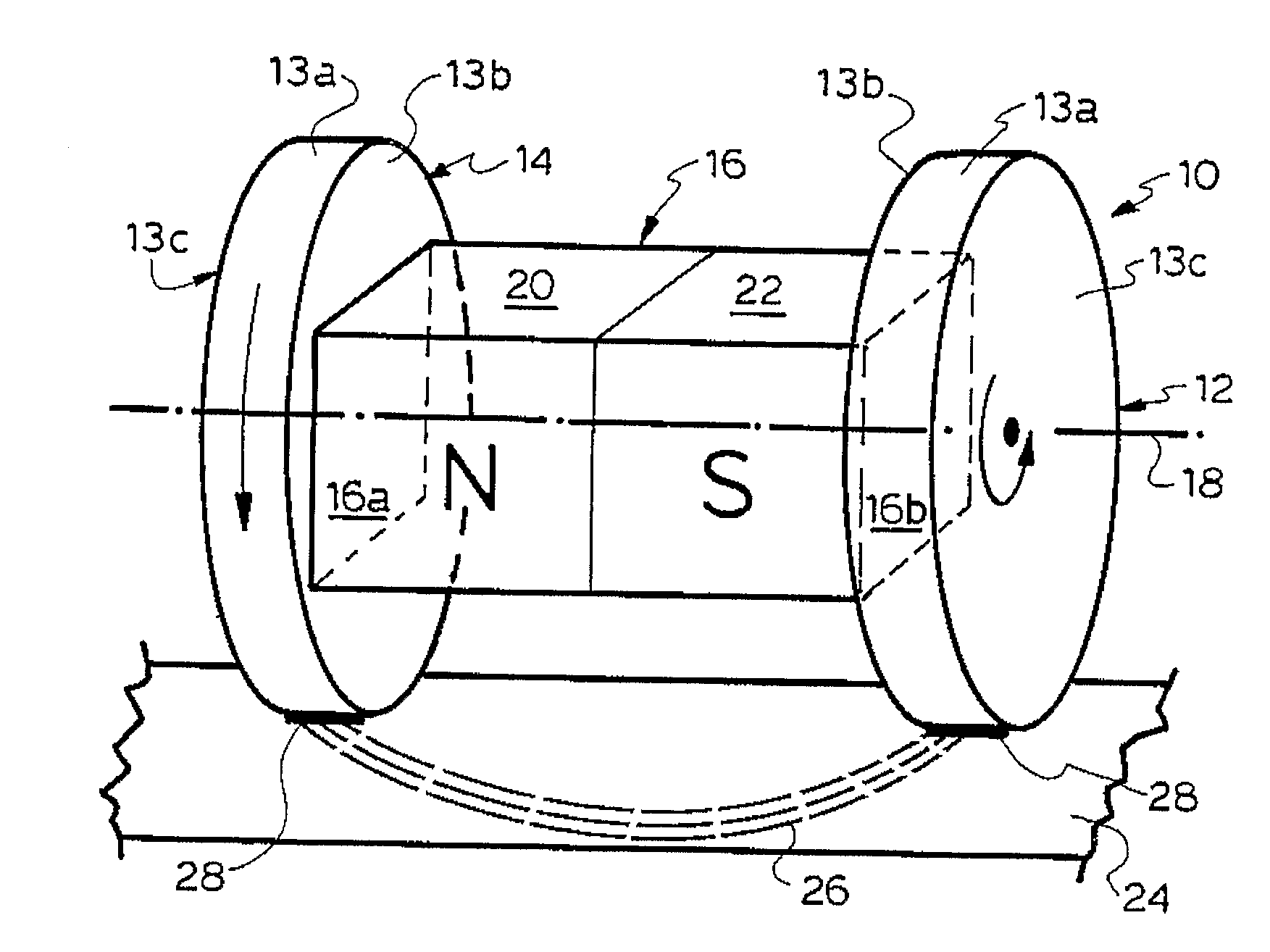

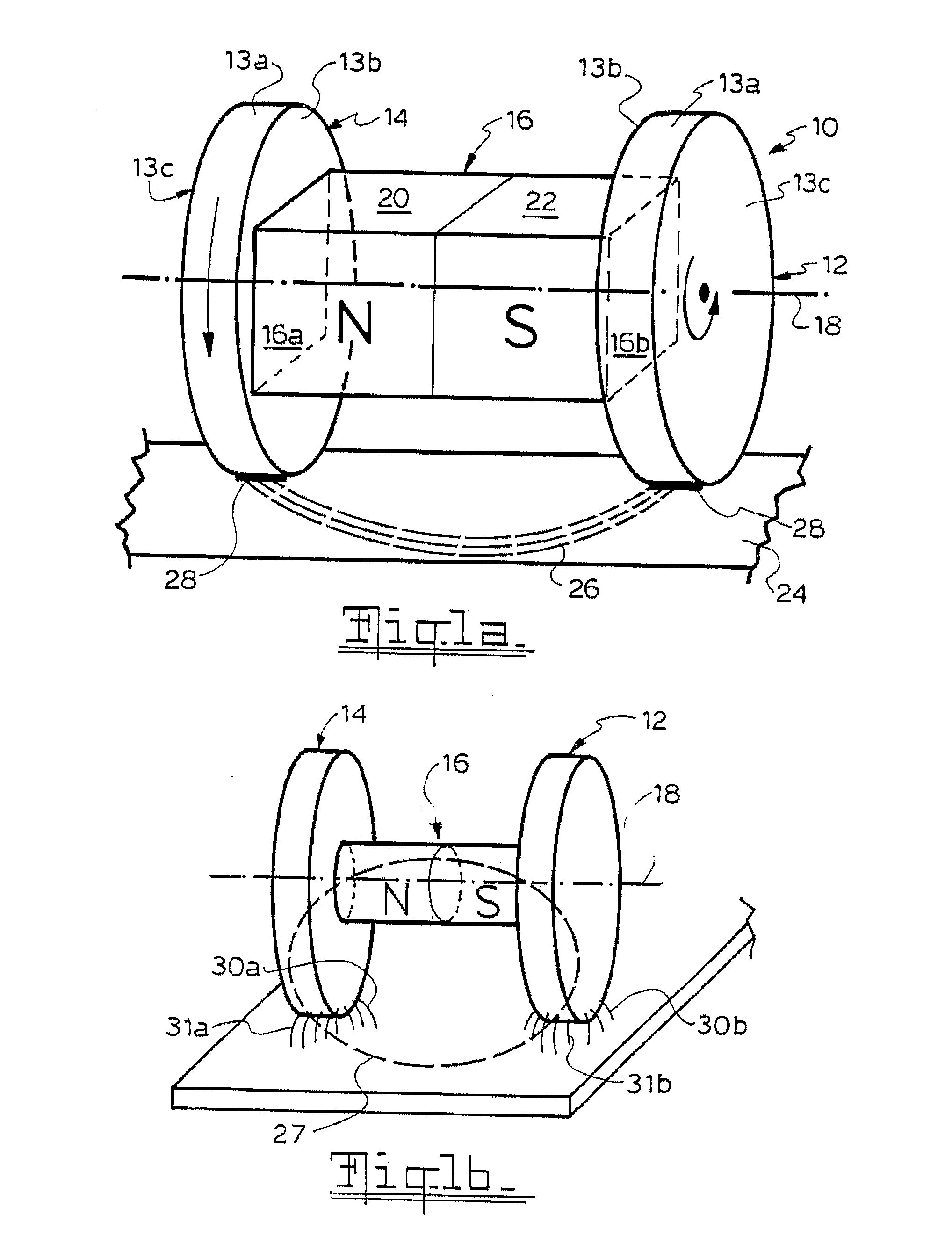

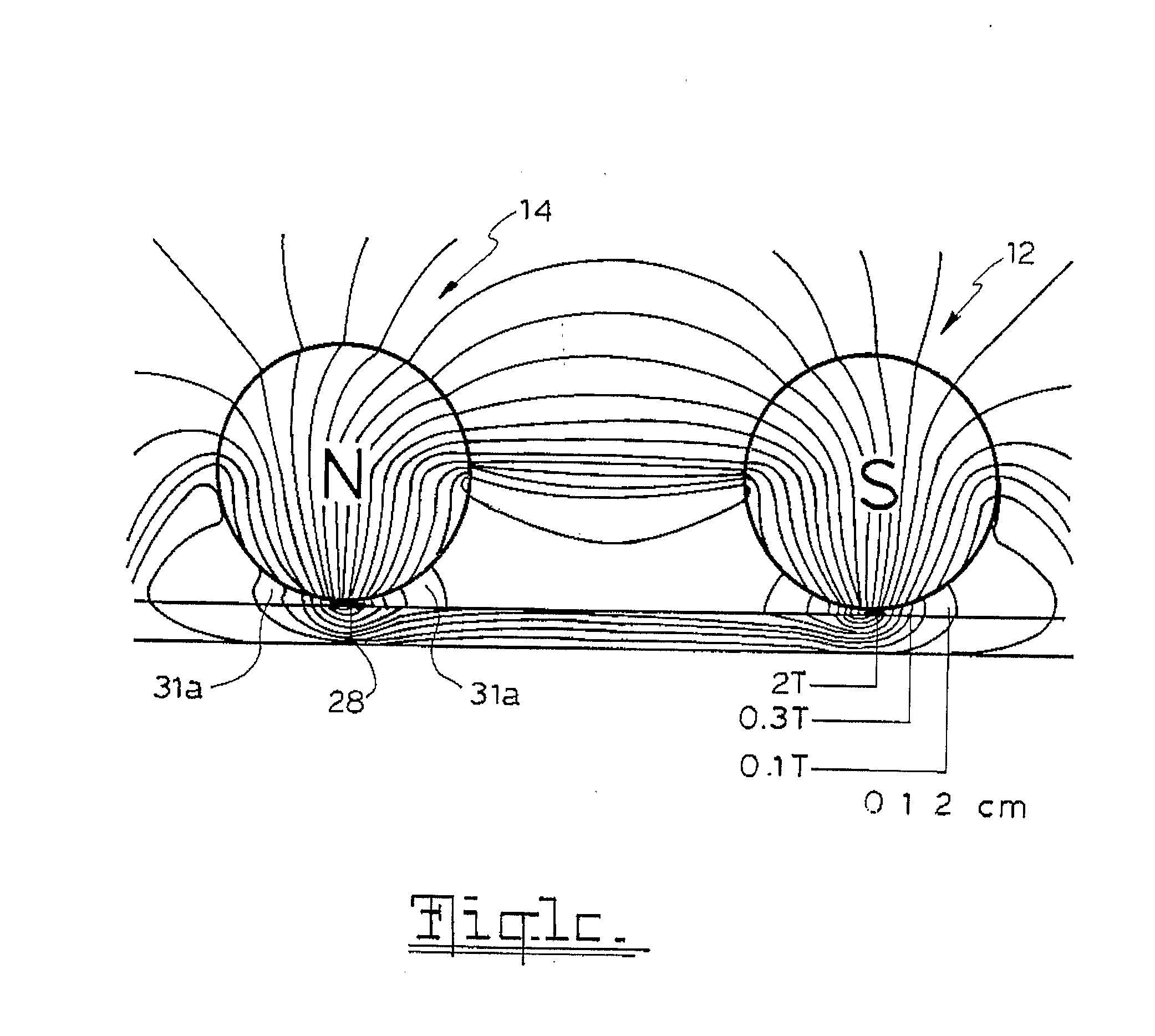

InactiveUS20090078484A1Improve traction efficiencyRestrict movementSki bindingsRailway vehiclesMagnetic polesMagnetic flux

Magnetic circuit that has (a) a source of magnetic flux which includes an electromagnet or one or more permanent magnets, (b) at least two oppositely polarisable pole extension bodies associated with the magnetic flux source, the bodies being disc, wheel, roller or similarly shaped with an outer circumferential surface and held rotatable about respective axes of rotation, and (c) a ferromagnetic counter body which is arranged to cooperate with the pole extension bodies such as to provide an external flux path for the magnetic flux when in magnetic proximity or contact with the circumferential surface of the pole extension bodies, which is characterised in that the magnetic flux source is held stationary relative to the rotatable pole extension bodies.

Owner:MAGSWITCH TECH WORLDWIDE PTY LTD

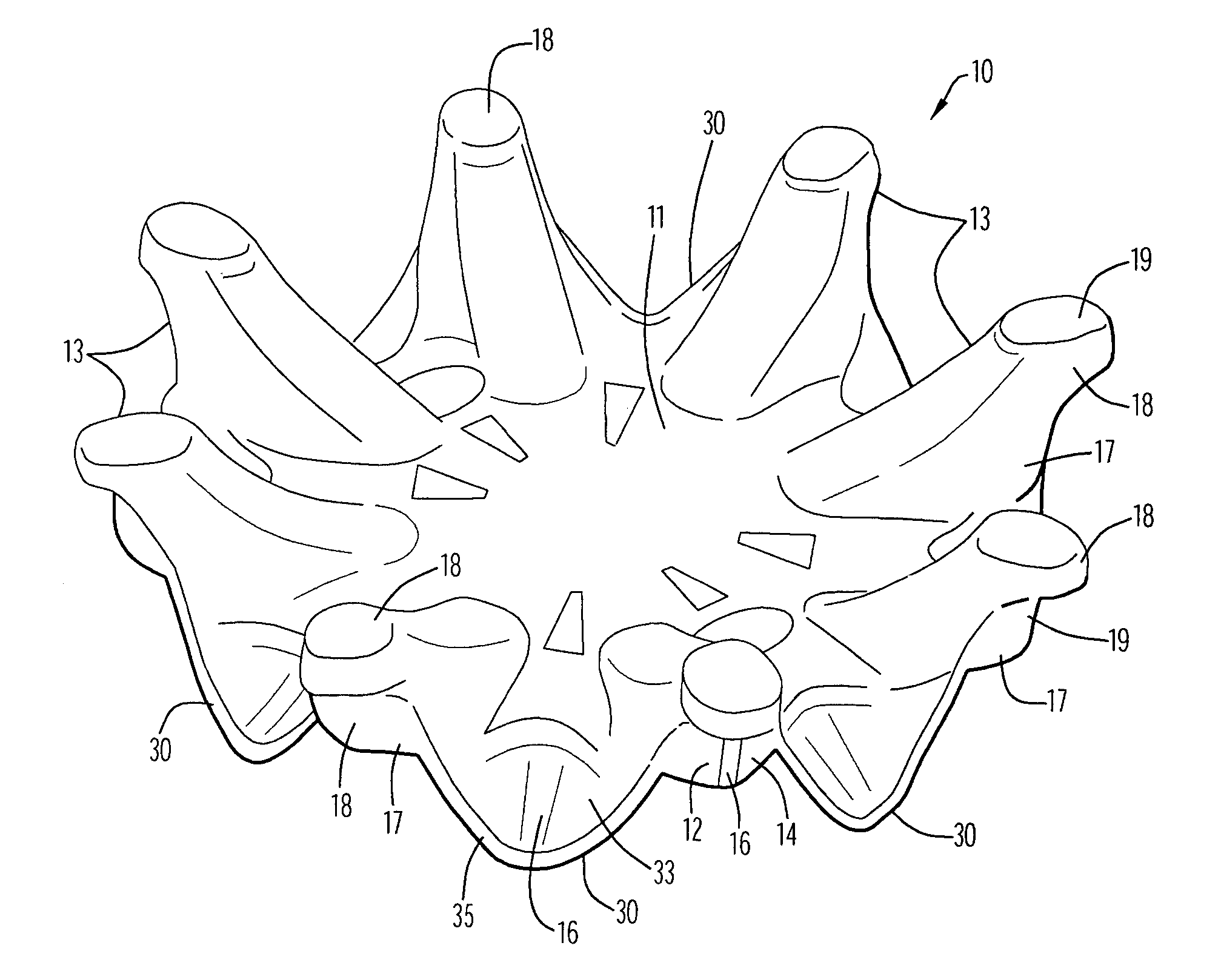

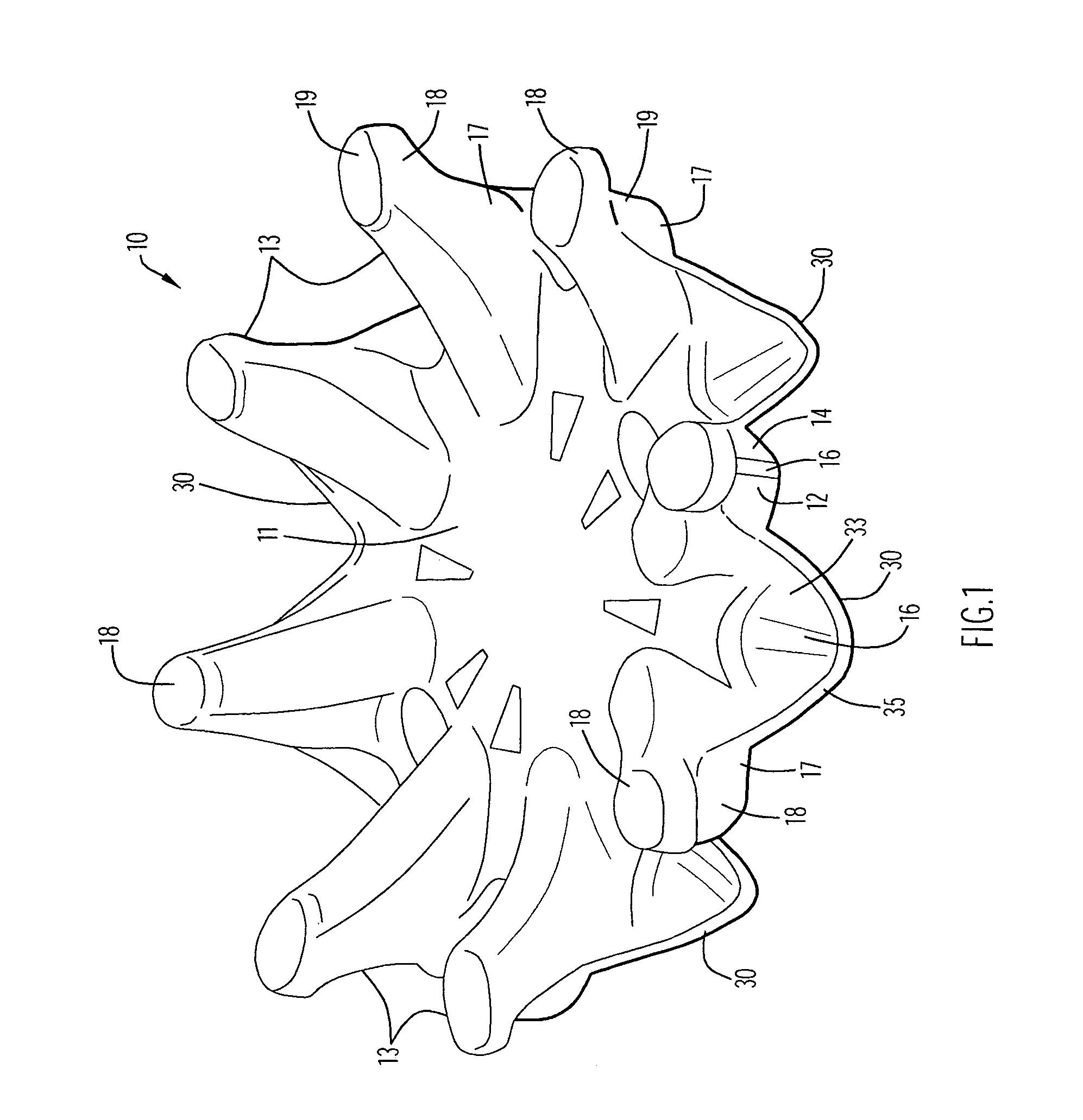

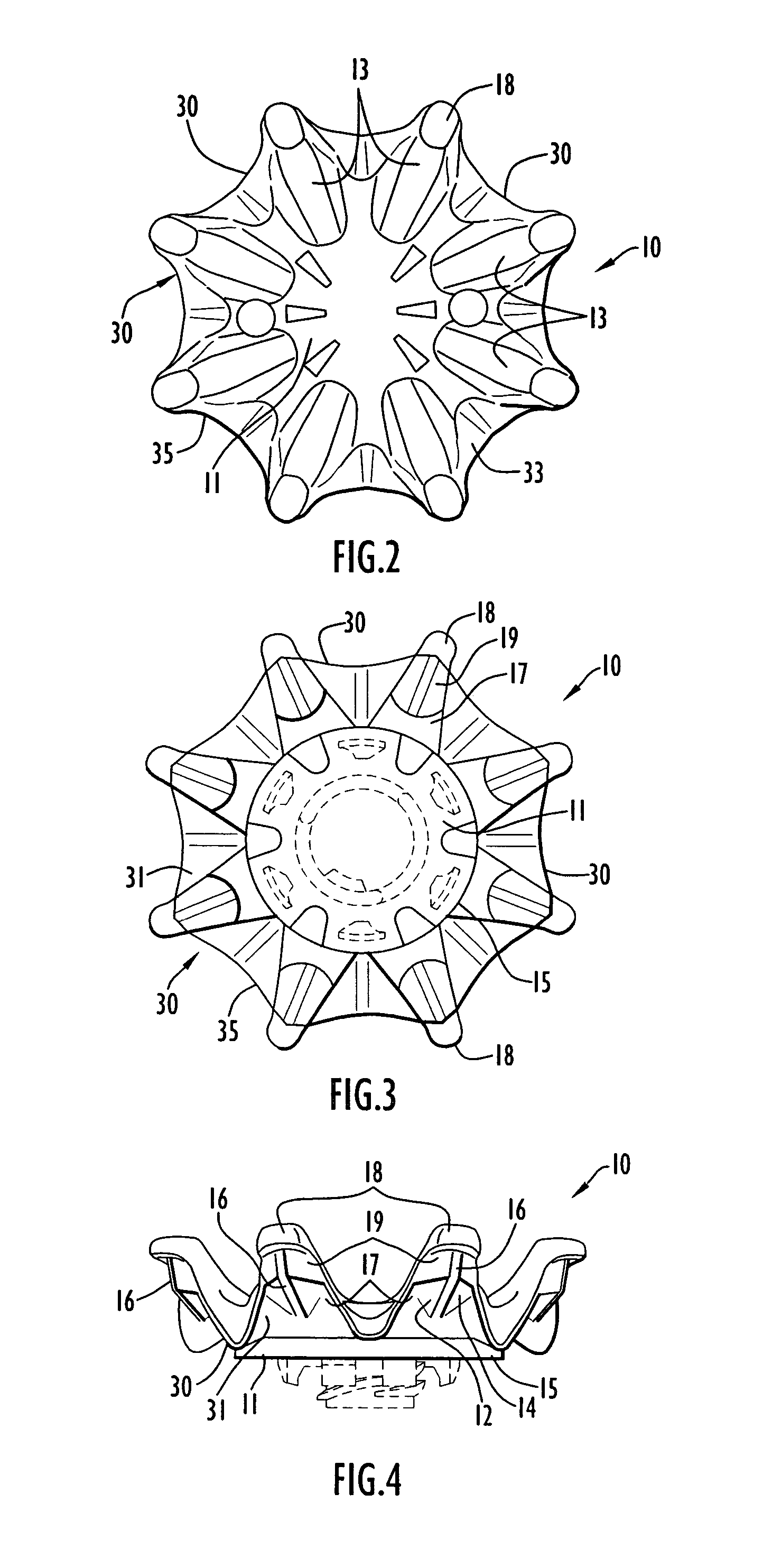

Shoe cleat

ActiveUS7040043B2Improve traction efficiencyReduce cloggingFasteningsWear resistanceUltimate tensile strength

An improved cleat for an athletic shoe provides for: enhanced strength and wear-resistance for the cleat traction element; and / or prevention of grass, mud and other debris from agglomerating and clogging the cleat. A resiliently flexible web is connected between adjacent traction elements to absorb the lateral and torsional forces tending to weaken the junctions between the cleat hub and the traction elements. The web is extended from the hub to prevent debris from entering the space between the shoe sole and the traction elements as well as between the traction elements themselves.

Owner:SOFTSPIKES

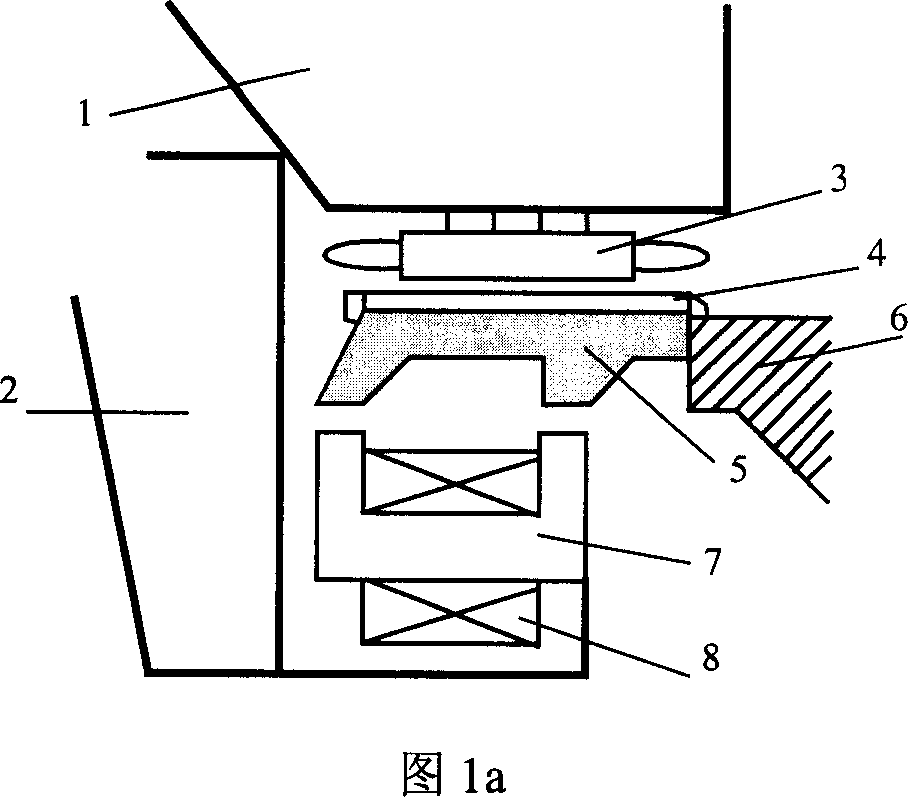

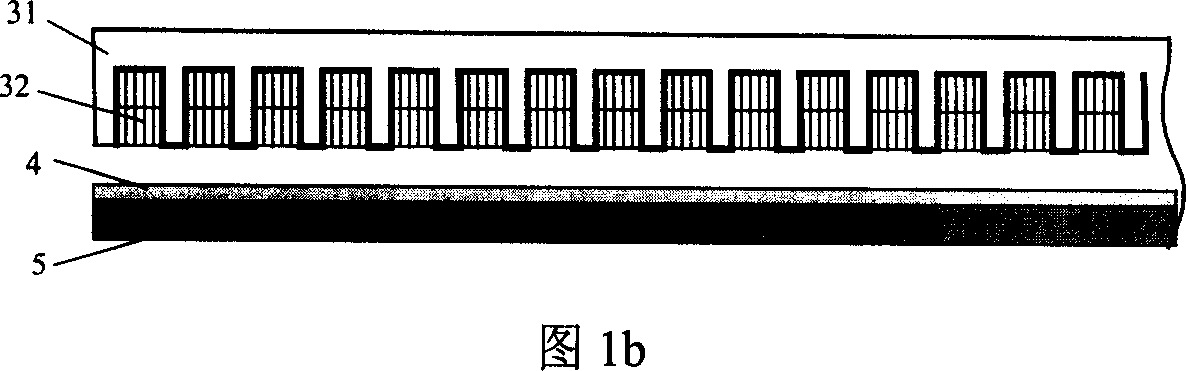

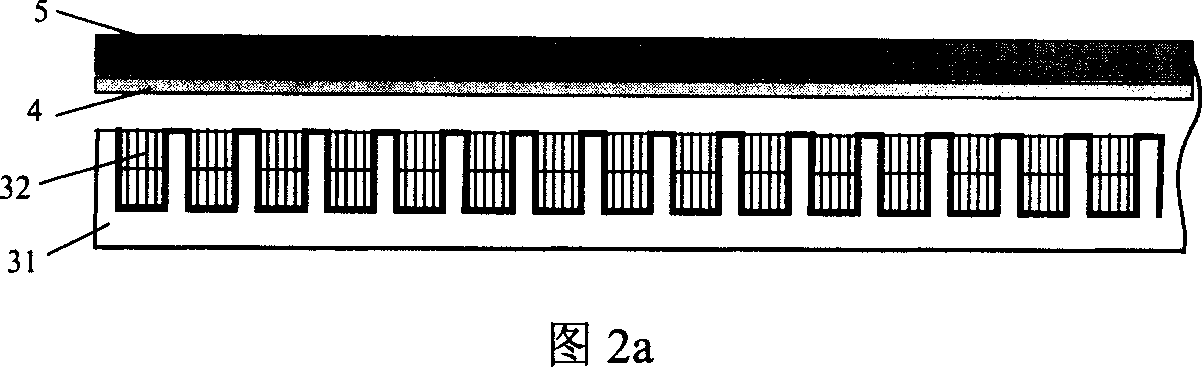

Linear induction motor traction carrying device

ActiveCN1990299ASimple body structureReduce body weightPropulsion systemsMagnetic holding devicesAluminiumEngineering

The invention discloses a tractive carrying device of straight line inductive motor, which adopts single-side short junior straight line inductive motor to provide suspending / unloading and tractive power, wherein the single-side short junior straight line inductive motor consists of overlapping ferric core [31] and junior [3] of winding [32] in the ferric core grove on two sides of bulk; when the surface of junior [3] faces upwards, the low grade fixed on two sides of rail; when the surface faces downwards, it opposites the surface of motor junior [3]; the low grade is made of aluminium or copper long reacting board [4] with back displaying excellent magnetic conductive steel board [5]; the reacting board and steel board are fixed on the rail beam [6].

