Model prediction control method of hub hydraulic motor auxiliary drive system

A technology of model predictive control and hydraulic motor, applied in the direction of control devices, etc., can solve the problems of ignoring the time-varying characteristics of system efficiency, unable to guarantee system adaptive control, and poor control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0161] specific implementation plan

[0162] The present invention is described in detail below in conjunction with accompanying drawing:

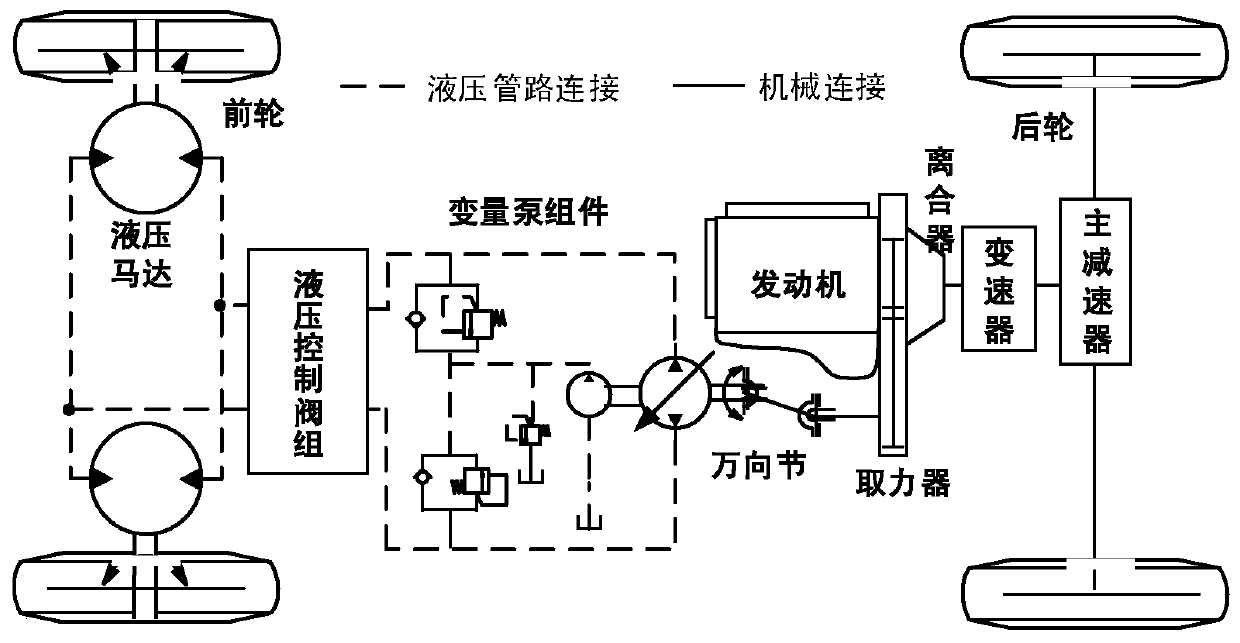

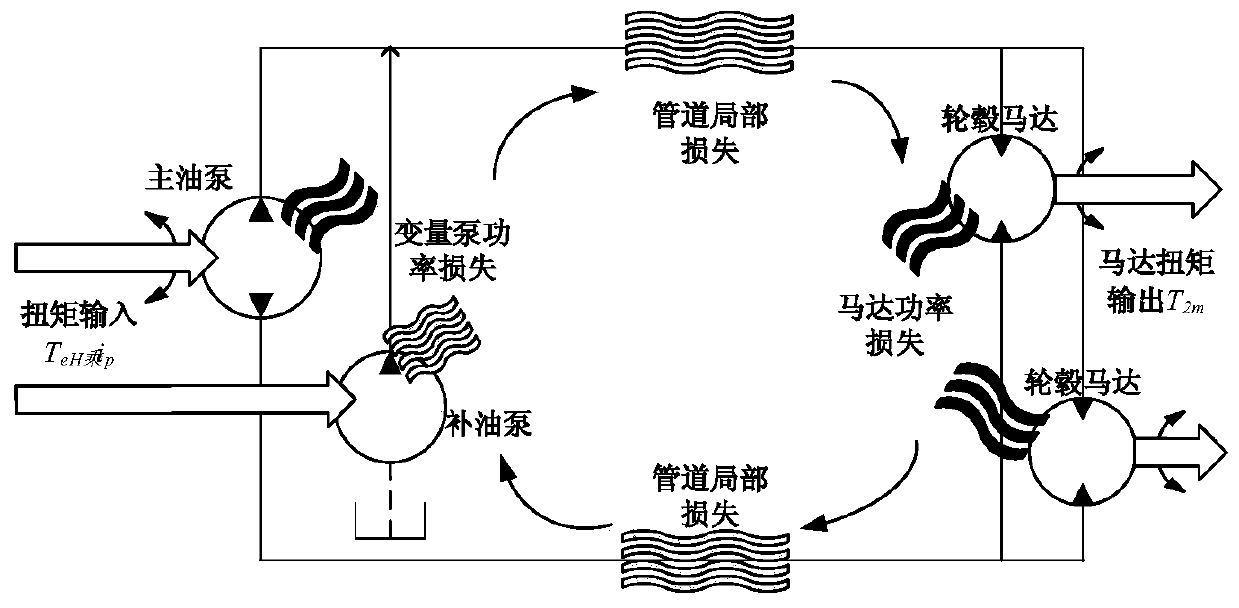

[0163] The invention discloses a model predictive control method for a wheel hub hydraulic motor auxiliary drive system. The control target is to quickly follow the