Patents

Literature

49results about How to "Simple fixture structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

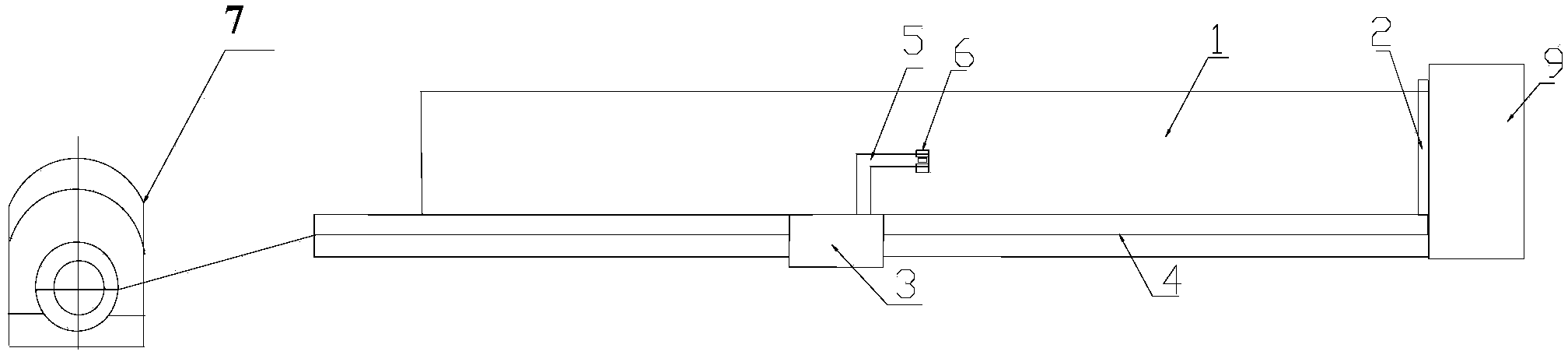

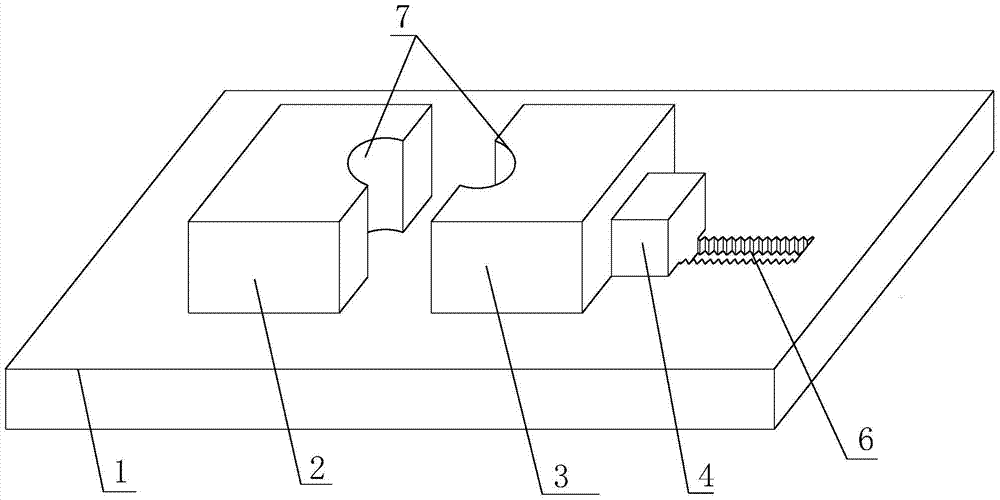

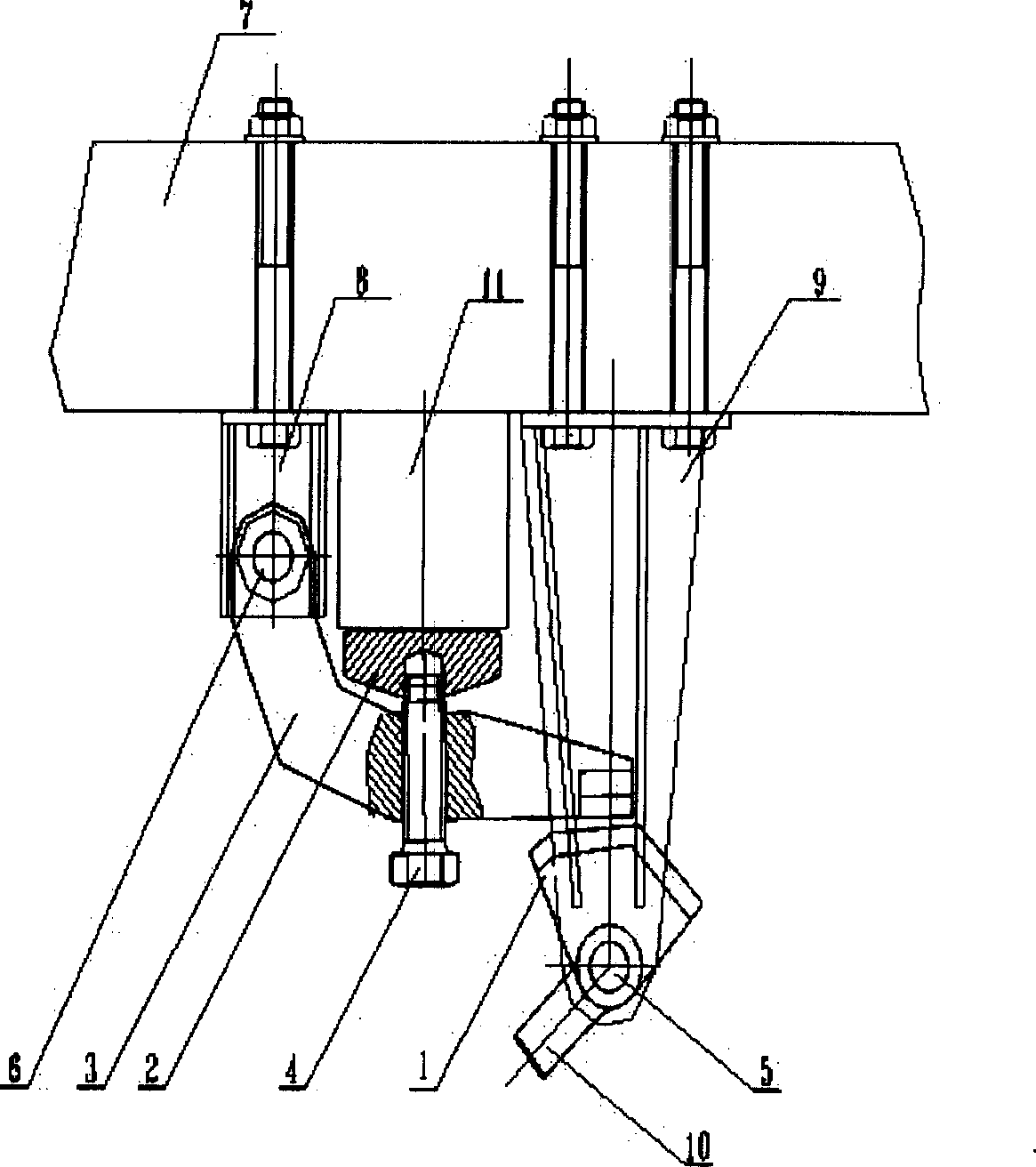

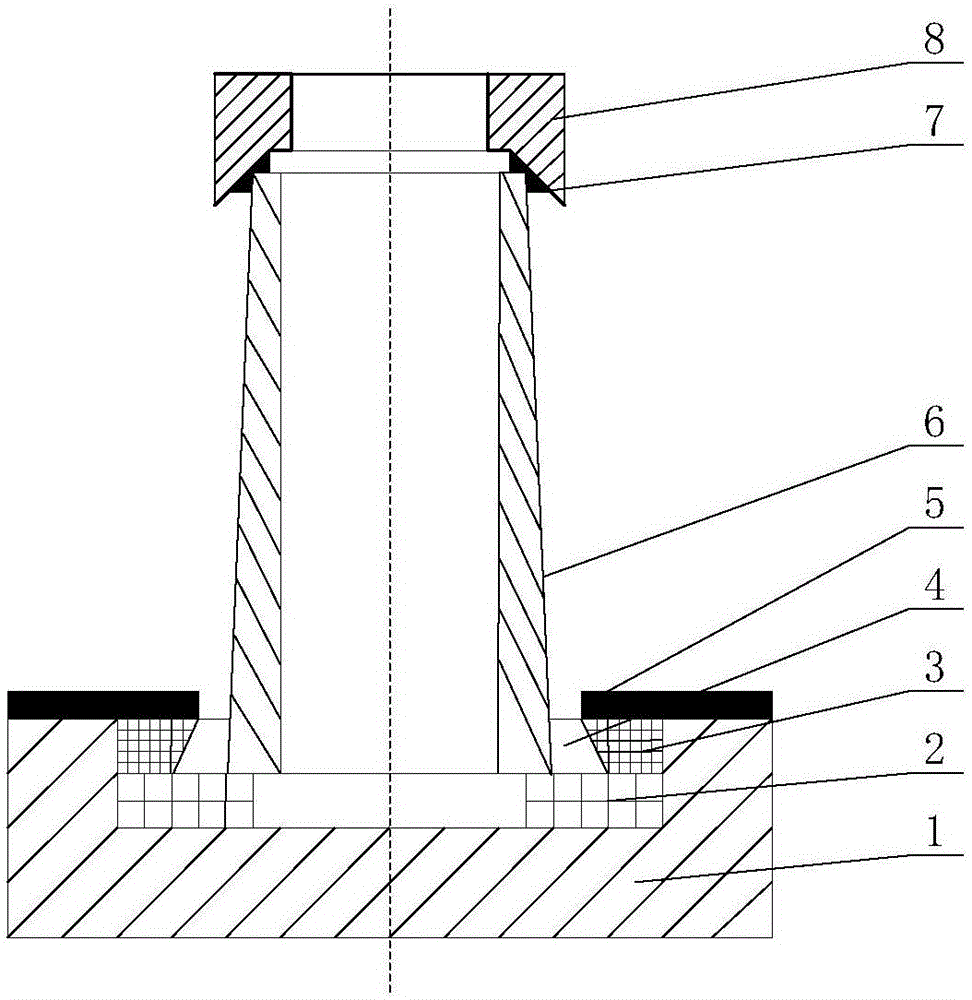

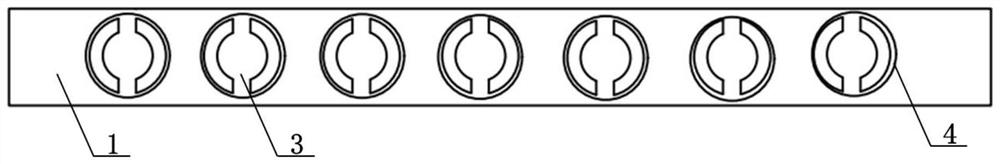

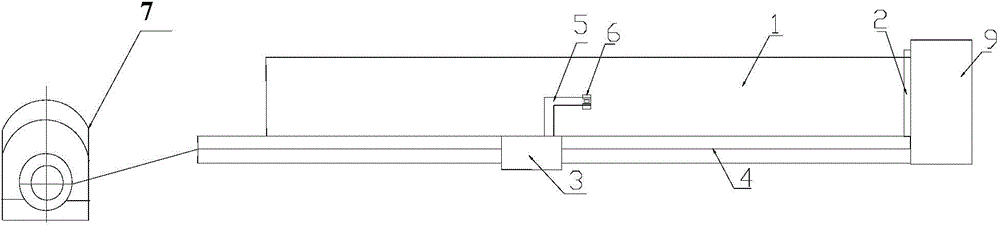

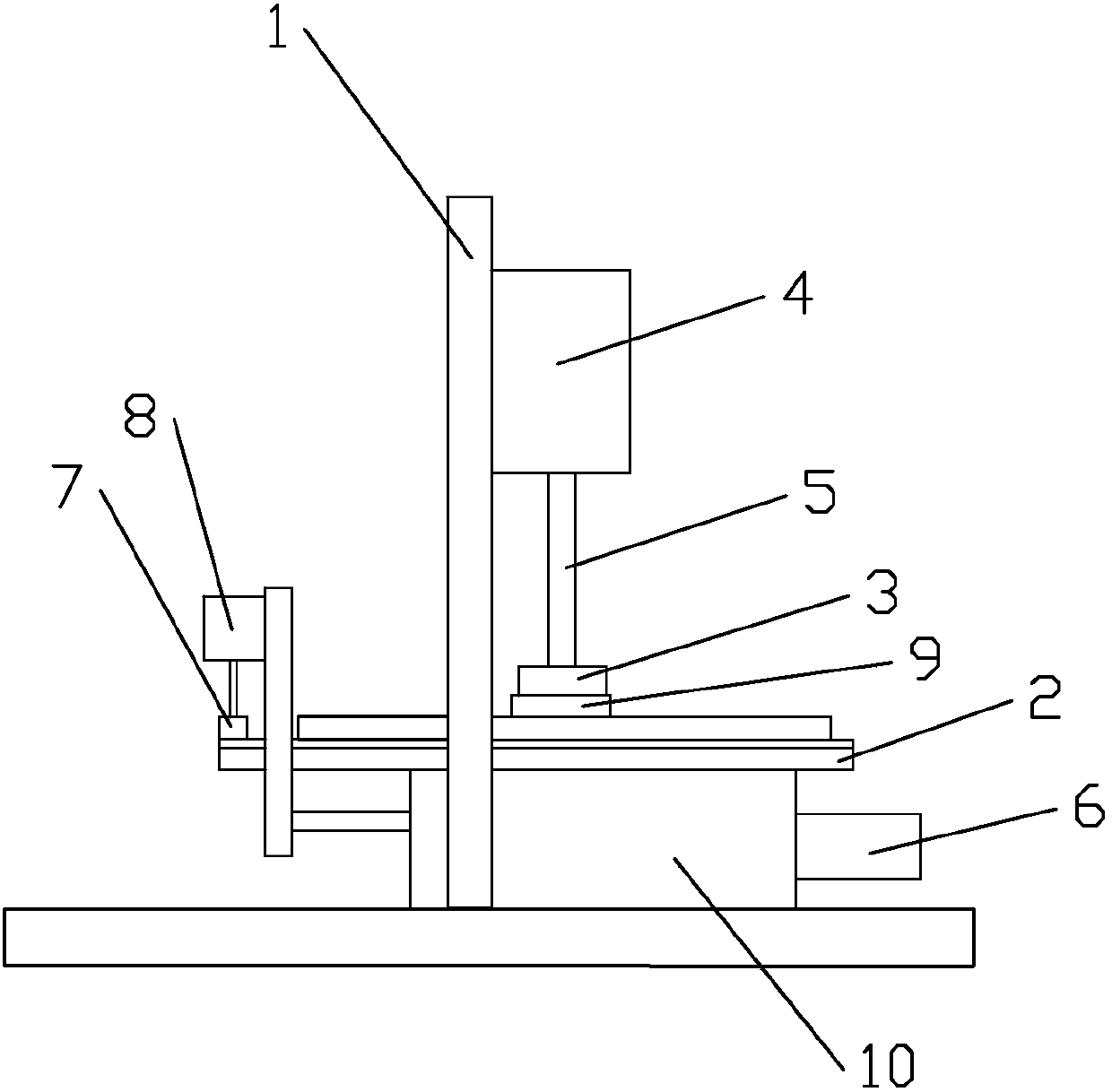

Clamp for processing a plurality of slender holes on workpiece and processing method thereof

InactiveCN101596684ALess investment in equipmentSimple fixture structureMilling equipment detailsPositioning apparatusProduct processingEngineering