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

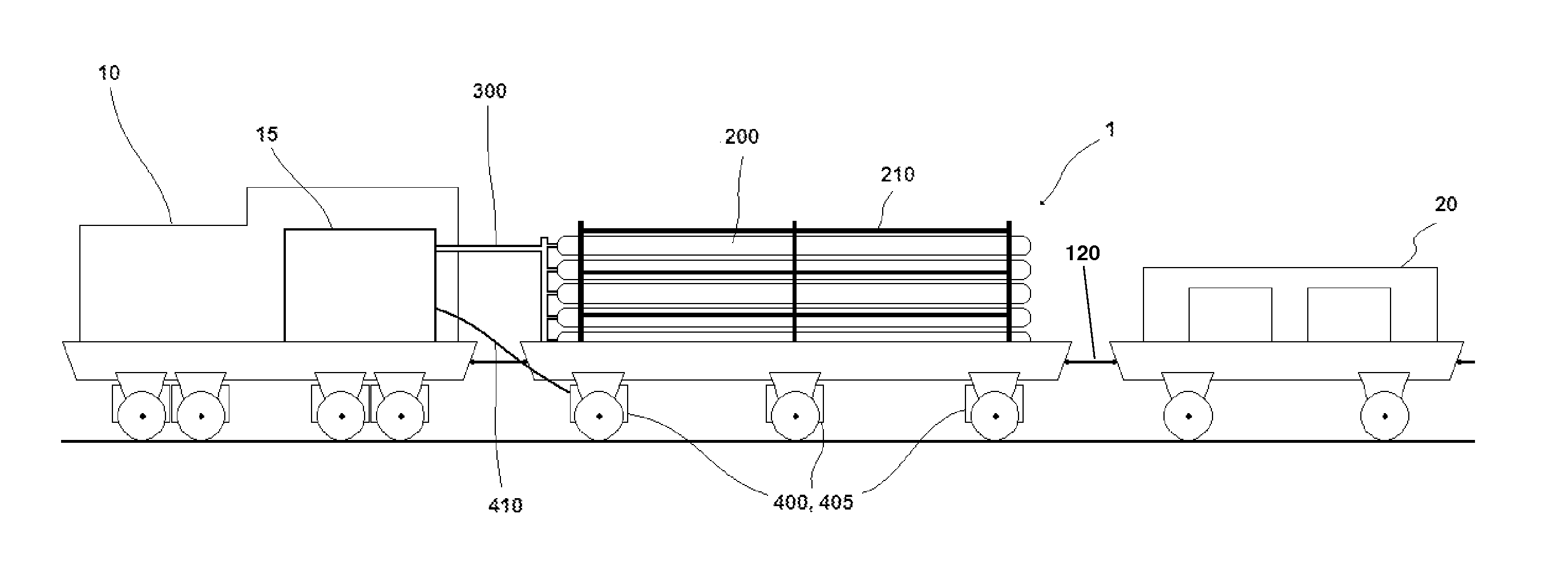

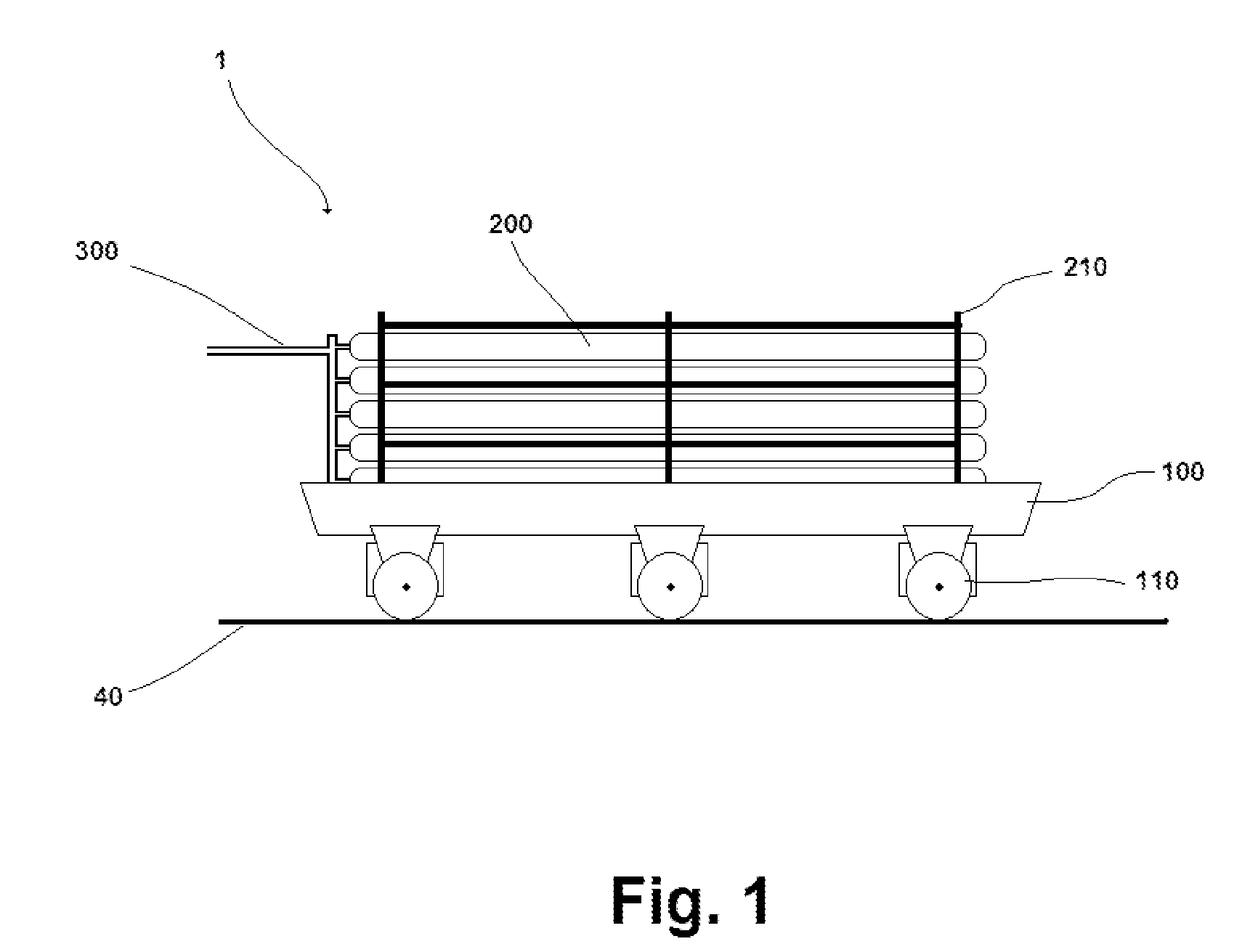

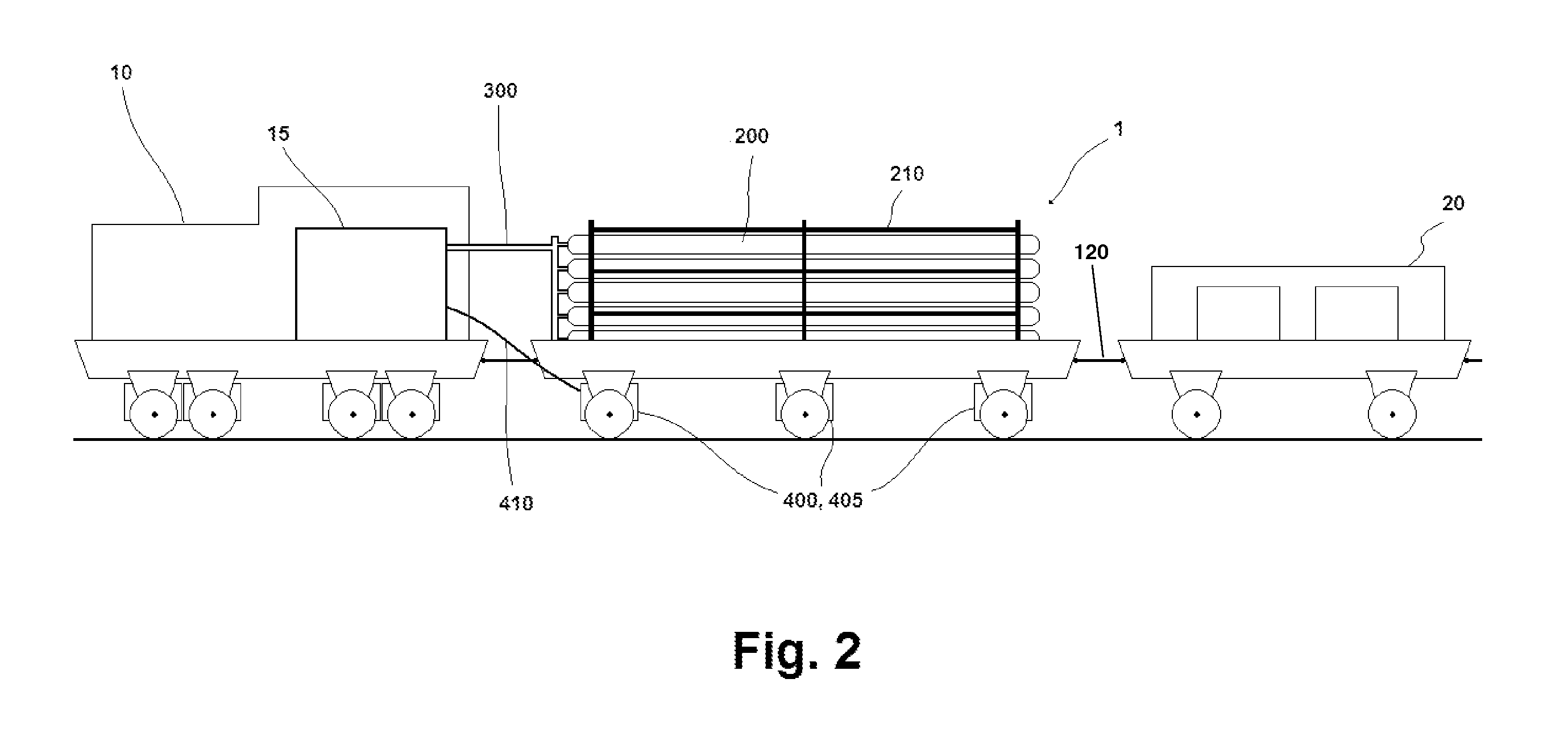

Rail system fuel tender

InactiveUS20120085260A1Improve traction efficiencyLessen maximum tractive effortSteam locomotivesIC engine locomotivesTractive effortRailway system

An improved rail system fuel tender for use with one or more railroad locomotives capable of transporting a plurality of fuel containers suitable for containing pressurized fuel and suitable for directly fueling the one or more locomotives. The improved fuel tender may be powered by the locomotives to increase tractive effort, and the fuel containers may be separately fillable and separately removable from the fuel tender.

Owner:NICHINI PAUL +1

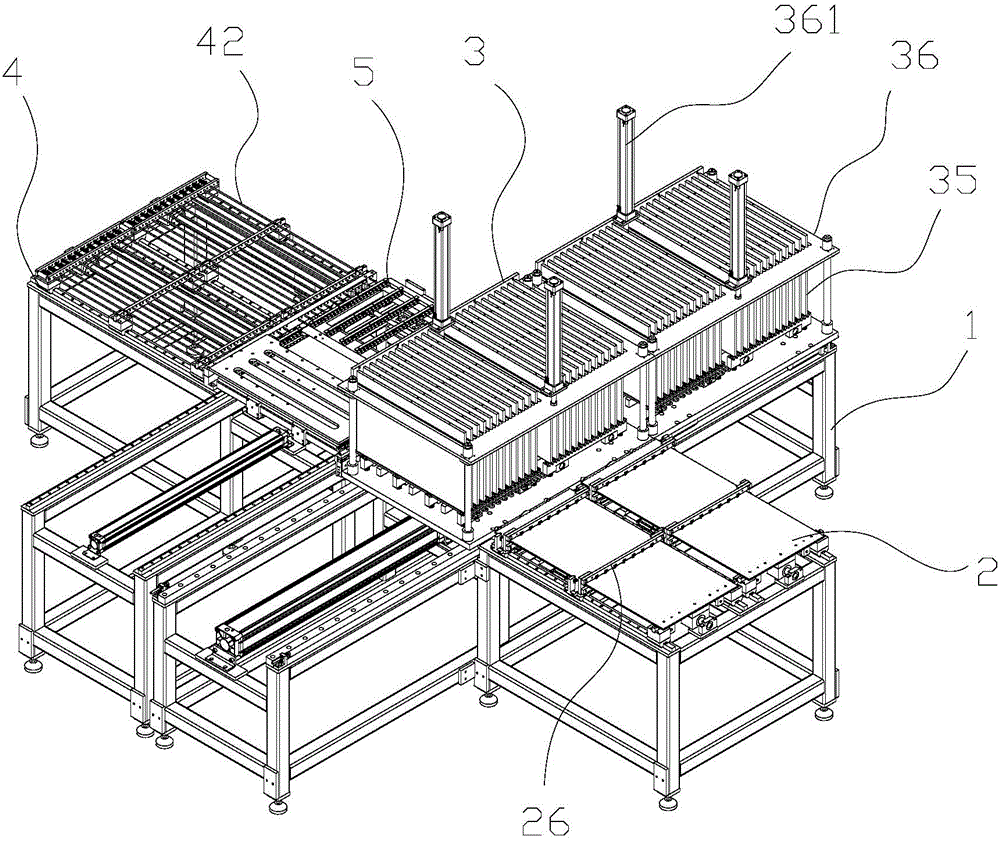

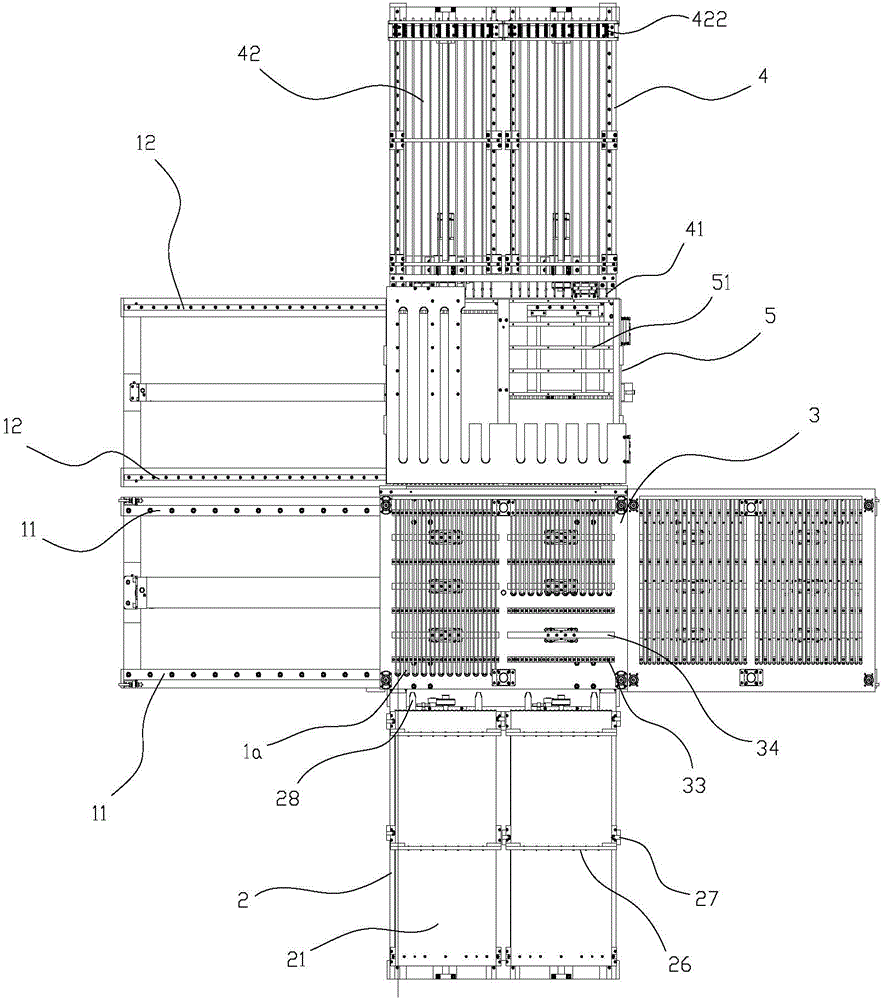

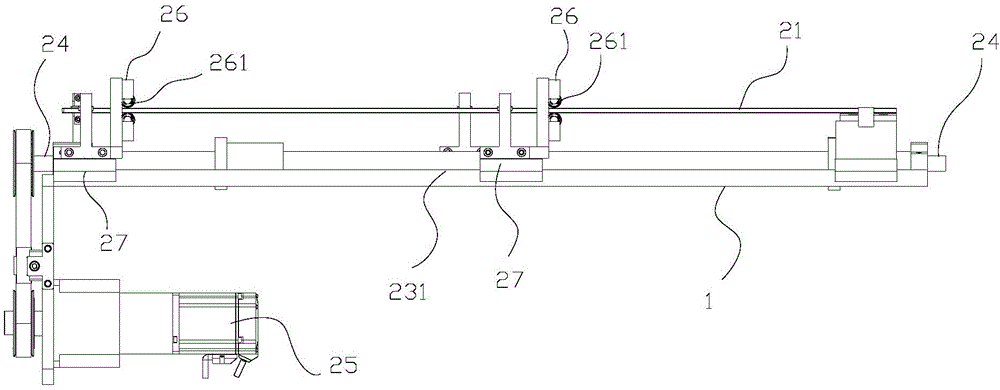

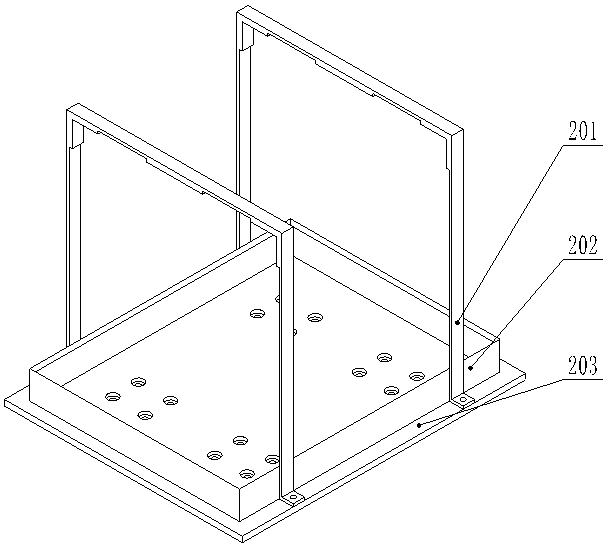

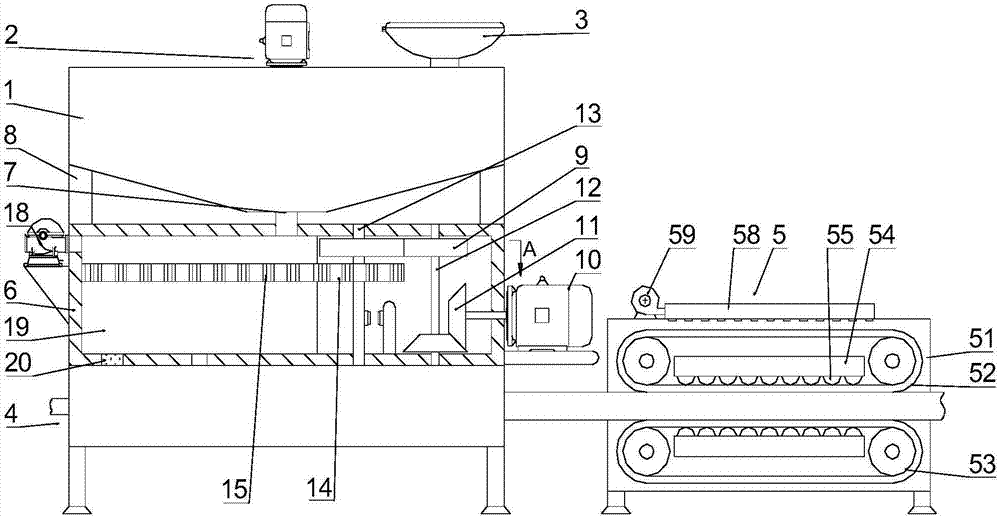

Equipment for enabling copper pipe to pass through fin of condenser

ActiveCN104308490AHigh degree of automationStable designHeat exchange apparatusMetal working apparatusEngineeringCopper tubing

The invention discloses equipment for enabling a copper pipe to pass through a fin of a condenser. The equipment comprises a support, as well as a push plate driving system, a copper pipe collector, a fin collecting disc and a traction device which are sequentially positioned on the support, wherein the copper pipe is placed on a supporting base of the copper pipe collector, and clearance layers formed between clapboards or partition posts are stacked; a push plate passes through the upper part of the supporting base which can reciprocate up and down so as to push the copper pipe into the fin hole of the fin collecting disc; meanwhile a draw rod enters into the fin hole from the other side of the fin collecting disc under the effect of a guide mechanism, so as to draw the copper pipe, and a drawing head is inserted into the opening end of the copper pipe; when the draw rod is retreated from the fin hole, the copper pipe is synchronously guided into the fin hole, after that, the push plate and the draw rod are reset, the upper-layer copper pipe orderly falls to the supporting base so as to be subjected to the next round of pipe passing. The equipment is simple in operation and high in stability and safety, and can be used for improving the pipe passing efficiency and the alignment accuracy, reducing the equipment stagnation period in a pipe passing process and reducing the human cost and the equipment loss.

Owner:广州绅特模具制造有限公司

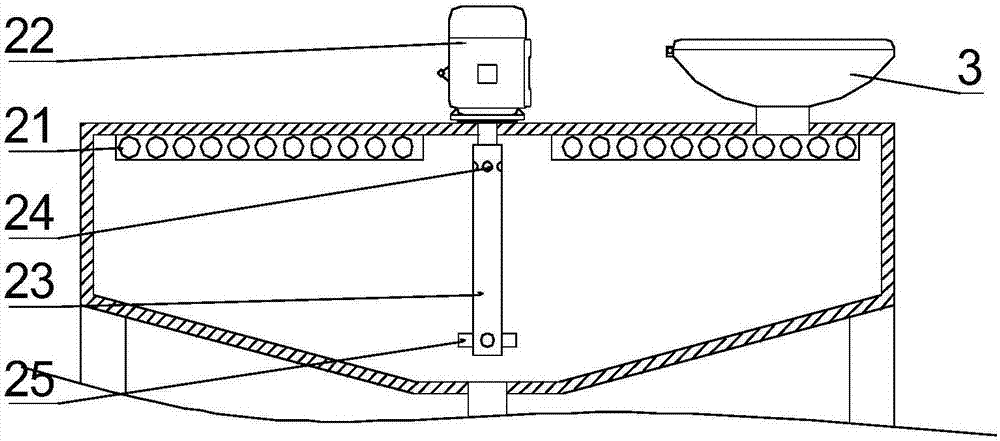

Electric tractor gravity center adjusting device

PendingCN110254202AReduce lossExtended service lifeElectric propulsion mountingPower batteryEngineering

The invention provides an electric tractor gravity center adjusting device which comprises a power battery, a power battery bracket, a gravity center horizontal-adjusting mechanism and a gravity center longitudinal-adjusting mechanism. The power battery is used for providing gravity required for gravity center adjusting; the power battery bracket is used for installing and fixing the power battery and providing anti-collision protection for the power battery; the gravity center horizontal-adjusting mechanism located below the power battery bracket is used for adjusting a gravity center of an electric tractor in a horizontal direction; and the gravity center longitudinal-adjusting mechanism located below the gravity center horizontal-adjusting mechanism is used for adjusting the gravity center of the electric tractor in a longitudinal direction. According to the electric tractor gravity center adjusting device provided by the invention, the characteristic of large weight of an electric tractor battery can be fully utilized, gravity center adjusting can be carried out in the horizontal direction and the longitudinal direction without extraly adding balancing weight blocks, the gravity center adjusting range is wide, the precision is high, the tractive efficiency and the stability of the electric tractor can be improved, the energy can be saved, and the environment can be protected.