wheel speed and reduce the system impact, and consider the power loss of the hydraulic system. According to the time-varying characteristics of the system state, a dynamic model of the vehicle transmission system is established, and the feedback control law is derived by controlling the engine torque and the variable pump opening value, and the design of the model predictive controller based on the time-varying efficiency is completed, and the wheel hub is improved. The self-adaptive capability of the hydraulic motor auxiliary drive system ensures the best traction performance of the vehicle.

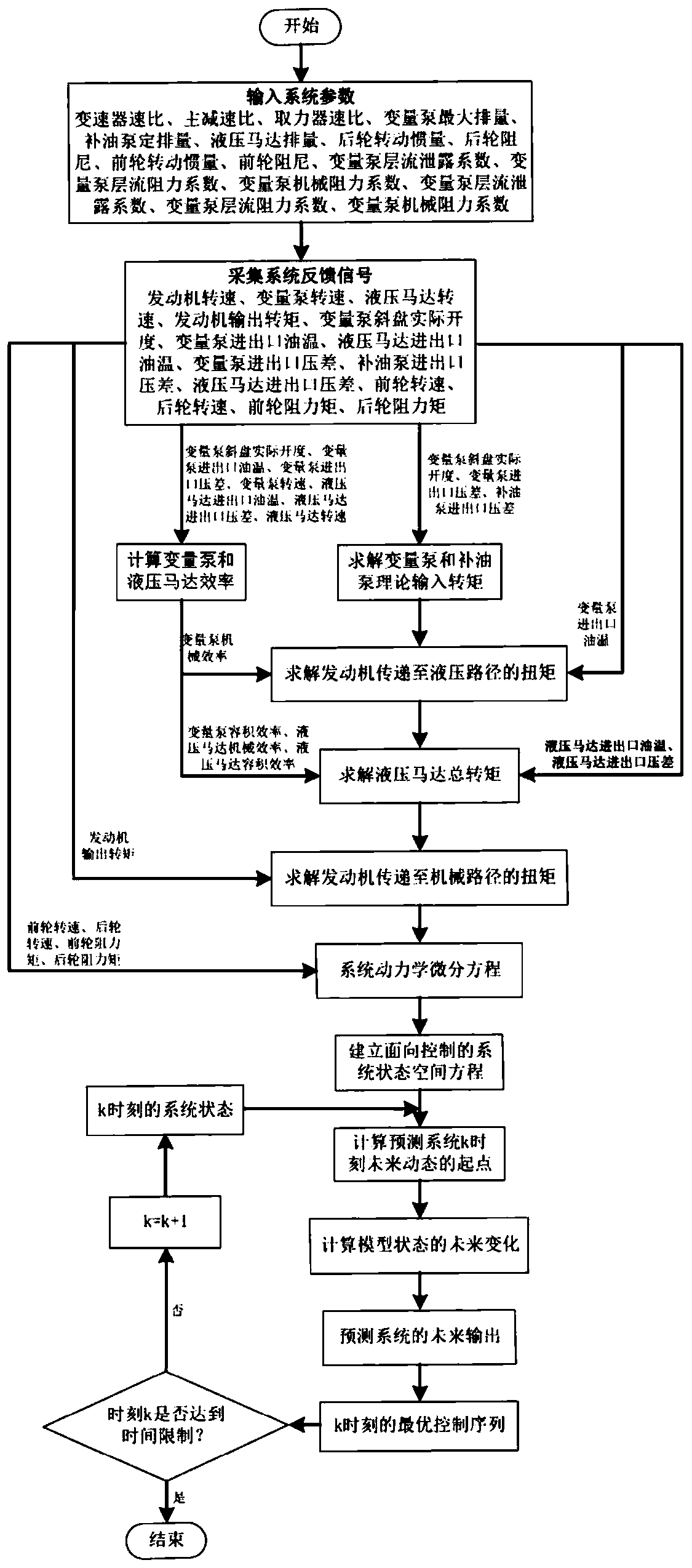

[0164] see figure 1 , the model predictive control method of a hub hydraulic motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com