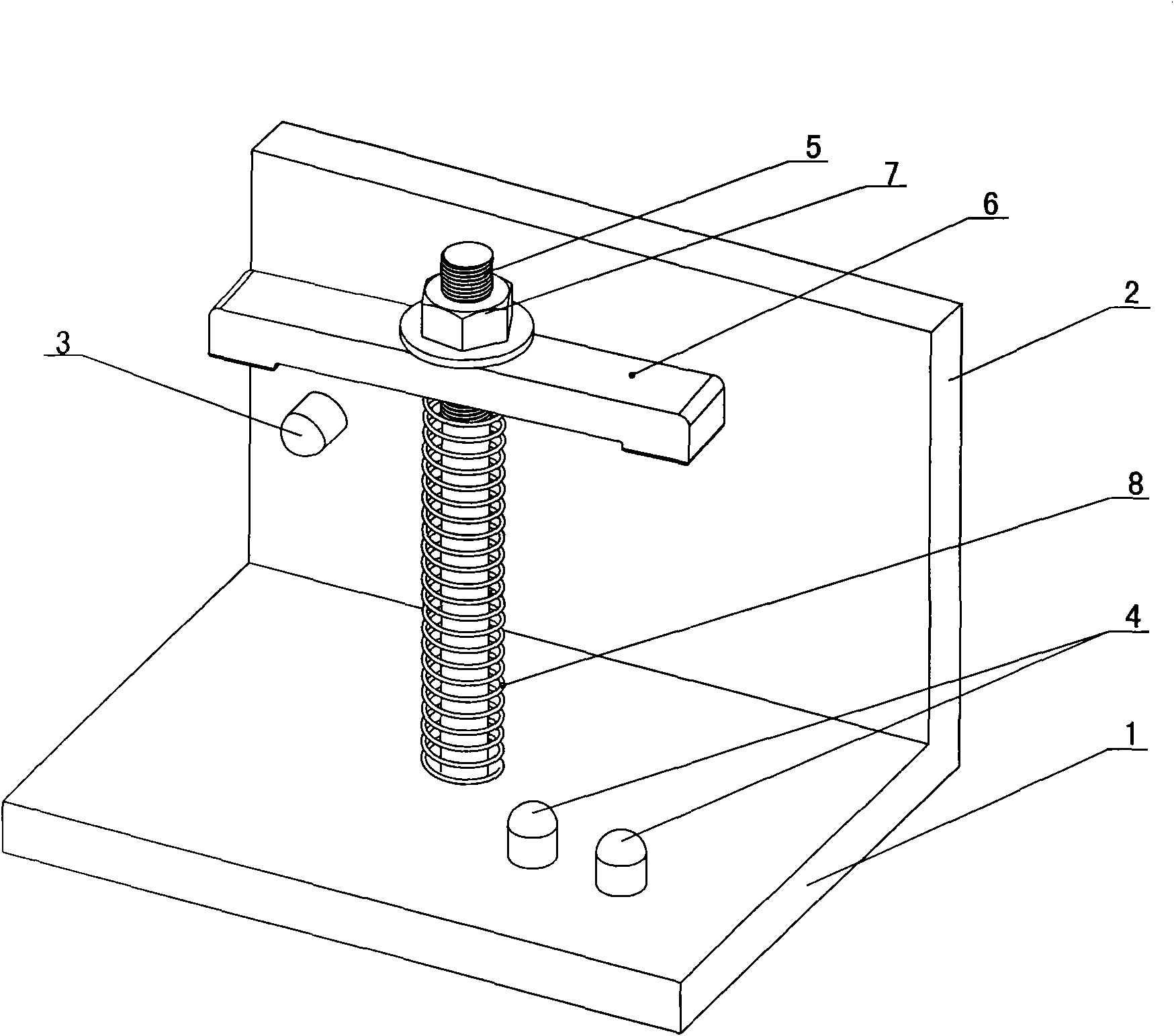

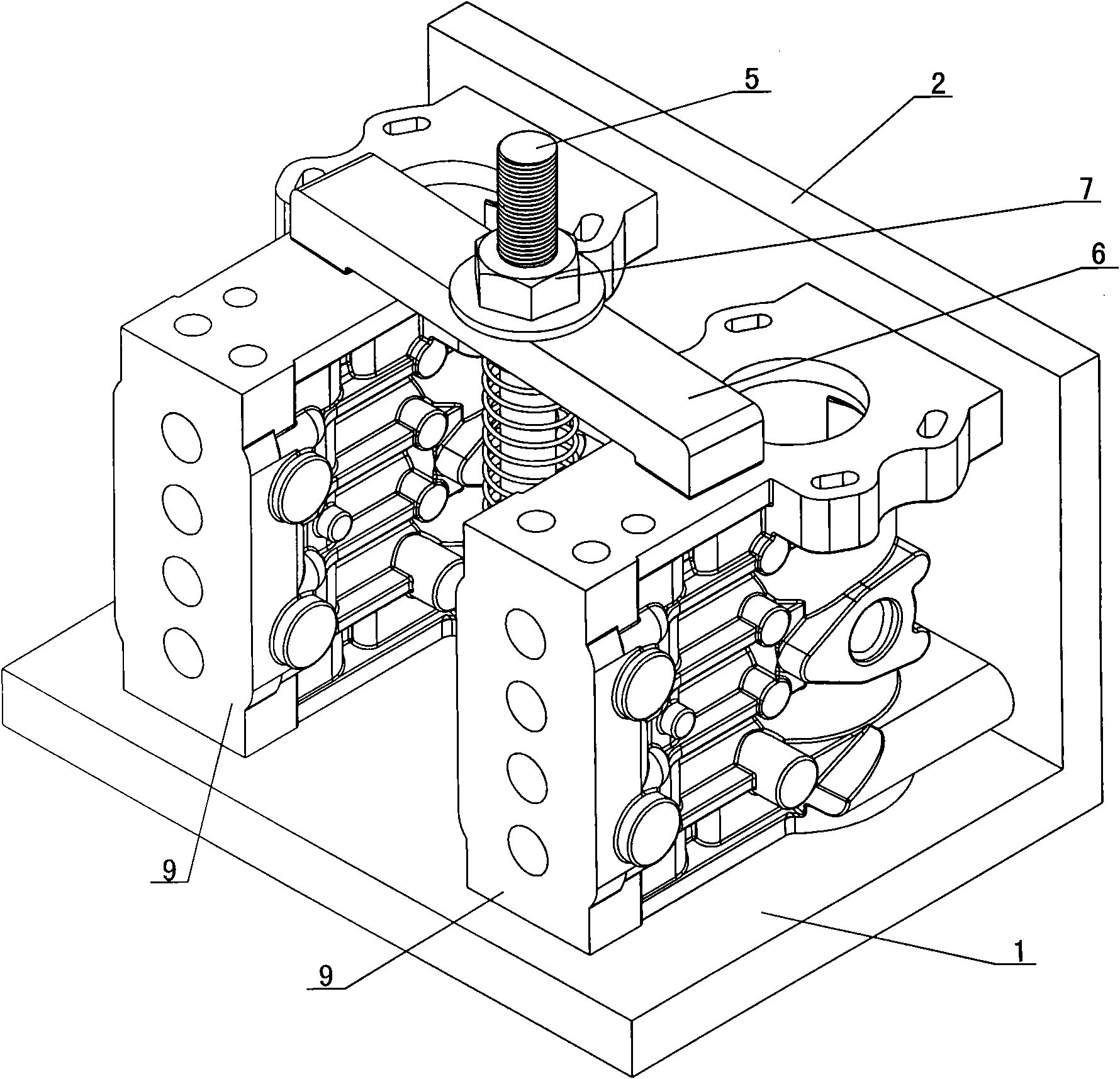

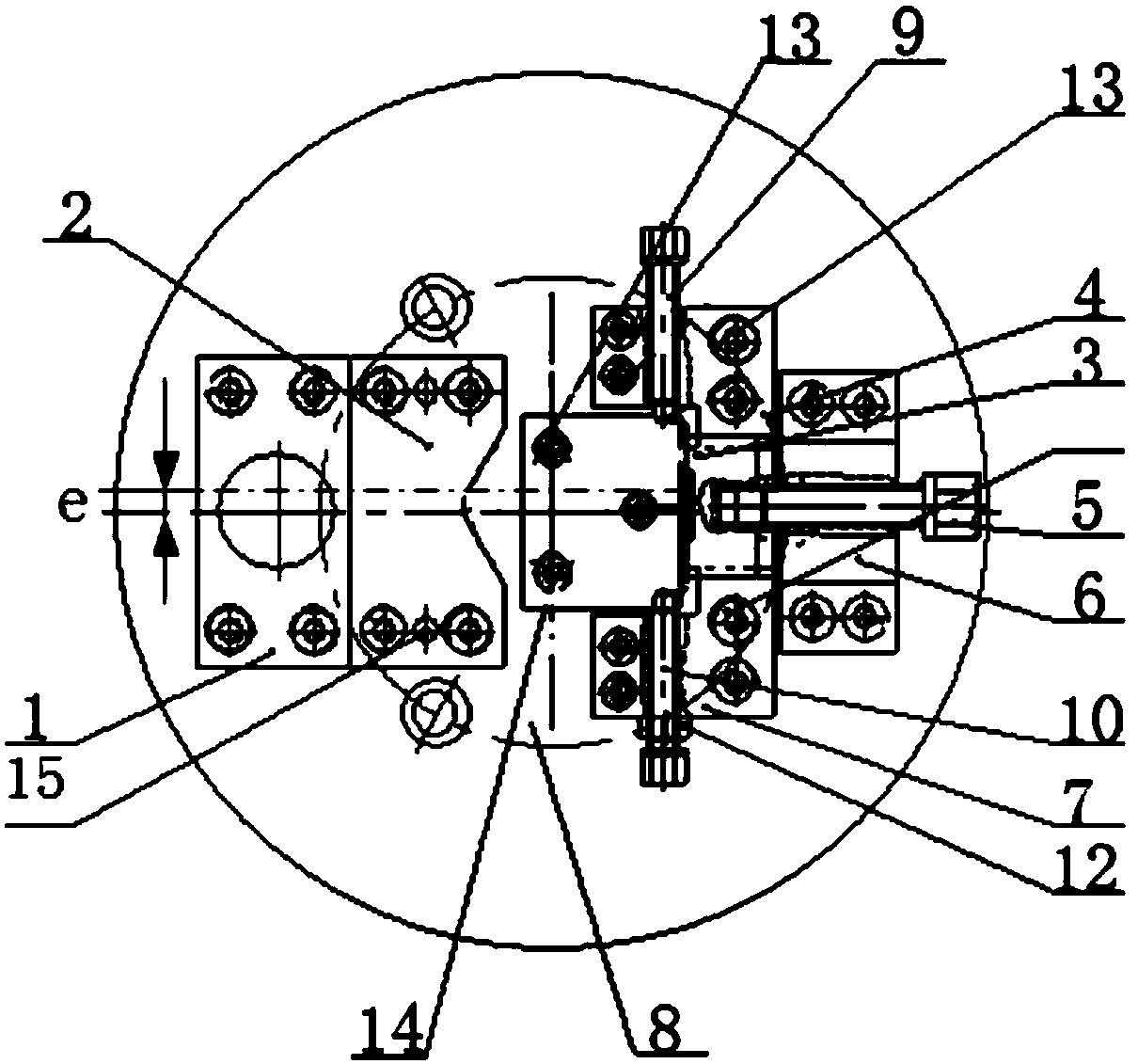

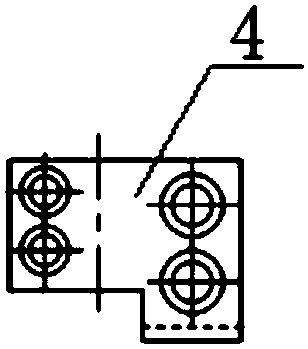

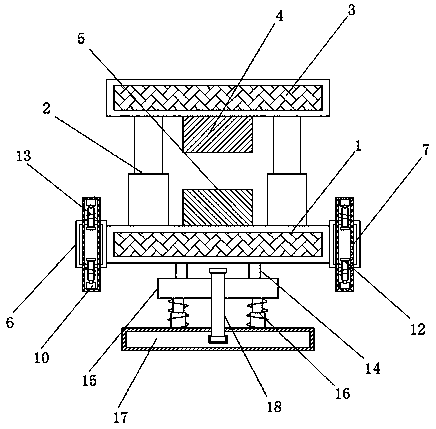

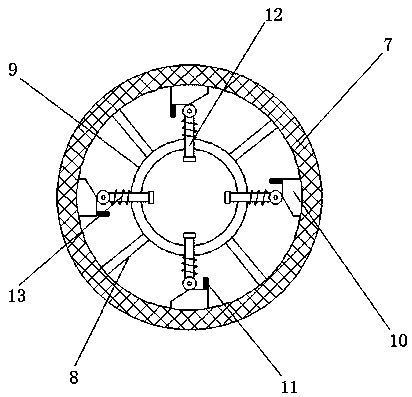

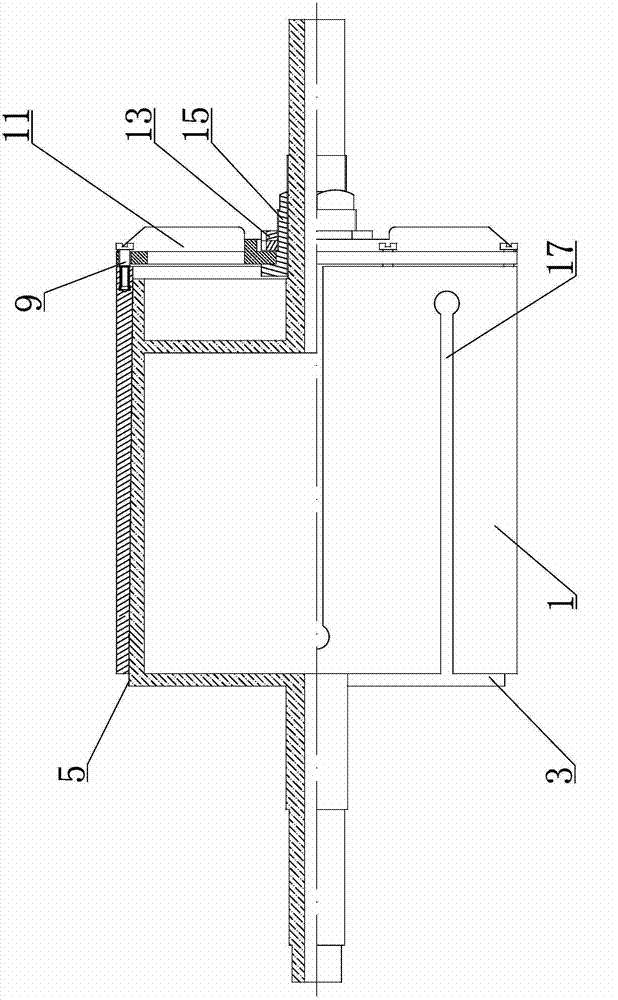

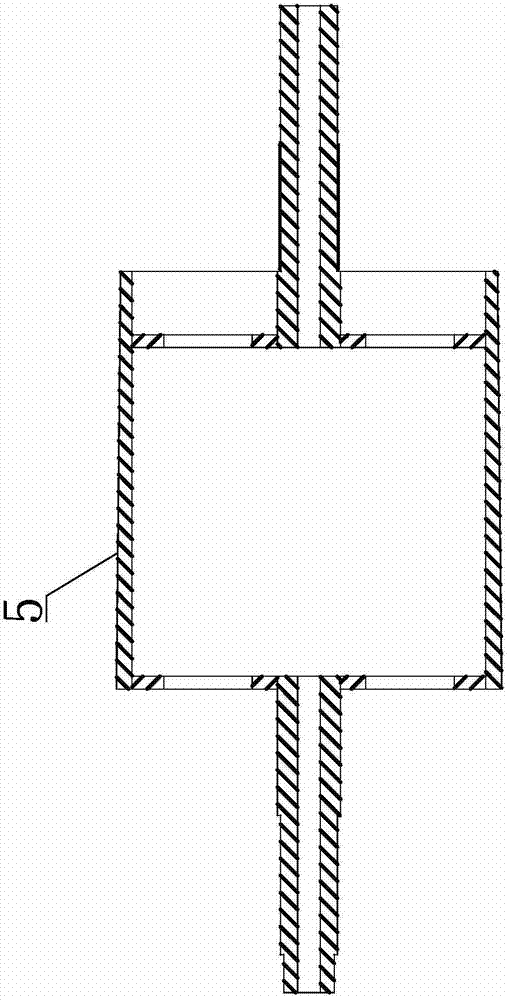

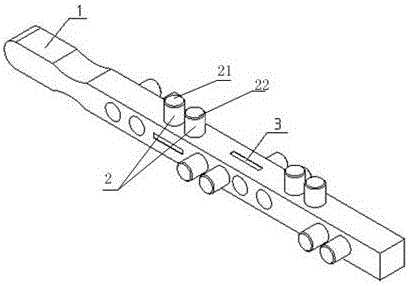

The invention relates to a clamp for processing a plurality of slender holes on a workpiece, belonging to machining technical field. A bottom plate (1) and a side plate (2) are in L-shaped; a stud bolt (5) is fixedly arranged in the middle of the bottom plate (1), and a spring (8) is sheathed on the stud bolt (5); the upper part of the stud bolt (5) is respectively provided with a pressure plate (6) and a nut (7); a guide pin (4) is arranged on one side of the stud bolt (5) on the bottom plate (1), and a positioning pin (3) is arranged on one side of the side plate (2). The invention fixes a workpiece by the simple clamp. Processing carried out on the existing high-cost horizontal processing center is changed for processing carried out on low-cost digital-control milling machines or vertical processing center, which reduces equipment investment. The clamp of the invention has simple structure and short production cycle, and therefore, the clamp of the invention is suitable for product processing with small lot, wide varieties and short development cycle. The invention has the advantages of reasonable design, simple method and the like.

Owner:洛阳古城机械有限公司

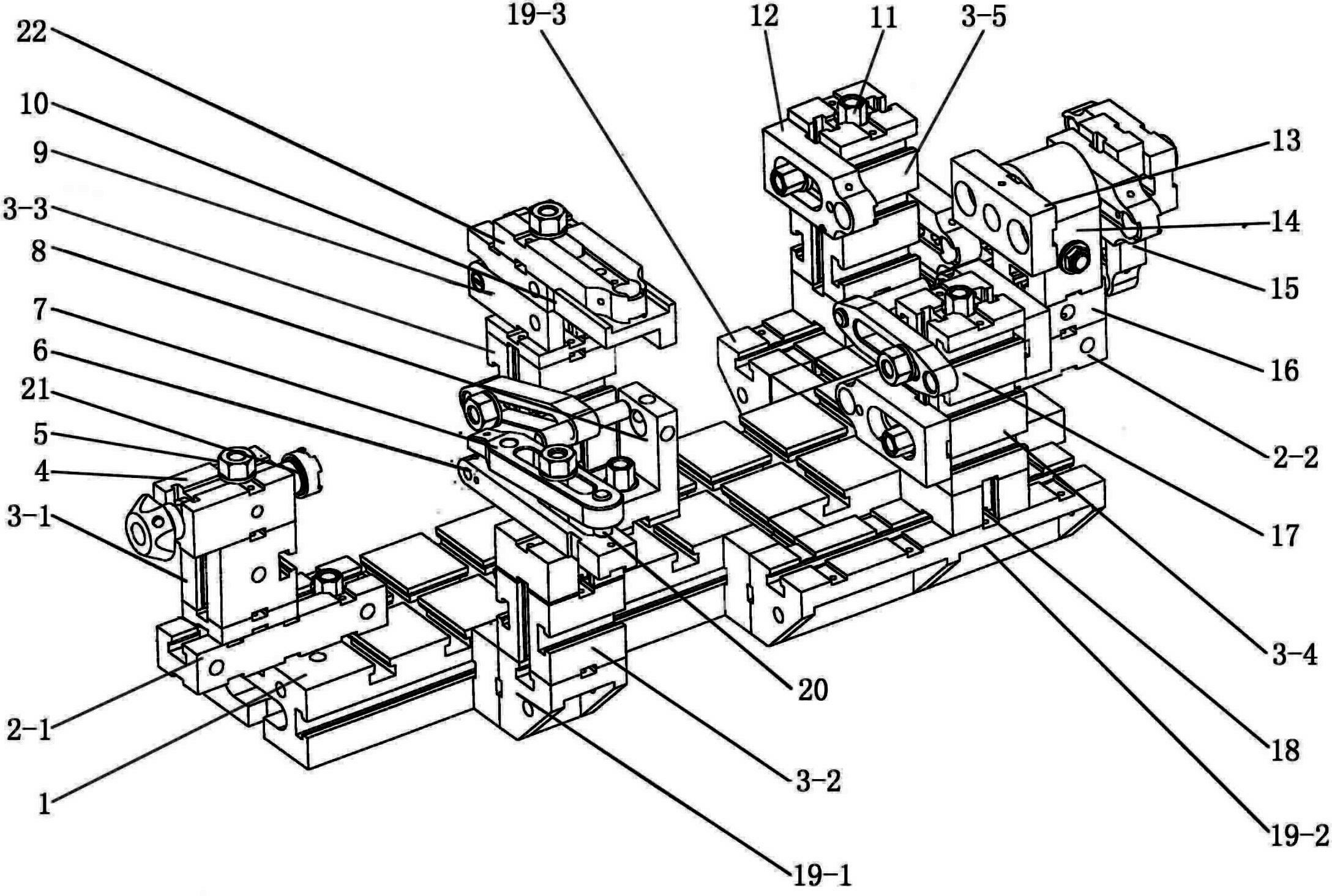

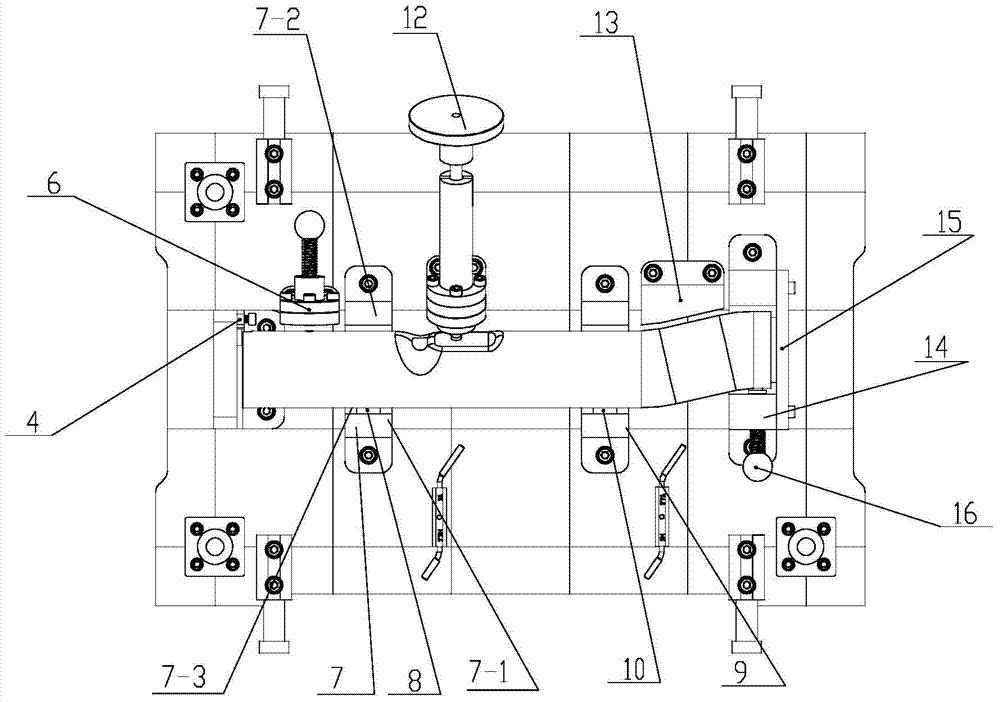

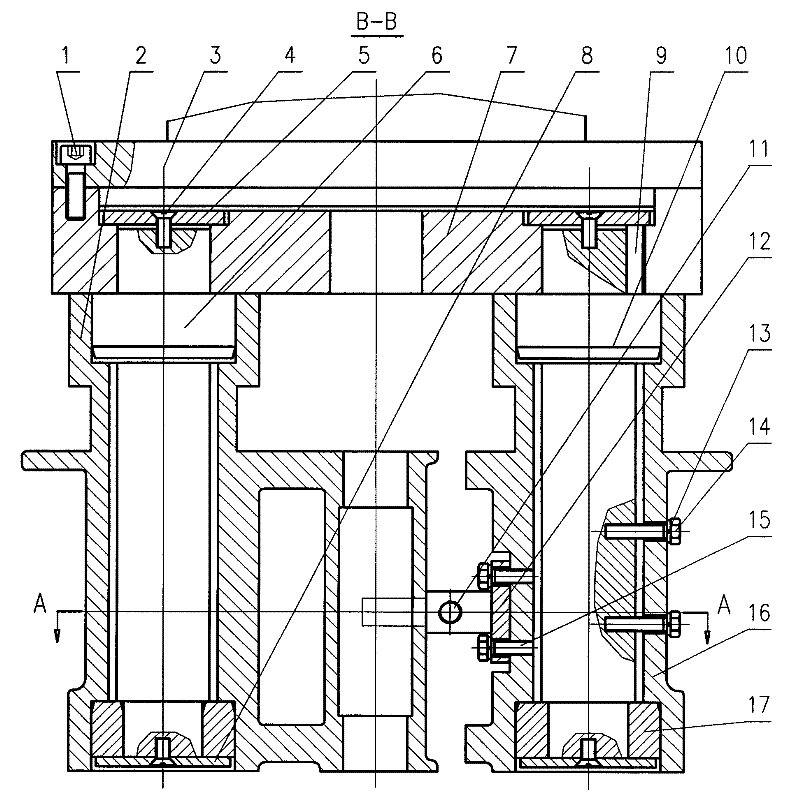

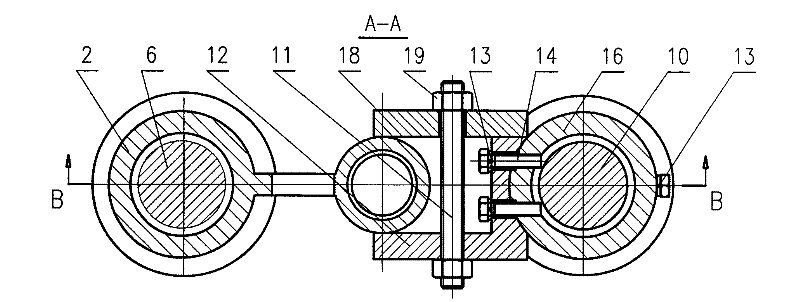

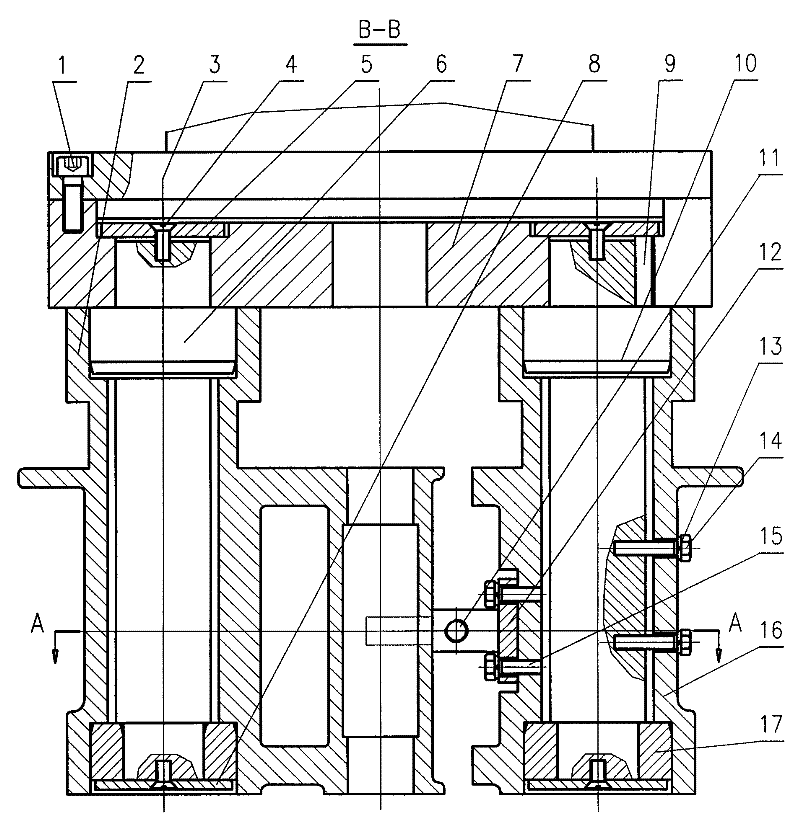

Combined clamp for drilling hole of torque tube assembling unit product

ActiveCN102689200ATechnical Requirements for Realizing DrillingTo achieve a multi-purpose functionPositioning apparatusMetal-working holdersPosition angleComputer module

