Simple aluminum section traction system

A traction system and aluminum profile technology, applied in the field of aluminum profile processing and production, can solve the problems of large size, large space occupation, and high energy consumption in operation, and achieve the effect of small and compact volume, small footprint, and high traction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

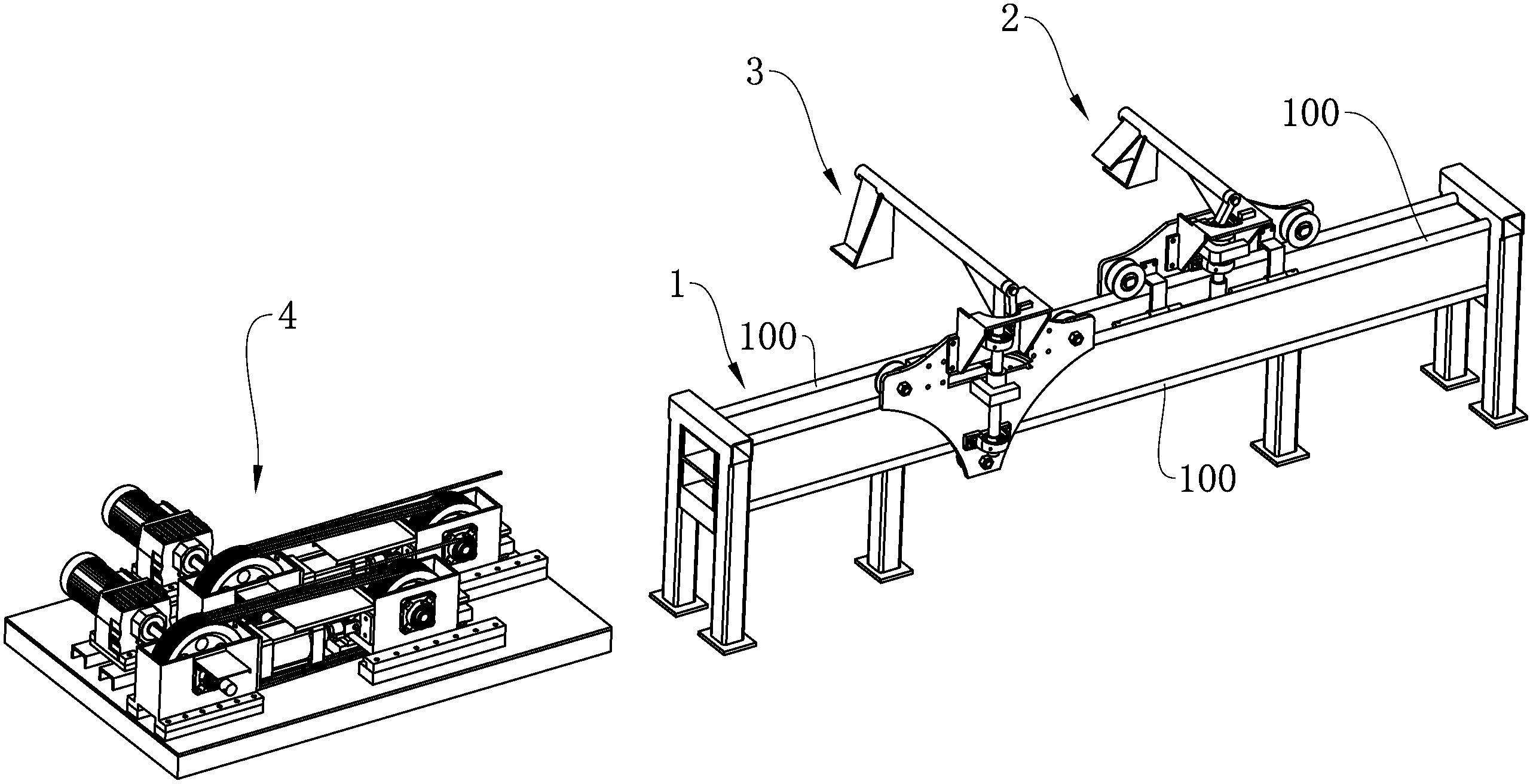

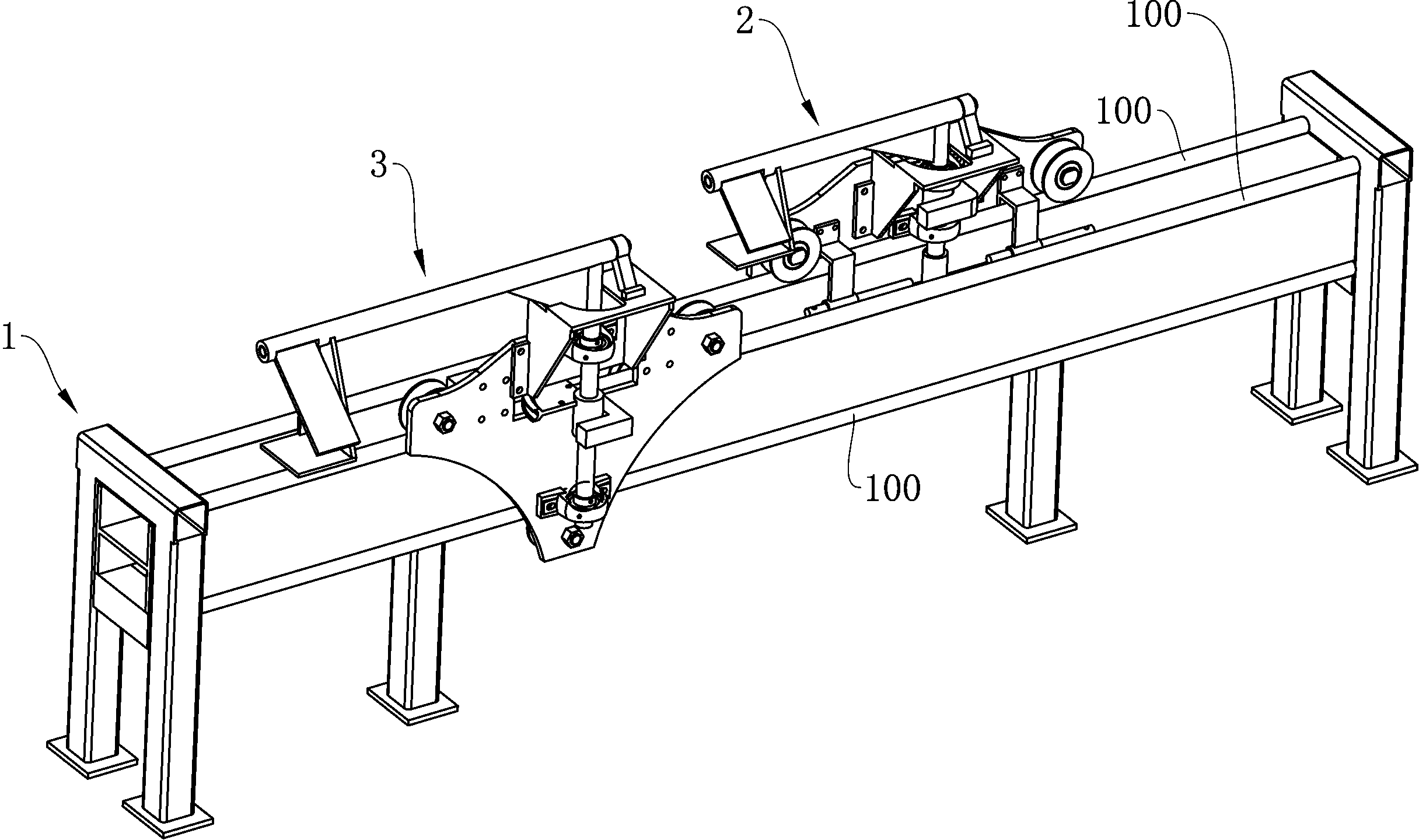

[0020] Such as figure 1 , figure 2 As shown, a simple aluminum profile traction system according to the present invention includes a frame 1, a first traction head device 2, a second traction head device 3 and a traction drive device 4, wherein