Owner:NORTHWEST A & F UNIV

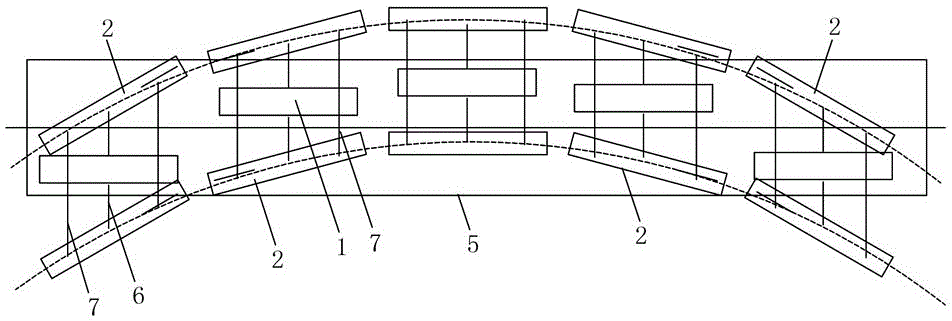

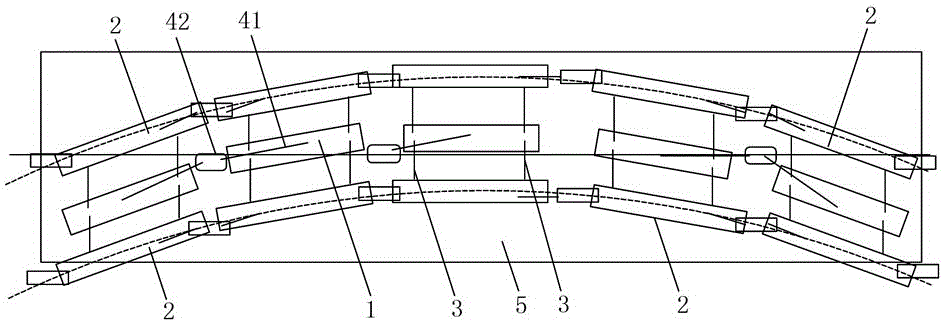

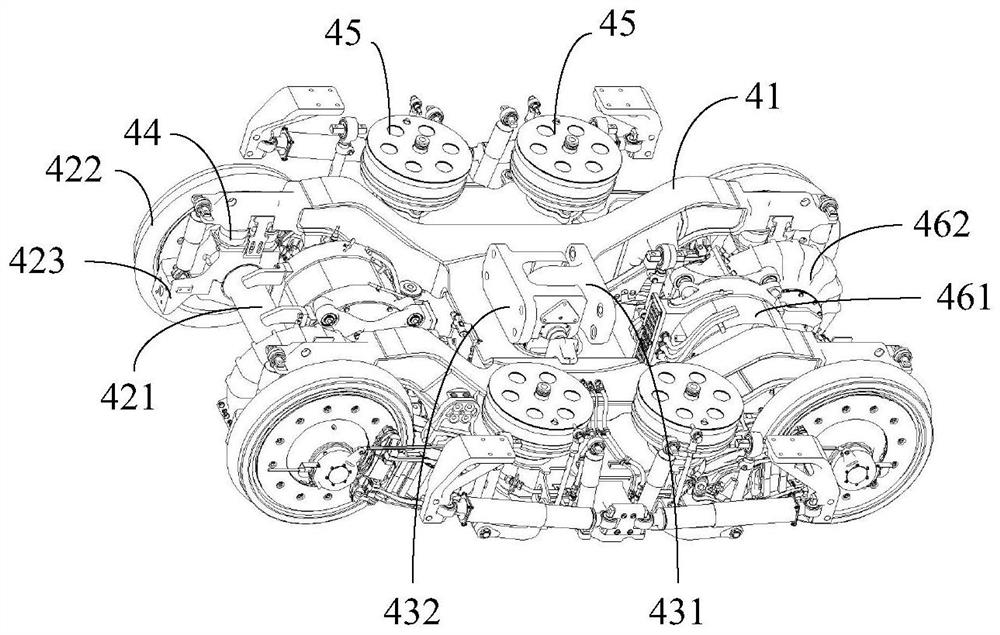

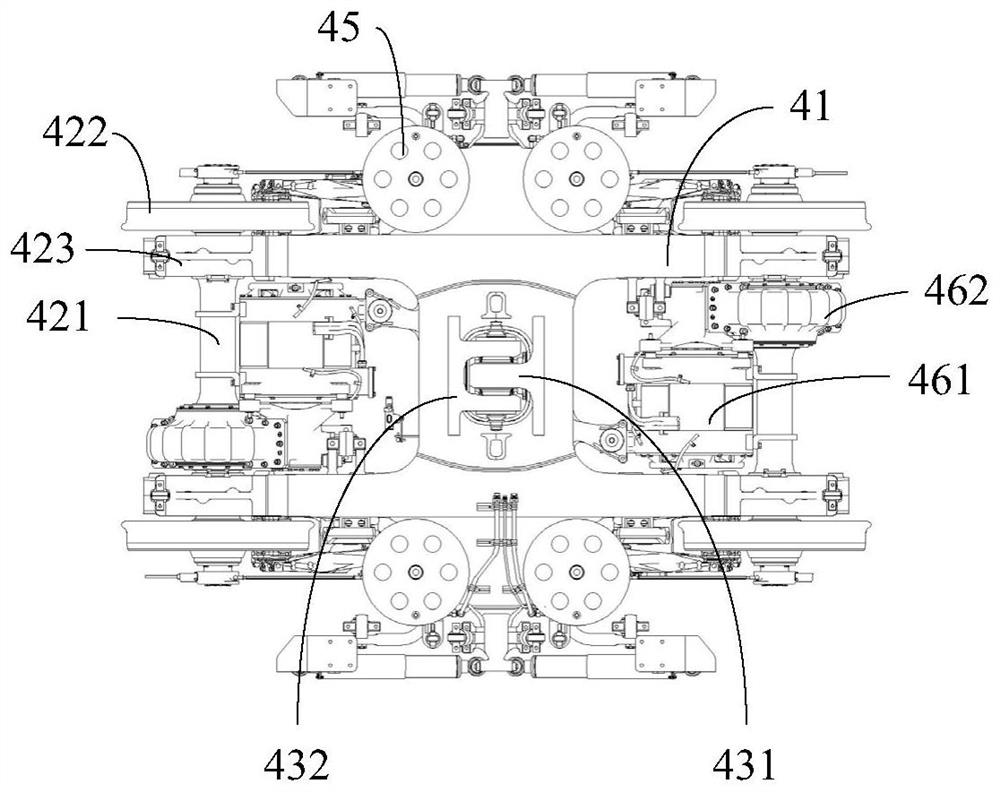

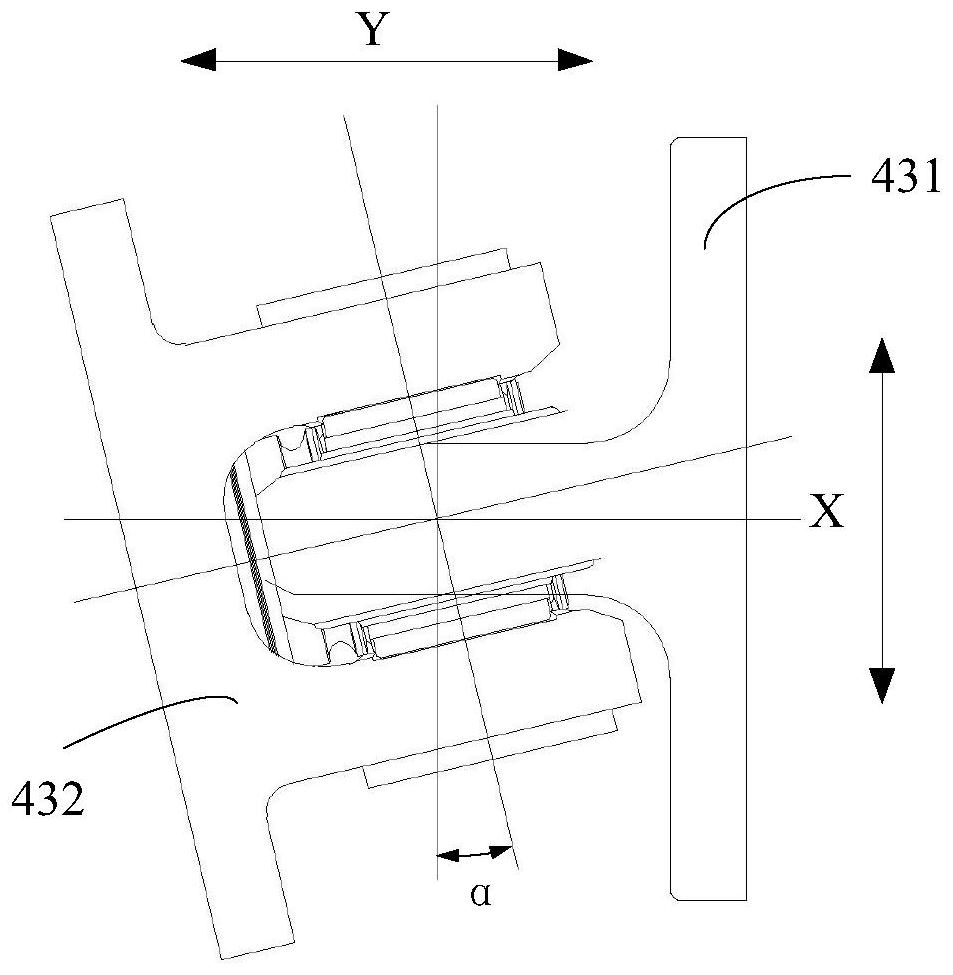

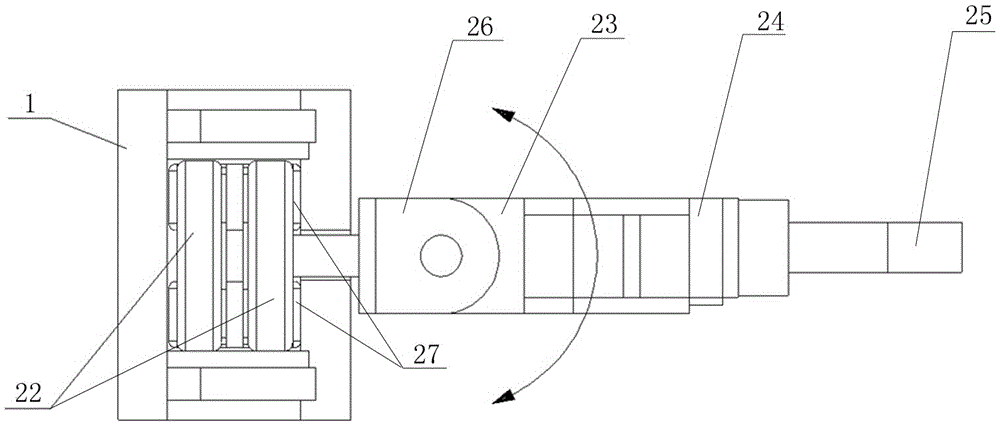

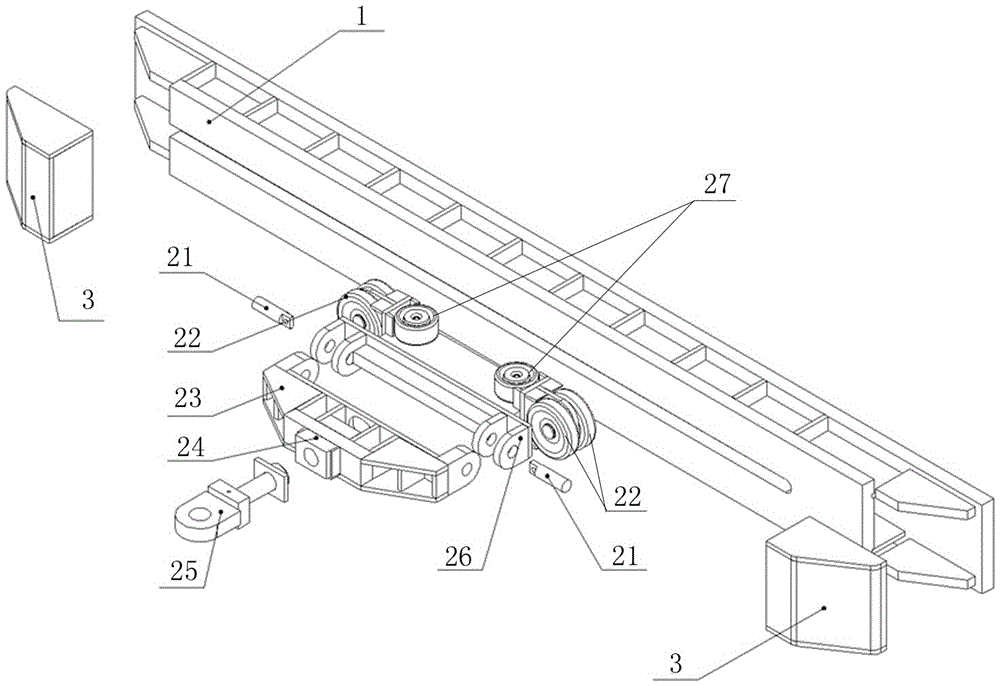

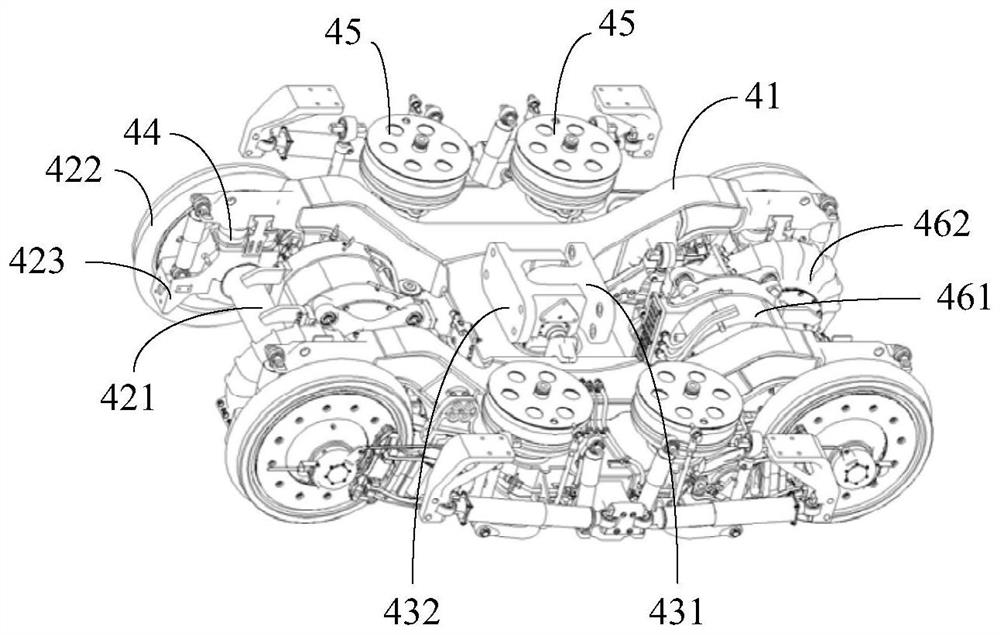

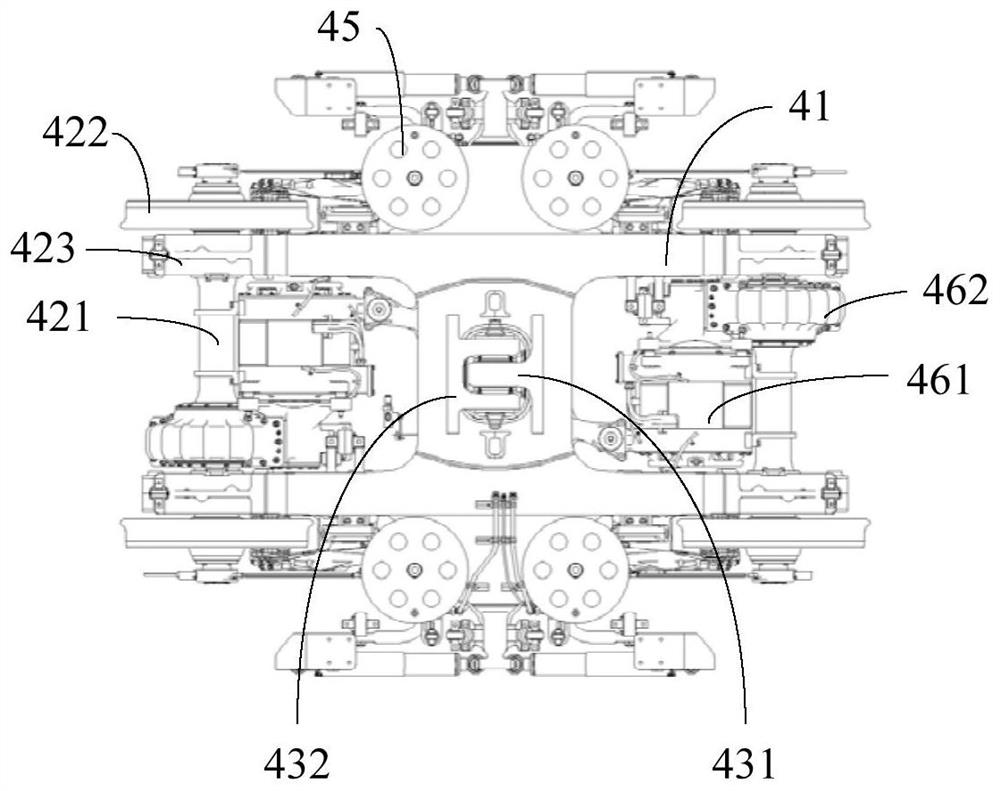

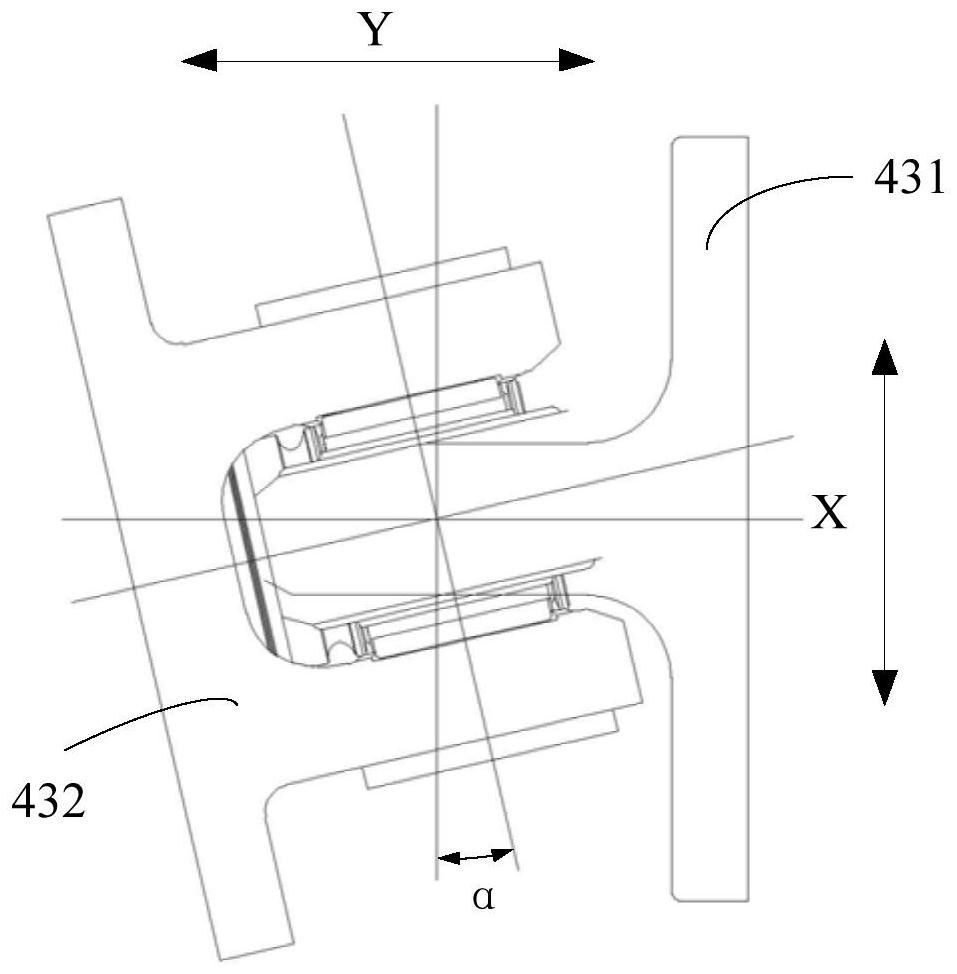

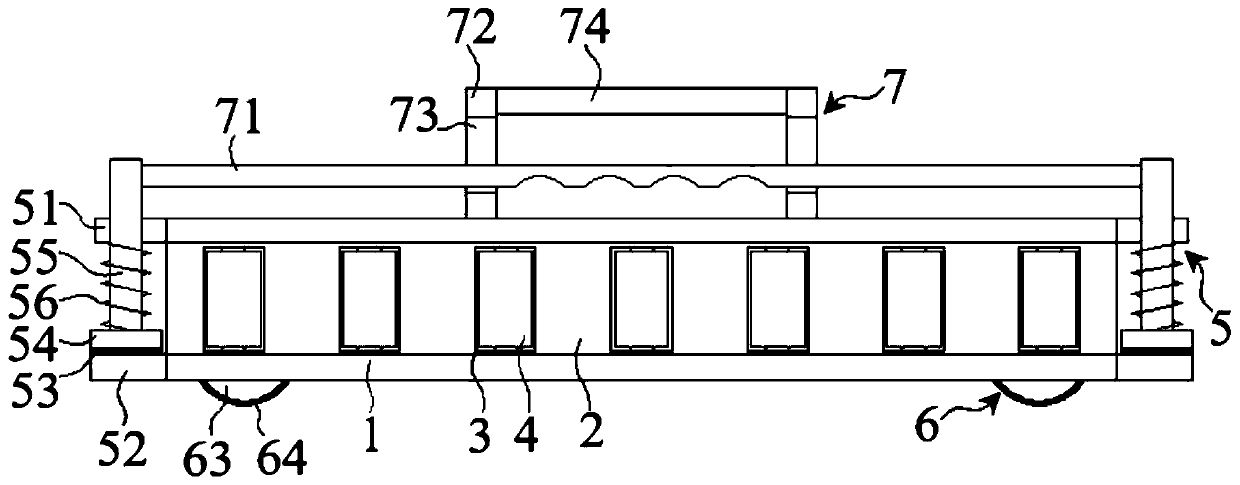

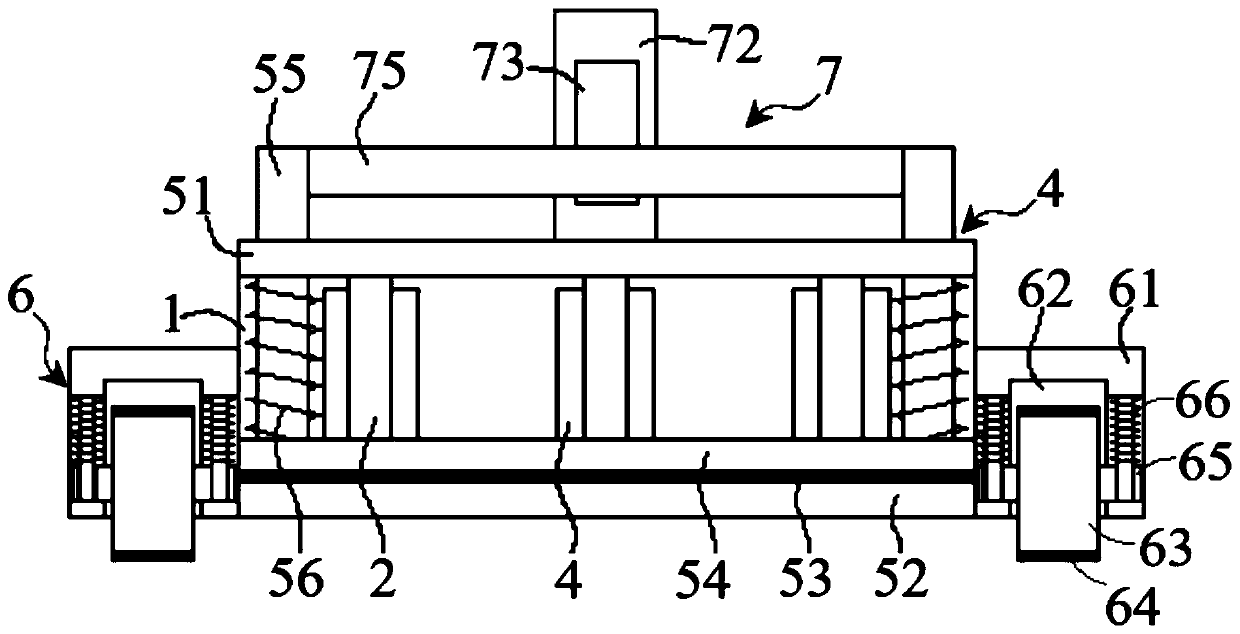

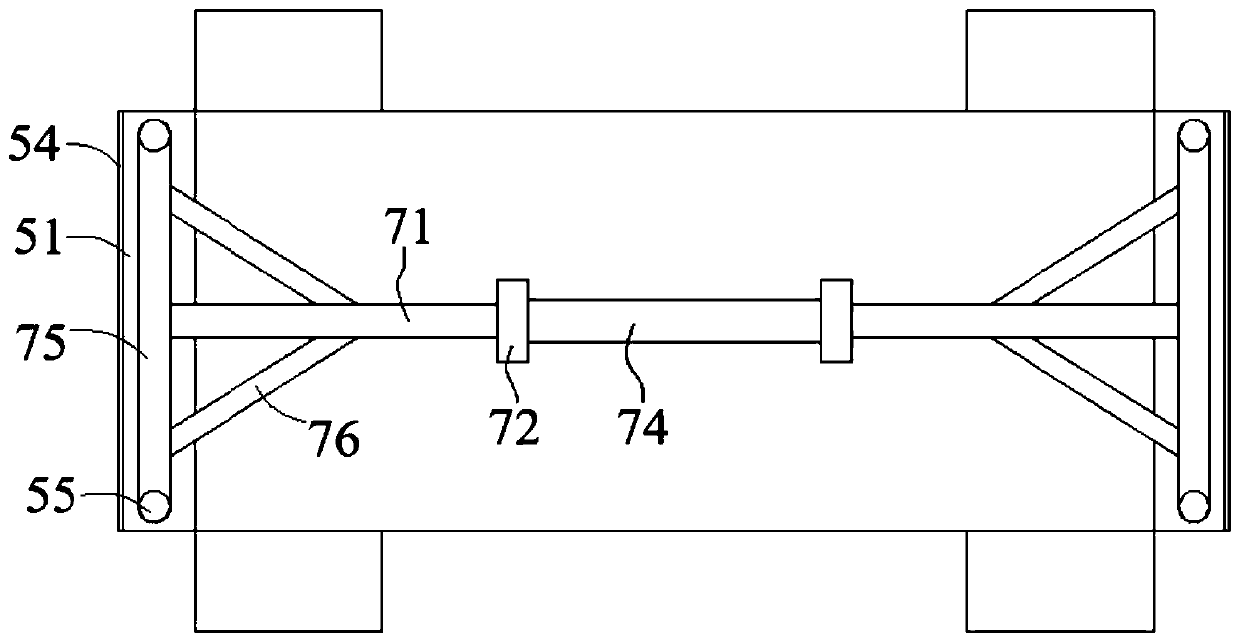

Framework-free type levitation chassis with traction linear motor arranged in center and magnetically levitated train

ActiveCN105904995AImprove anti-roll performanceGuaranteed Minimum Clearance ValueElectric propulsionLevitationLinear motor

The invention discloses a framework-free type levitation chassis with a traction linear motor arranged in the center and a magnetically levitated train. The levitation chassis comprises the traction linear motor and a pair of levitation modules, wherein the traction linear motor is arranged between the levitation modules in parallel, and the two sides of the traction linear motor are each provided with at least two sets of anti-rolling decoupling mechanisms. The anti-rolling decoupling mechanisms are arranged in the longitudinal direction of the traction linear motor. Each anti-rolling decoupling mechanism comprises two anti-rolling beams arranged oppositely and an anti-rolling pull rod. The two ends of each anti-rolling beam are hinged to the traction linear motor and the corresponding levitation module correspondingly, one end of each anti-rolling pull rod is hinged to the corresponding two anti-rolling beams, and the other end of each anti-rolling pull rod is hinged to the traction linear motor. The magnetically levitated train comprises a plurality of train bodies and a plurality of framework-free type levitation chassis with the traction linear motors arranged in the center, and the train bodies are mounted on the levitation chassis. The framework-free type levitation chassis with the traction linear motor arranged in the center and the magnetically levitated train have the advantages that the structure is simple, installation and maintenance are convenient, traction efficiency is high, and the turning capacity is high.