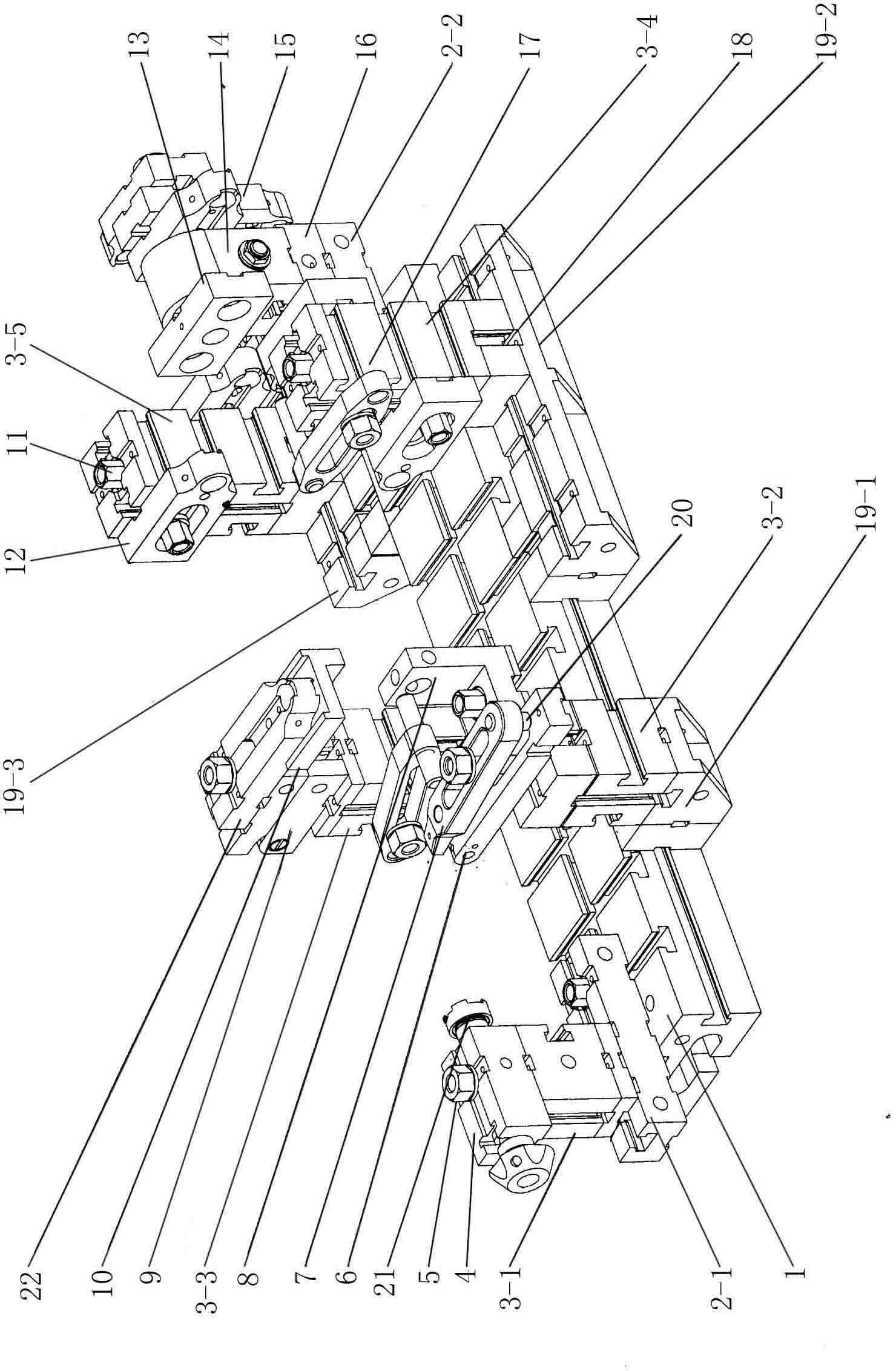

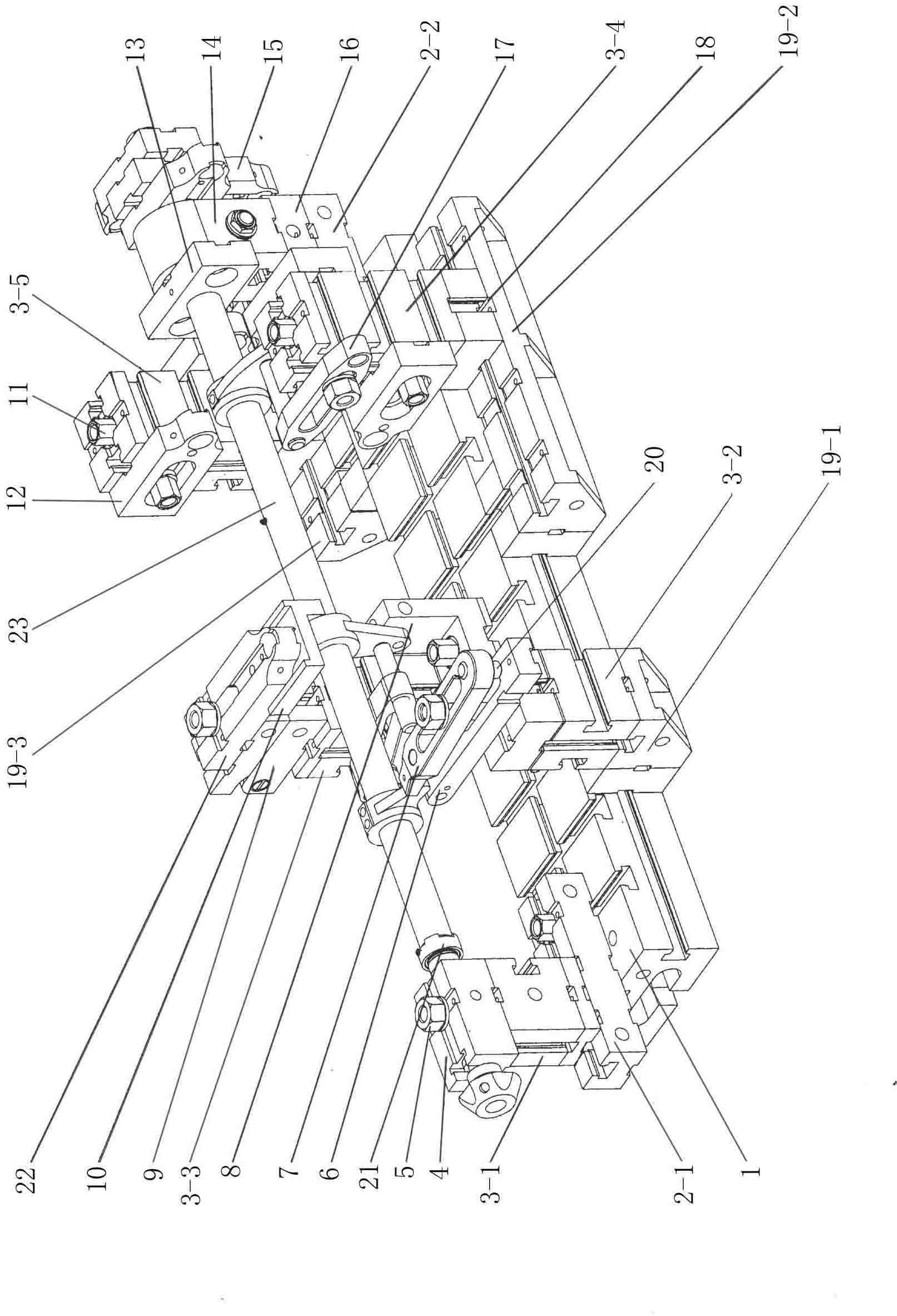

The invention relates to a combined clamp for a drilling hole of a torque tube assembling unit product. According to the technical scheme adopted by the invention, a support I, a movable positioning support base and a shouldered nut I are sequentially arranged on an extension plate I; the movable positioning support base is connected with a cylinder positioning pin; ribbing angle iron I, ribbing angle iron II and ribbing angle iron III are fixed on a base plate; a support II, a vertical drilling template and an extension pressing plate are sequentially arranged on the ribbing angle iron I; a locking nail is arranged on the extension pressing plate; positioning angle iron is arranged on the base plate; a support III, a key slot folding plate, a special template and a double-sided slot drilling template I are sequentially arranged on the positioning angle iron; a positioning key, a support IV and a connection board are sequentially arranged on the ribbing angle iron II; a support V, a counter-bore type drilling template and a shouldered nut II are sequentially arranged on the ribbing angle iron II; and a hole support and a rotary support are sequentially arranged on the extension plate II; and a double-sided slot drilling template II and a middle hole positioning plate are respectively fixed on two sides of the rotary support. With the adoption of the combined clamp, the repeated design and the assembly of the clamp are reduced, the loss of raw materials is reduced, the product quality is improved and the production efficiency is improved.

Owner:SHENYANG AIRCRAFT CORP

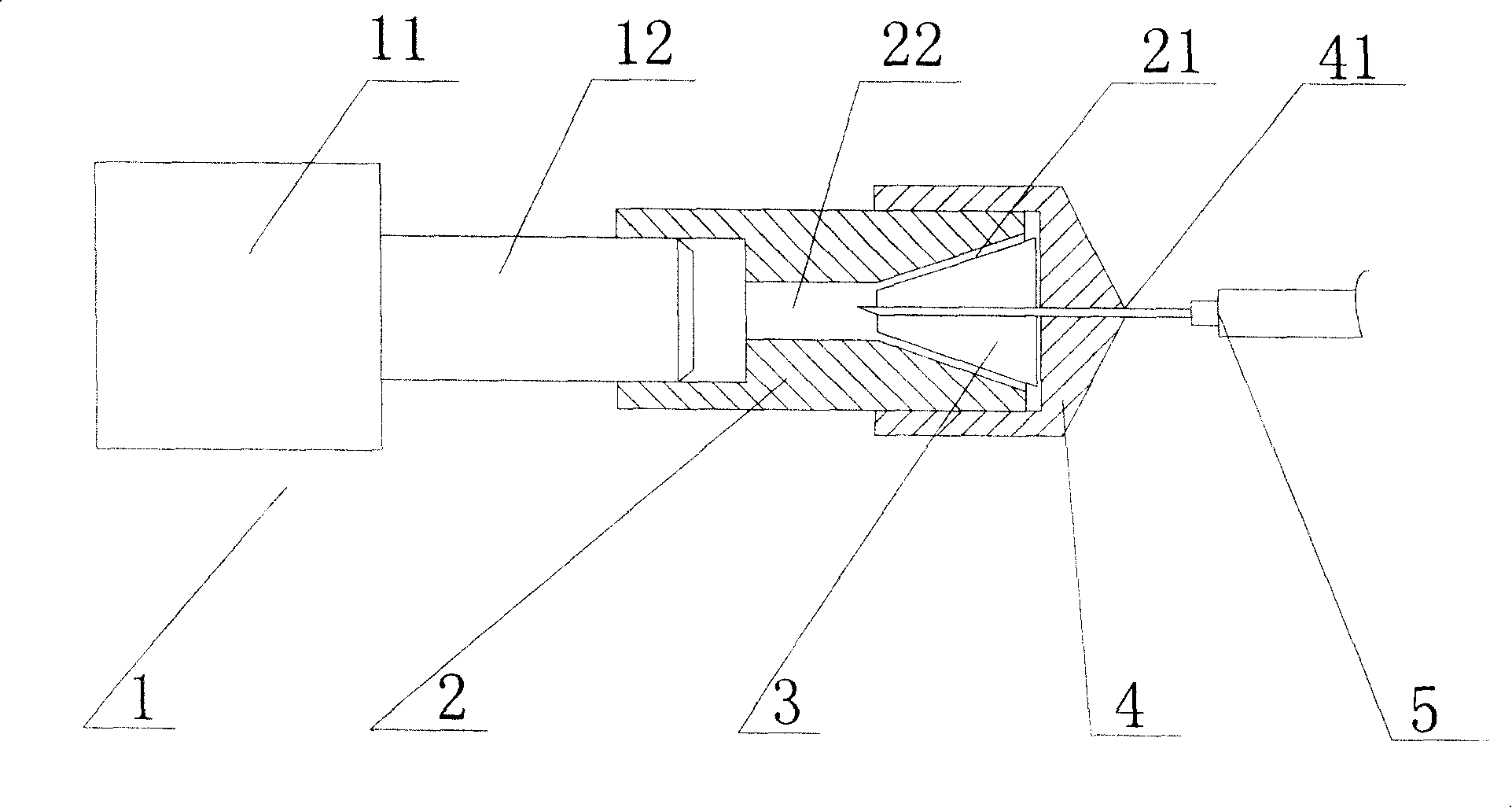

0.4mmquick-speed jigs for needle tube under 0.4mm and method of use thereof

ActiveCN101210849AEasy to useSimple fixture structureMeasurement apparatus componentsForce measurementEngineeringCoupling

A needle tube rapid clamping apparatus comprises a coupling rod, a locking element, two locking blocks and a locking cap. The locking element is connected on the coupling rod, the two locking blocks are positioned inside a conical groove on the locking element, and the locking cap is connected with the locking element for clamping the two locking blocks. The application method of the invention comprises the following steps of: releasing the locking cap to relax the two locking blocks, inserting the detected needle tube from a needle hole on the locking cap and inserting into the space between the two locking blocks from the conical groove above the two locking blocks, and winding the locking cap to lock the two locking blocks, so as to clamp the detected needle tube. The invention solves the clamping difficult of the needle tube with diameter less than 0.4mm, and has the advantages of convenient, rapid and safe application, simple structure, easy production, low cost, and easiness for popularization.

Owner:SHANGHAI KANGDELAI ENTERPRISE DEV GRP CO LTD

Fixture of car gearbox valve body

The invention discloses a fixture of a car gearbox valve body. The fixture comprises a tray rack used for bearing the valve body, a pair of valve body fixing claws arranged oppositely are installed on the tray rack, and the valve body fixing claws are further connected with a pressing device used for making the pair of valve body fixing claws get close to generate pretightening force. The tray rack is further provided with a positioning surface making contact with the valve body. The clamping direction of the pair of valve body fixing claws is parallel to the positioning surface, and the positioning surface is further provided with a valve body positioning pin and a valve element baffle. The axis of the valve body positioning pin is perpendicular to the positioning surface. The valve element baffle is provided with a stop surface perpendicular to the positioning surface. In this way, the fixture of the car gearbox valve body is simple in structure, firm, reliable, good in abrasion resistance and rigidity, and not prone to deformation; and meanwhile, the positioning reference and the limiting reference coincide, and errors are reduced.

