Framework-free type levitation chassis with traction linear motor arranged in center and magnetically levitated train

A technology for maglev trains and linear motors, which is applied in electric traction, electric vehicles, vehicle components, etc., can solve the problems of reducing the overall traction capacity of maglev vehicles, affecting the traction capacity of linear motors, and reducing the efficiency of linear motors, and achieves reliable dynamic assistance. Support, prevent collision track, reduce the effect of yaw angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

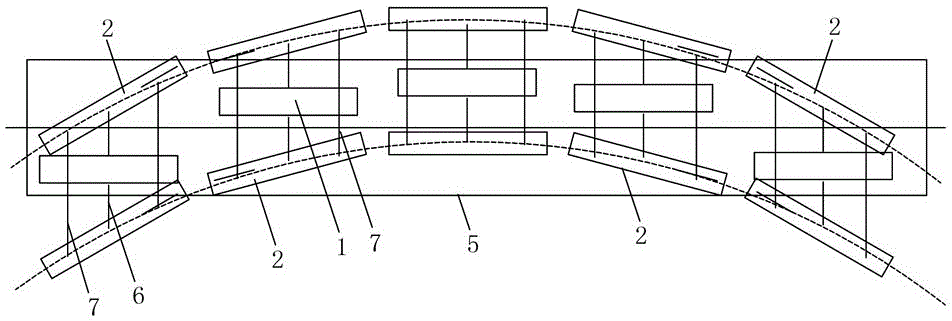

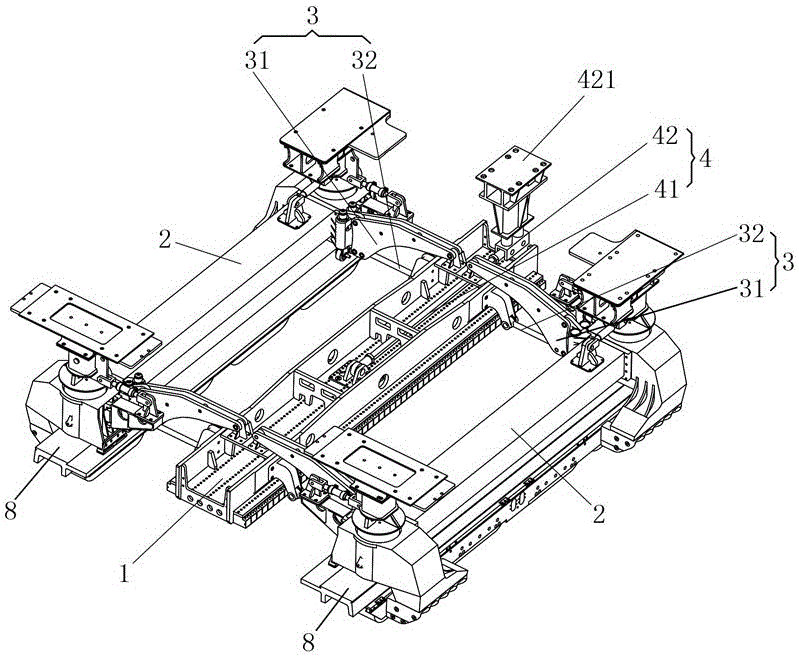

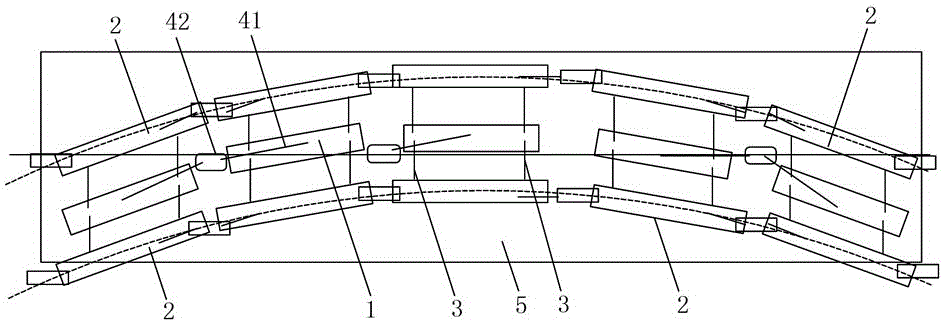

[0025] figure 2 It shows an embodiment of a suspension frame with a frameless traction linear motor in the middle of the present invention, including a traction linear motor 1 and a pair of suspension modules 2, and the traction linear motor 1 is arranged in parallel between the pair of suspension modules 2 , both sides of the traction linear motor 1 are provided with at least two sets of anti-roll decoupling mechanisms 3, the anti-roll decoupling mechanisms 3 are arranged longitudinally along the traction linear motor 1, and the anti-roll decoupling mechanisms 3 include two oppositely arranged anti-roll beams 31 and an anti-roll rod 32, the two ends of the anti-roll beam 31 are respectively hinged on the traction linear motor 1 and the suspension module 2, one end of the anti-roll rod 32 is hinged between the two anti-roll beams 31,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com