Owner:NAT UNIV OF DEFENSE TECH

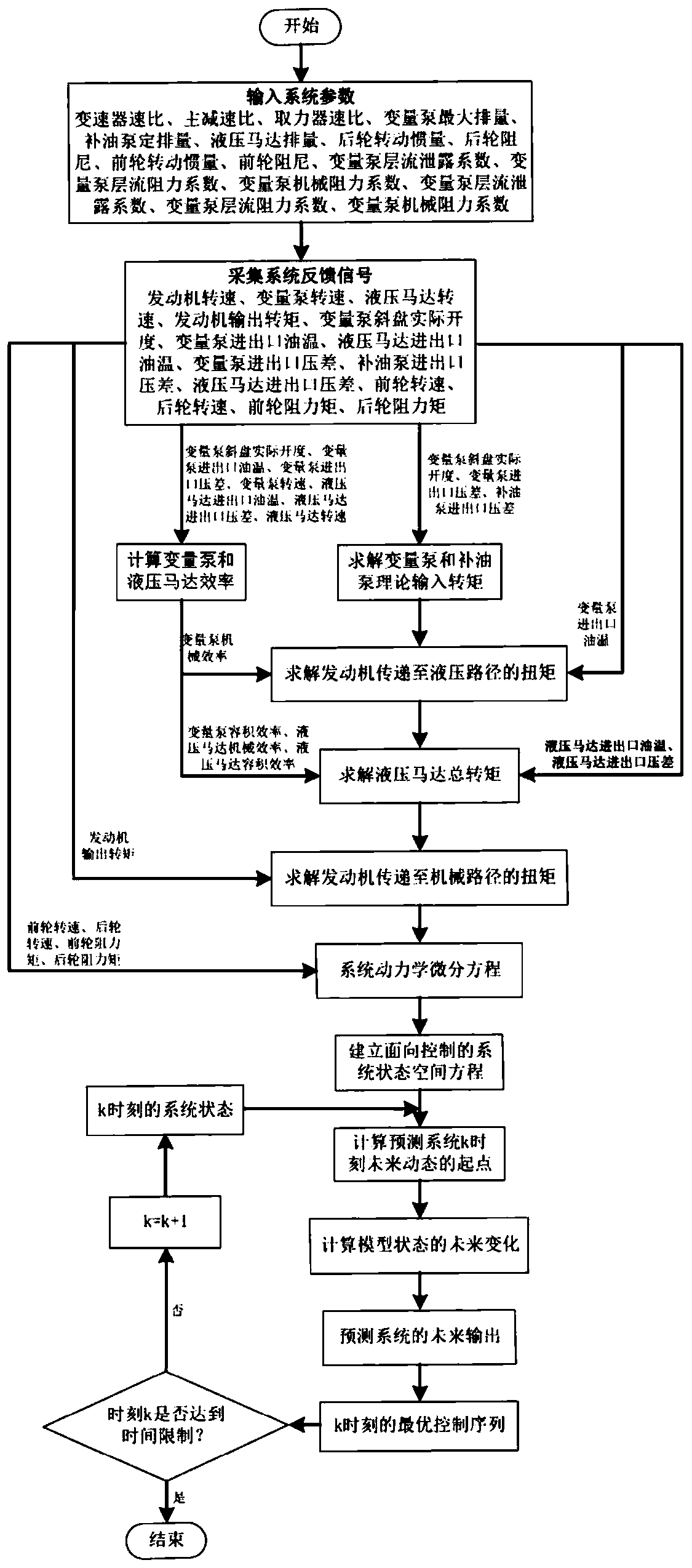

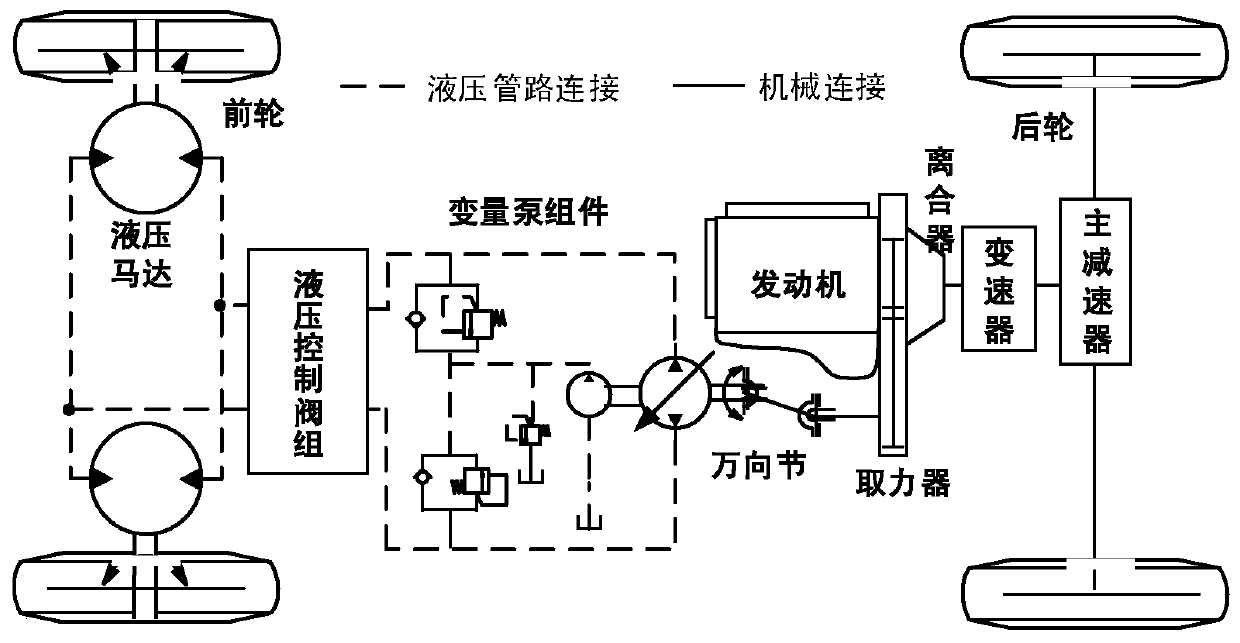

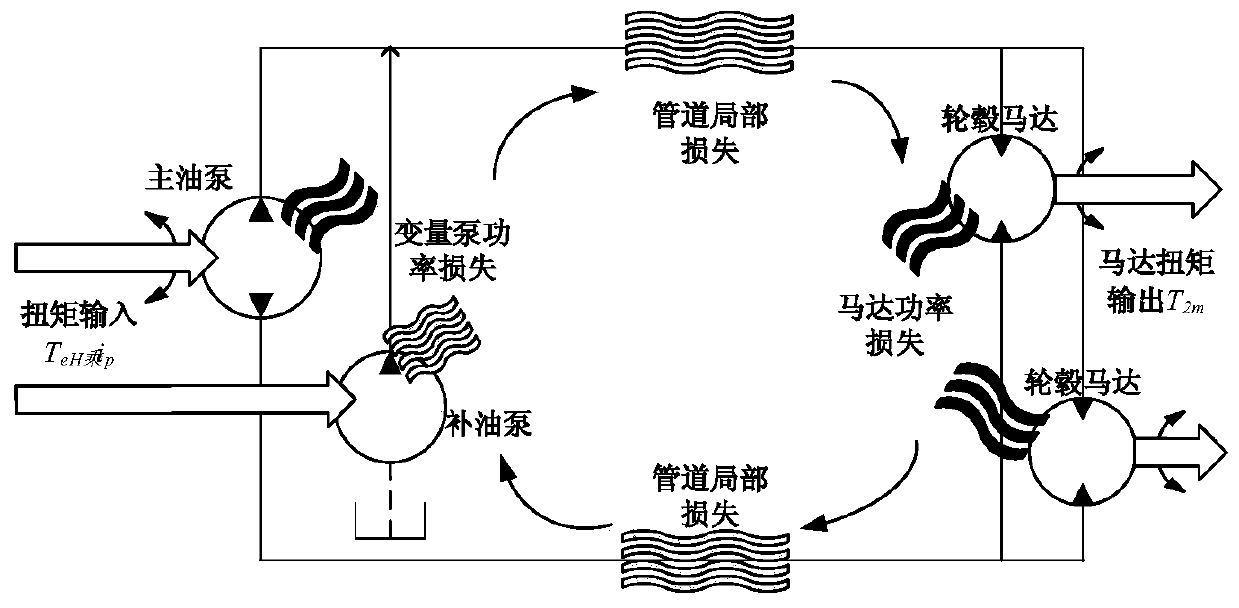

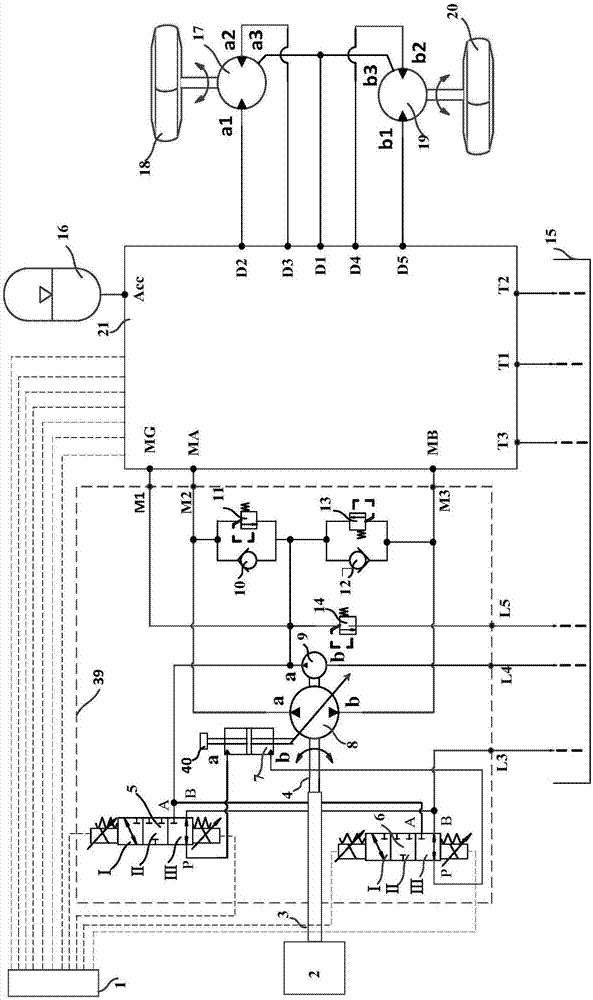

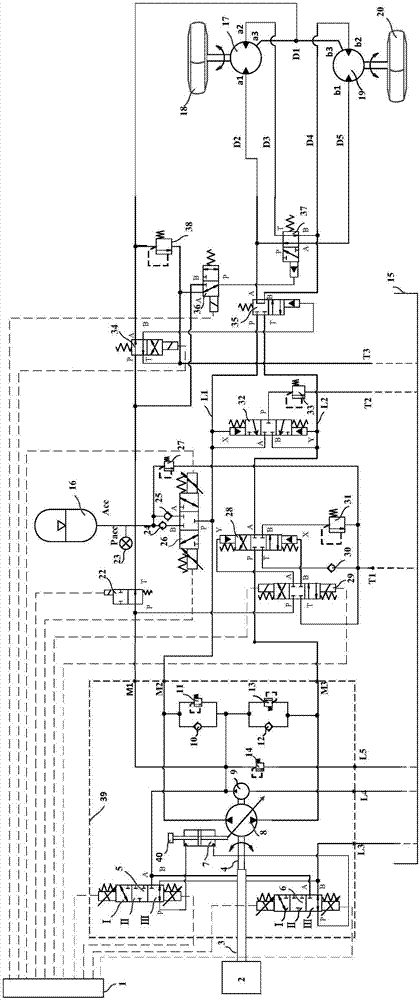

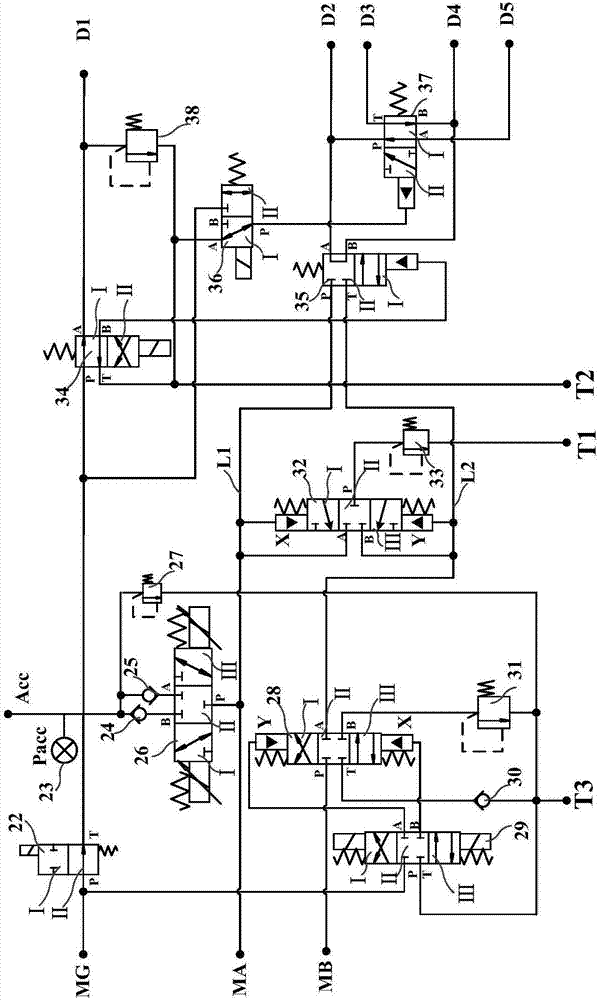

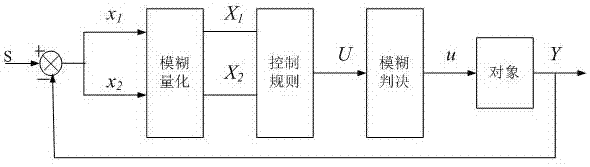

Model prediction control method of hub hydraulic motor auxiliary drive system

InactiveCN110077419ARapid self-regulationShorten the development cycleControl devicesAutomotive control systemsSystem model

The invention aims at solving the problems that in an existing hub hydraulic drive system control method, the time-varying characteristic of system efficiency is ignored, control parameter calibrationis complex, control accuracy is poor, and self-adaptive control of a system cannot be guaranteed, provides a model prediction control method of a hub hydraulic motor auxiliary drive system and belongs to an automobile control system. In the control method, according to a kinetic equation and the actual control requirement of a hub hydraulic drive vehicle transmission system and with considerationof the characteristics that hydraulic system efficiency varies time to time along with the parameters such as temperature, pressure and the rotation speed, a vehicle transmission system kinetic modelis established, a control increment acting on system model prediction control is solved through a derivation feedback control law, and design of a model prediction controller based on time-varying efficiency is finished. The method has the advantages that the control parameters are optimized through consideration of the efficiency time-varying problem of the system, meanwhile, the feedback control law is explored, the accuracy of a control algorithm and the self-adaptive ability of system control are improved, quick self-adjustment of the system is achieved, and it is guaranteed that the vehicle traction performance is optimal.

Owner:JILIN UNIV

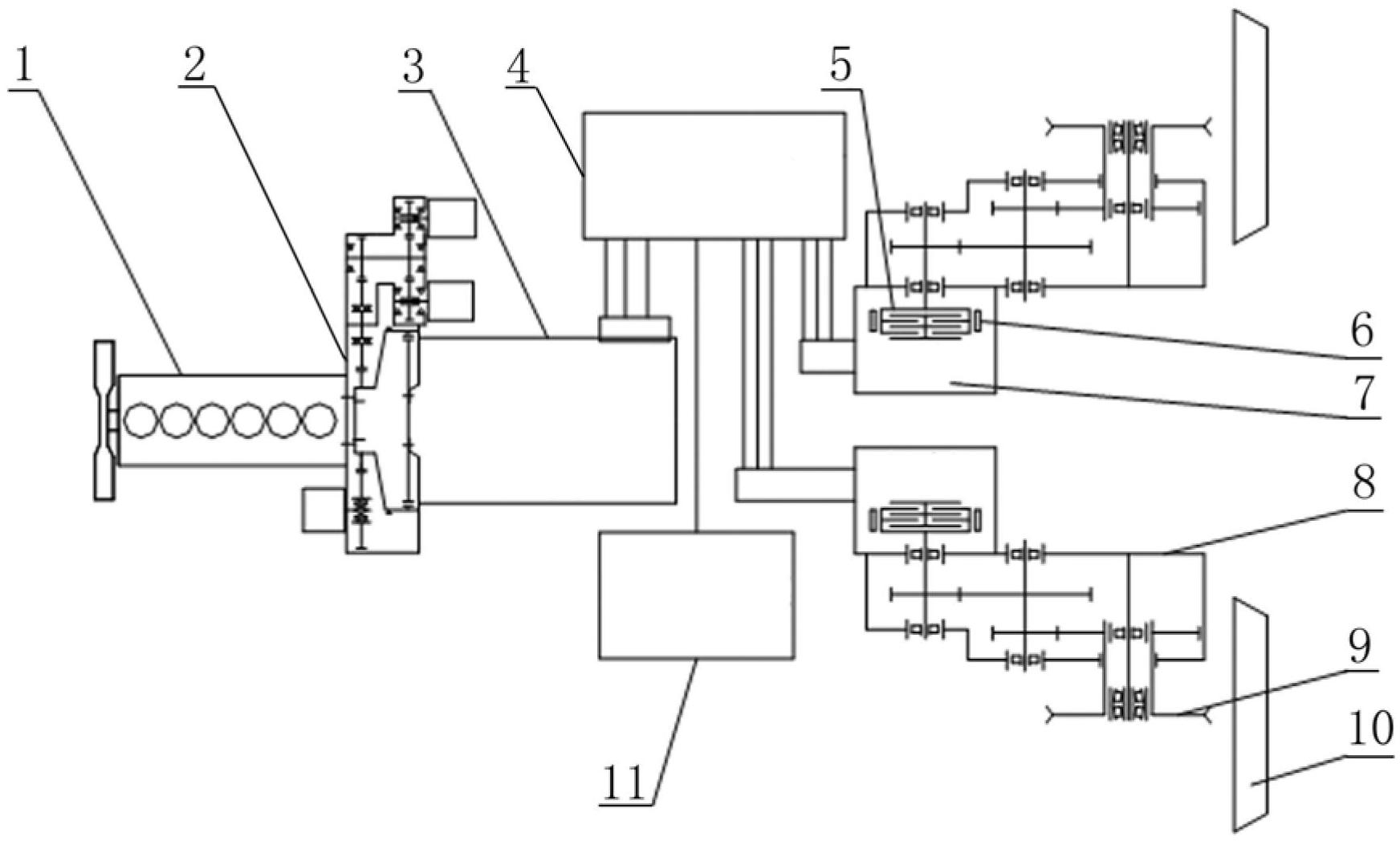

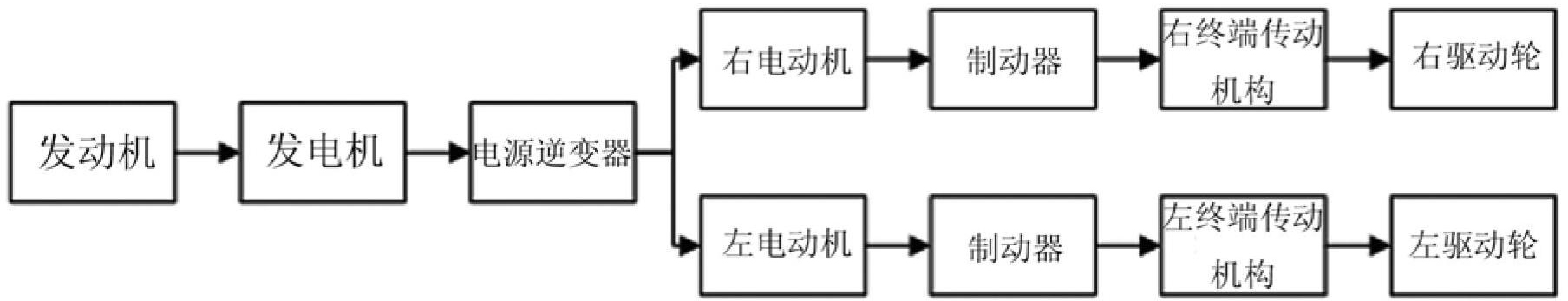

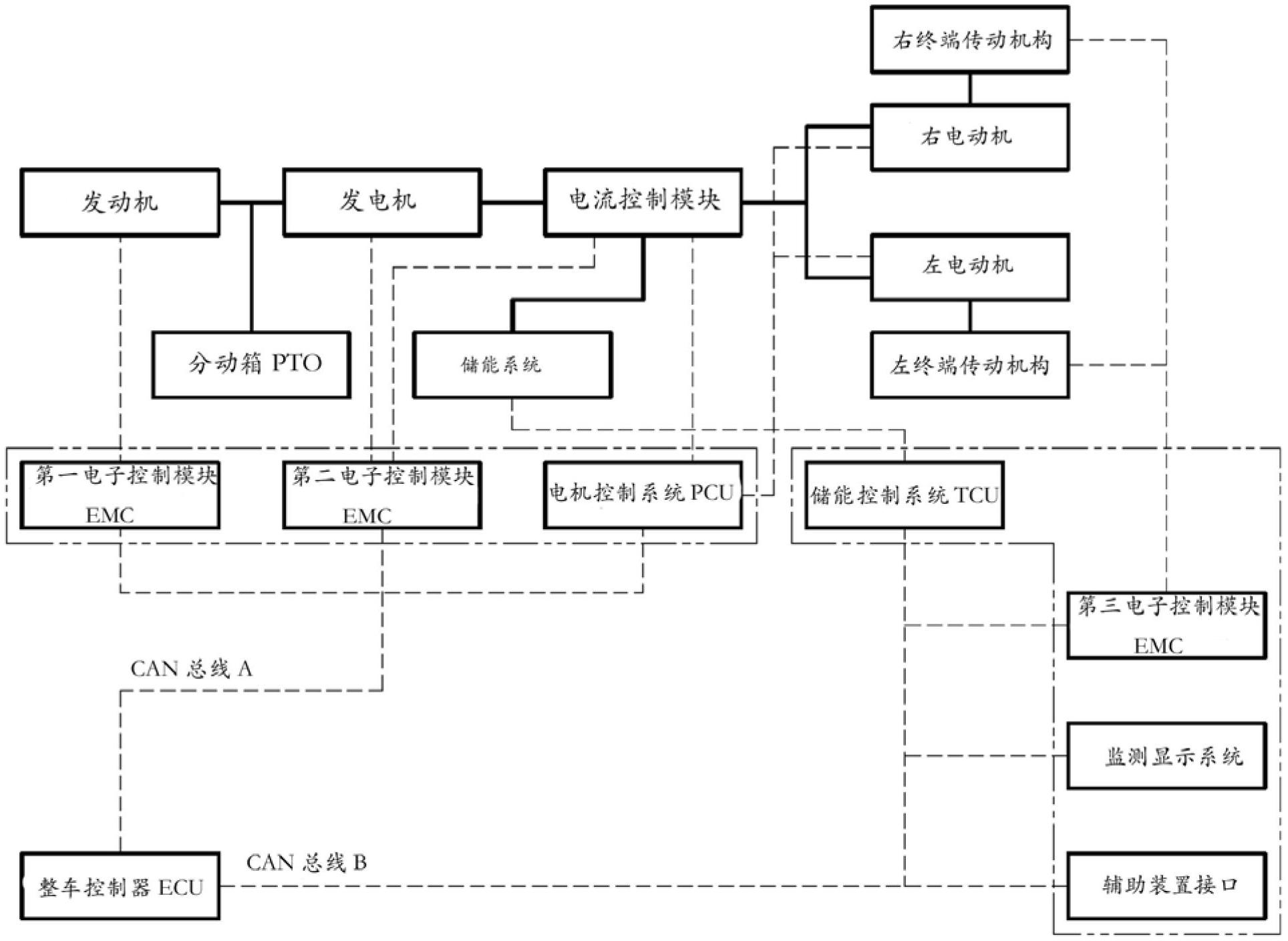

Hybrid power driving device of bulldozer and bulldozer

InactiveCN102642461AReduce weightQuick responseHybrid vehiclesGas pressure propulsion mountingDynamoSprocket

The invention discloses a hybrid power driving device of a bulldozer, which comprises an engine, a generator, a current control module and an electrical motor, wherein an output shaft of the engine is connected with a power distribution device, an output shaft of the power distribution device is connected with the generator, alternating current generated by the generator is converted by the current control module and then drives the electrical motor, and the electrical motor drives a drive sprocket and an apron wheel. The driving device is steady and reliable in transmission and low in noise and oil consumption, has high transmission efficiency, can respond to changes of loads quickly, and can achieve stepless speed change. The invention also discloses the bulldozer with the driving device.

Owner:SHANTUI CONSTR MASCH CO LTD

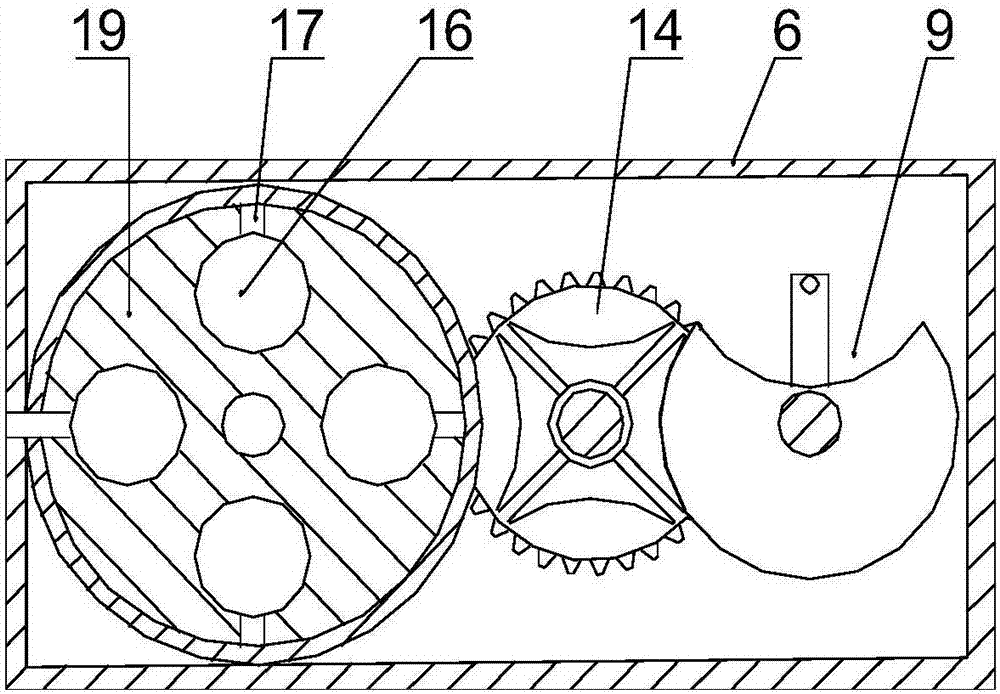

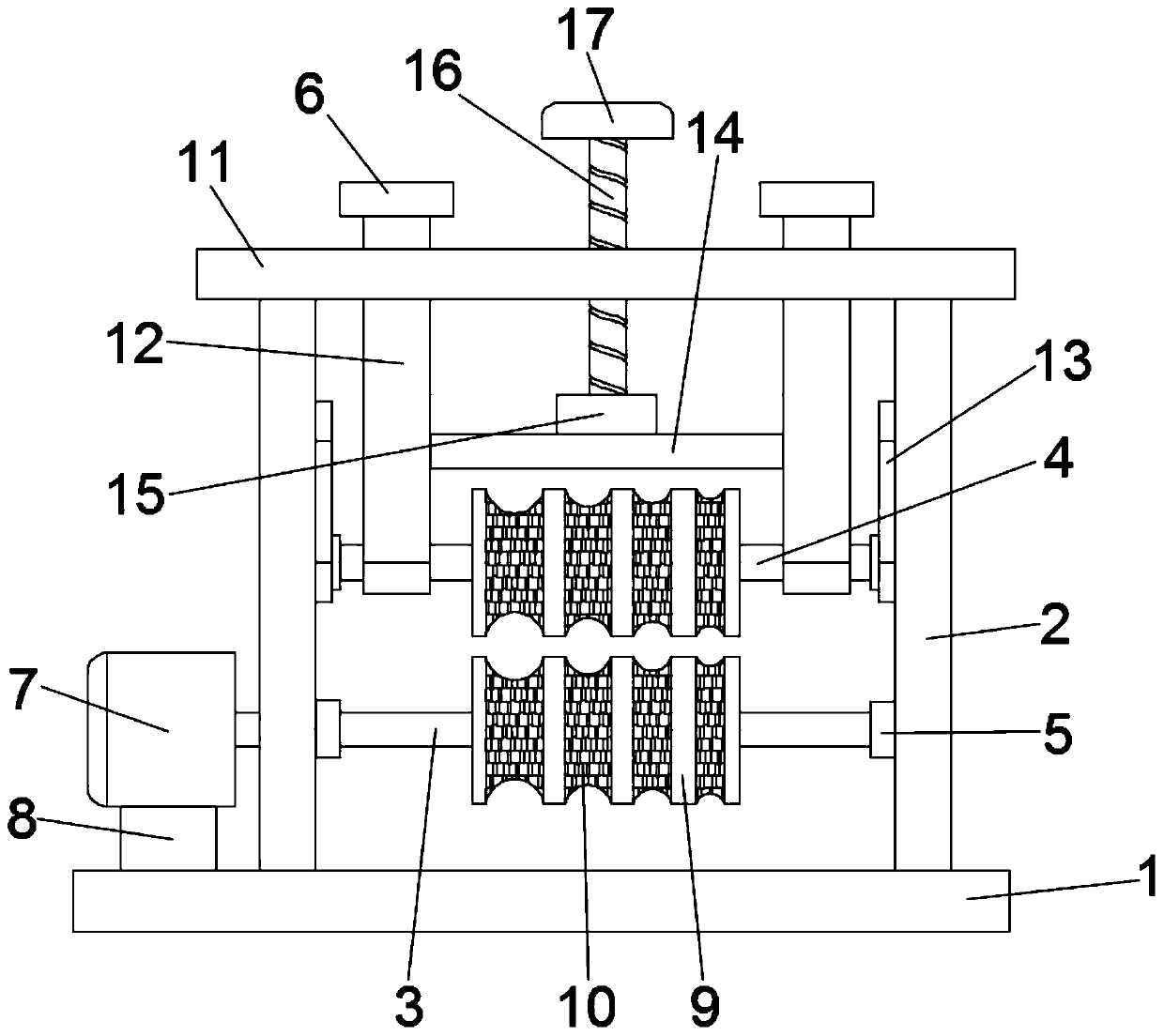

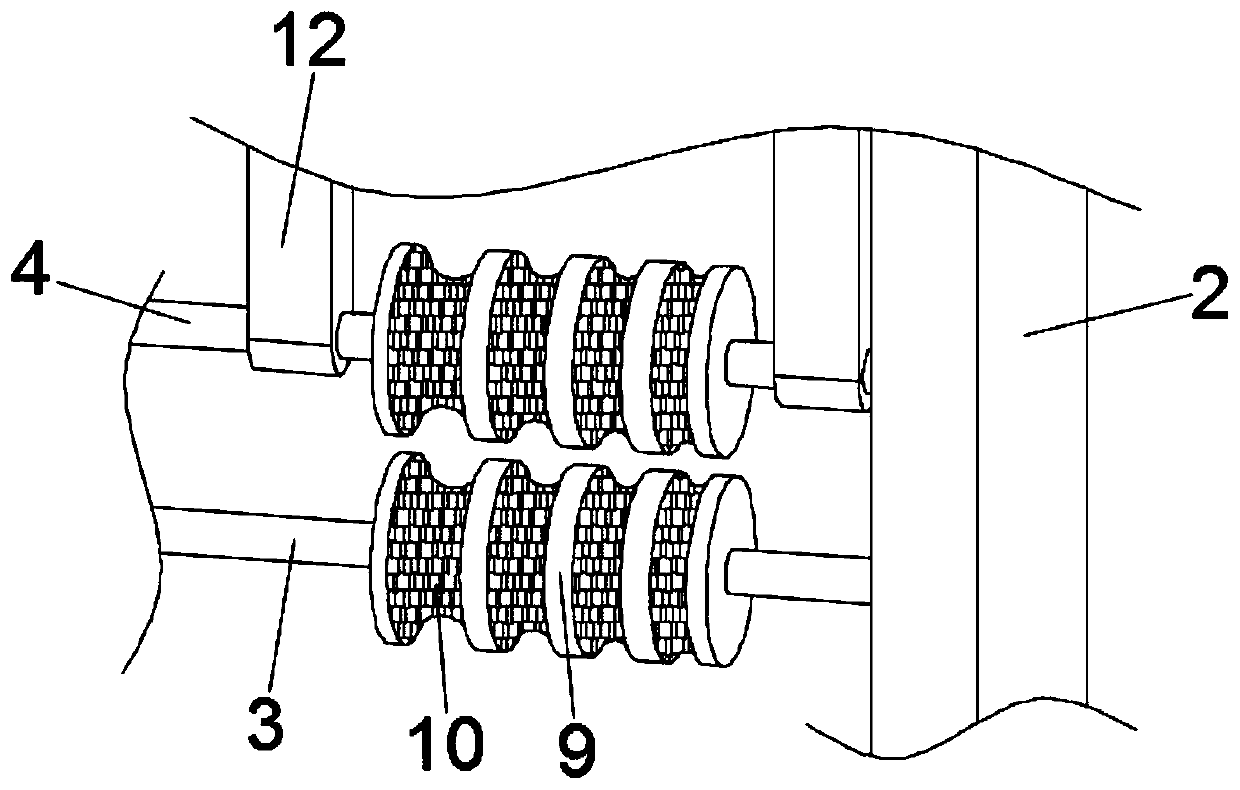

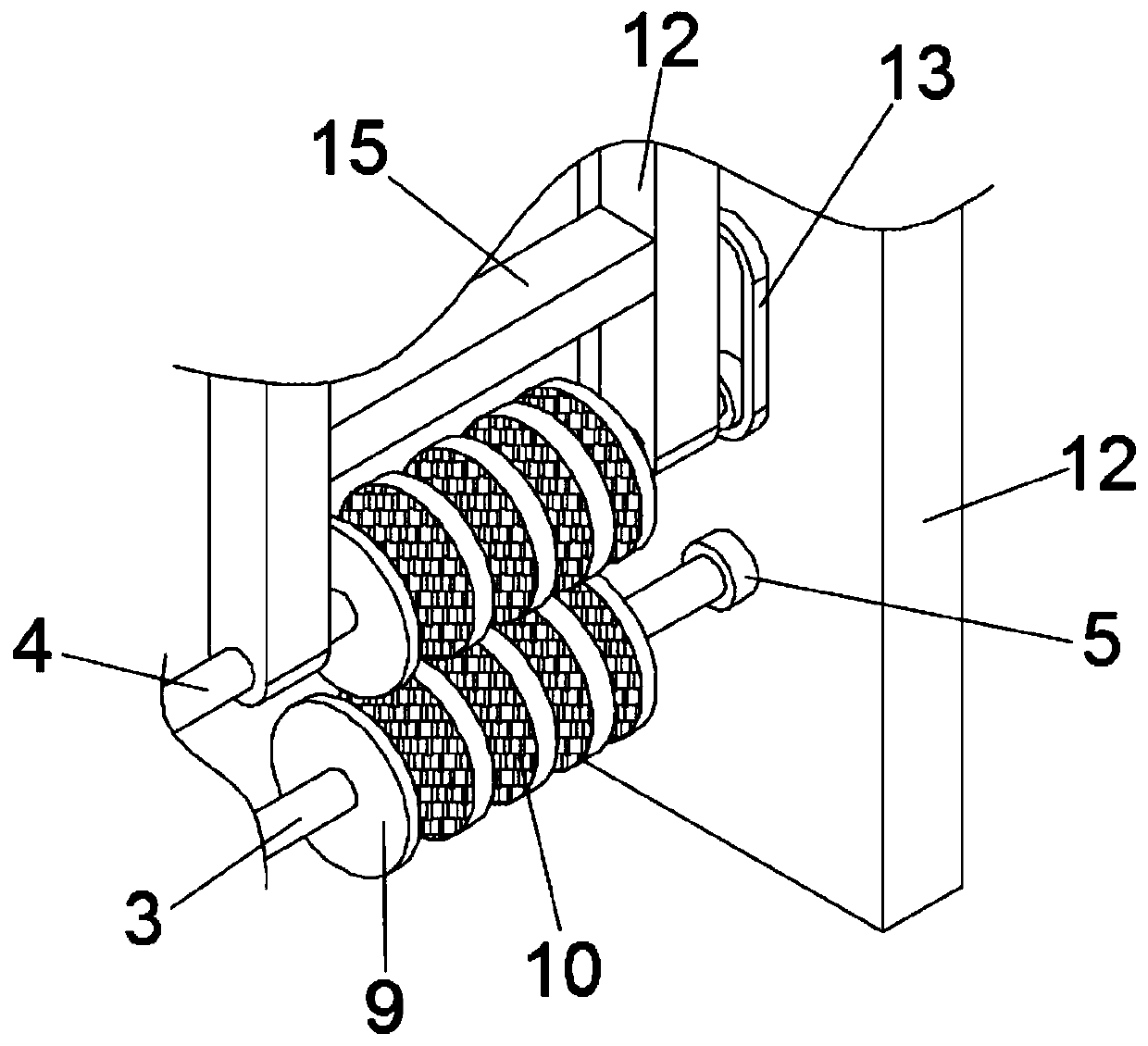

Building construction cable continuous extrusion molding machine

InactiveCN107086092AEvenly heatedAvoid temperatureInsulating conductors/cablesMolding machineGear wheel

The invention discloses a building construction cable continuous extrusion molding machine that comprises a melting box, a heating device, a first outer sheave mechanism, a driving gear, a driven gear, a booster pump, a coating device and an adjusting traction device. A hot gas located at the upper side in the melting box is injected into a molten material through an air intake so that the molten material is heated uniformly to prevent a case that a conventional heating device causes high temperature at a position close to heating device and low temperature at a position away from the heating device and to improve the melting quality of a raw material. Since the rotation of a rotating column and the intermittent traction of the adjusting traction device are synchronous, a wire core can be completely coated. Thus, a case is avoided that too fast or too slow speed of the traction device leads to too little or too much insulating material coating the wire core, and product quality is improved. By adjusting a tightening bolt, the height of a pinch roller can be adjusted. Thus, adjustment is performed according to needs of different wire diameters. By means of surface contact traction, traction efficiency is improved and a cable is protected.