Owner:山东双林新能源科技有限公司

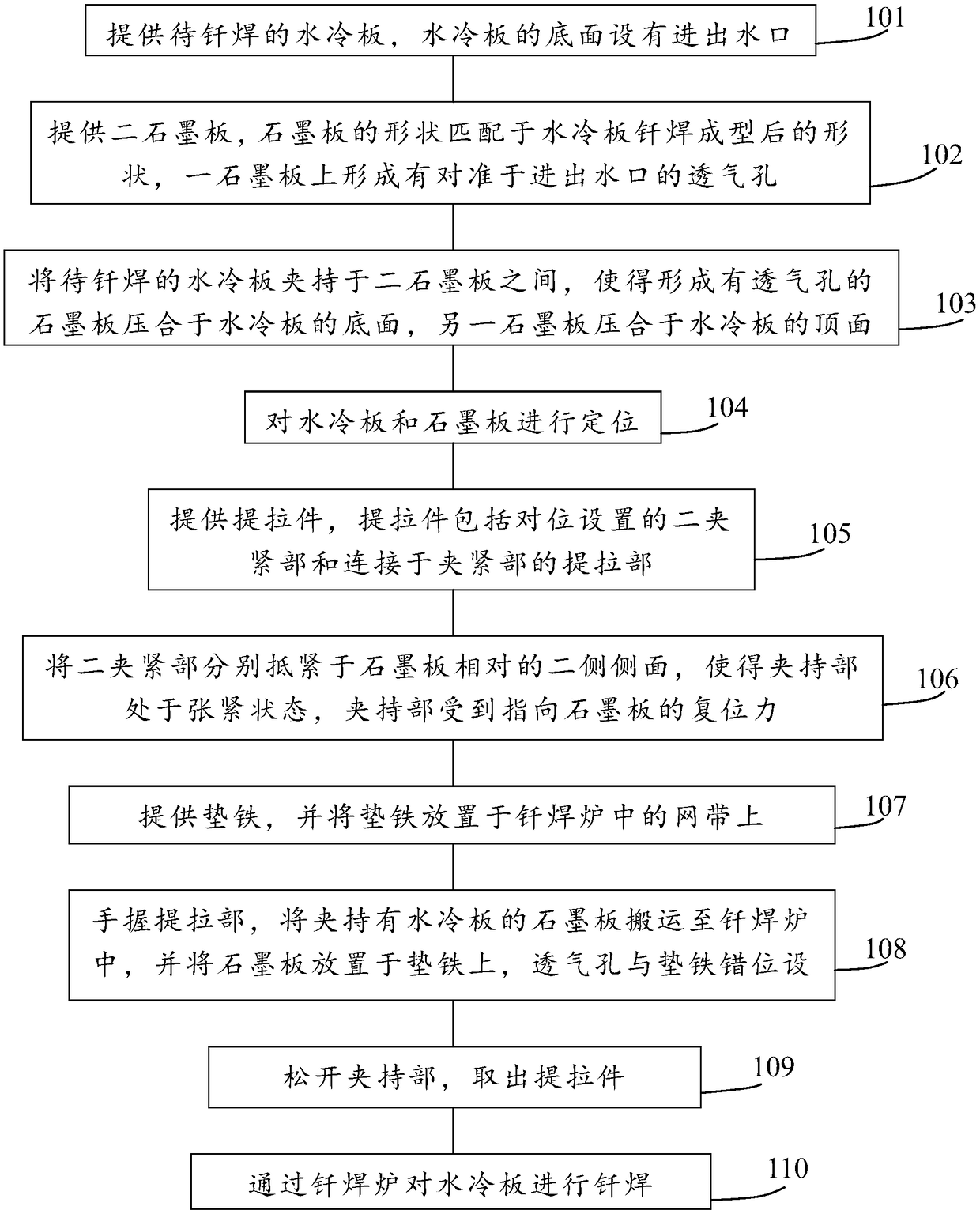

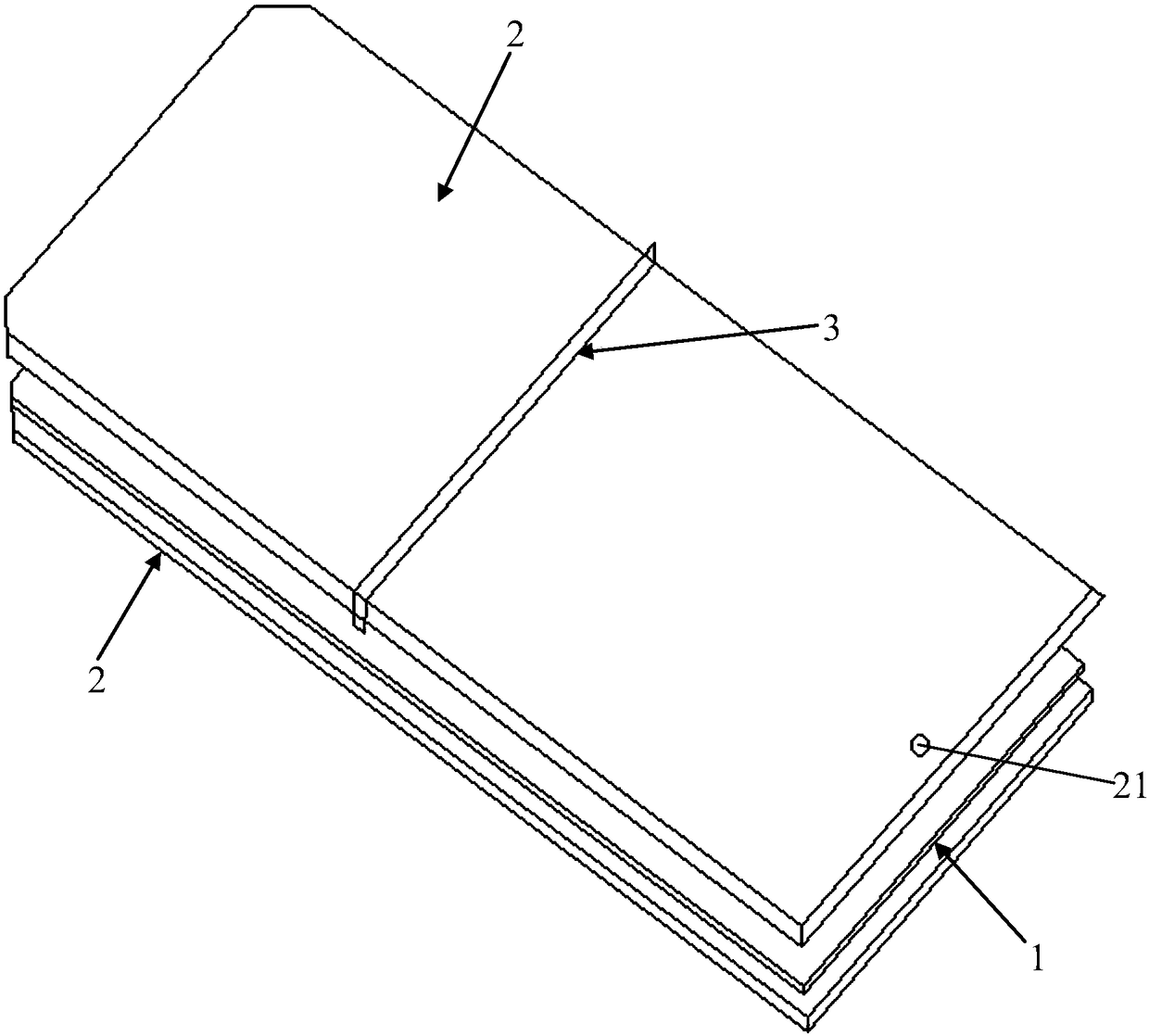

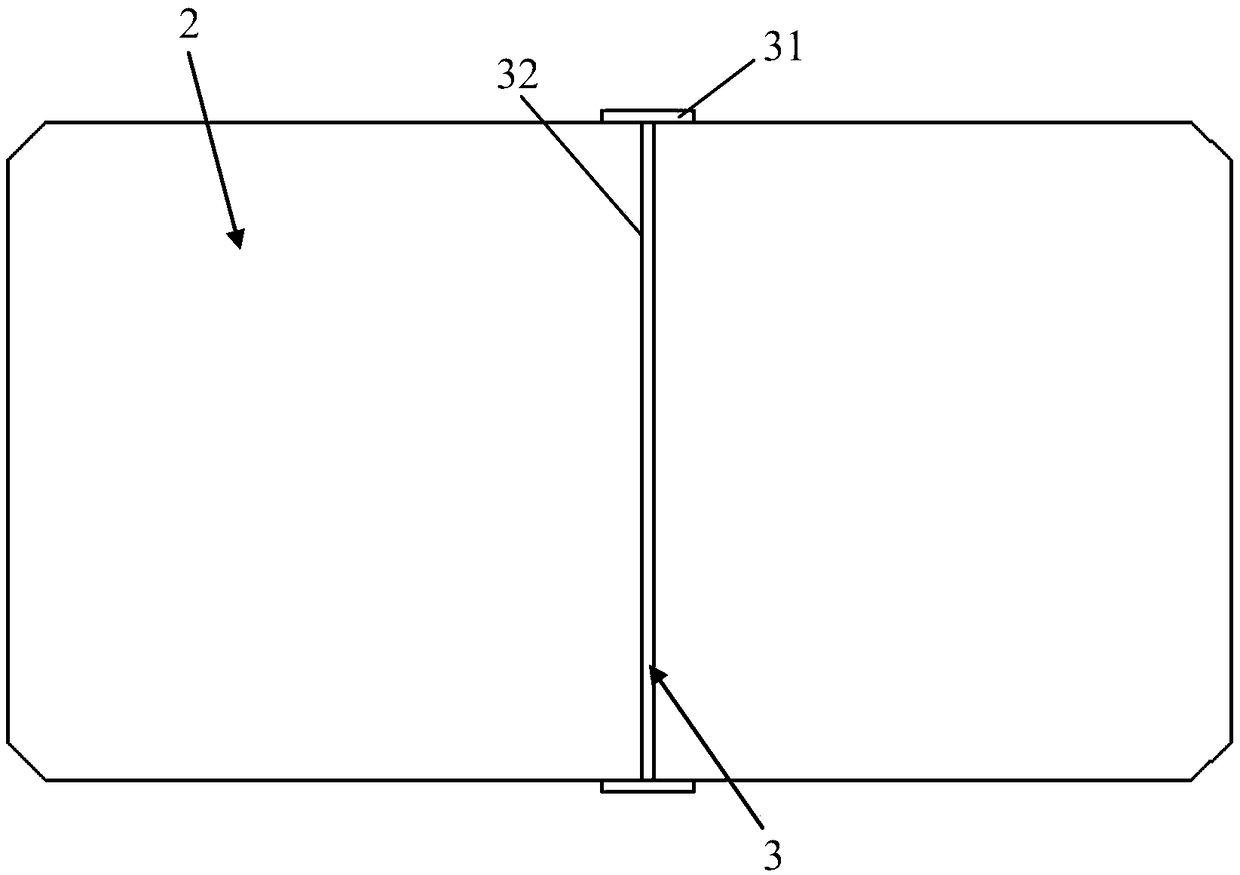

Brazing method for water-cooling plates

InactiveCN109396587ASimple fixture structureEasy positioning and clampingSoldering auxillary devicesBrazingGraphite

The invention provides a brazing method for water-cooling plates. The brazing method comprises the following steps: providing water-cooling plates to be brazed, providing two graphite plates, and putting the water-cooling plates between the two graphite plates; locating the water-cooling plates and the graphite plates; providing a lifting element, specifically, the lifting element comprises two clamping parts which are set oppositely and a lifting part which is connected with the clamping parts; making the two clamping parts correspondingly abut against the two opposite sides of the graphite plates so that the clamping parts can be in tension state and bear reset force which points to the graphite plates; providing an iron cushion, placing the iron cushion on a net belt in a brazing furnace, holding the lifting part with hands, and carrying the graphite plates which clamp the water-cooling plates to the brazing furnace; and placing the graphite plates on the iron cushion, releasing theclamping parts, taking out the lifting element, and brazing the water-cooling plates by the brazing furnace. The brazing method of the invention can improve the brazing quality and production efficiency of the water-cooling plates.

Owner:扬州嘉和新能源科技有限公司

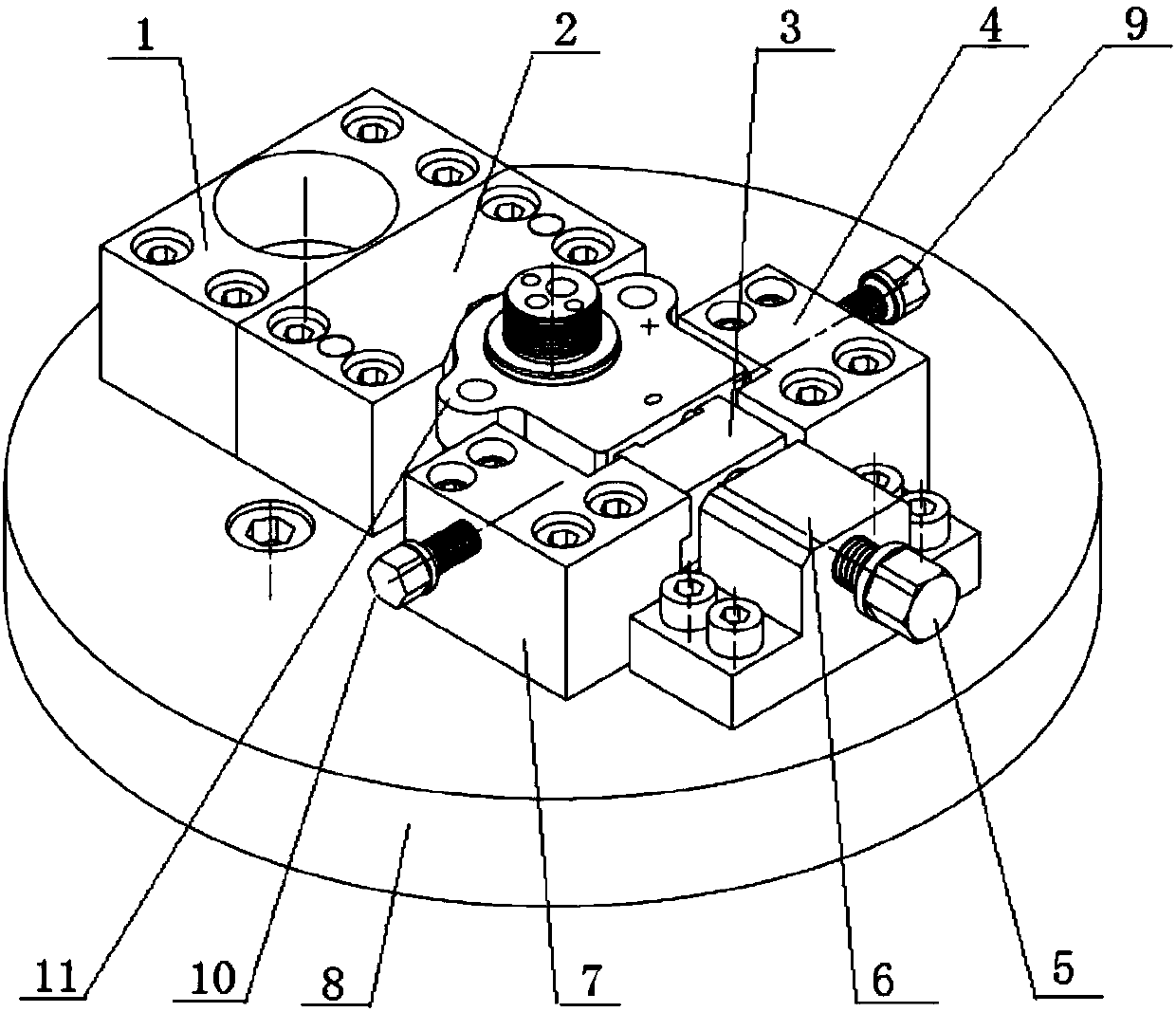

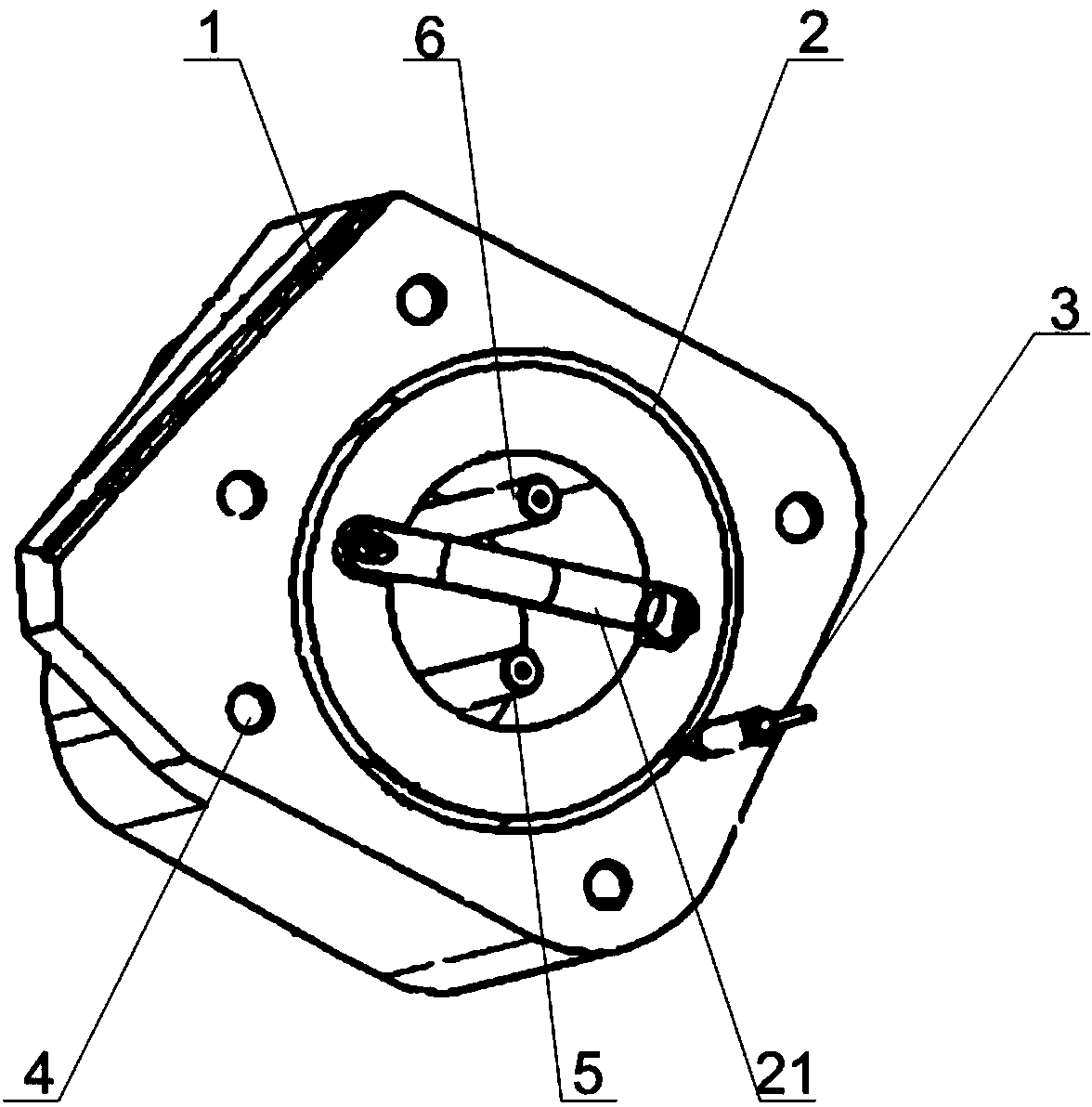

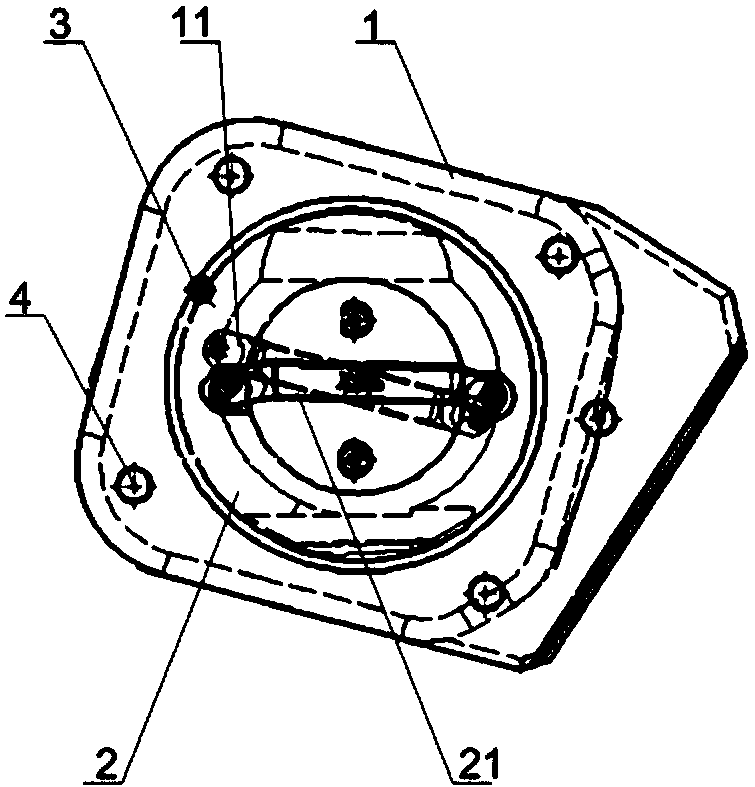

Turning center clamp of irregular eccentric valve deck

InactiveCN107813173ASimple fixture structureEasy to clamp and disassembleWork clamping meansPositioning apparatusLower limitEngineering

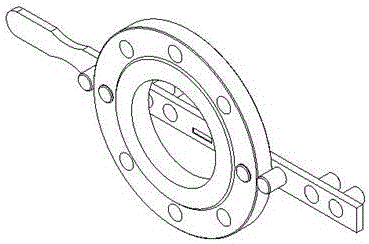

The invention provides a turning center clamp of irregular eccentric valve deck. The turning center clamp comprises a flange plate, a positioning mechanism, a clamping mechanism and a balancing weight. The positioning mechanism, the clamping mechanism and the balancing weight are installed on the flange plate. The positioning mechanism comprises a V-shaped positioning block, a positioning bottom plate, an upper limiting block, a lower limiting block, a movable screw and a first compression screw. The clamping mechanism comprises a movable pressing block, a second compression screw and a pressing base. A space where valve deck parts are placed is formed among the V-shaped positioning block, the upper limiting block, the lower limiting block and the movable pressing block. The valve deck parts are placed on the positioning bottom plate and located in the middle of the flange plate. The movable screw, the first compression screw and the movable pressing block clamp the valve deck parts. The balancing weight is used for balancing the center of mass of all the parts on the flange plate. The turning center clamp is simple in structure, easy to assemble and disassemble, capable of effectively fixing valve deck parts and low in machining cost.

Owner:JIANGSU UNIV

Mold convenient to install

The invention discloses a mold convenient to install. The mold comprises a lower template; aligning devices, fixedly connected with the lower template, are symmetrically arranged on the upper side ofthe lower template; an upper template is arranged at the ends, far from the lower template, of the aligning devices; a convex mold, fixedly connected with the upper template, is arranged on the lowerside of the upper template; a concave mold, fixedly connected with the lower template, is arranged on the upper side of the lower template; sleeves, fixedly connected with the lower template, are symmetrically arranged at the two ends of the lower template; grooves are formed in one ends of the sleeves; the sleeves are sleeved with limiting rings; multiple connecting rods are symmetrically arranged on the inner side walls of the limiting rings; and clamping rings are arranged at the other ends of the connecting rods. The mold has the following advantages that firstly, a connecting device is additionally arranged on the mold; a transmission device drives a clamping structure to move to be clamped with a machine to fix the mold; a fixing device is simple in structure and convenient to disassemble; and meanwhile, a lifting device is added under the mold, so that the height of the mold is conveniently adjusted according to actual installation demands, and the installation is convenient.