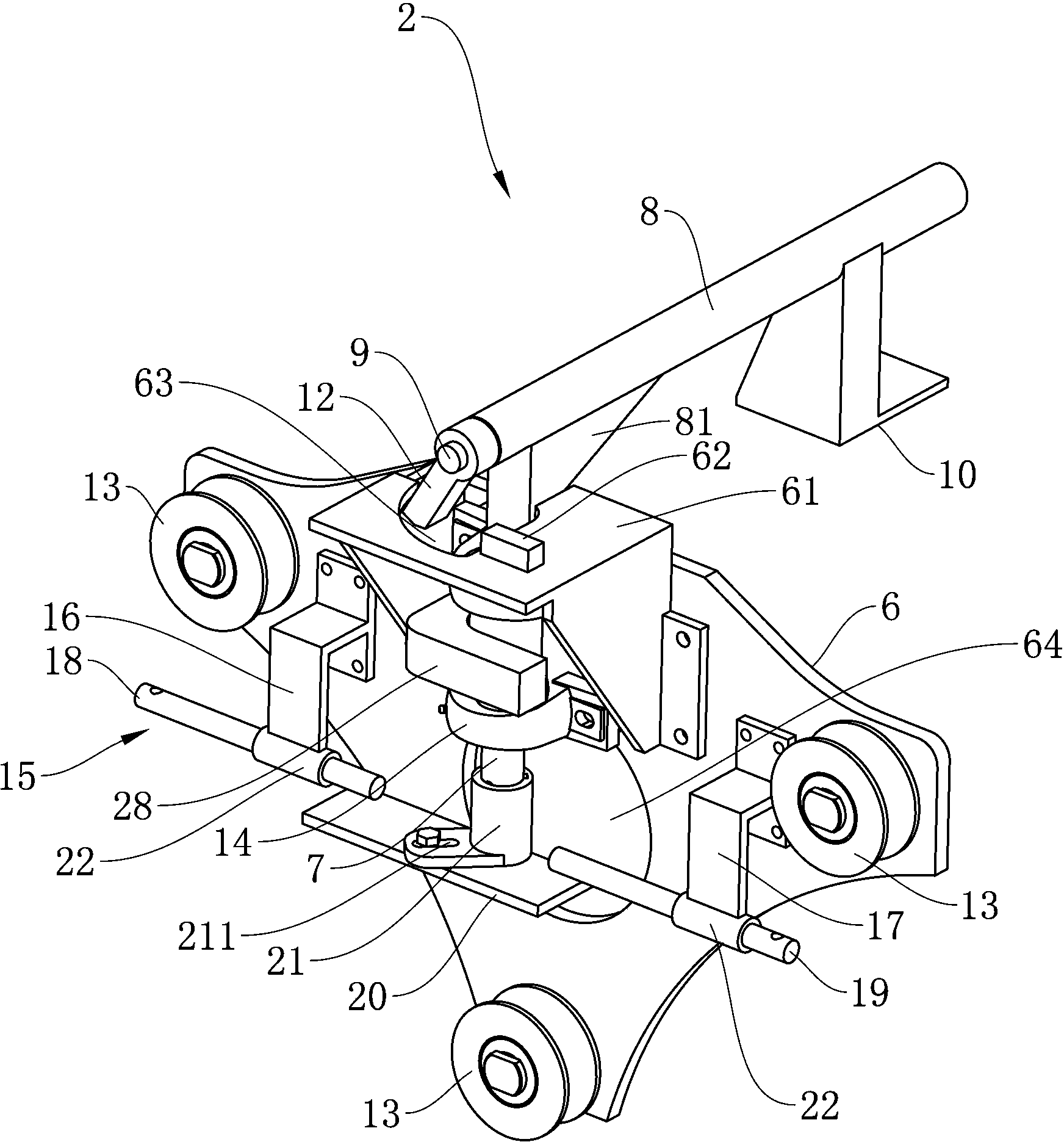

[0021] Such as Figure 3 to Figure 7 As shown, the first pulling head device 2 and the second pulling head device 3 respectively include a vertical plate 6, a vertical shaft 7, a swing arm 8, a rotating shaft 9, a material holder 10, a material clamping block 11 and a shifting block 12, wherein The side surface of vertical plate 6 is provided with slide rail wheel 13, and described first traction head device 2 and second traction head device 3 are respectively installed on the guide rail 100 that makes on frame 1 by slide rail wheel 13, and this first A traction head device 2 and a second traction head device 3 are respectively connected in drive with the traction drive device 4 through steel cables 5 .

[0022] Described vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com