Owner:刘月明

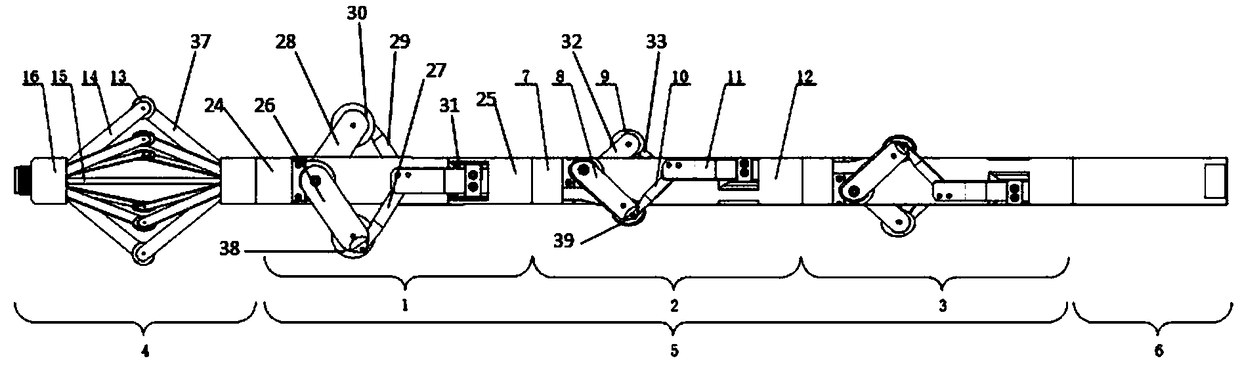

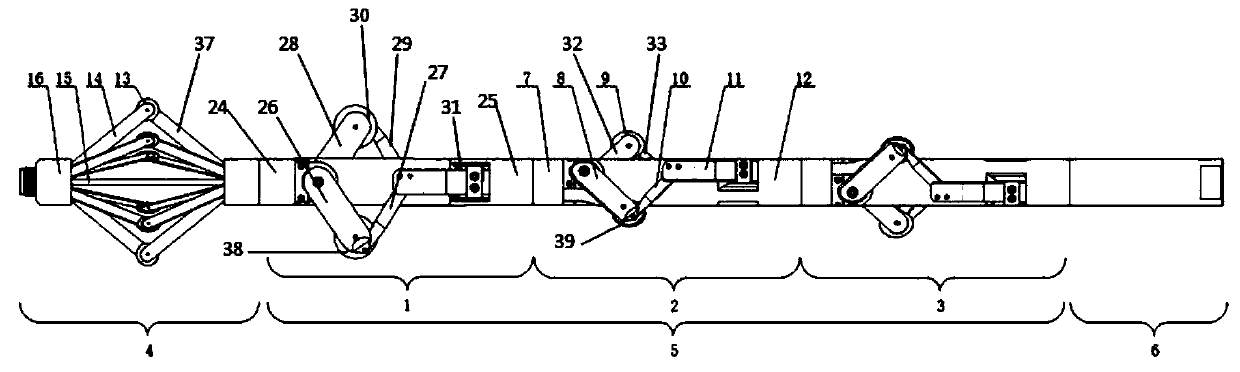

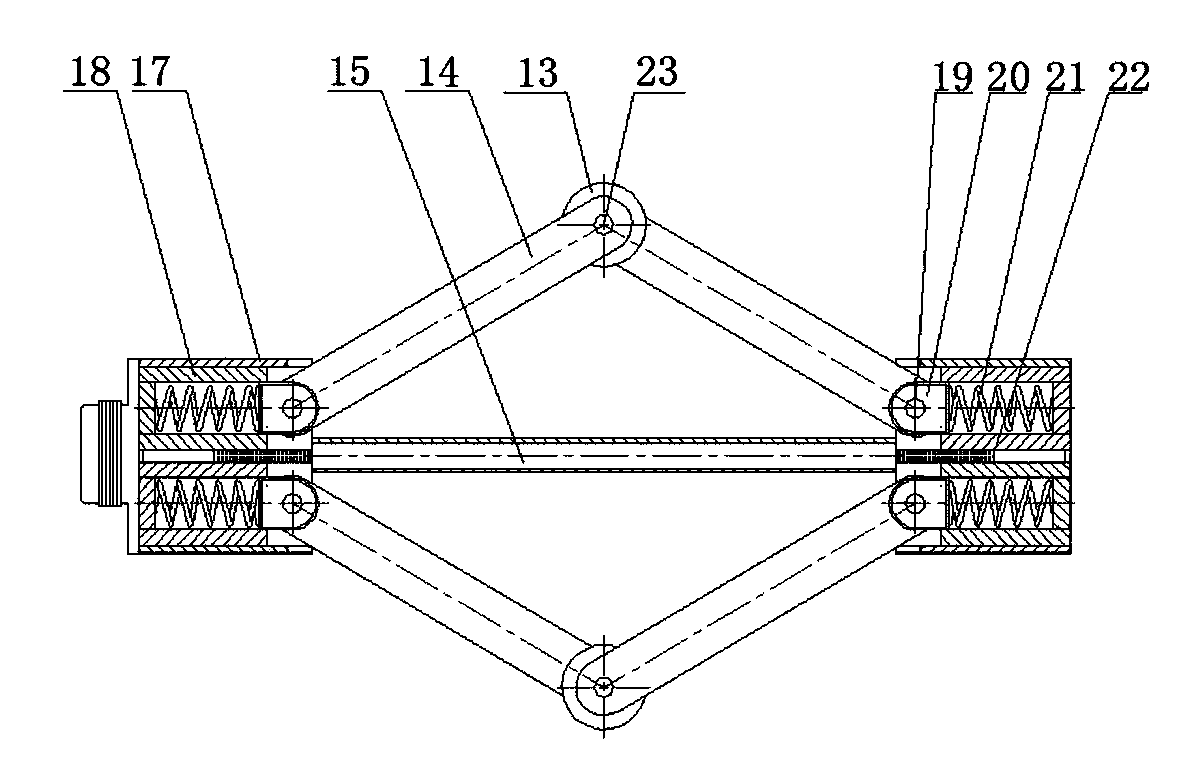

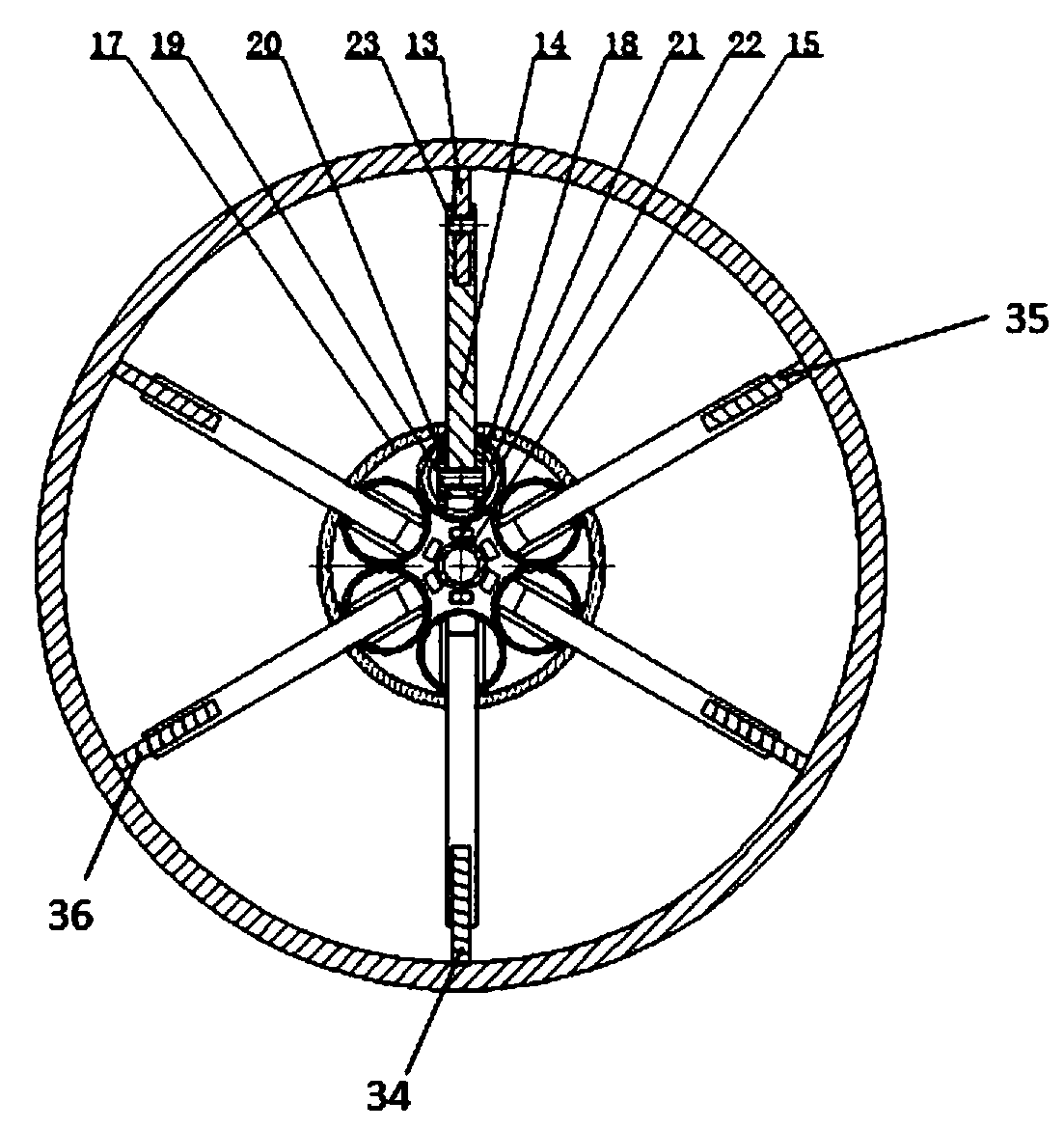

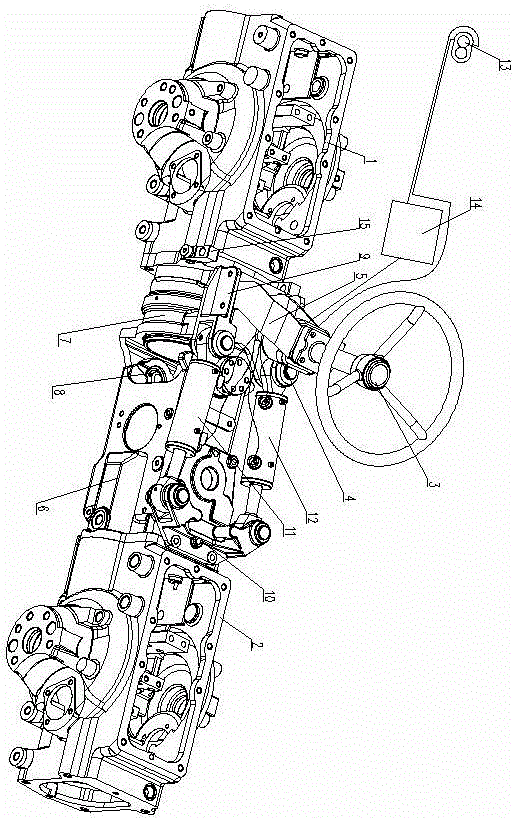

Petroleum horizontal well obstacle-crossing tractor and application method thereof

ActiveCN108999582AIncrease motivationIncrease torqueDrilling rodsConstructionsDrive wheelHorizontal wells

The invention discloses a petroleum horizontal well obstacle-crossing tractor, which comprises a detection centralizer, a first traction mechanism, a second traction mechanism and a control mechanism,wherein the detection centralizer is used for detecting information such as the location and size of obstacles in the wellbore; the traction mechanisms are connected at a certain angle, each tractionmechanism is equipped with a driving wheel, the installation directions of the driving wheels respectively correspond to the located directions of corresponding centralizing wheels on the centralizer, and the control mechanism achieve a purpose of fast obstacle crossing through controlling the support and contraction of different driving wheels. The petroleum horizontal well obstacle-crossing tractor performs obstacle crossing in a crossing mode, and is rapid in obstacle crossing process and controllable in obstacle crossing action, thereby being an obstacle-crossing tractor specially appliedto petroleum horizontal wells with varying pipe diameter and many downhole obstacles.

Owner:游精学

Hub motor hydraulic hybrid system

InactiveCN105459804BSmall structure sizeOptimize layoutBraking element arrangementsServomotor componentsFreewheelRoad surface

Owner:JILIN UNIV

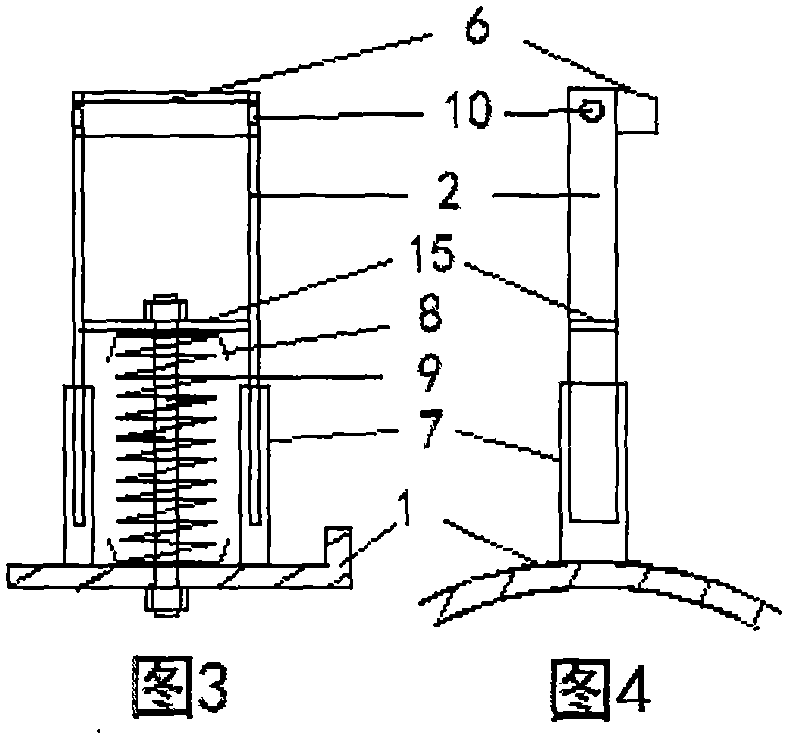

Thigh traction bed

The invention relates to a traction bed, in particularly to a thigh traction bed and aims to provide a thigh traction bed capable of performing thigh traction and preventing secondary injury. According to the technical scheme, the thigh traction bed comprises a bed underframe, bed supports, a bed board, a first slider, a support plate, a tightening belt, a first support, first pulleys, a second support, a second pulley and a steel wire rope, wherein the two bed supports are mounted on the left side and the right side of the top of the bed underframe respectively; the bed board with a supporting function is fixedly mounted between tops of the two bed supports on left side and the right side; a first opening is formed in the left part of the bed board; a second opening with a guiding effectis formed in the middle of the bed board. A thigh of a patient can be stretched rightwards to reach the appropriate position for traction by anticlockwise rotating a rotating disc, the thigh is fixedby the tightening belt, therefore, the traction of the thigh can be facilitated, and the secondary injury can be prevented; the body of the patient can be prevented from moving rightwards with the thigh during traction by adjusting a clamping device.

Owner:周睿

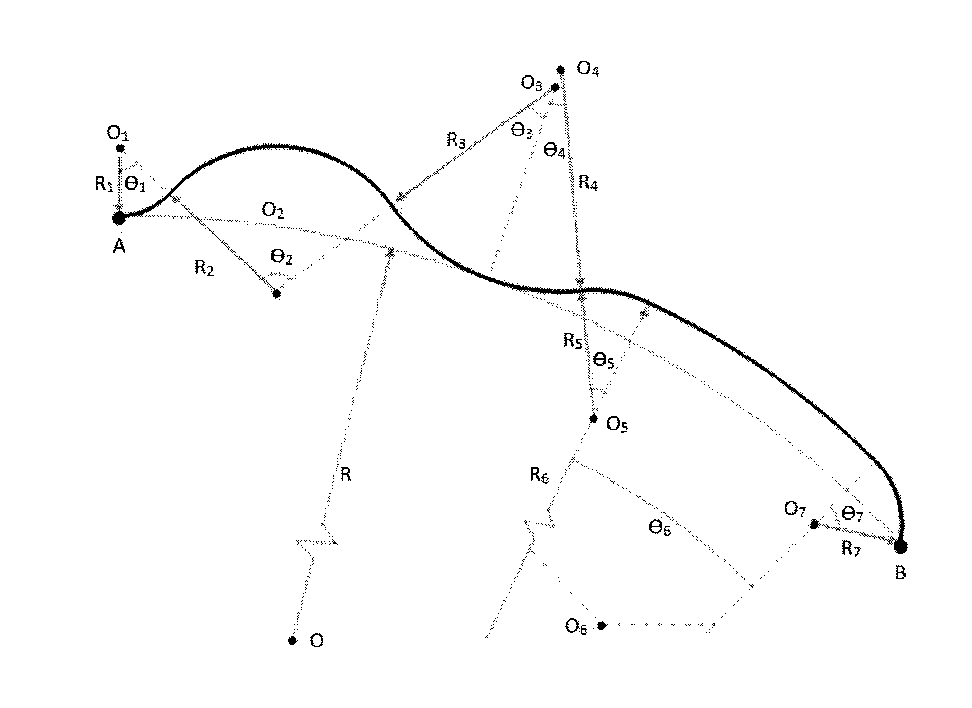

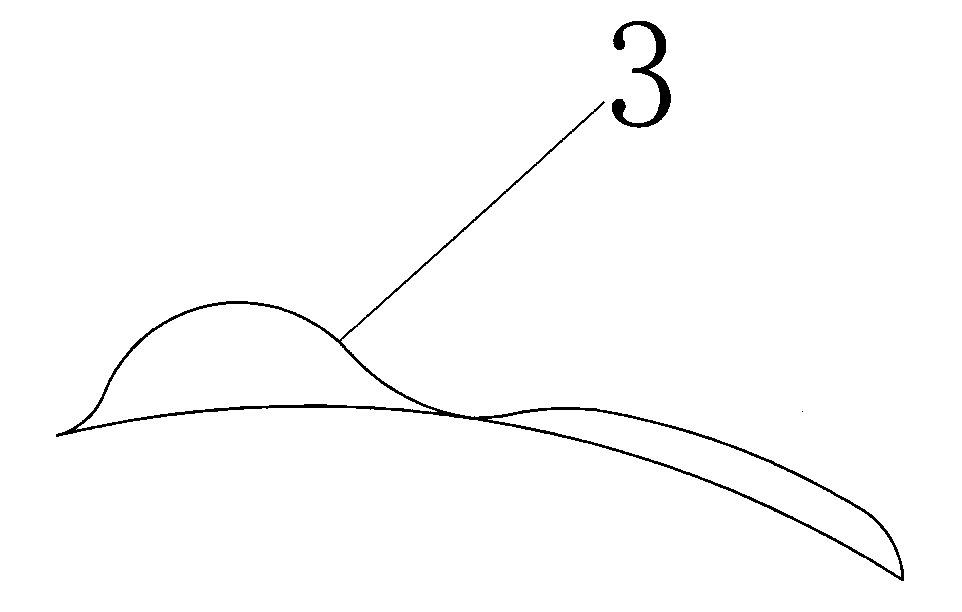

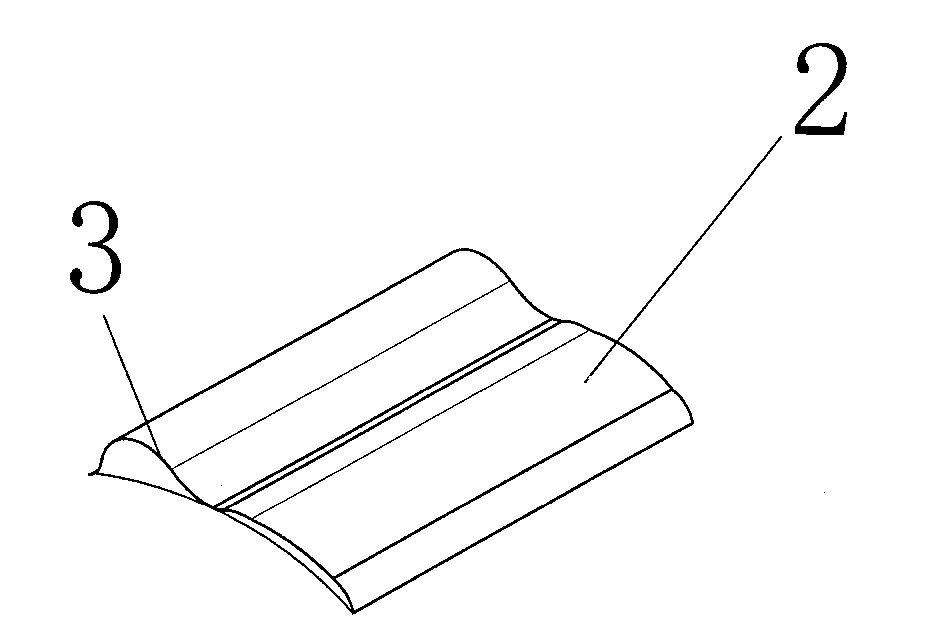

High-trafficability simulated sand crossing wheel face structure

InactiveCN103223820AImproved hitch tractionImprove traction efficiencyWheelsStructure of the EarthSoil stress

The invention discloses a high-trafficability simulated sand crossing wheel face structure which is characterized in that a plurality of wheel face structures are formed on the surface of a reference wheel, and each wheel face structure is formed that a curved section composed of seven arc segments which are smoothly overlapped stretches along the width of a wheel. Compared with the sand crossing wheel in a smooth wheel face structure with the same size, the sand crossing wheel in the high-trafficability simulated sand crossing wheel face structure provided by the invention has the advantages that the tractive force of a hook is improved by 3.2 to 6.5 percent, the traction efficiency is increased by 3.9 to 7.1 percent, in the invention, the sandy soil stress field distribution range under wheel is effectively increased, and the effect of the wheel face to sandy soil can be enhanced; in addition, the relative flow velocity of sandy soil under the wheel face is reduced. Compared with a smooth wheel face, the simulated sand crossing wheel face has the advantage that the lateral sand soil flowing speed under the simulated sand crossing wheel face is lowered by 11.1 to 13.7 percent, and the superior sand stabilizing and flow restricting effect of the simulated sand crossing wheel face can be embodied.

Owner:JILIN UNIV

Traction device, bogie and railway vehicle

The embodiment of the invention provides a traction device, a bogie and a railway vehicle, the traction device comprises a first traction pin and a second traction pin which are rotationally connected, and the sides, deviating from each other, of the first traction pin and the second traction pin are used for being connected with two adjacent carriages correspondingly; the first traction pin is matched with the cross beam to transmit longitudinal force. According to the traction device, the bogie and the railway vehicle, the self weight of the vehicle is reduced, and the traction efficiency is improved.

Owner:CRRC TANGSHAN CO LTD

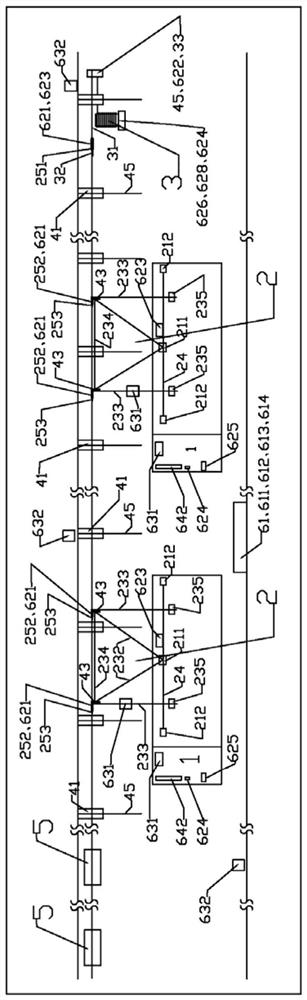

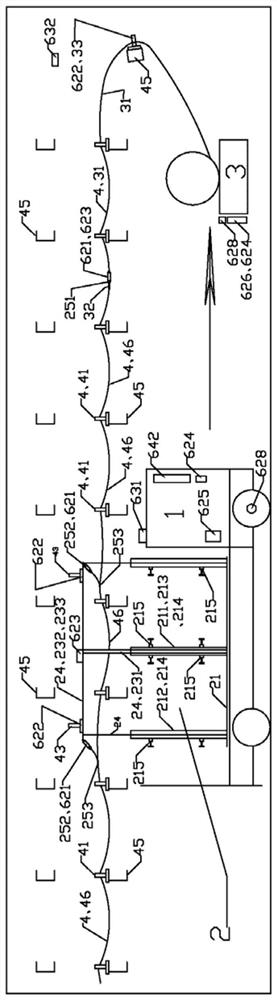

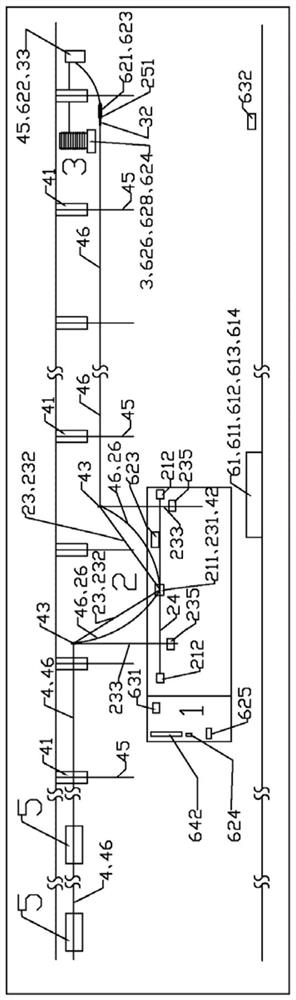

Comprehensive pipe gallery cable traction and displacement laying system and application method

ActiveCN112310890AImprove traction efficiencyEasy to use for common settingsApparatus for laying cablesVisual monitoringVoice communication

The invention relates to a comprehensive pipe gallery cable traction and displacement laying system and an application method. The system comprises a cable traction process on a cable roller channel which is located at one side of a comprehensive pipe gallery and is parallel to and close to a cable design laying position, and a displacement process which enables a cable to be displaced to the cable design laying position, wherein a comprehensive pipe gallery electric vehicle, a cable traction and displacement device and a process parameter wireless sensing detection device are additionally arranged on the basis of an existing cable laying machine so as to improve the process efficiency, a video and safety monitoring control system is adopted in the laying process, and on the basis of traction machinery, a traction mode is optimized, a cable laying dynamic laying diagram in the comprehensive pipe gallery is established, and a cable laying process is managed and controlled, so that automatic calculation of a process traction force limit value, a protection value parameter and a segmented traction distance parameter, process cable laying dynamic display monitoring chart and process parameter visual monitoring, process voice communication normalization, process protection automation and fault reason processing and process video and voice informatization are realized.