Owner:NANJING ZHUONAI HEAVY MACHINERY MFG CO LTD

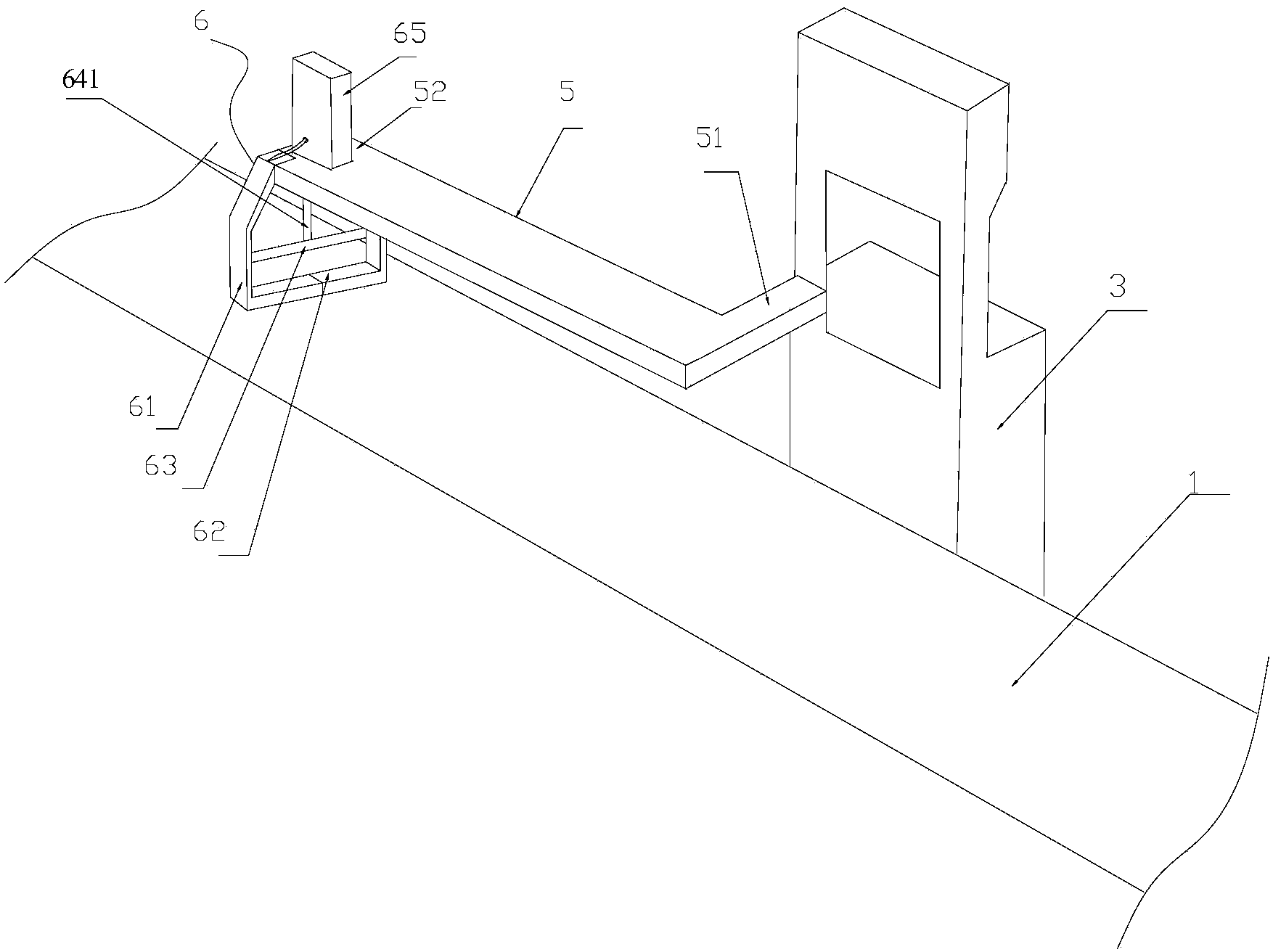

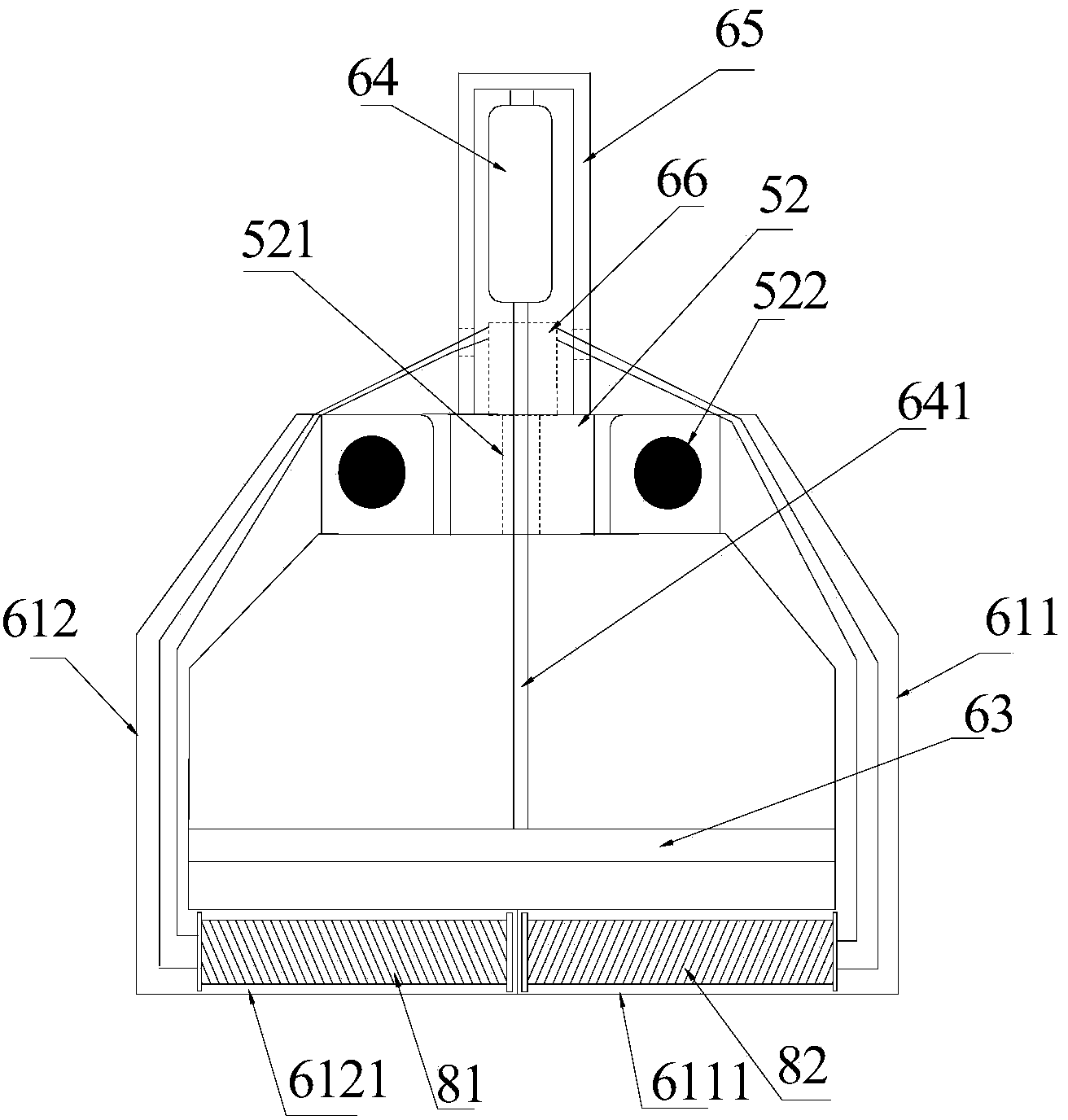

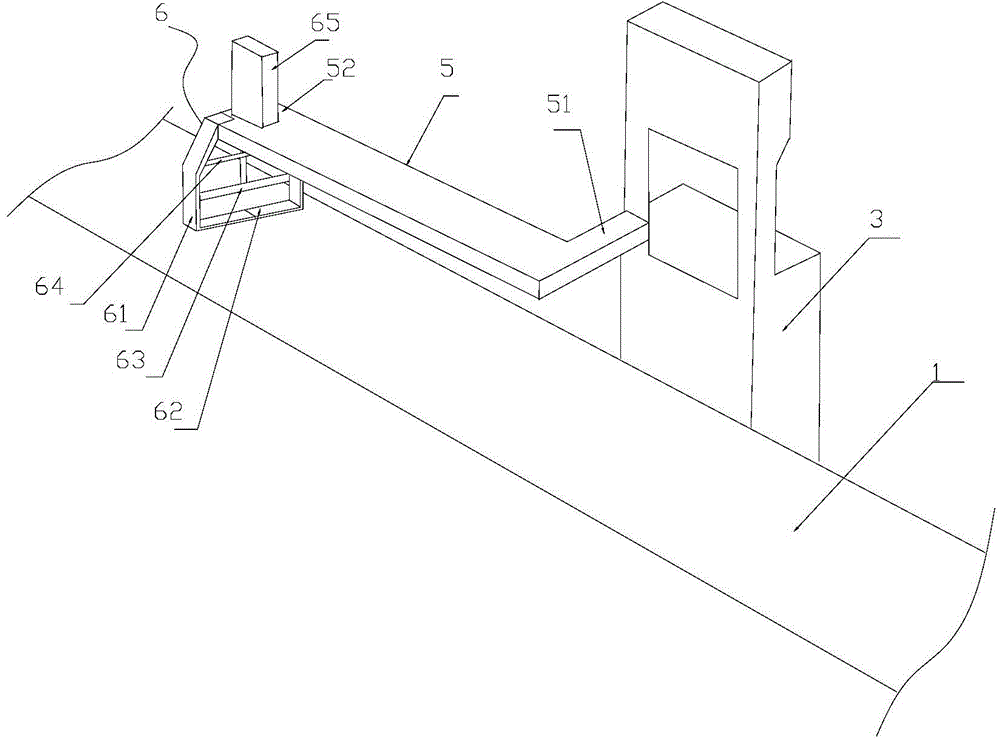

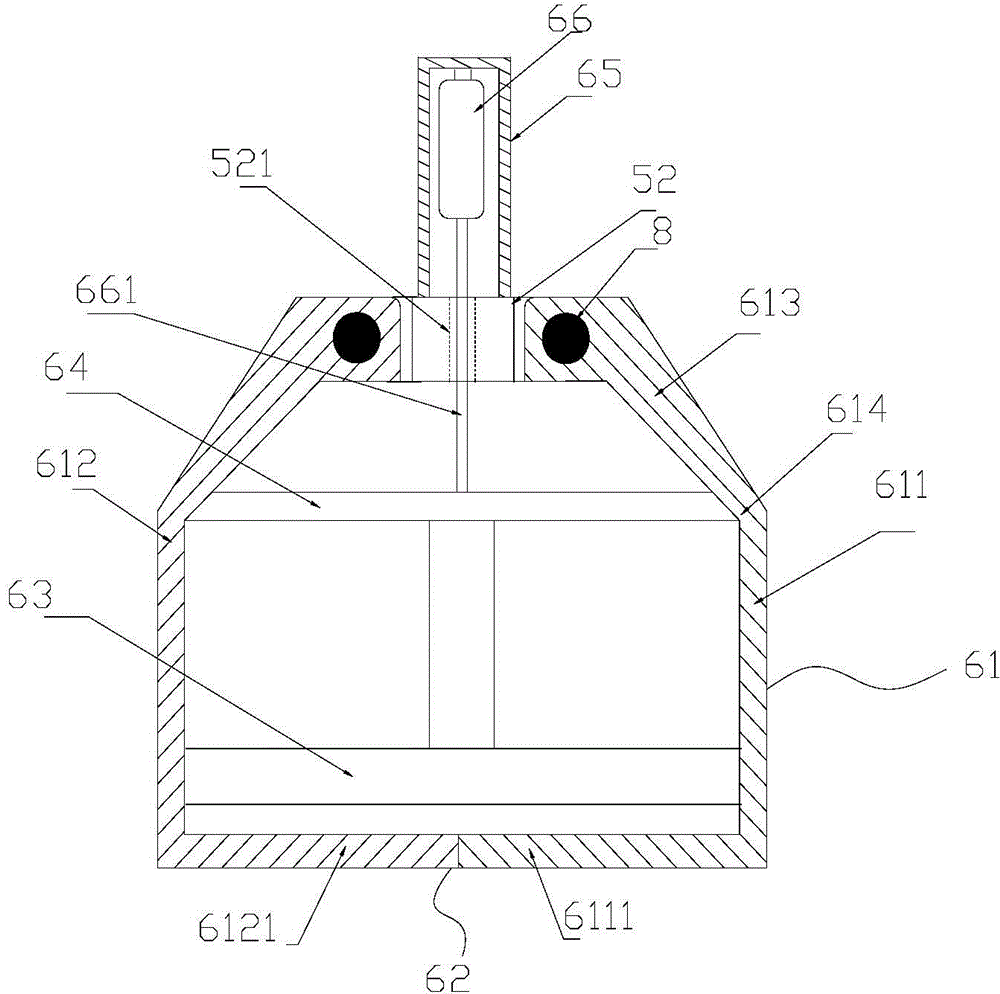

Novel aluminium section dragger

The invention discloses a novel aluminium section dragger. The novel aluminium section dragger comprises a guide rail arranged roughly in parallel with an aluminium section discharging platform, a tractor slideablely arranged on the guide rail, an installing arm, and a clamp; a first end of the installing arm is fixedly connected with the tractor, and a second end is hanged above the aluminium section discharging platform; the clamp is arranged on the second end of the installing arm, and comprises a material clamping frame, a pressing plate, a cylinder, and two electromagnets; the material clamping frame comprises a pair of support plates which are arranged on the second end of the installing arm and vertically to each other; the top parts of the two support plates are both connected with the second end of the installing arm via hinge joint; the bottoms of the two support plates are bent to each other so as to form a support plate bottom; the pressing plate is arranged in the material clamping frame, and is driven by the cylinder so as to move upward and downward with relative to the second end of the installing arm in the material clamping frame; and the two electromagnets are arranged on the bottoms of the two support plates respectively. The clamp of the novel aluminium section dragger is simple and skillful in structure design, and is capable of realizing clamping of aluminium section, and discharging with high efficiency.

Owner:台澳铝业(台山)有限公司

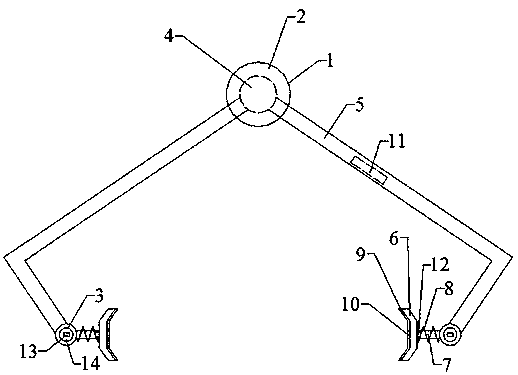

Automobile operating lever assembling fixture

InactiveCN107097163ASimple fixture structureEasy to operateWork holdersEngineeringAutomobile handling

Owner:CHENGDU HONGYU TIMES TECH CO LTD

Anode clamp of pre-calcining anode electrolytic cell

This invention discloses an anode jig for prebaked anodic aluminum reduction cells. Two supports are fixed on both sides of the aluminum reduction cell anode bus bar by bolts. A connecting rod is connected with the left support through a bearing, and the front end of the connecting rod is contacted with the face of a hand-operated eccentric wheel. This invention directly fixes a light anode jig with simple structure on the anode bus bar, thus can achieve the work of fastening-loosing the anode without the assistance from a multifunctional overhead traveling crane. This invention has such advantages as simple structure, low weight, easy operation, simple manufacturing process.