Owner:中色十二冶金建设有限公司

Street lamp cable efficient traction device

InactiveCN111049064AReduce volumeEasy to moveApparatus for laying cablesDrive shaftStructural engineering

The invention discloses a street lamp cable efficient traction device comprising a base. Supporting plates are vertically fixed to the two sides of the upper end face of the base. A plurality of traction assemblies are horizontally arranged between the supporting plates on the two sides, each traction assembly comprises a driving shaft and a driven shaft, the two ends of each driving shaft and thetwo ends of each driven shaft are rotationally installed on the supporting plates through bearing pedestals, traction wheels matched with each other are fixed to the driving shafts and the driven shafts, and a plurality of grooves are formed in the traction wheels; a top plate is fixed to the top of the supporting plate and provided with a lifting mechanism for driving the driven shaft to move upward and downward. According to the street lamp cable efficient traction device, traction force is dispersed through multiple traction assemblies, and traction is more stable and reliable; a pluralityof grooves with different opening widths and depths are formed in the traction wheels so that the cable traction device is suitable for traction of cables of different specifications, wide in application range, convenient and rapid to operate and high in traction efficiency.

Owner:赣州雄安照明科技有限公司

Novel aluminium section dragger

The invention discloses a novel aluminium section dragger. The novel aluminium section dragger comprises a guide rail arranged roughly in parallel with an aluminium section discharging platform, a tractor slideablely arranged on the guide rail, an installing arm, and a clamp; a first end of the installing arm is fixedly connected with the tractor, and a second end is hanged above the aluminium section discharging platform; the clamp is arranged on the second end of the installing arm, and comprises a material clamping frame, a pressing plate, a cylinder, and two electromagnets; the material clamping frame comprises a pair of support plates which are arranged on the second end of the installing arm and vertically to each other; the top parts of the two support plates are both connected with the second end of the installing arm via hinge joint; the bottoms of the two support plates are bent to each other so as to form a support plate bottom; the pressing plate is arranged in the material clamping frame, and is driven by the cylinder so as to move upward and downward with relative to the second end of the installing arm in the material clamping frame; and the two electromagnets are arranged on the bottoms of the two support plates respectively. The clamp of the novel aluminium section dragger is simple and skillful in structure design, and is capable of realizing clamping of aluminium section, and discharging with high efficiency.

Owner:台澳铝业(台山)有限公司

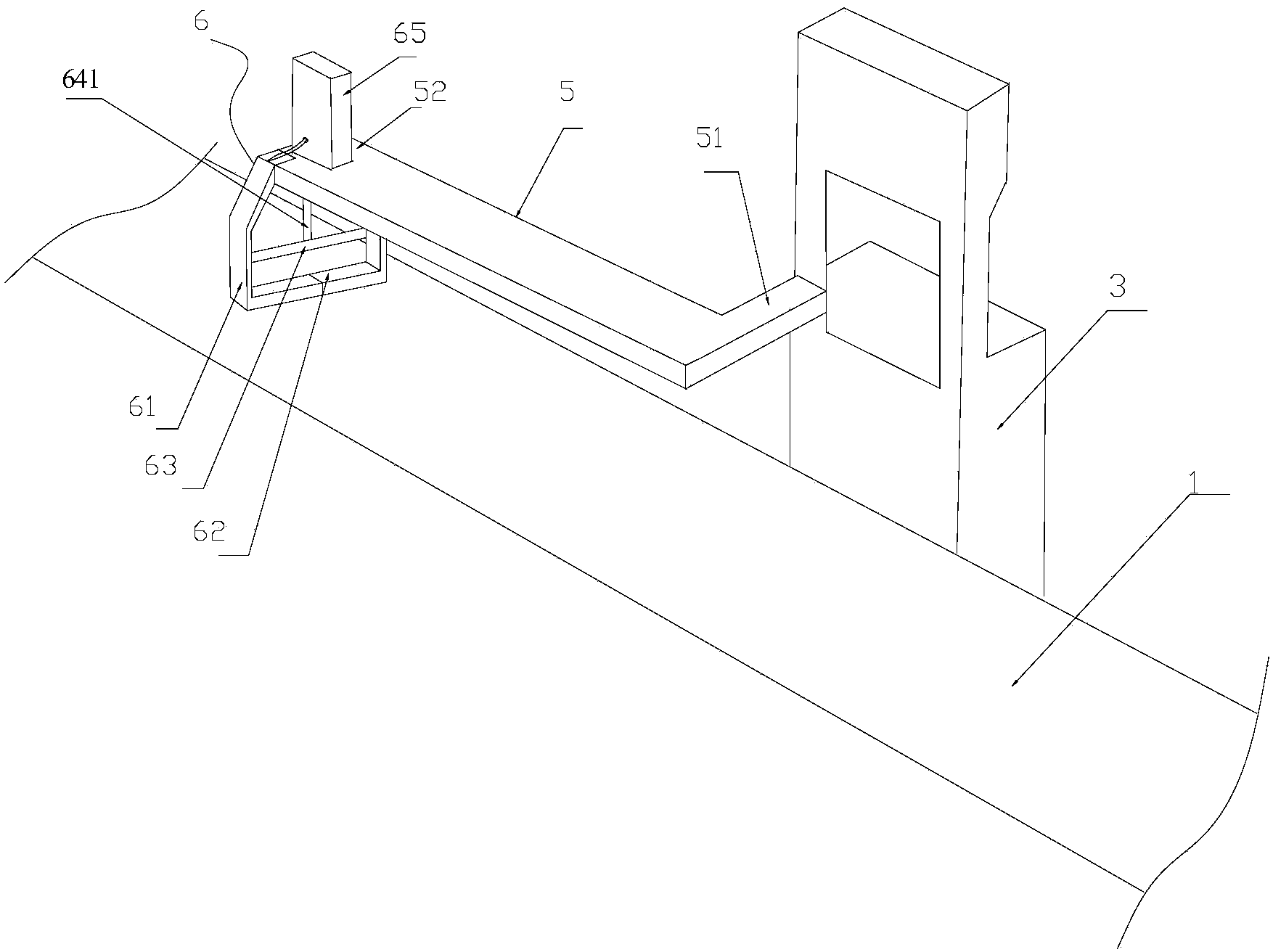

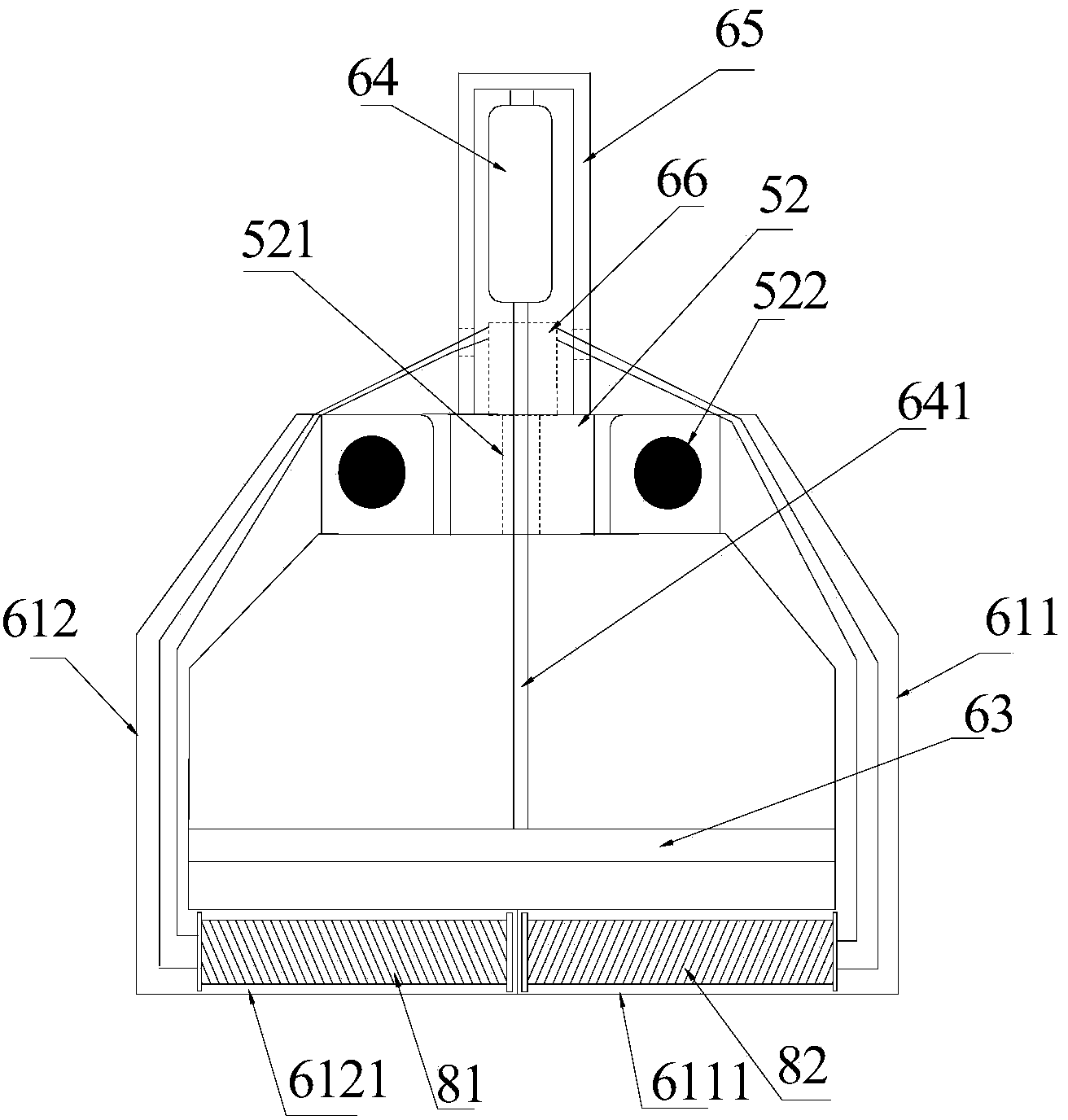

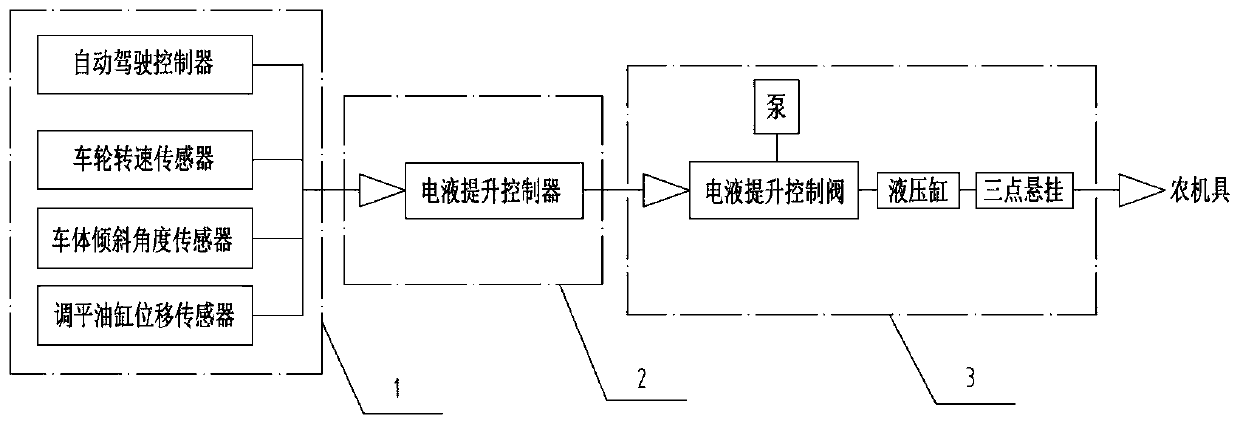

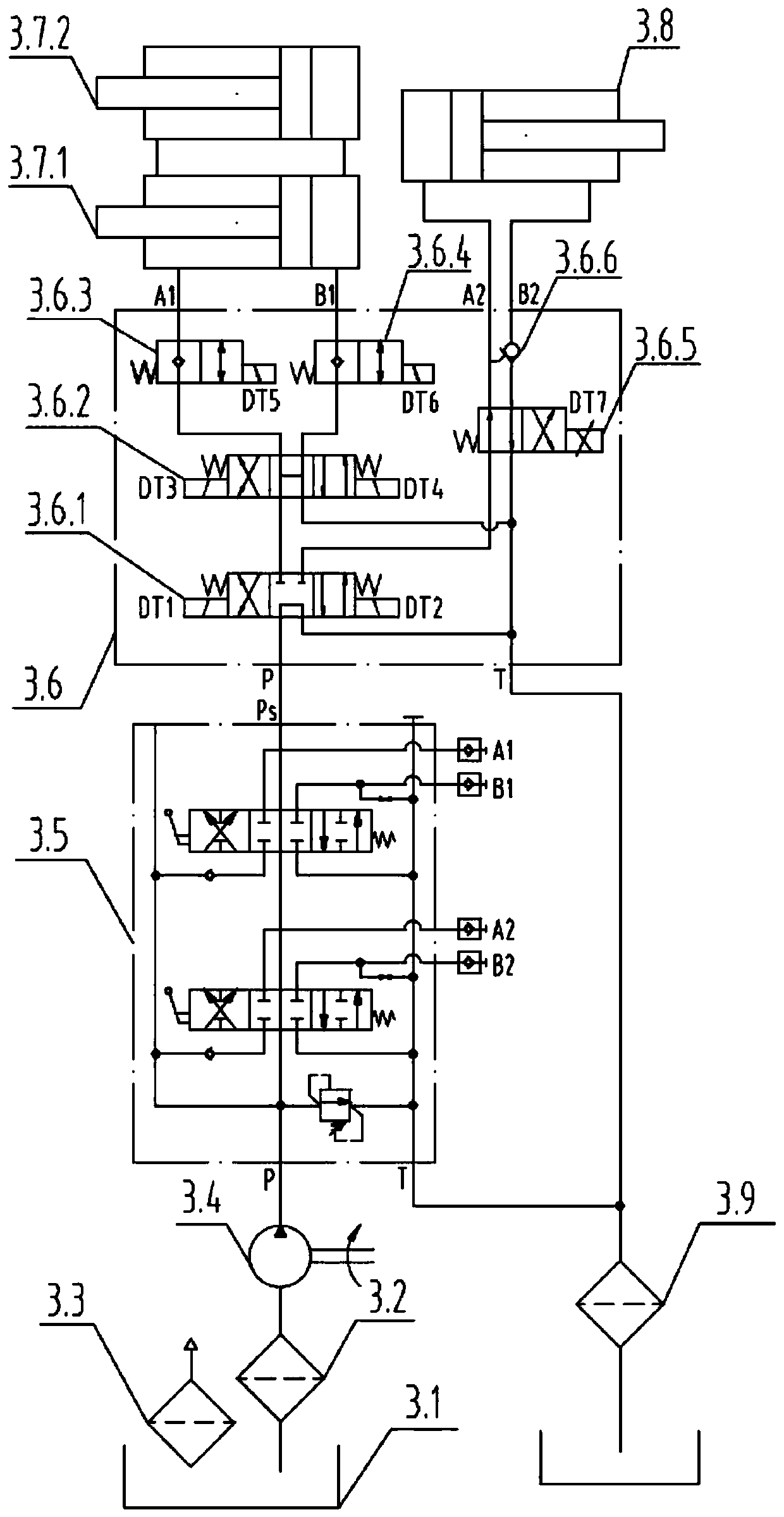

Intelligent electro-hydraulic lifting control device and intelligent electro-hydraulic lifting control method for paddy field agricultural machine

PendingCN110741761AImprove traction efficiencyImprove work efficiencyAgricultural machinesAdjusting devicesHydraulic cylinderWheel speed sensor

The invention discloses an intelligent electro-hydraulic lifting control device for a paddy field agricultural machine. The intelligent electro-hydraulic lifting control device comprises a detection module, a control module and an execution module. The control module makes an action judgment according to agricultural machine information acquired by the detection module and sends a signal. The execution module controls automatic lifting, lowering and leveling of agricultural implements. The detection module comprises an automatic driving controller, a wheel speed sensor, a body tilt angle sensor and a leveling cylinder displacement sensor. The control module comprises an electro-hydraulic lifting controller. The execution module comprises an electro-hydraulic lifting control valve, a pump,a hydraulic cylinder and a three-point suspension, and is used for executing instructions sent by the control module to control movement of the agricultural implements. The agricultural machine information includes a straight travelling signal, a turning and reversing signal and an agricultural implement leveling signal. The invention further discloses an intelligent electro-hydraulic lifting control method for the paddy field agricultural machine. Straight travelling of the paddy field agricultural machine, the tilling depth of the agricultural implements during turning and reversing, and automatic leveling of the agricultural implements in a paddy field can be controlled.

Owner:ZOOMLION HEAVY MASCH CO LTD

Obstacle-surmounting tractor for oil horizontal well and its application method

ActiveCN108999582BIncrease motivationIncrease torqueDrilling rodsConstructionsDrive wheelHorizontal wells

The invention discloses a petroleum horizontal well obstacle-crossing tractor, which comprises a detection centralizer, a first traction mechanism, a second traction mechanism and a control mechanism,wherein the detection centralizer is used for detecting information such as the location and size of obstacles in the wellbore; the traction mechanisms are connected at a certain angle, each tractionmechanism is equipped with a driving wheel, the installation directions of the driving wheels respectively correspond to the located directions of corresponding centralizing wheels on the centralizer, and the control mechanism achieve a purpose of fast obstacle crossing through controlling the support and contraction of different driving wheels. The petroleum horizontal well obstacle-crossing tractor performs obstacle crossing in a crossing mode, and is rapid in obstacle crossing process and controllable in obstacle crossing action, thereby being an obstacle-crossing tractor specially appliedto petroleum horizontal wells with varying pipe diameter and many downhole obstacles.

Owner:游精学

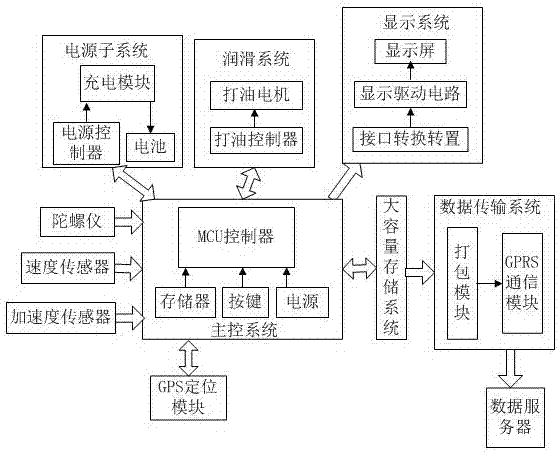

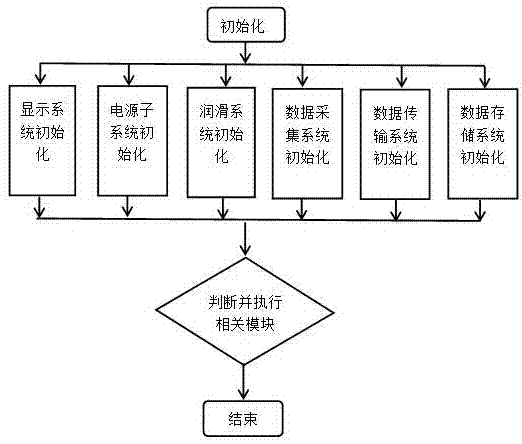

Intelligent lubrication control system for yrain wheel track curve motion

ActiveCN107544345AReasonable and effective lubricationReduce wearProgramme controlComputer controlControl systemData acquisition

The invention provides an intelligent lubrication control system for train wheel track curve motion and aims to solve the problem that an existing train steel rail lubrication system is not high in precision and is largely affected by train speed. The intelligent lubrication control system comprises a master control system, a display system, a power subsystem, a lubrication system, a mass storagesystem, a data acquisition system, a data transmission system and a data storage system. The master control system comprises an MCU controller, a memorizer, a key and a power supply, the memorizer, the key, the power supply, the display system, the power subsystem, the lubrication system, the mass storage system and the data acquisition system are connected with the MCU controller, the mass storage system is connected with the data transmission system, and the data transmission system is connected with the data storage system. The intelligent lubrication control system has the advantages of being simple in structure, convenient, safe, reliable in performance, intelligentized, capable of saving energy, environmentally friendly, low in power consumption and the like and adopts a common chip,the cost is reduced, the circuit integration level is high, a technique is mature, few board manufacturing processes are adopted, and production is easy.

Owner:ZHONGYUAN ENGINEERING COLLEGE

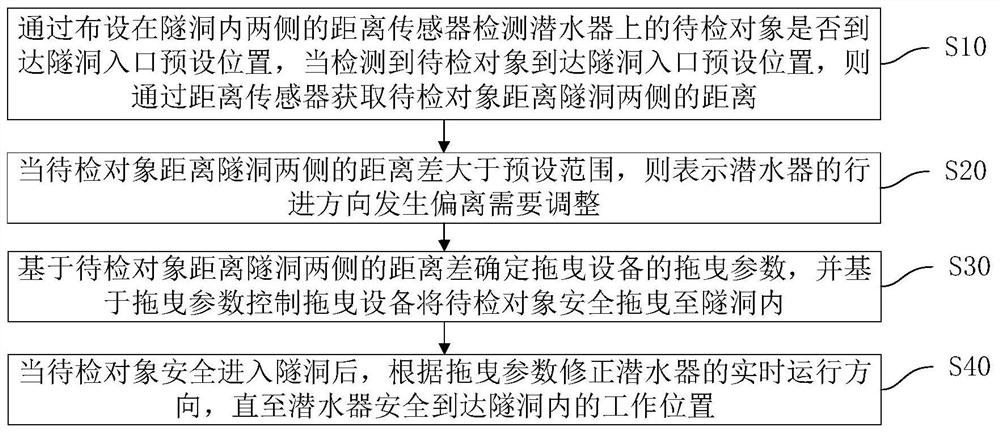

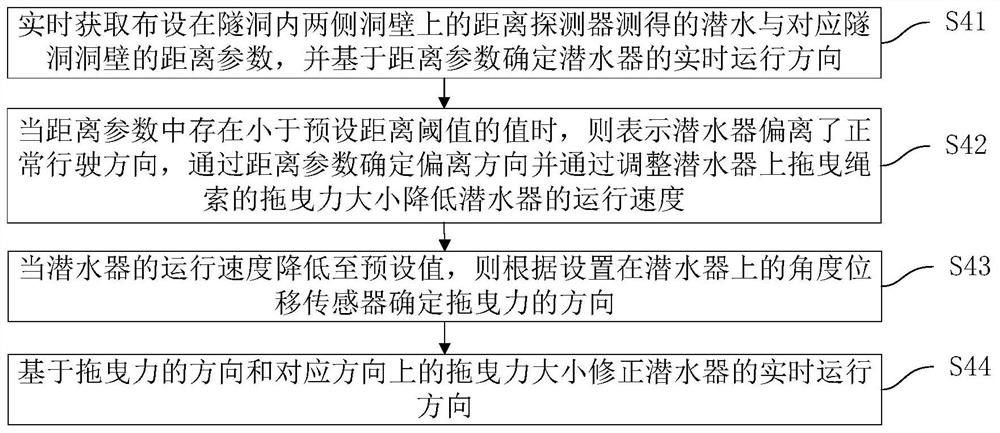

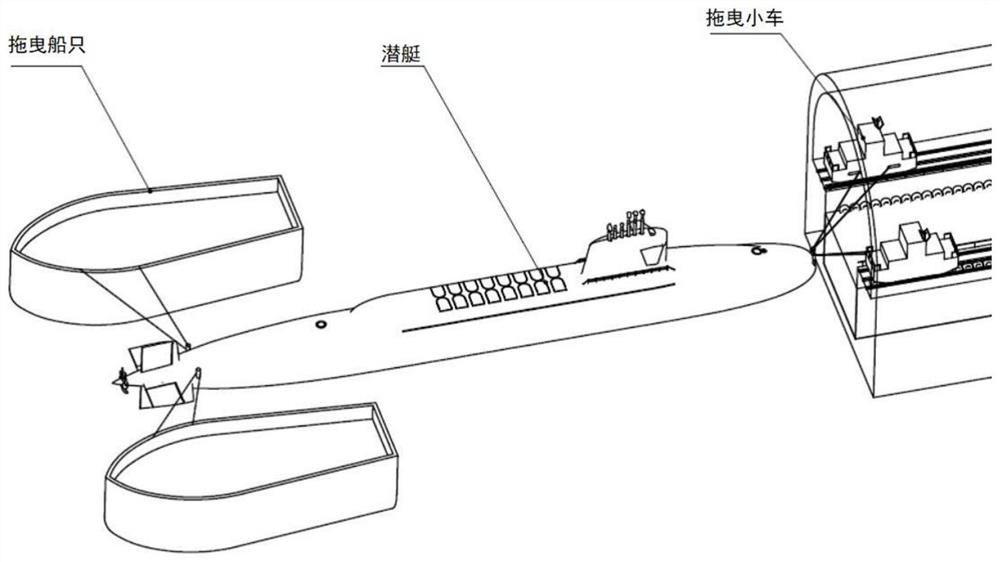

Automatic traction method and system for submersible to go in and out of tunnel

ActiveCN113525591AStreamlined Auto CalibrationReduce labor costsTowing/pushing equipmentPosition/course control in two dimensionsDistance sensorsStructural engineering

The invention discloses an automatic traction method and system for a submersible to go in and out of a tunnel. The method comprises the steps of detecting whether a to-be-detected object on the submersible reaches a preset position of a tunnel entrance through distance sensors disposed at two sides in the tunnel, and when detecting that the to-be-detected object reaches the preset position of the tunnel entrance, acquiring the distance between the to-be-detected object and the two sides of the tunnel through the distance sensors, and if the distance difference between the to-be-detected object and the two sides of the tunnel is larger than a preset range, indicating that the advancing direction of the submersible deviates and needs to be adjusted, determining dragging parameters of dragging equipment based on the distance difference between the to-be-detected object and the two sides of the tunnel, and safely dragging the to-be-detected object into the tunnel, and after the to-be-detected object safely enters the tunnel, correcting the real-time running direction of the submersible according to the dragging parameters until the submersible safely reaches the working position in the tunnel. Rapid and simple automatic calibration of the system is achieved, the labor cost is reduced, and the positioning accuracy and the traction efficiency are improved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