Owner:GUIYANG AL-MG DESIGN & RES INST

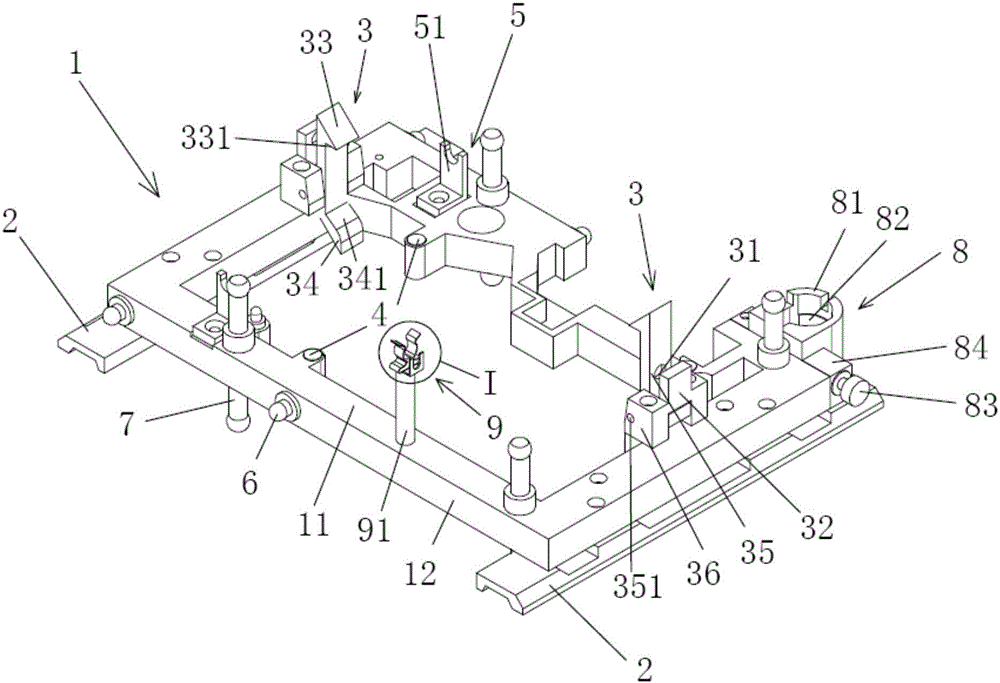

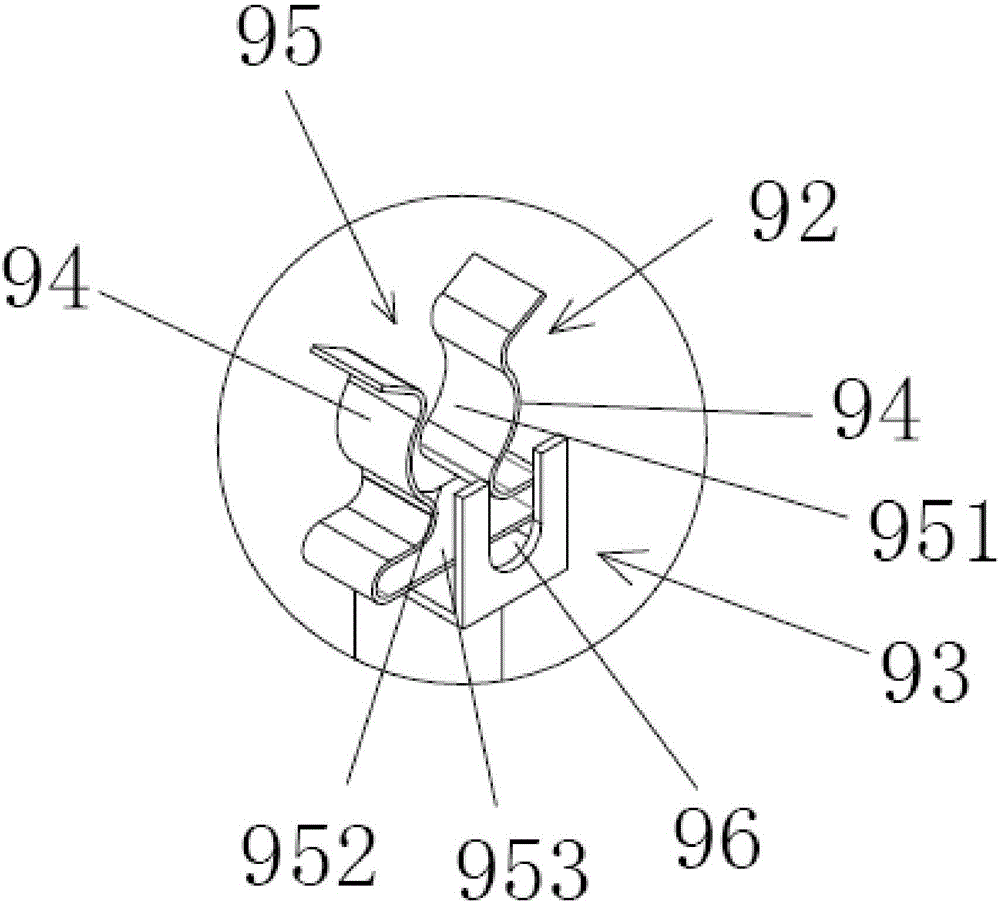

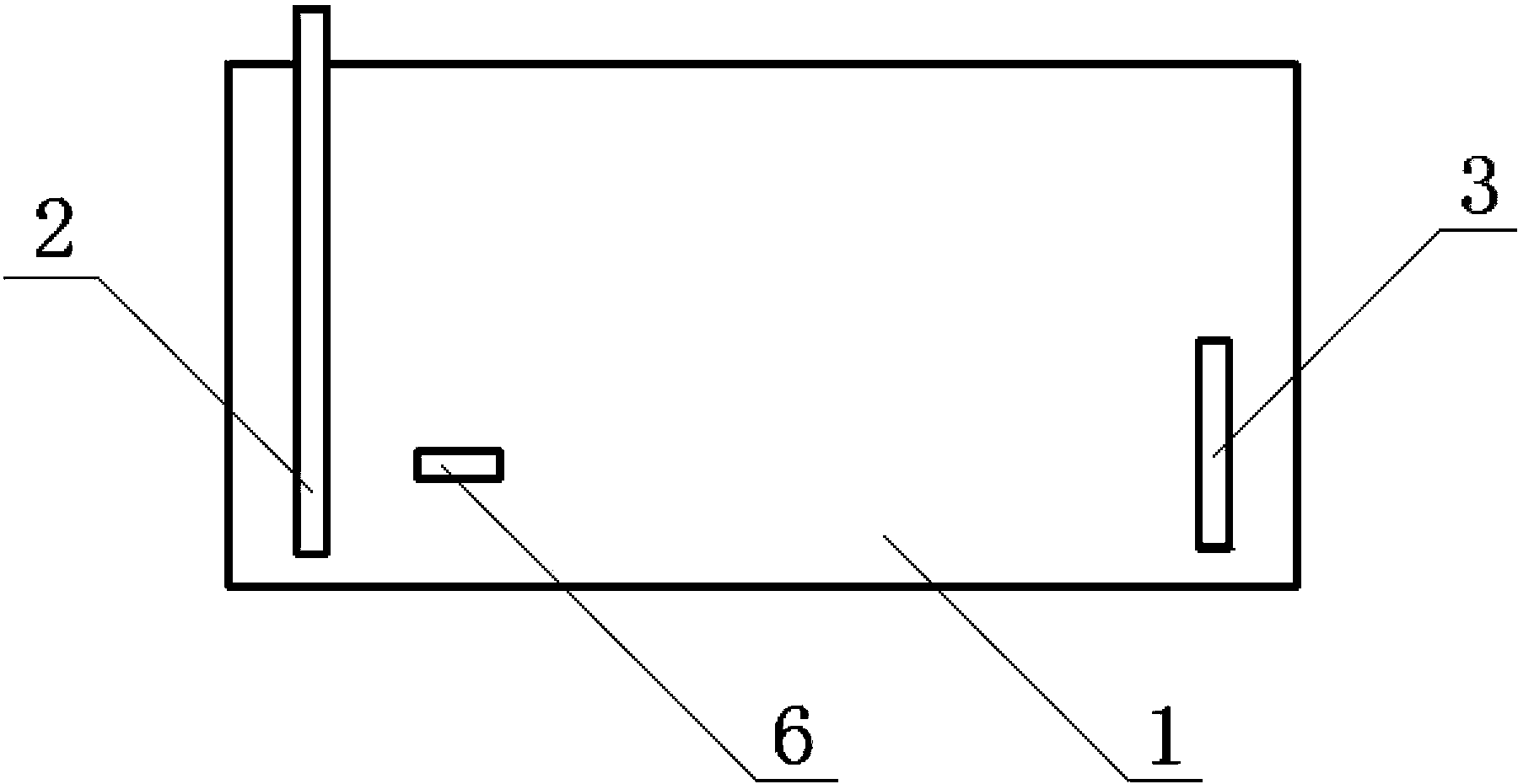

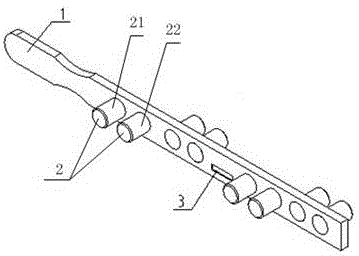

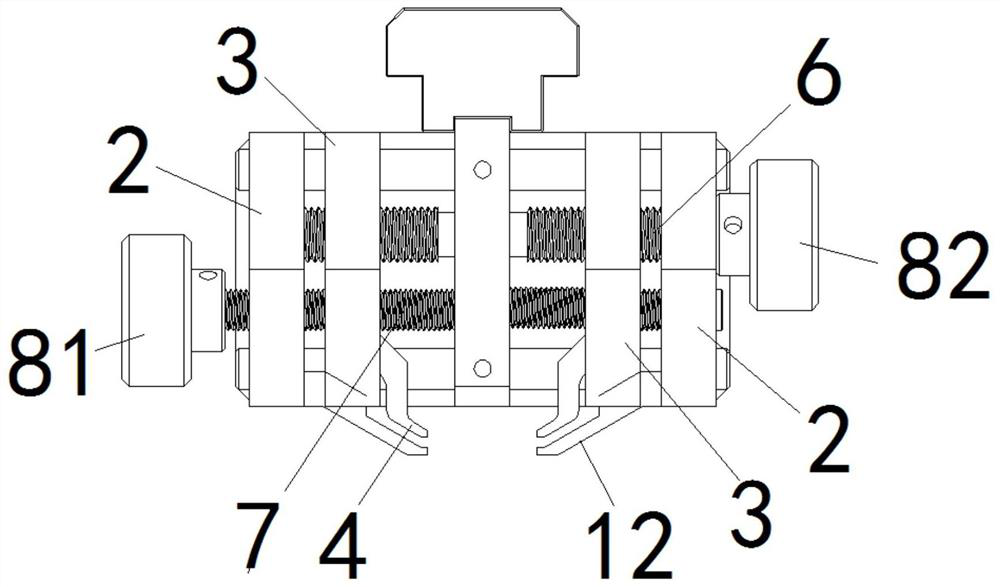

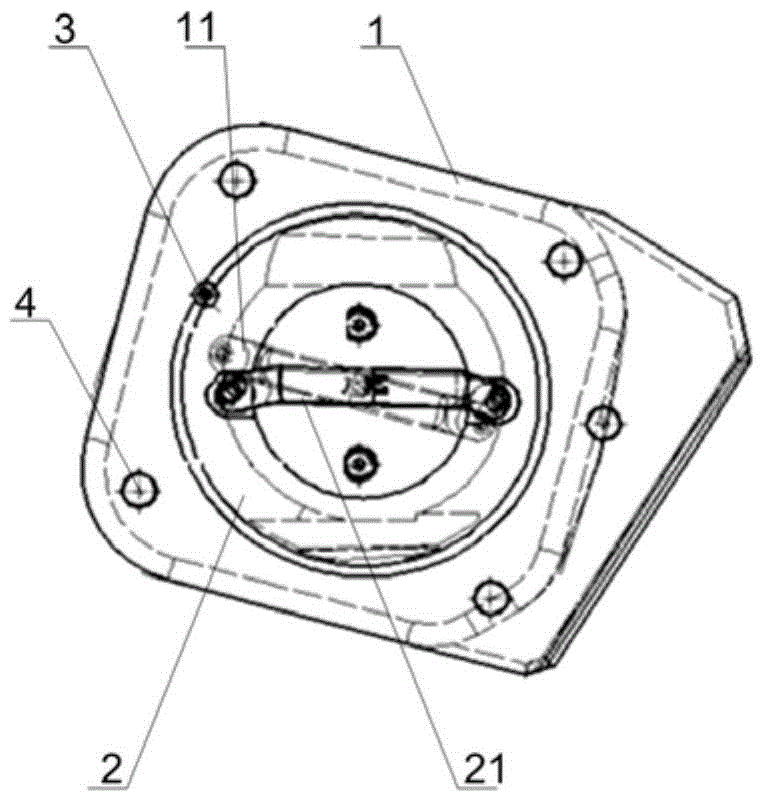

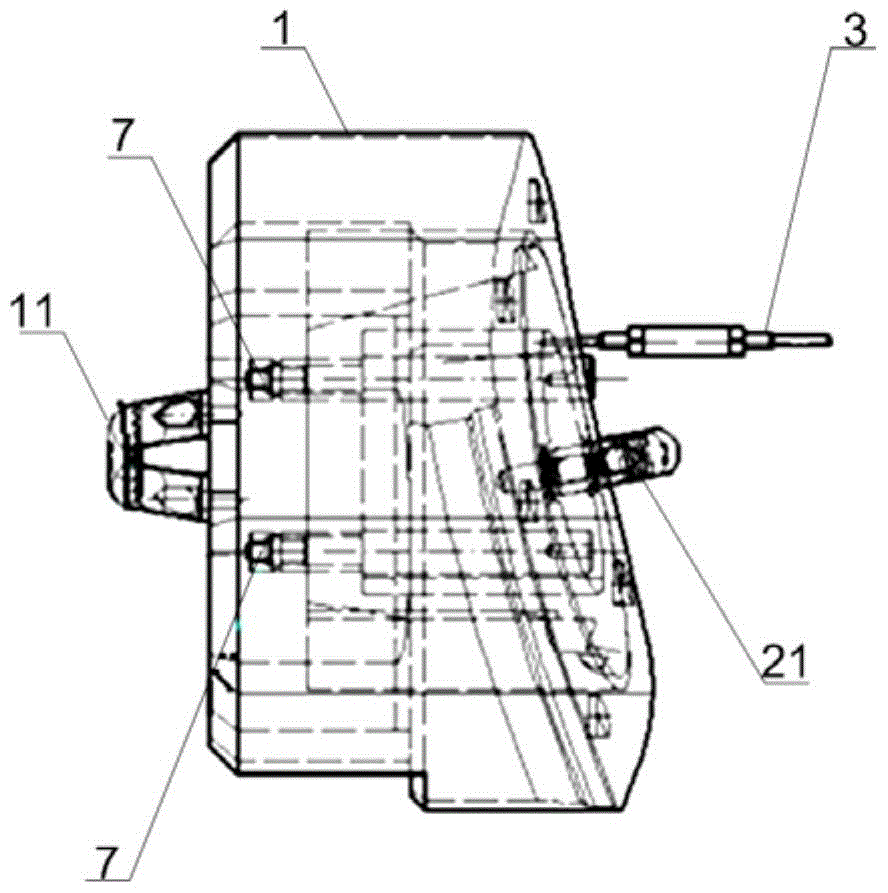

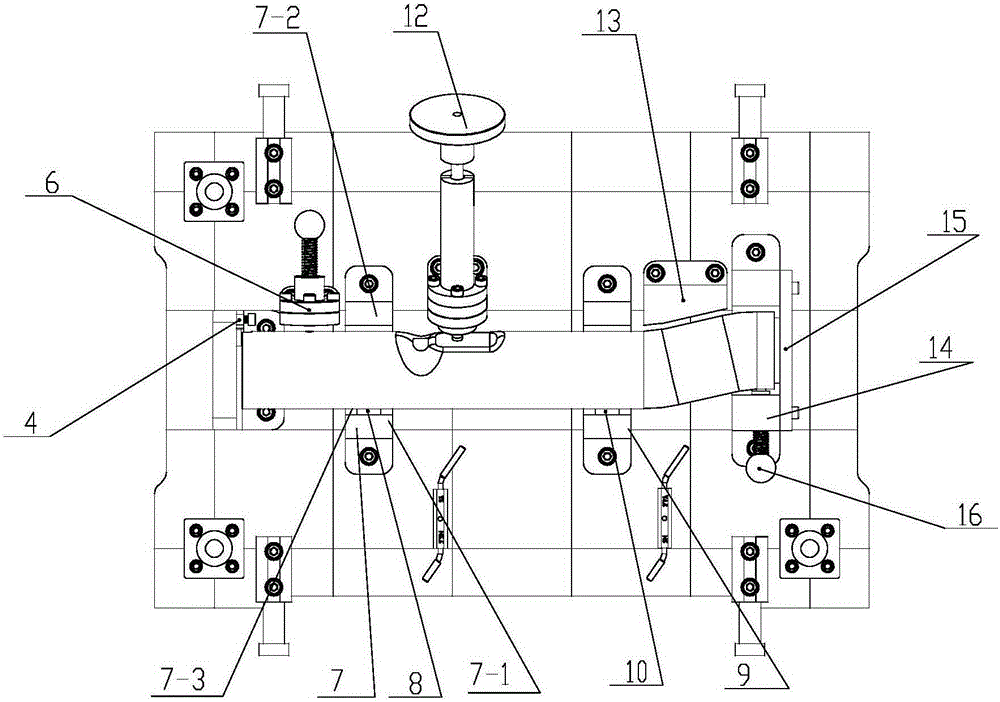

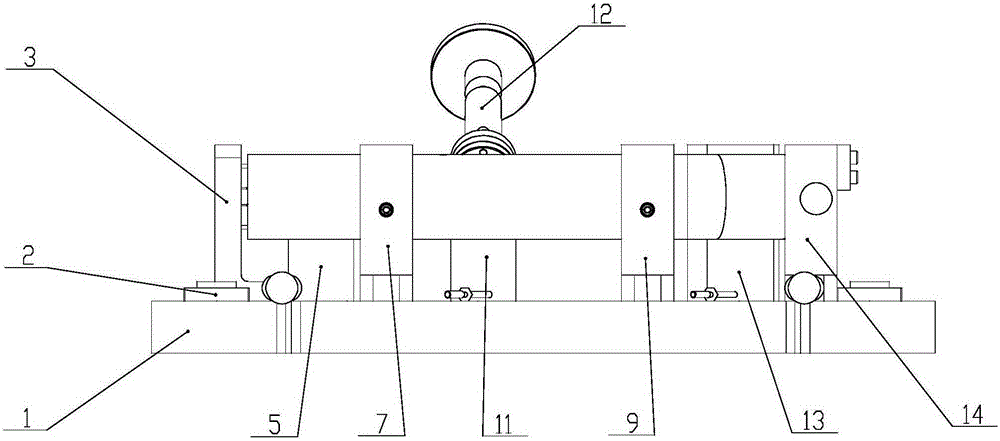

Inspection tool for breaker break-brake half shaft and inspection method thereof

ActiveCN103411520AImprove quality and efficiencyImprove labor efficiencyMechanical measuring arrangementsSpatial structureEngineering

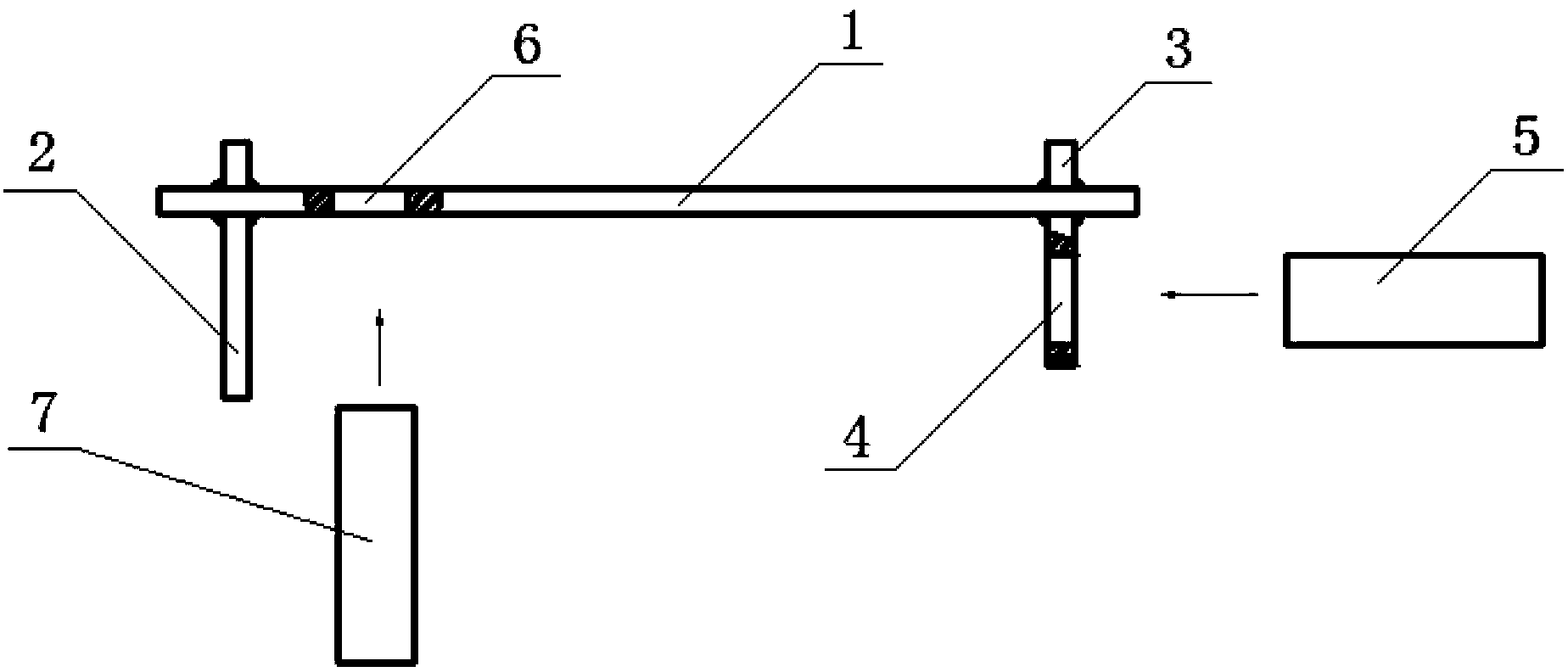

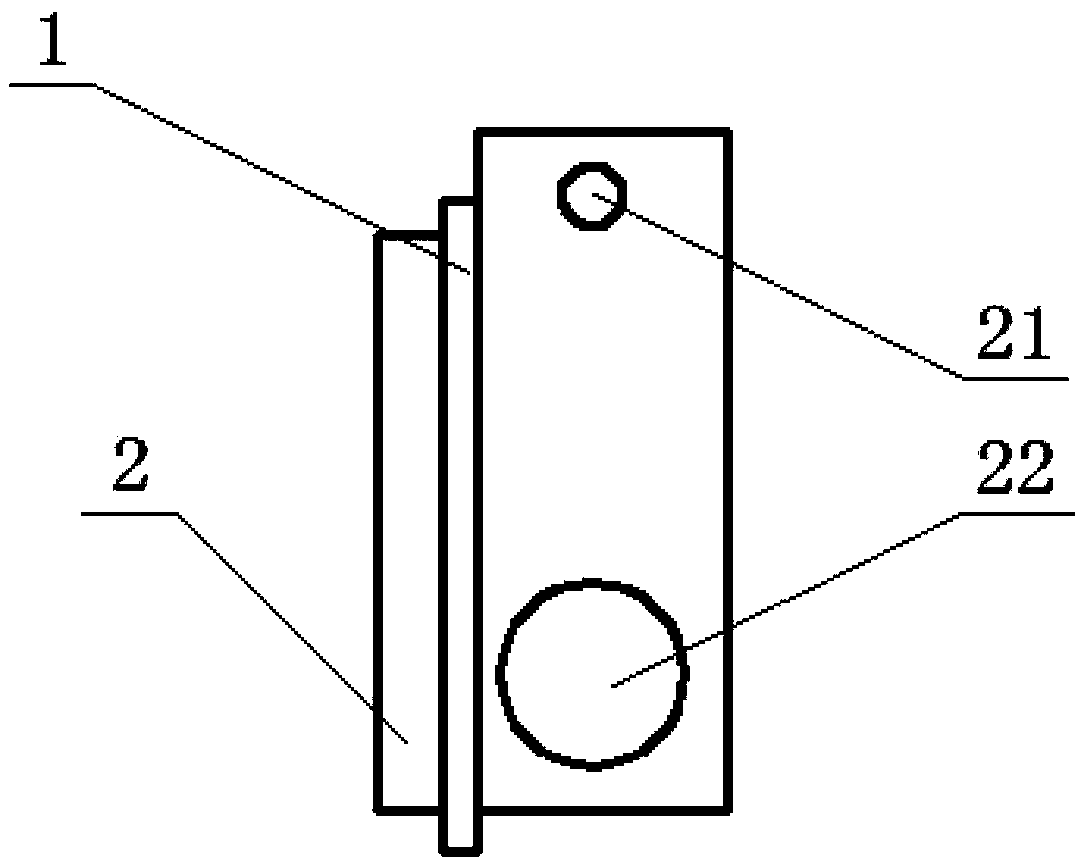

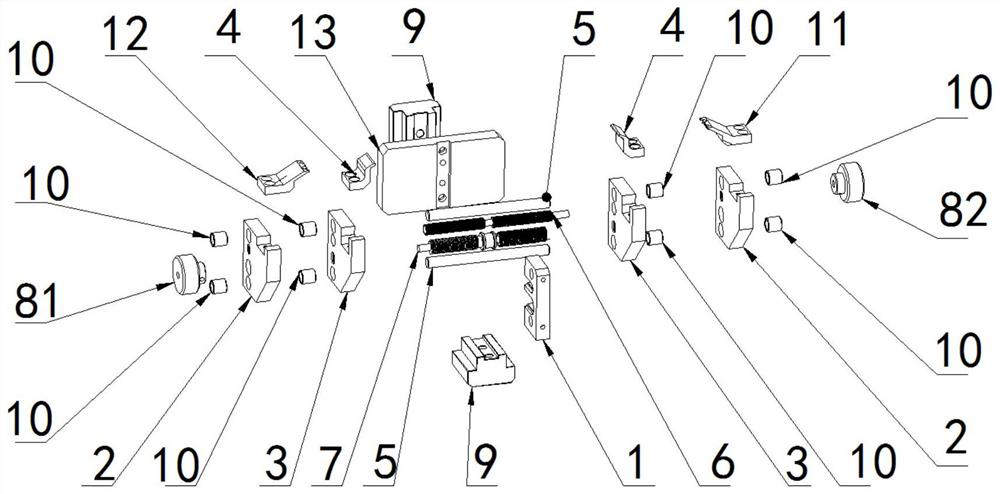

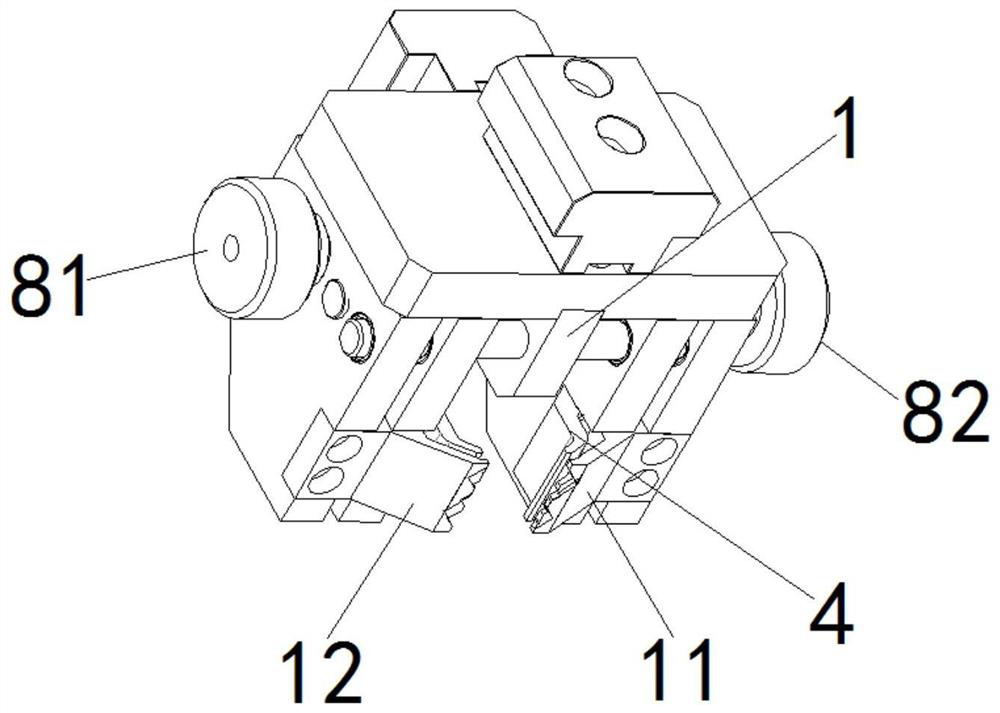

The invention discloses an inspection tool for a breaker break-brake half shaft and an inspection method of the inspection tool. The inspection tool comprises a positioning plate (1), the positioning plate (1) is provided with a left side plate (2) and a right side plate (3), wherein the left side plate (2) and the right side plate (3) are in parallel, and the left side plate (2) and the right side plate (3) are vertically installed on the positioning plate (1); the left side plate (1) is provided with a first positioning hole (21) and a second positioning hole (22), wherein the first positioning hole (21) and the second positioning hole (22) are matched with two cylindrical bosses on a manual plastic connecting lever (8); the right side plate (3) is provided with a first positioning groove (4), and a first pin plate (5) is installed in the first positioning groove (4); the positioning plate (1) is further provided with a second positioning groove (6), and a second pin plate (5) is installed in the second positioning groove (6). According to the inspection tool for the breaker break-brake half shaft and the inspection method of the inspection tool, space structure angles of plastic injection parts can be inspected effectively, inspection quality and labor efficiency are improved, and meanwhile, the inspection tool is simple in structure and nimble in operation.

Owner:ANHUI ZHONGDIAN XINGFA & XINLONG TECH CO LTD

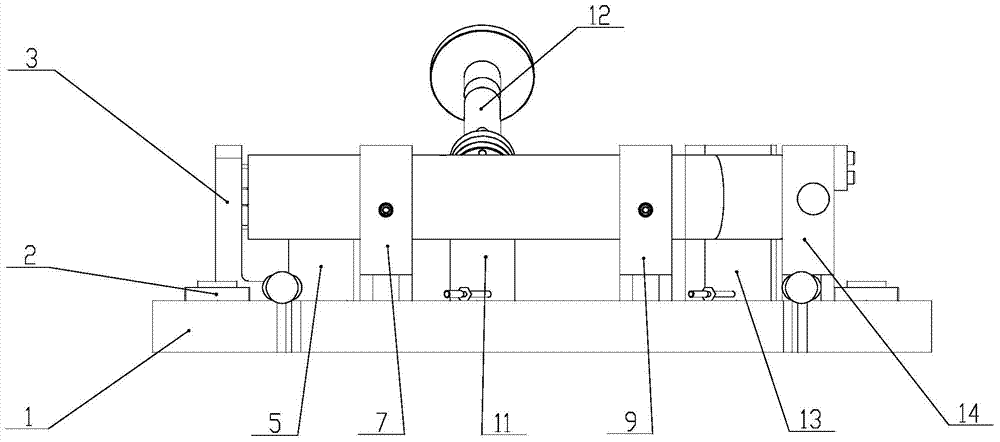

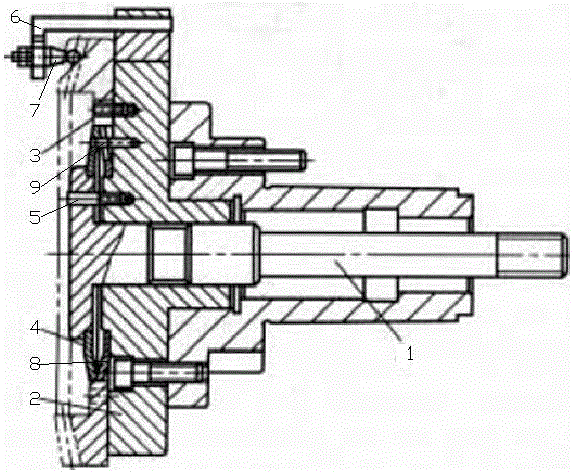

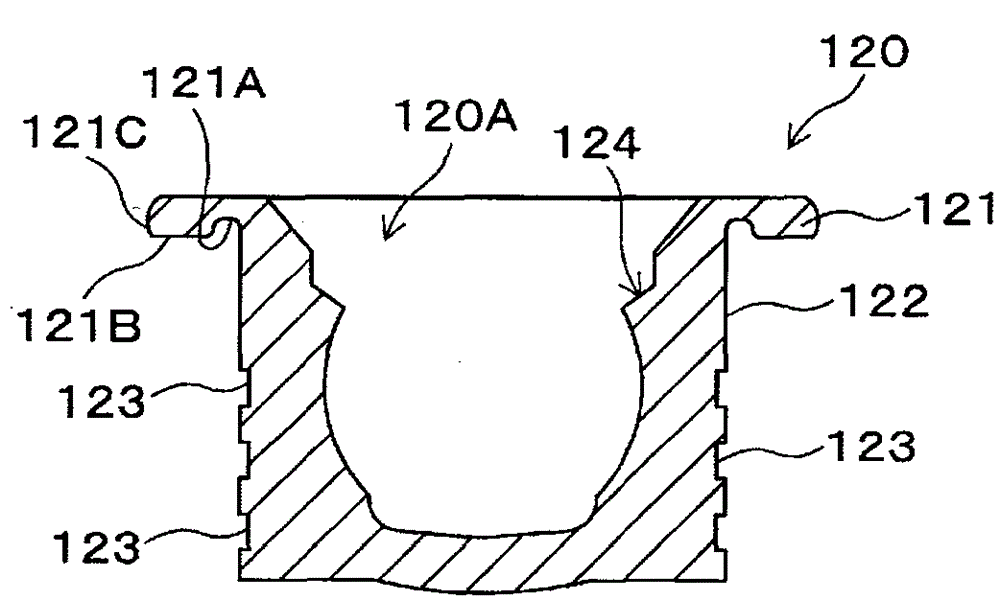

Method for measuring radial circular run-out quantity of iron core inner circle reference axes from stopping openings at two ends of stator

InactiveCN103486949ASimple fixture structureEasy to measureMechanical measuring arrangementsEngineeringConical surface

The invention relates to a method for measuring the radial circular run-out quantity of the iron core inner circle reference axes from stopping openings at two ends of a stator. The method is applied to indirect measurement of the radial circular run-out quantity of the public reference axes of the stopping openings at two ends for a stator iron core inner circle. The method comprises the steps of using a detection device to contain the stator iron core inner cylindrical surface, enabling center shafts at two ends of a detection device mandrel to be positioned on the center line of the stator iron core inner cylindrical surface, and then conventionally measuring the radial circular run-out quantity of the center shafts at two ends of the detection device mandrel for the stopping openings at two ends. The detection device is composed of the mandrel, an elastic sleeve, a pressing ring, a mandrel nut and a step-shaped screw. The middle of the mandrel is provided with the outer conical surface, the elastic sleeve is cylindrical, non-penetrating groove slits are alternately bi-directionally arranged on the elastic sleeve in the axial direction to equally divide a sleeve body along the circumference, the inner conical surface of the elastic sleeve is matched with the outer conical surface of the mandrel, the mandrel nut penetrates through a central round hole of the pressing ring, and the pressing ring is constrained in an outer circle ring groove of the mandrel nut two nuts and connected with the annular end face of the elastic sleeve through the step-shaped screw. The method has the advantages that the detection device is simple in structure and measurement operation is convenient.

Owner:FUJIAN NANDIAN

A clamp for a vehicle transmission valve body

The invention discloses a fixture of a car gearbox valve body. The fixture comprises a tray rack used for bearing the valve body, a pair of valve body fixing claws arranged oppositely are installed on the tray rack, and the valve body fixing claws are further connected with a pressing device used for making the pair of valve body fixing claws get close to generate pretightening force. The tray rack is further provided with a positioning surface making contact with the valve body. The clamping direction of the pair of valve body fixing claws is parallel to the positioning surface, and the positioning surface is further provided with a valve body positioning pin and a valve element baffle. The axis of the valve body positioning pin is perpendicular to the positioning surface. The valve element baffle is provided with a stop surface perpendicular to the positioning surface. In this way, the fixture of the car gearbox valve body is simple in structure, firm, reliable, good in abrasion resistance and rigidity, and not prone to deformation; and meanwhile, the positioning reference and the limiting reference coincide, and errors are reduced.

Owner:山东双林新能源科技有限公司

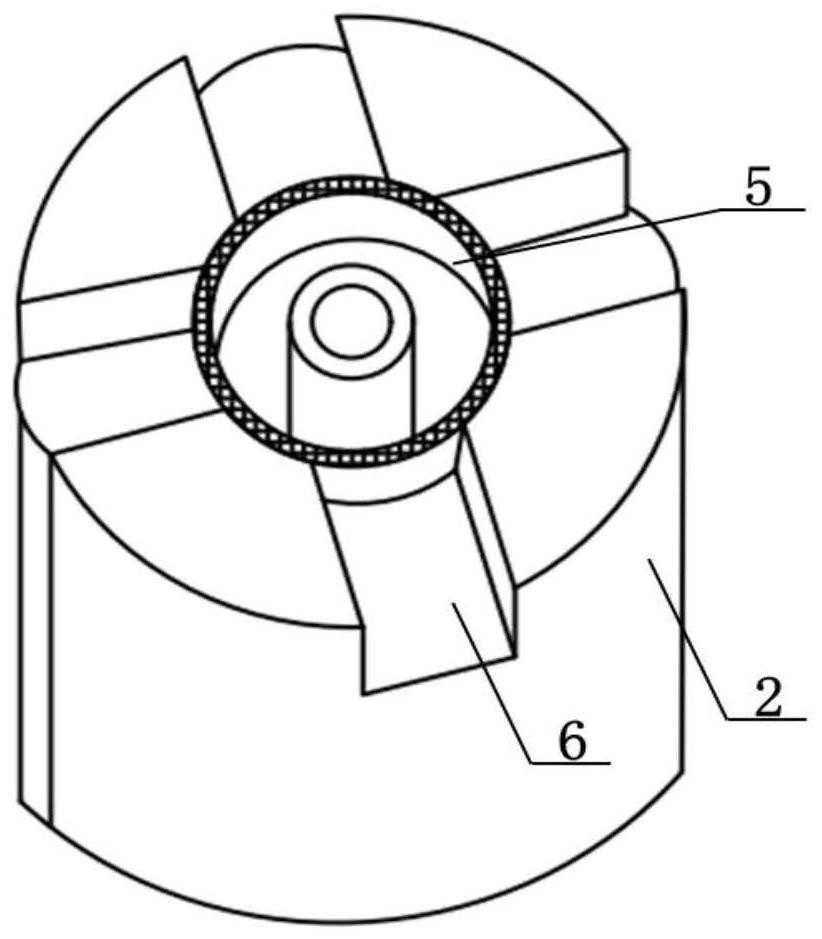

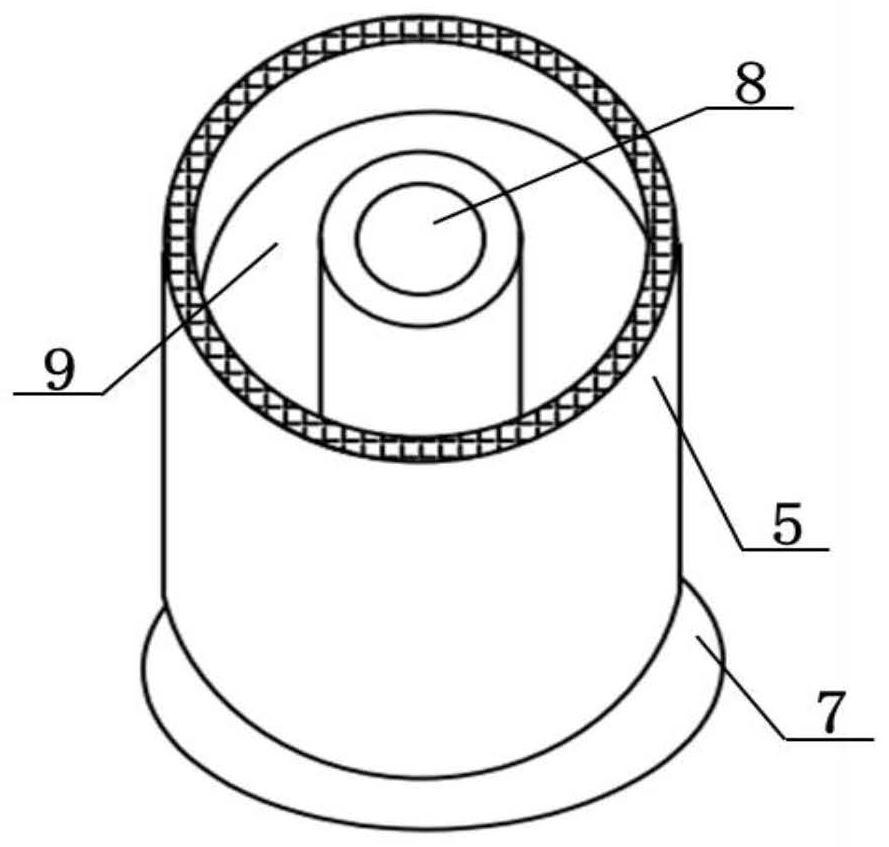

Fixture for cylinder jacket rough boring

InactiveCN106736696ASimple fixture structureEasy to manufacturePositioning apparatusMetal-working holdersRubber ringRejection rate

The invention discloses a fixture for cylinder jacket rough boring. The fixture comprises a base, a tooth ring, a rubber ring, a positioning ring and a pressing head; the base is provided with a groove; the tooth ring, the rubber ring and the positioning ring are mounted in the groove; the tooth ring is mounted at the bottom of the groove; the positioning ring and the rubber ring are respectively mounted on the inner and outer sides of the upper part of the tooth ring; a cylinder jacket is mounted on the base, and is connected with the positioning ring; and the pressing head is mounted at the upper part of the cylinder jacket. The fixture for cylinder jacket rough boring is simple in structure and convenient to manufacture, maintain and use, reduces the rejection rate in cylinder jacket rough boring, and improves the economic benefit of enterprises.

Owner:ANHUI RUITAI AUTO PARTS

Vehicle oil filler cover online detection tool

ActiveCN104296627AAvoid affecting assembly efficiencySimple fixture structureMechanical clearance measurementsProduction lineRound bar

The invention relates to the technical field of a detection tool and discloses a vehicle oil filler cover online detection tool. The vehicle oil filler cover online detection tool comprises a concave detection block, a convex detection block and a pass-stop gauge; both the concave detection block and the convex detection block are magnetic detection blocks; the concave detection block is provided with an accommodating space for the convex detection block; a plurality of groups of through holes for fixing magnets are formed between the upper surface and the lower surface of the concave detection block and the through holes are uniformly distributed in the peripheral direction of the accommodating space; moreover, the sides, close to the accommodating space, of the through holes are communicated with the accommodating space; one end of the convex detection block is a detection end head in clearance fit with an oil filler to be detected; round bars at both ends of the pass-stop gauge have different diameters. The detection tool has a simple structure, is convenient to carry, can detect the size of the oil filler of an online side hoarding at any time, and avoids an unqualified workpiece entering a production line to cause rework of a finished vehicle and influence assembling efficiency.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Detection tool for distinguishing different standards of flanges and detection method thereof

ActiveCN106052526AAccurate distinctionGuaranteed accuracyMechanical diameter measurementsEngineeringFlange

Owner:科泷(重庆)环保科技有限公司

Wire harness terminal fixation double-layer fixture

The invention relates to the technical field of wire harness terminal fixtures, in particular to a wire harness terminal fixation double-layer fixture. Through the wire harness terminal fixation double-layer fixture, the problems that the machining detection effect is affected and the structure is complex in the prior art are solved. The wire harness terminal fixation double-layer fixture comprises a chuck fixing plate, a locating pin and chuck linings. A supporting plate is fixed to the chuck fixing plate through screws. The bottom of the chuck fixing plate is rotatably provided with an outerside plate adjusting lead screw and an inner side plate adjusting lead screw correspondingly. Chuck outer side plates and chuck inner side plates arranged symmetrically are assembled to the outer portion of the outer side plate adjusting lead screw and the outer portion of the inner side plate adjusting lead screw in a sliding mode. The wire harness terminal fixation double-layer fixture is provided with a first adjusting knob, a second adjusting knob, the outer side plate adjusting lead screw, the inner side plate adjusting lead screw and the like. A worker can drive the two chuck outer sideplates and the two chuck inner side plates to move synchronously by rotating the first adjusting knob or the second adjusting knob so as to drive two clamping jaws to motion synchronously. The wire harness terminal fixation double-layer fixture is convenient to operate, the fixture structure on the market is simplified, and the workers can use the wire harness terminal fixation double-layer fixture conveniently.