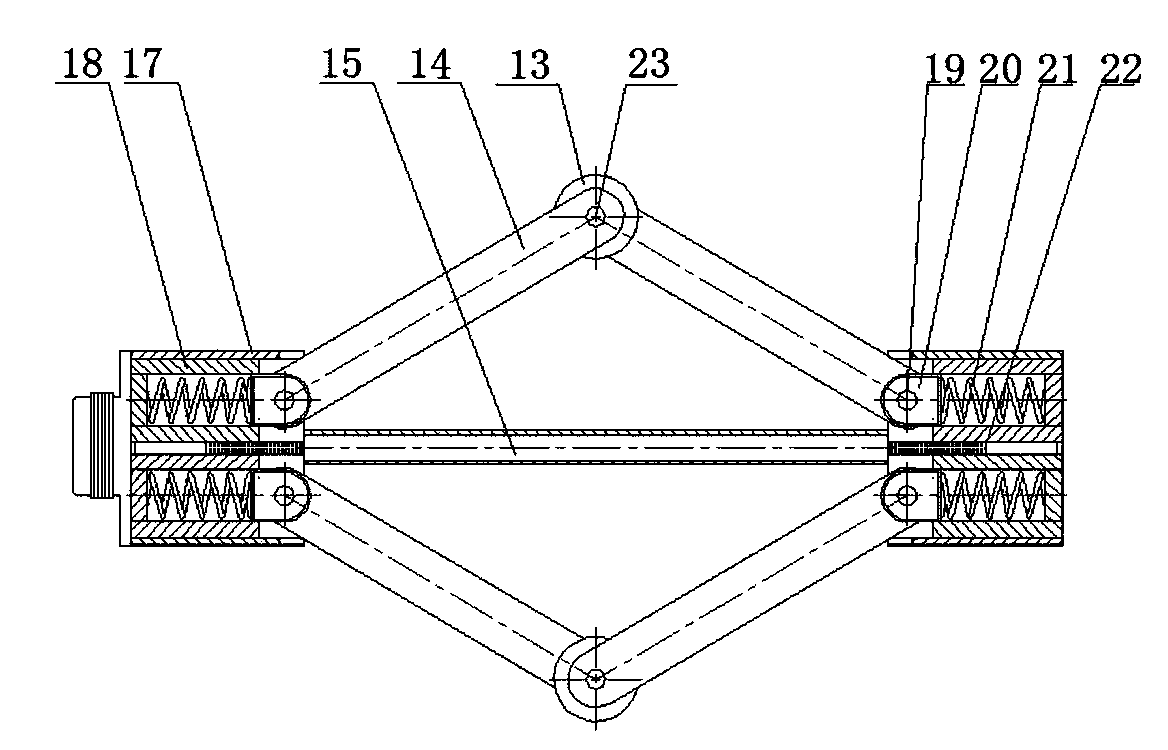

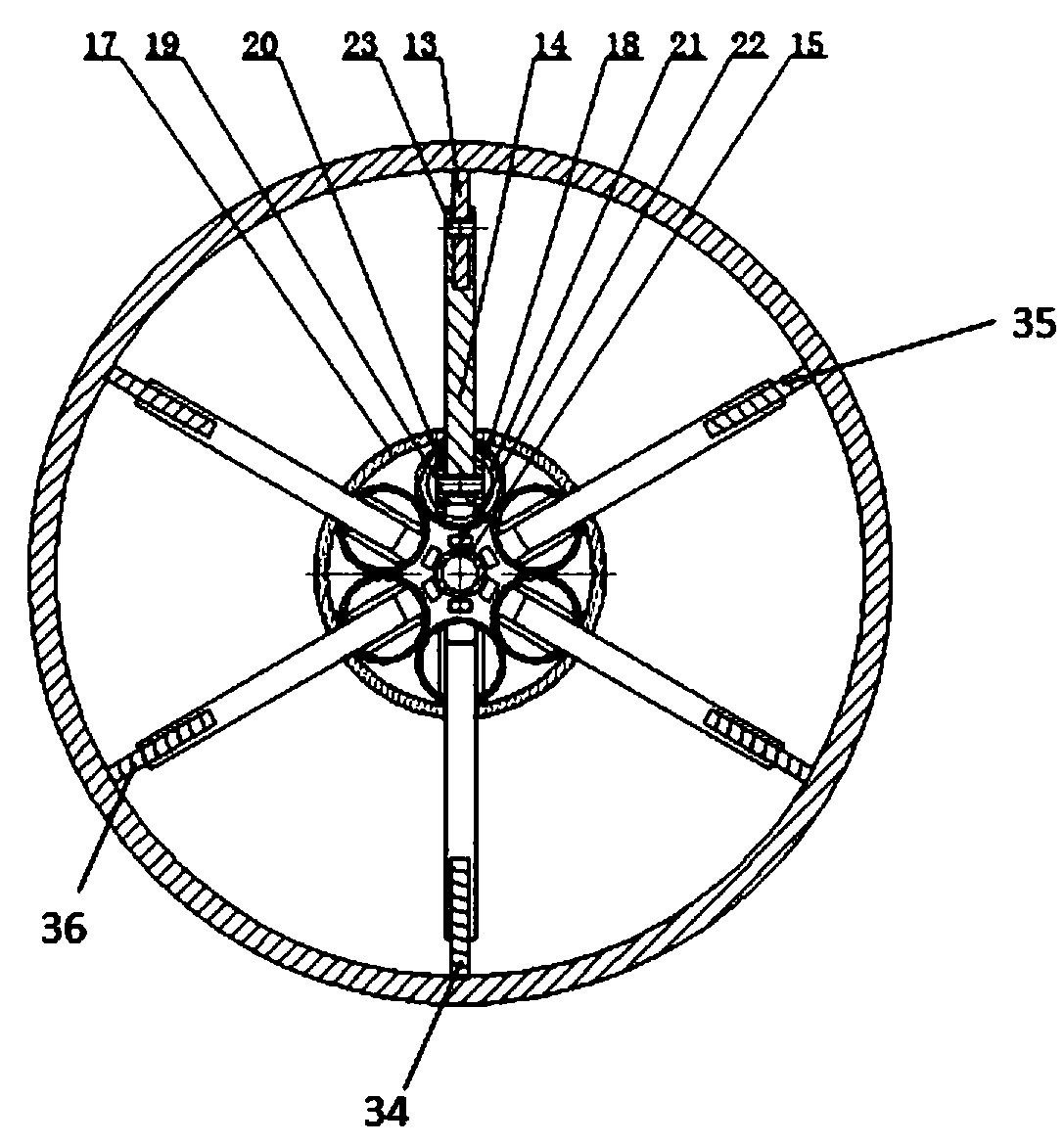

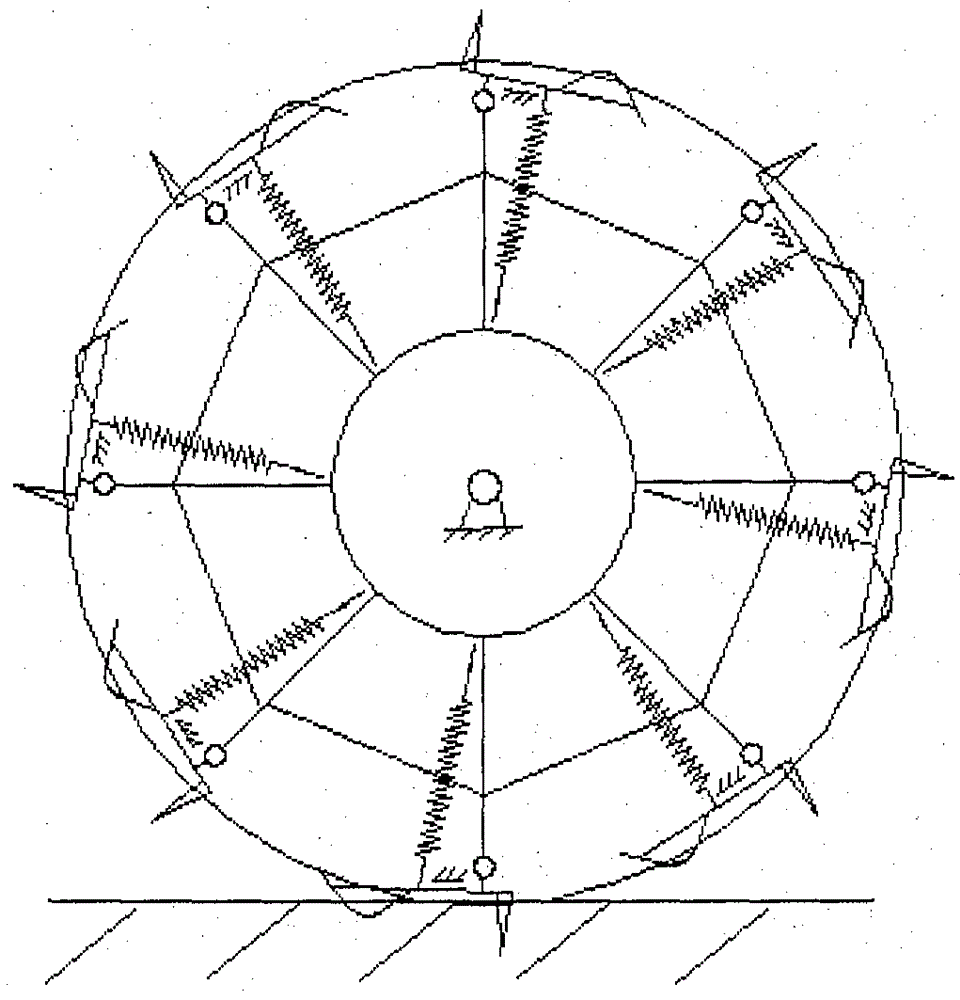

Foldable type walking wheel

InactiveCN106080022ASimple structureEasy to operateWheels with spade lugsDrive wheelRolling resistance

The invention discloses a foldable type walking wheel which is simple in structure, low in manufacturing cost, easy and convenient to operate, wide in application and especially suitable for skidding and sinking prevention of various wheel machines like boat tractors in paddy fields and upland fields. The foldable type walking wheel has the beneficial effects that before and after operation, a drive wheel does not need to be replaced, labor intensity is relieved, the hard bottom layer of the paddy fields is not destroyed, and the benignant and sustainable operation of mechanical cultivation of the paddy fields is ensured. During running, the riding comfort is good, adhesive force is high, rolling resistance is small, and traction efficiency is high. The foldable type walking wheel comprises a hub, a drive tire and the like. The hub or a rigid connection body thereof is concentrically and rigidly connected with a rim 1; a plurality of supporting frames 2 are evenly distributed on the outer circumferential face of the rim 1 in a radial shape; the upper ends of the supporting frames 2 are hinged with supporting legs 3; the supporting legs 3 are provided with hinge holes 12 and antiskid teeth 4; the antiskid teeth 4 can extend out of an outer edge 14 of the drive tire; the supporting legs 3 can be folded around a hinge shaft 11 under the effect of external force; the supporting frames 2 are provided with limiting check blocks 6; and extension springs 5 are connected between the supporting legs 3 and the lower portions of the supporting frames 2.

Owner:李琪

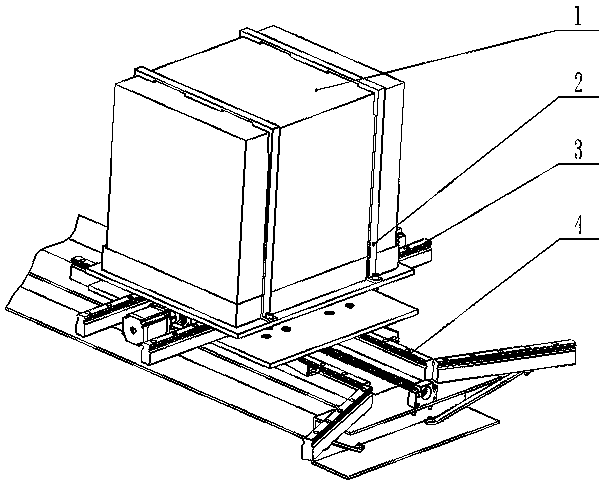

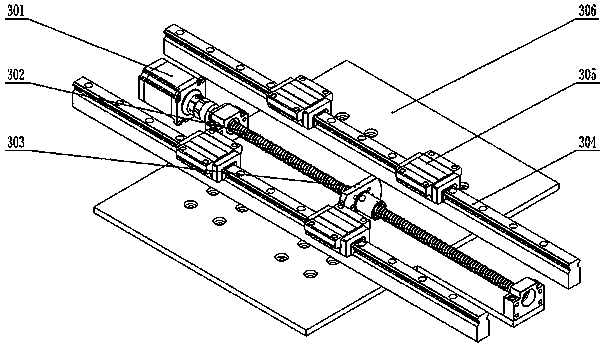

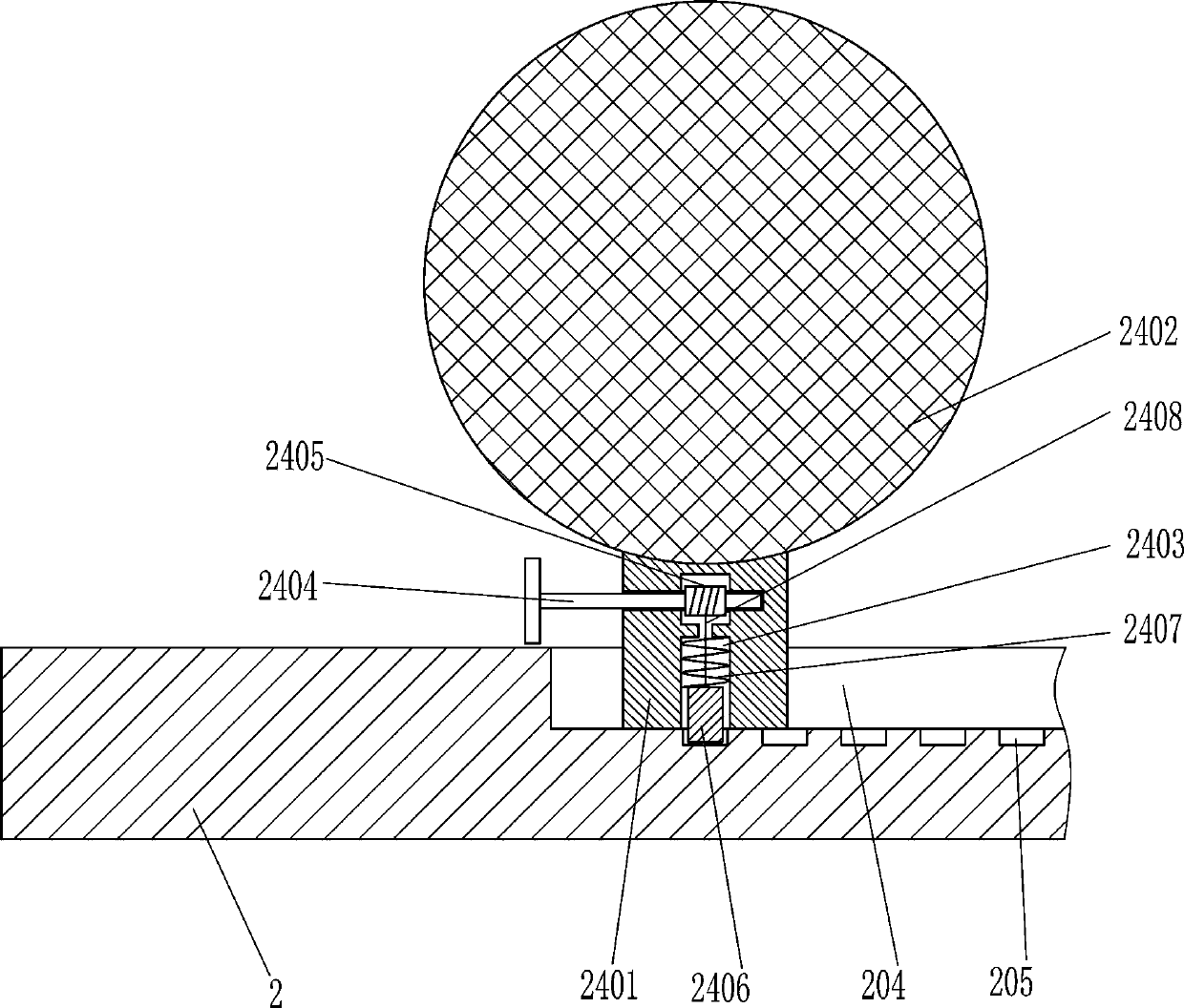

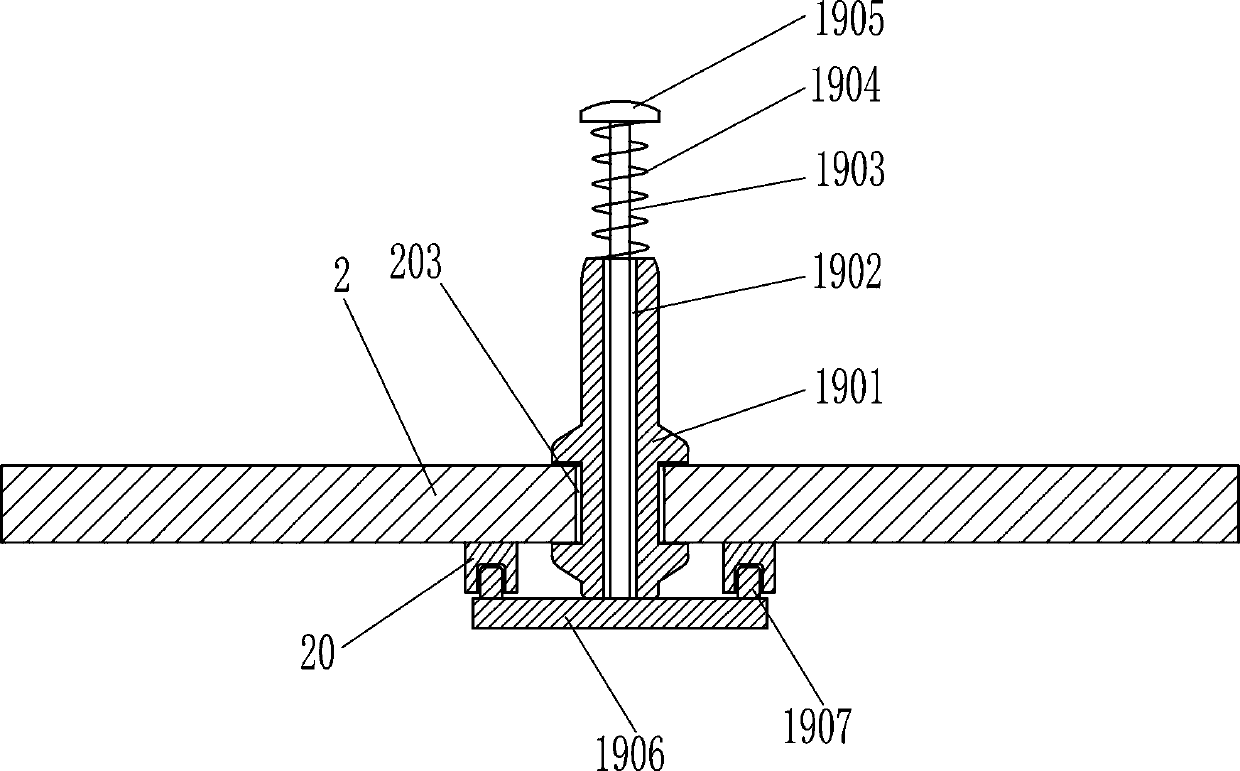

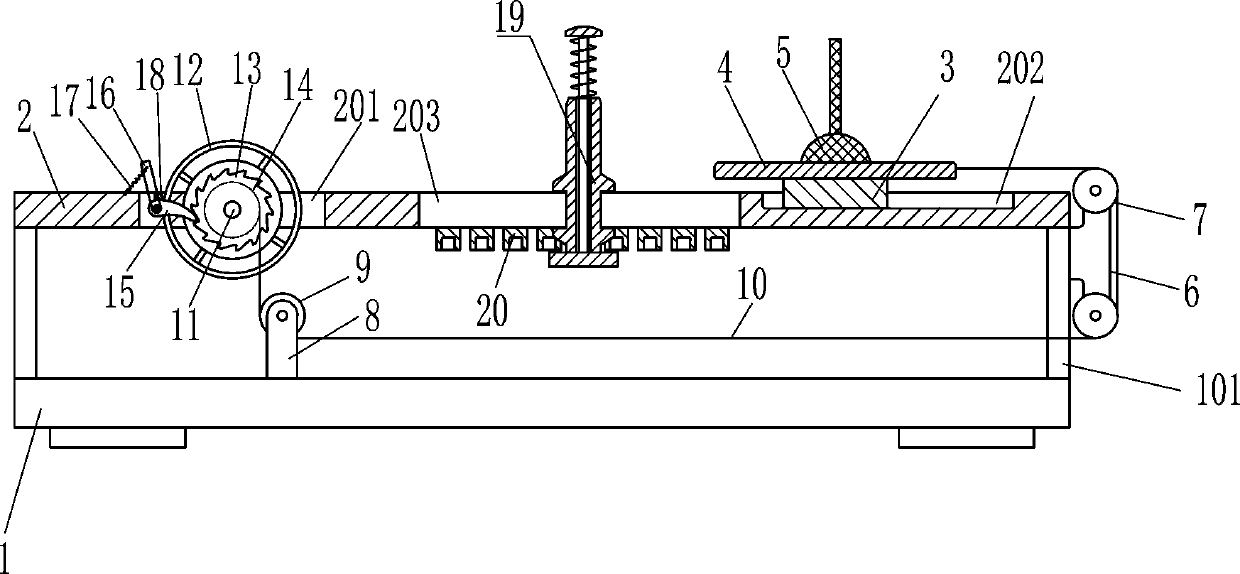

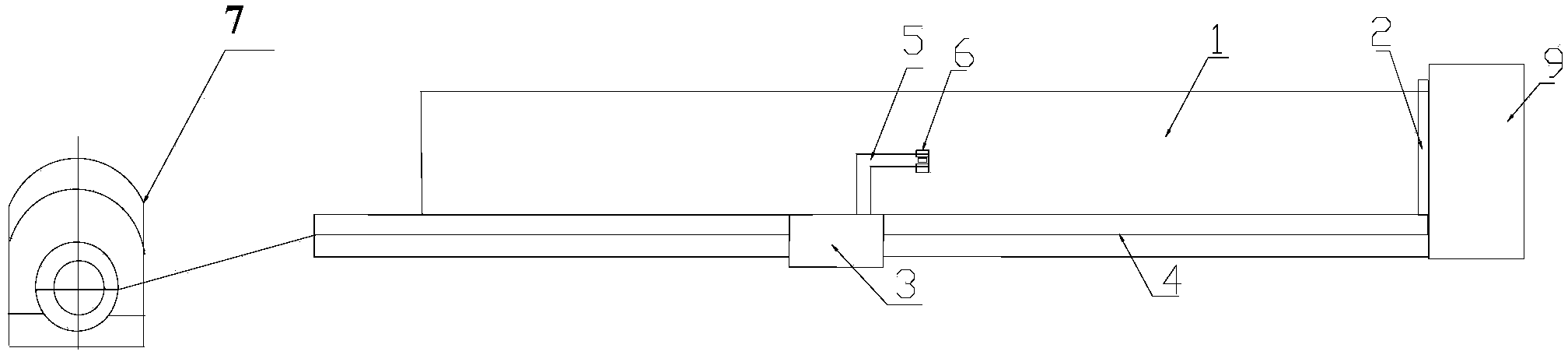

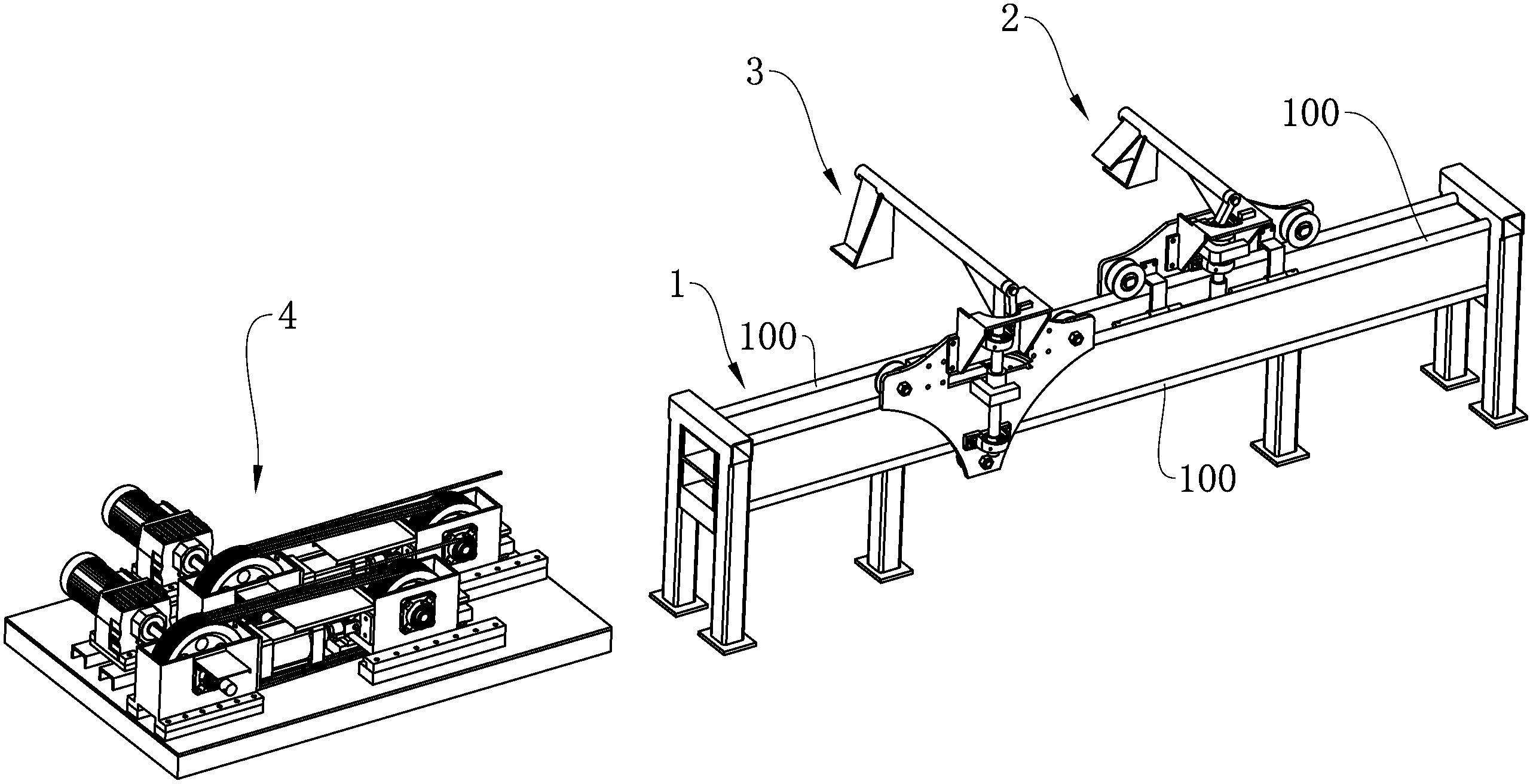

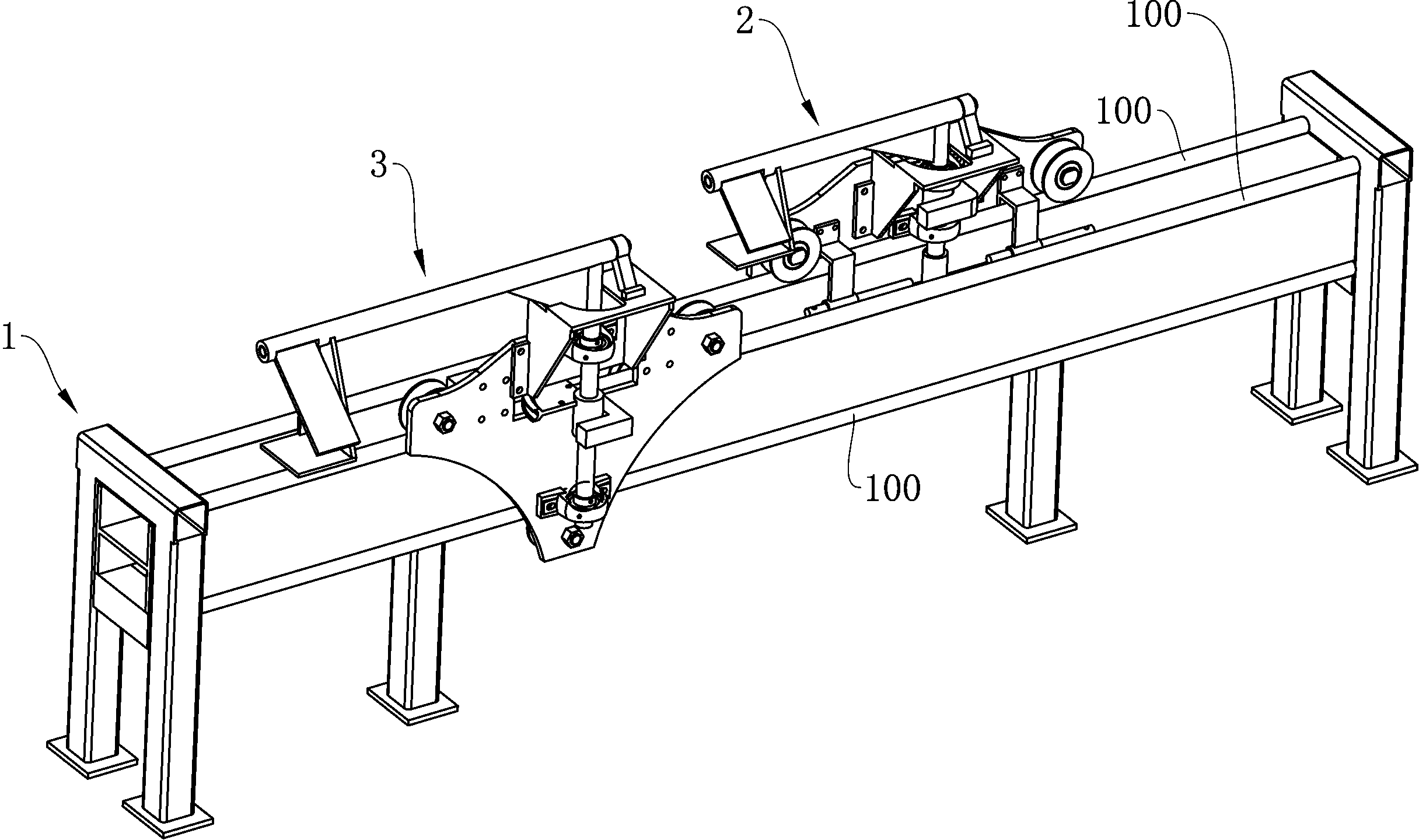

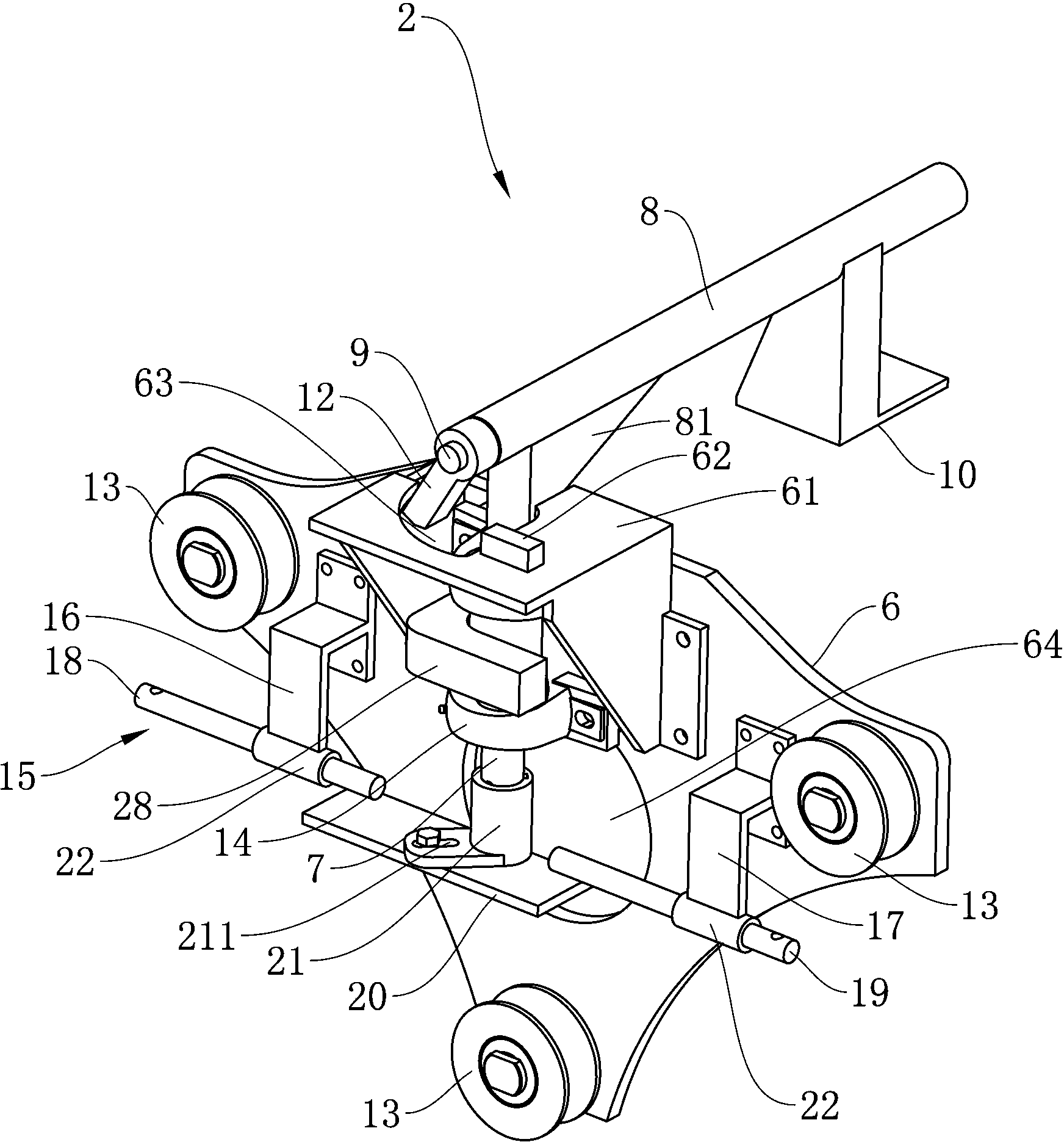

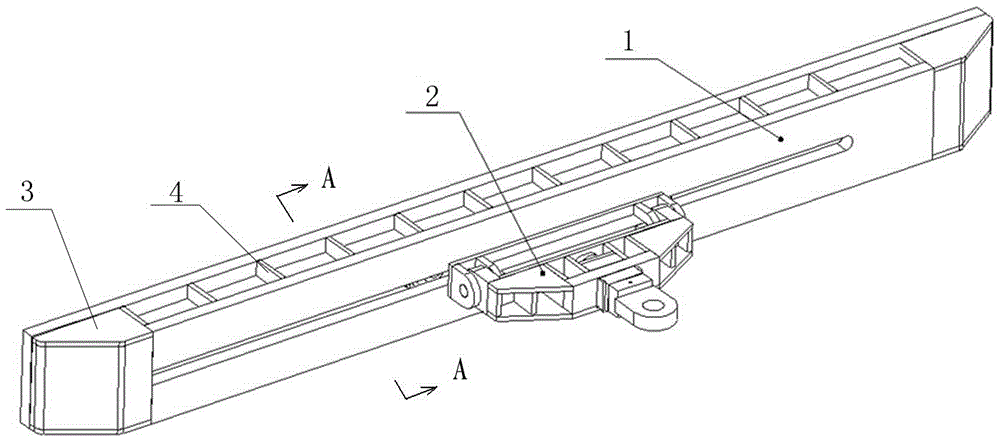

Simple aluminum section traction system

InactiveCN104338774AMeet the needs of continuous extrusionImprove traction efficiencyTraction systemHigh energy

The invention relates to a simple aluminum section traction system. The system is characterized in that the system comprises a frame, a first traction head device, a second traction head device and a traction driving device, the first traction head device and the second traction head device are respectively composed of a vertical plate, a vertical shaft, a swing arm, a rotating shaft, a material supporting seat, a material clamping block and a shifting block, and the traction driving device is composed of an underframe, and a first motor mechanism, a first transmission mechanism, a first tension regulating mechanism, a second motor mechanism, a second transmission mechanism and a second tension regulating mechanism which are arranged on the underframe. The system using the first traction head device and the second traction head device with very simple structures to realize alternated traction on a same guide rail frame cooperates with and meets continuous extrusion needs of aluminum sections and realizes a high traction efficiency; and the system has the advantages of very simple structure, small size, compactness, small occupied space, very less electric energy consumed during running, and high energy saving and environmental protection.

Owner:FOSHAN ALUMAC MACHINERY EQUIP

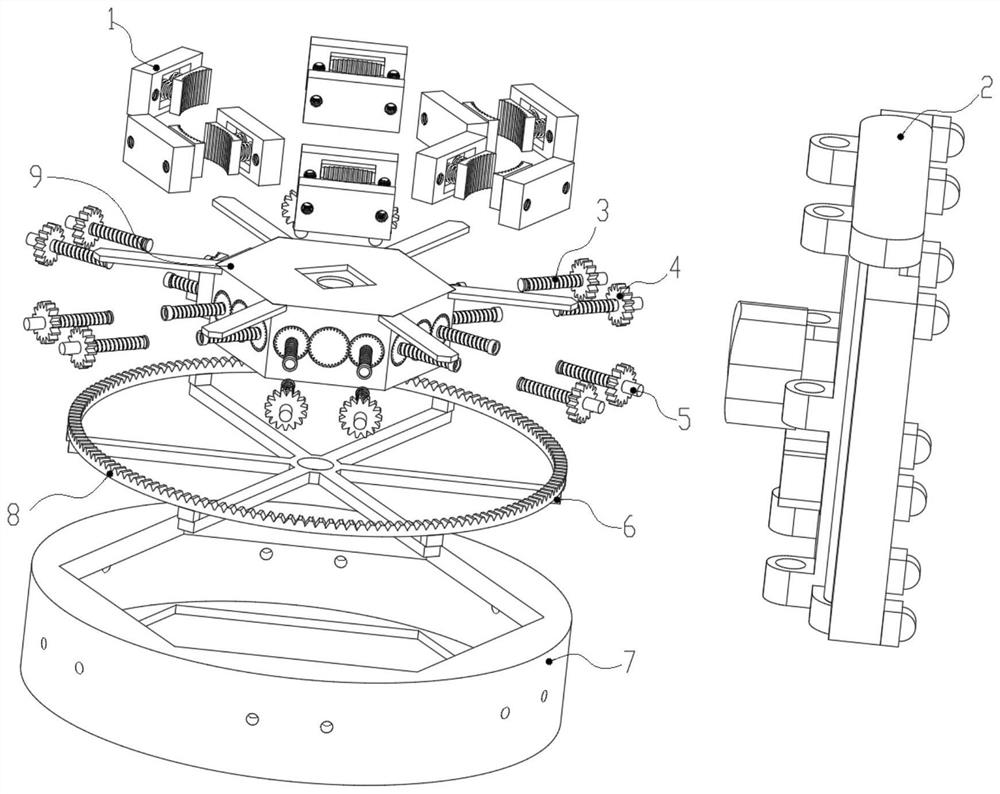

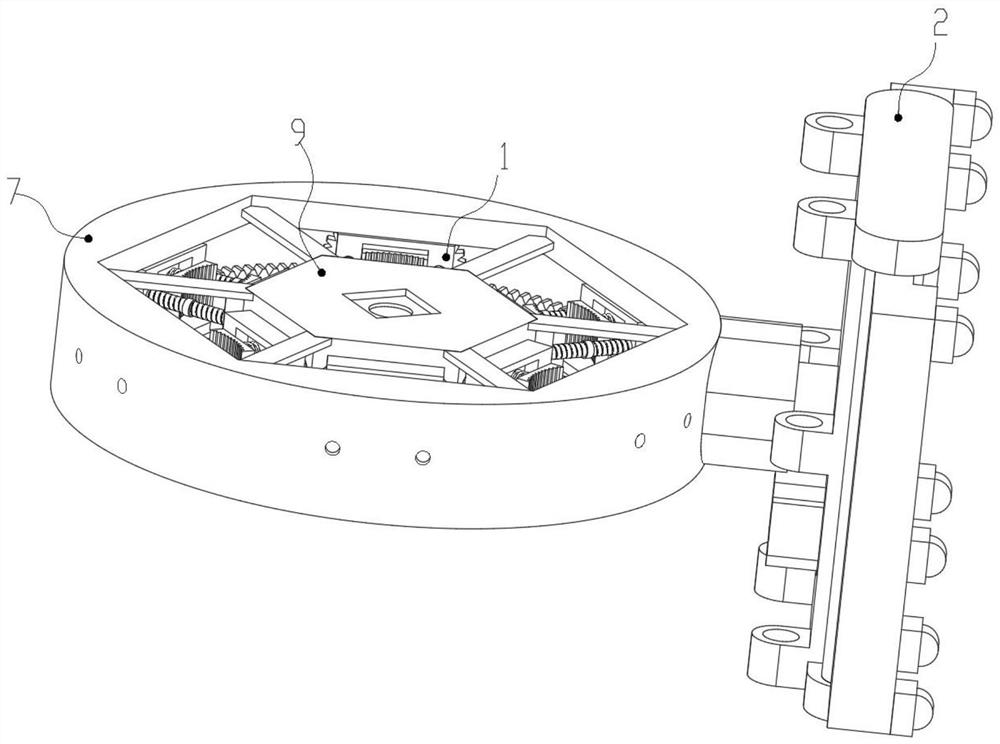

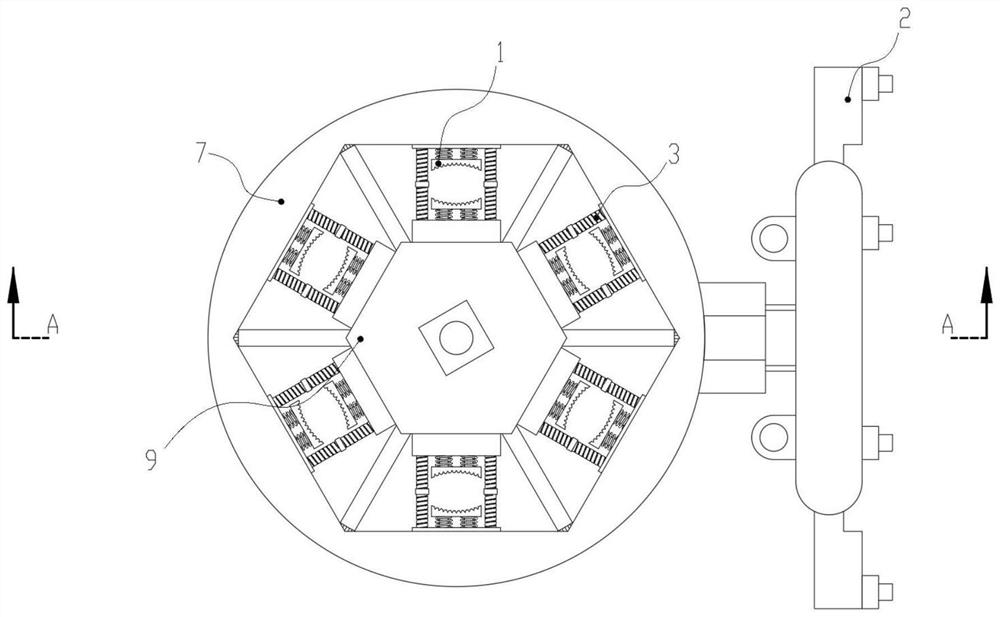

Mounting equipment for building outer wall water tube

PendingCN112503257AImprove efficiencyImprove adaptive performancePipe supportsRoof drainageWater pipeWater pressure

The invention discloses mounting equipment for a building outer wall water tube. The mounting equipment comprises limiting mechanisms, a positioning mechanism, a first threaded rod, a connecting gear,a limiting blocking shaft, a supporting frame, a connecting sleeve, a gear ring and an adjusting mechanism, wherein the outer end surface of the adjusting mechanism is fixedly connected to the connecting sleeve for supporting through a fixed plate. The adjusting mechanism is arranged, so that efficiency of pulling and positioning the outer water tube is effectively improved; the mounting equipment can be suitable for water tubes with different radiuses, and effectively improves adaptability; when the two groups of limiting mechanisms get close to each other for clamping the outer water tube,spring shafts can provide enough elastic force to clamping plates to buffer, so that damages to the water tube as a result of too great contact water pressure between the clamping plates and the watertube are prevented, and clamping stability and protection on the water tube is improved.

Owner:李强

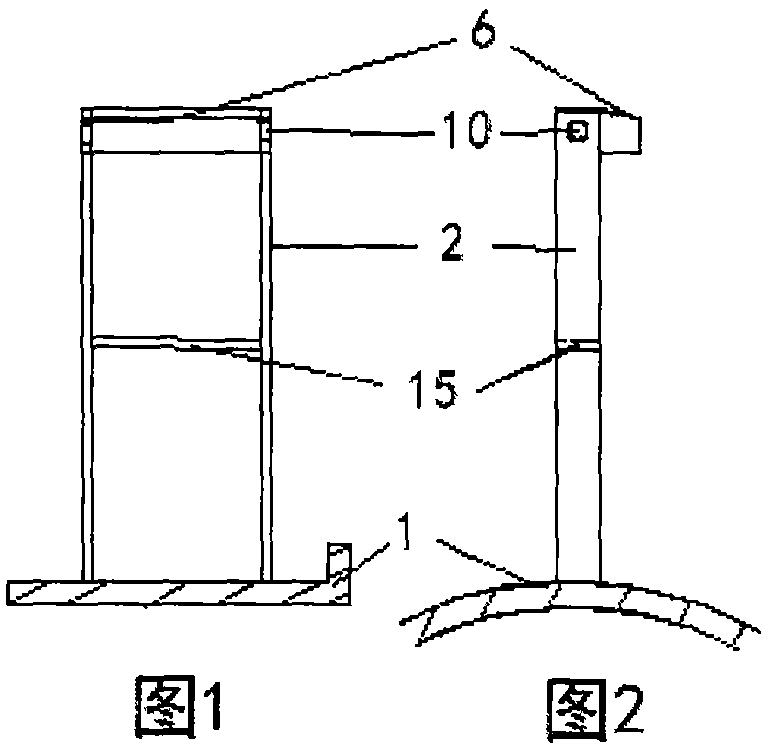

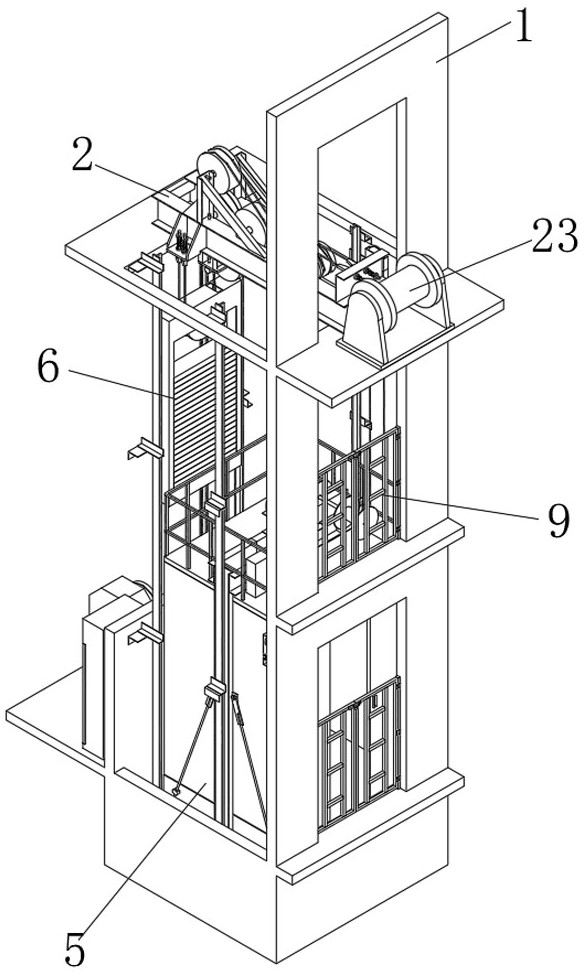

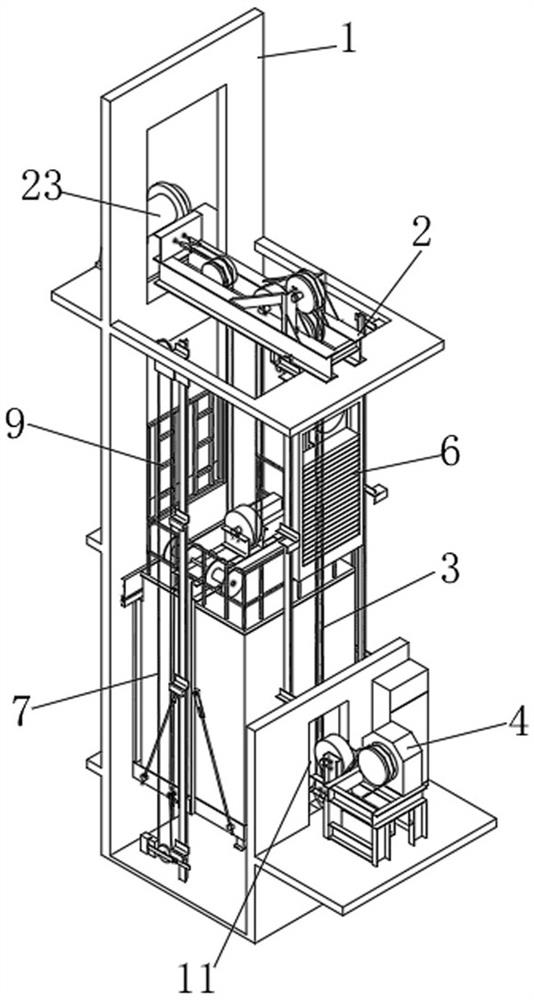

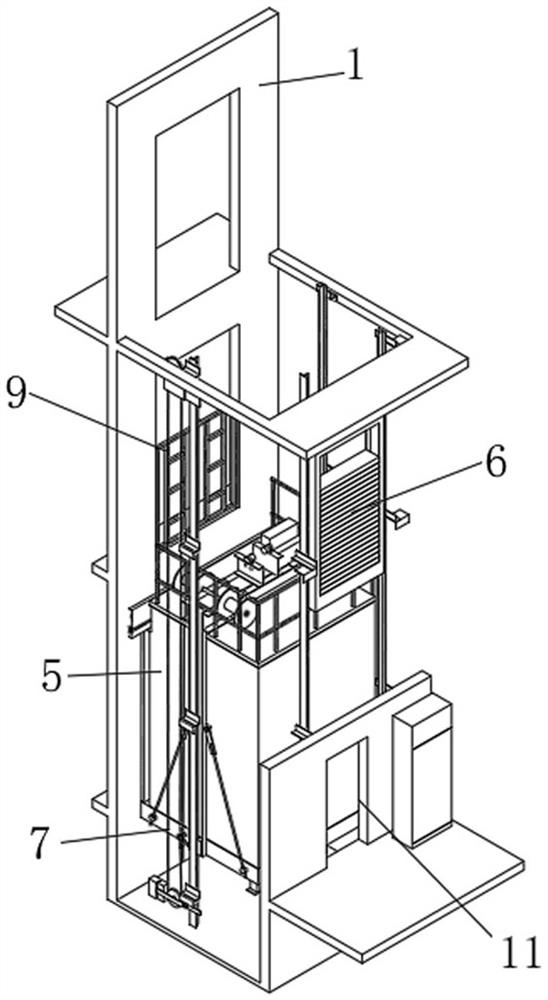

Hoistway elevator for construction

PendingCN112645181AIncreased traction capacityImprove traction efficiencyElevatorsBuilding liftsDrive wheelMachine

The invention discloses a hoistway elevator for construction. The hoistway elevator comprises a building hoistway, a sky beam, a traction medium, a traction machine, a cage and a counterweight; the sky beam is connected to the top end of the building hoistway, and the traction machine is connected to the lower portion of the building hoistway; and the sky beam is fixedly connected with a friction wheel and is rotatably connected with a second guide wheel, a third guide wheel, a fourth guide wheel and a fifth guide wheel, one end of the traction medium is connected to one end of the sky beam, and the traction medium sequentially bypasses the friction wheel, the cage, the second guide wheel, the third guide wheel, a driving wheel of the traction machine, the fourth guide wheel, the fifth guide wheel and the counterweight from the end until the other end of the traction medium is connected to the bottom face of the other end of the sky beam. According to the hoistway elevator for construction, the plurality of guide wheels and the traction medium are adopted to enable the cage to be located at a movable pulley, so that the traction capacity of the traction machine is doubled, the traction efficiency is improved, and the operation safety of the elevator is improved.

Owner:杭州百科新材料有限公司

Rubber-tired track mine car traction device with offset compensation function

ActiveCN105599782APrevent derailmentWide range of slope applicationsDraw-gearAutomotive engineeringAdhesion force

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

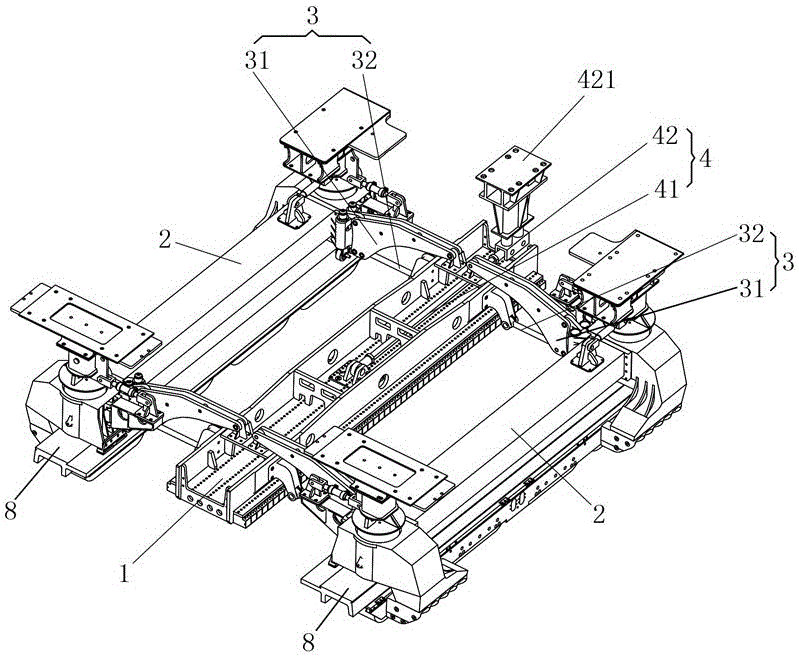

Bogie and railway vehicle

PendingCN114194241AReduce in quantityLose weightBogiesBogie-underframe connectionsBogieSuspension (vehicle)

The embodiment of the invention provides a bogie and a railway vehicle, and the bogie comprises a framework; the framework comprises two side beams extending in the longitudinal direction and a cross beam arranged between the two side beams. The wheel pairs are arranged below the two ends of the side beams; the wheel pair comprises an axle, wheels symmetrically arranged on the axle and an axle box. A traction device; the traction device comprises a first traction pin and a second traction pin which are rotationally connected, and the first traction pin is matched with the cross beam to transmit longitudinal force; the first traction pin and the second traction pin are respectively used for being connected with two adjacent carriages; the primary suspension device is arranged between the end part of the side beam and the axle box; and the secondary suspension device is arranged on the framework. The bogie and the railway vehicle provided by the embodiment of the invention are beneficial to reducing the self weight of the vehicle and improving the traction efficiency.

Owner:CRRC TANGSHAN CO LTD

Cable laying traction device and method for intelligent pipe gallery construction

PendingCN111431100AStable clampingEasy to operateApparatus for laying cablesStructural engineeringControl theory

The invention discloses a cable laying traction device and traction method for intelligent pipe gallery construction. A traction device relates to the technical field of cable laying and comprises a main bin body, a clamping mechanism, a moving mechanism and a pulling mechanism, the clamping mechanism comprises an upper plate, a lower plate, a clamping plate and a sliding rod, the sliding rod penetrates through the upper plate and is connected to the clamping plate to move vertically; a clamping spring is arranged between the upper plate and the clamping plate; and a cable penetrating throughthe main bin body is clamped by means of elastic force; the moving mechanism is arranged on the outer side of the main bin body and drives the whole device to move through rollers of the moving mechanism; and the damping assembly is arranged, so that moving is more stable; a pull rod of the pulling mechanism is connected with a sliding rod; clamping operation of operators is facilitated; a pull handle of the pulling mechanism is connected with the main bin body; and traction operation of the operators is facilitated in cooperation with the moving mechanism. According to the invention, batch cable traction can be realized, and the cable can be conveniently and stably pulled to a required position.

Owner:CHINA MCC17 GRP

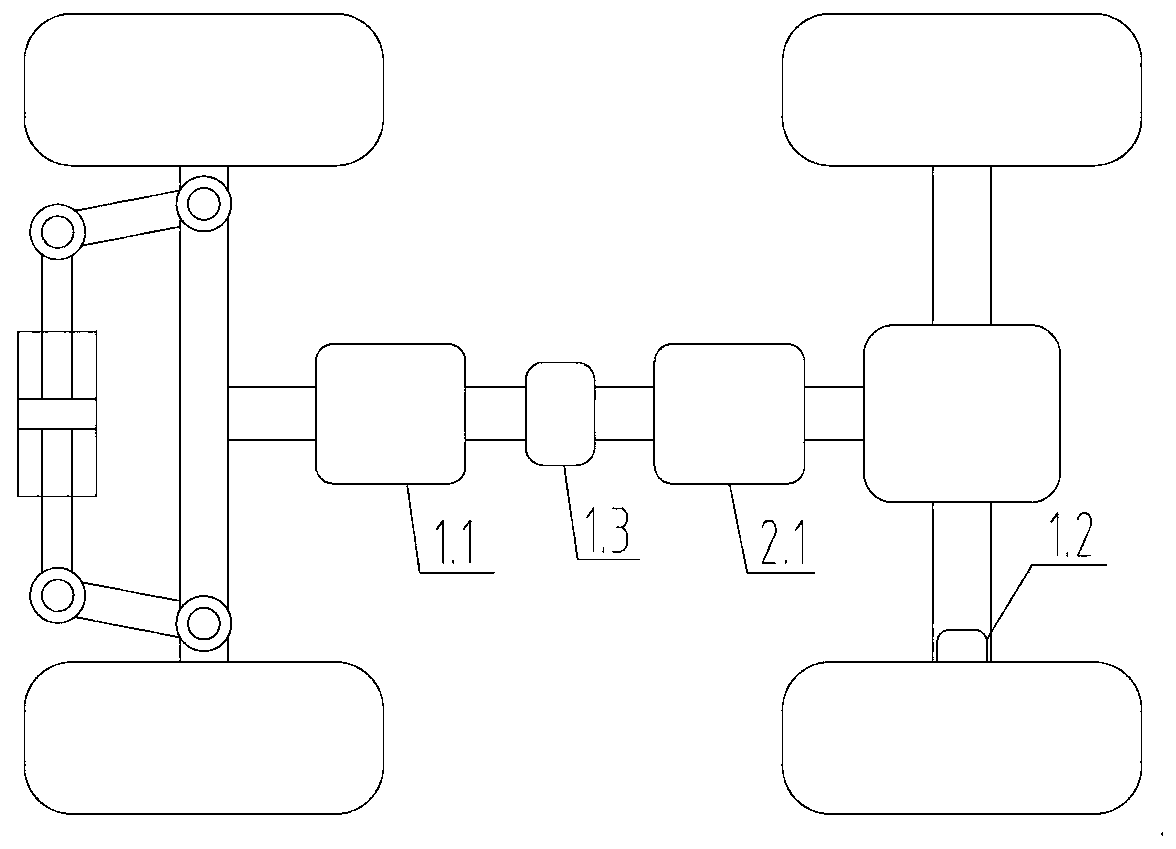

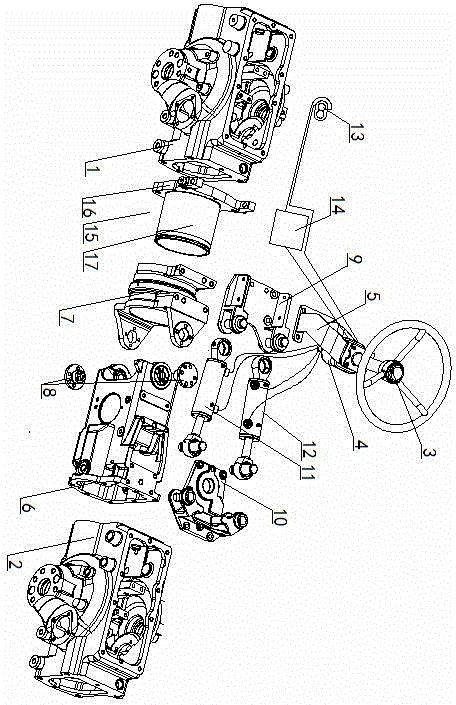

Articulated steering mechanism for use on tractor

PendingCN106741162ACompact structureIngenious designFluid steeringSteering for vehicles in tandemSteering wheelGreenhouse

The invention discloses an articulated steering mechanism for use on a tractor; the articulated steering mechanism comprises a front transmission box (1), a rear transmission box (2) and a steering wheel (3); a steering mechanism connected with the front transmission box (1) and the rear transmission box (2) is arranged between the front transmission box (1) and the rear transmission box (2), and a steering push mechanism connected with the steering mechanism is disposed on the upper end face of the steering mechanism; the steering wheel (3) is connected with the upper end face of one end of the steering push mechanism through a hydraulic steering gear (4) and a steering wheel mount (5), and the steering push mechanism is connected with a hydraulic system through the hydraulic steering gear (4). The articulated steering mechanism has the advantages of compact structure, ingenious design, and good reliability of use, may be used to provide small steering radius, good steering flexibility and good maneuverability for a tractor, and is effective to operate in hilly areas, vegetable greenhouses and orchards.

Owner:CHONGQING ZONGSHEN GENERAL POWER MACHINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com