Owner:苏州施卡尼光电科技有限公司

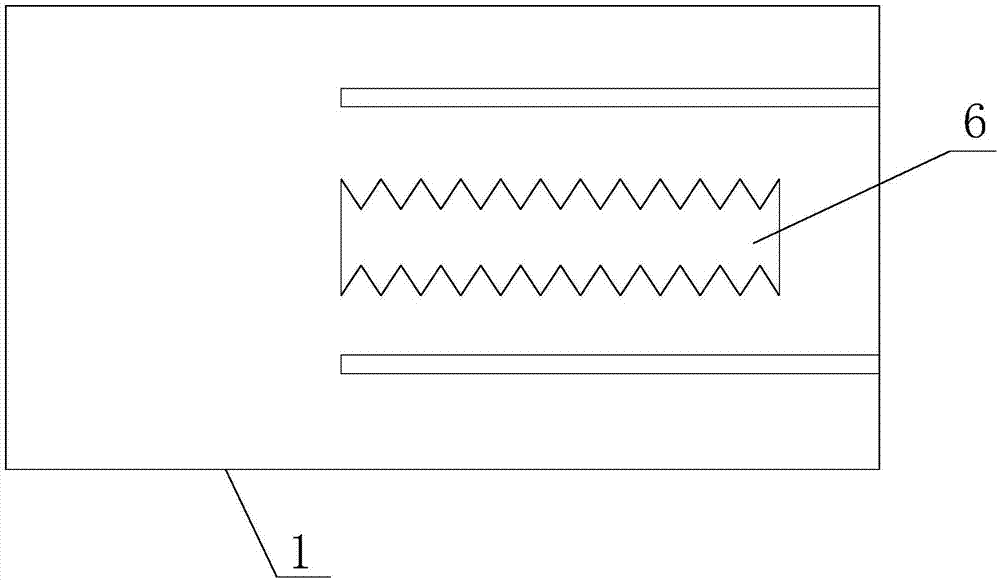

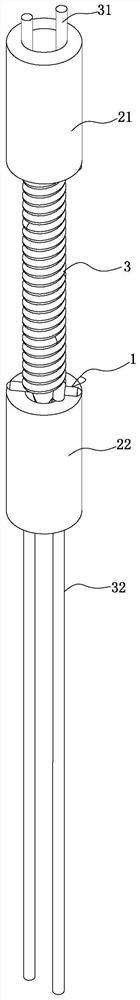

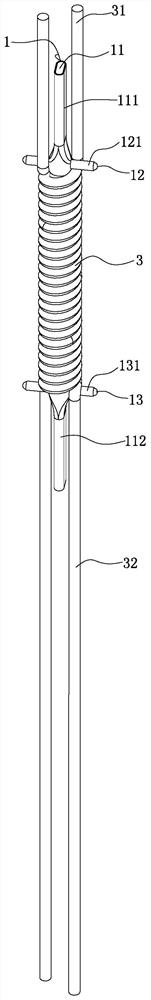

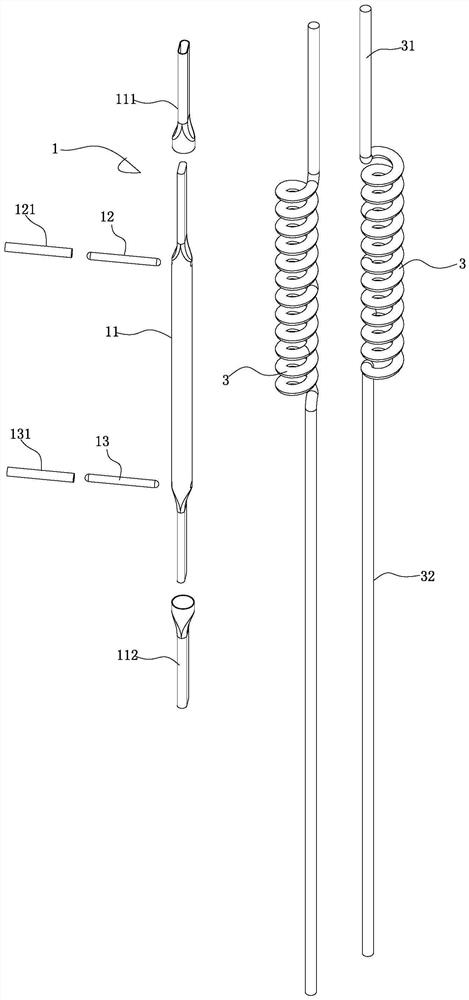

Method and jig for manufacturing equidistant coiled wires

ActiveCN112547987ASimple fixture structureThe production method is reasonableManufacturing extensible conductors/cablesEngineeringElectric wire

The invention discloses a method and jig for manufacturing equidistant coiled wires. The method comprises the following steps that S001, the jig is prepared, the jig comprises a winding bar, an upperpositioning pin and a lower positioning pin, wherein the upper positioning pin and the lower positioning pin are installed at the upper end and the lower end of the winding bar, and sand blasting treatment is conducted on the surface of the winding bar; S002, two electric wires with the same diameter are prepared; S003, wire ends of the two electric wires are pressed on the upper positioning pin in a front-back staggered mode, then positioning is conducted through an upper fixing sleeve piece, meanwhile, the two electric wires are pulled to be attached in parallel, the electric wires are woundon the winding bar clockwise or anticlockwise into a coil until the wire tails of the two electric wires get close to the lower positioning pin, the wire tails of the two electric wires are pressed on the lower positioning pin in a front-back staggered mode, and then a lower fixing sleeve piece is adopted for positioning; S004, a semi-finished product is placed in an oven at the temperature of 120 DEG C to be baked for 25-30 min, and thus the winding part of the electric wires is shaped; S005, the electric wires are taken out after shaping, and placed in clear water to be cooled for 2-3 minutes; and S006, the upper fixing sleeve piece, the lower fixing sleeve piece and the two electric wires are taken down to form the two independent equidistant coiled wires.

Owner:DONGGUAN KAILAI ELECTRONICS CO LTD +1

Electromagnetic folding clamp for polycrystalline silicon wafer

InactiveCN108657812ASimple fixture structureAvoid damageConveyor partsInductorPolycrystalline silicon

The invention discloses an electromagnetic folding clamp for a polycrystalline silicon wafer. The electromagnetic folding clamp comprises a folding support, and the folding support is composed of a folding device and two rotary arms. Fixed clamps are mounted at the bottom ends of the rotary arms, and adjusting devices are mounted between the rotary arms and the fixed clamps. A gyroscope and an adjusting motor are mounted in each adjusting device, and electromagnets are mounted in the fixed clamps. Buffer mats are mounted on the opposite faces of the two fixed clamps, and pressure inductors aremounted between the buffer mats and the fixed clamps. A processing chip is mounted on the folding support, and connected with the gyroscopes, the adjusting motors, a folding motor, the electromagnetsand the pressure inductors through wires. In this manner, the electromagnetic folding clamp for the polycrystalline silicon wafer is simple in structure, the polycrystalline silicon wafer can be directly clamped, the polycrystalline silicon wafer can be prevented from being damaged, and maintenance costs are saved.

Owner:SUZHOU SUNWELL NEW ENERGY CO LTD

Pipe fitting inspection device

InactiveCN103542788ARealize test inspectionSimple fixture structureAngles/taper measurementsMechanical counters/curvatures measurementsPipe fittingEngineering

The invention relates to an inspection device, in particular to a pipe fitting inspection device. A coordinate base is fixedly mounted on each side of one end of the upper end face of a bottom plate along the width direction through screws, a first end face fixing plate is arranged correspondingly to the middles of the two coordinate bases, and a fixing block is fixed on the first end face fixing plate through screws. A second end face fixing plate matched with the first end face fixing plate is fixedly arranged at the other end of the upper end of the bottom plate along the length direction, and a shaft pin is arranged on the second end face fixing plate. A first supporting seat and a second supporting seat of the same structure are arranged between the first end face fixing plate and the second end face fixing plate. The brand-new pipe fitting developed through technological innovation is simple in structure and reasonable and ingenious, testing on pipe fitting parallelism, length and bending profile can be realized by the special structural design of the inspection device, and additionally, test and inspection of holes can be realized through a unique hole site testing jig.

Owner:无锡申宝汽车钢管有限公司

An online inspection tool for automobile fuel filler cap

ActiveCN104296627BAvoid affecting assembly efficiencySimple fixture structureMechanical clearance measurementsProduction lineEngineering

The invention relates to the technical field of a detection tool and discloses a vehicle oil filler cover online detection tool. The vehicle oil filler cover online detection tool comprises a concave detection block, a convex detection block and a pass-stop gauge; both the concave detection block and the convex detection block are magnetic detection blocks; the concave detection block is provided with an accommodating space for the convex detection block; a plurality of groups of through holes for fixing magnets are formed between the upper surface and the lower surface of the concave detection block and the through holes are uniformly distributed in the peripheral direction of the accommodating space; moreover, the sides, close to the accommodating space, of the through holes are communicated with the accommodating space; one end of the convex detection block is a detection end head in clearance fit with an oil filler to be detected; round bars at both ends of the pass-stop gauge have different diameters. The detection tool has a simple structure, is convenient to carry, can detect the size of the oil filler of an online side hoarding at any time, and avoids an unqualified workpiece entering a production line to cause rework of a finished vehicle and influence assembling efficiency.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

A pipe inspection tool

InactiveCN103542788BRealize test inspectionSimple fixture structureAngles/taper measurementsMechanical counters/curvatures measurementsPipe fittingSite testing

The invention relates to an inspection device, in particular to a pipe fitting inspection device. A coordinate base is fixedly mounted on each side of one end of the upper end face of a bottom plate along the width direction through screws, a first end face fixing plate is arranged correspondingly to the middles of the two coordinate bases, and a fixing block is fixed on the first end face fixing plate through screws. A second end face fixing plate matched with the first end face fixing plate is fixedly arranged at the other end of the upper end of the bottom plate along the length direction, and a shaft pin is arranged on the second end face fixing plate. A first supporting seat and a second supporting seat of the same structure are arranged between the first end face fixing plate and the second end face fixing plate. The brand-new pipe fitting developed through technological innovation is simple in structure and reasonable and ingenious, testing on pipe fitting parallelism, length and bending profile can be realized by the special structural design of the inspection device, and additionally, test and inspection of holes can be realized through a unique hole site testing jig.

Owner:无锡申宝汽车钢管有限公司

Detection tool for boss of ring piece and detection method and application of detection tool

PendingCN113587768ASimple fixture structureEasy to processMechanical diameter measurementsMechanical thickness measurementsEngineeringMechanical engineering

The invention provides a detection tool for a ring boss and a detection method and application of the detection tool. The testing fixture for the boss of the ring piece comprises a base and a die, wherein the die comprises an upper die assembly and a lower die assembly; the lower die assembly is fixed to the surface of the base, the ring piece boss is arranged in the upper die assembly, and then the upper die assembly and the lower die assembly are buckled; when the upper die assembly completely covers the lower die assembly, the ring part boss is detected to be qualified. The detection tool for the ring part bosses is simple in structure, easy to machine, capable of detecting whether the ring part bosses meet the standard or not at the same time, high in detection efficiency and capable of saving detection time and labor cost and guaranteeing accuracy in the mode of full detection of the detection tool and sampling detection of one ring part boss through a caliper.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Aluminum profile tractor

The invention provides a traction machine of an aluminium profile. The traction machine comprises a guide rail and a tractor and also comprises an installing arm and a clamp, wherein the guide rail is approximately parallel to a discharging platform of the aluminium profile; the tractor is arranged on the guide rail in a sliding manner; the first end of the installing arm is fixedly connected with the tractor, and the second end of the installing arm is overhung above the discharging platform; the clamp is arranged at the second arm of the installing arm and comprises a clamping frame, a pressing mechanism and a cylinder; the clamping frame comprises a pair of supporting plates which are oppositely and vertically arranged at the second end of the installing arm; the top parts of the two supporting plates are respectively hinged with the second end of the installing arm by hinge pieces; the bottom parts of the two supporting plates are bent oppositely to form a supporting-plate bottom surface; and the pressing mechanism is arranged in the clamping frame and can do up-down movement in the clamping frame relatively to the second end of the installing arm by driving of the cylinder. The traction machine provided by the invention has the advantages that not only the production efficiency of the aluminium profile can be effectively improved, the labor intensity of workers can be reduced, but also the clamp has the characteristic of simple and ingenious structure and can realize clamping and unloading of the aluminium profile well.

Owner:台澳铝业(台山)有限公司

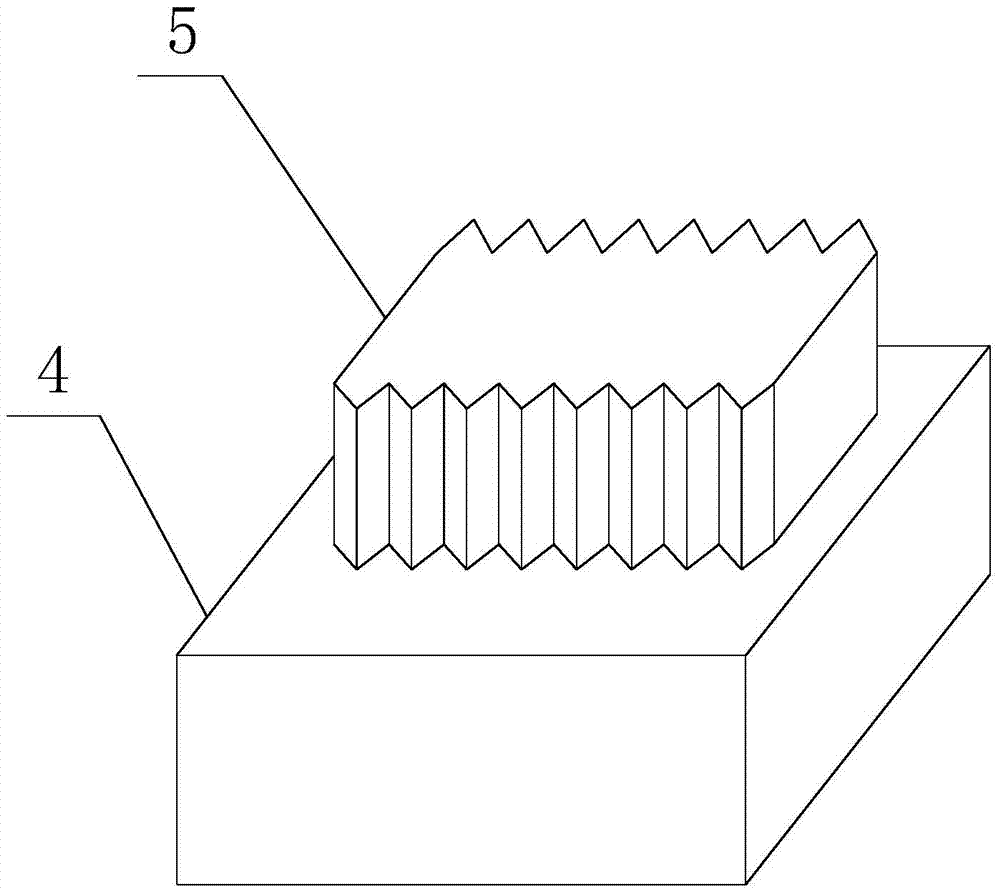

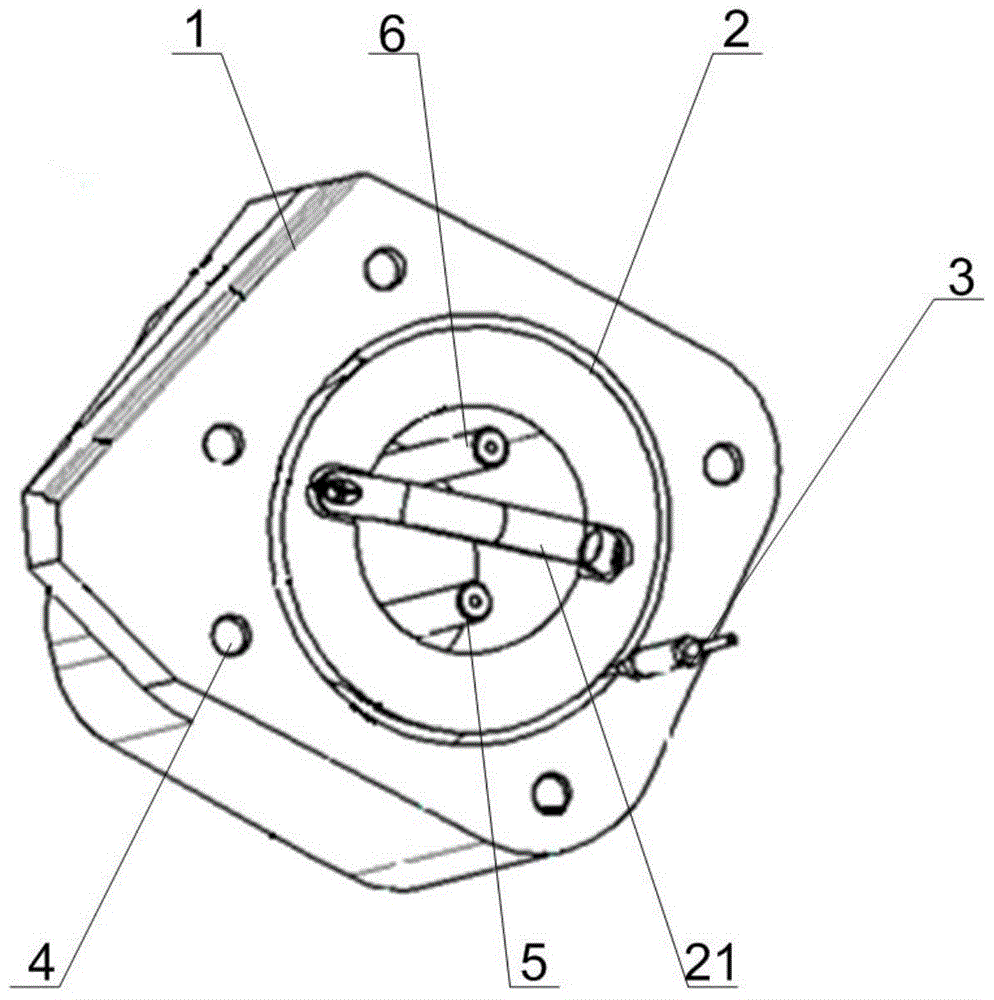

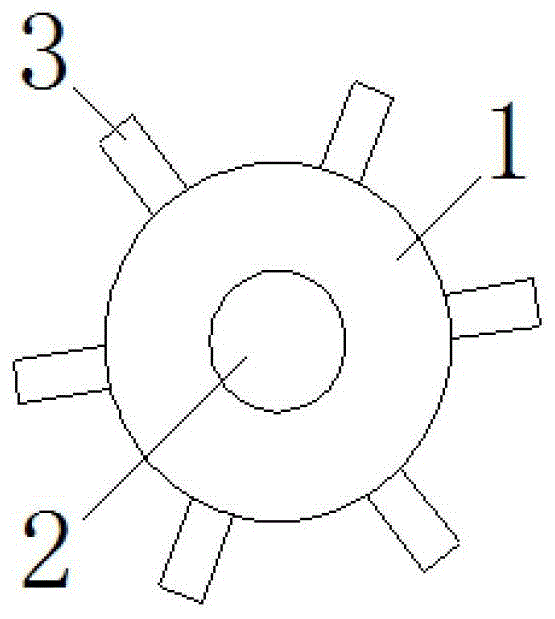

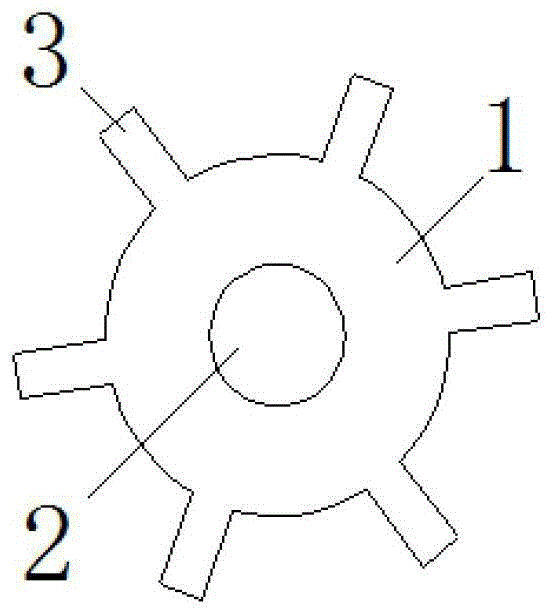

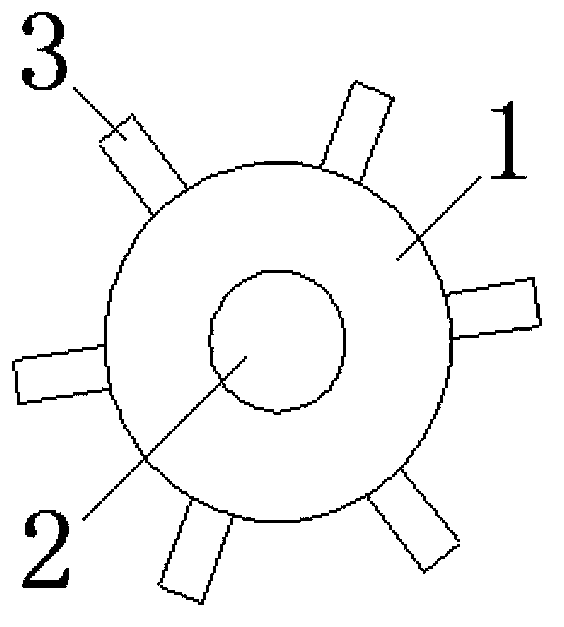

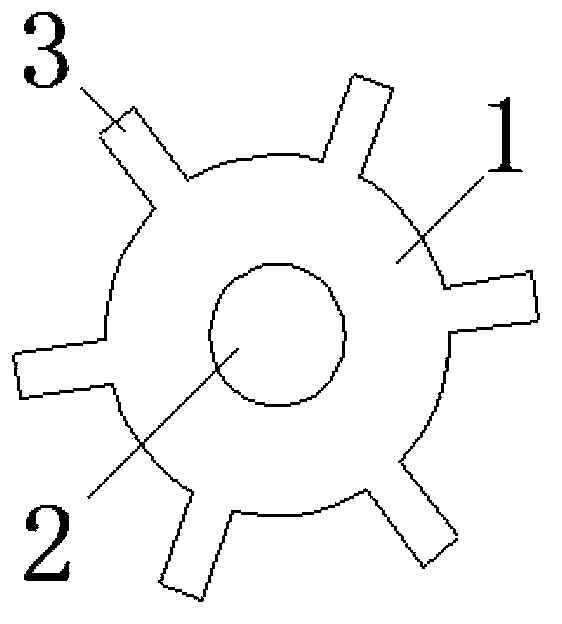

Gear milling clamp for bevel gear

InactiveCN105750661AEasy clampingSimple fixture structureGear-cutting machinesGear teethEngineeringBevel gear

The invention discloses a gear milling clamp for a bevel gear. The gear milling clamp comprises a pull rod and a positioning plate coaxially nested on the pull rod, wherein the positioning plate and the pull rod are glidingly matched in the axial direction, an edge-chamfered positioning pin is arranged on the end surface of one side of the positioning plate, and a spigot shaft section is integrally arranged on the end surface of the other side of the positioning plate; a press plate is integrally arranged at the end part of the pull rod, and an annular step is arranged at one end, close to the positioning plate, of the press plate and sleeved with a first belleville spring; the gear milling clamp further comprises a first circumferential positioning pin which is arranged on the positioning plate and is glidingly matched with the press plate in the axial direction. According to the gear milling clamp for the bevel gear, during rough machining of a gear, the center position of the gear is positioned through matching of the belleville spring and an inner hole of the gear, the circumferential position of the gear is positioned through the edge-chamfered positioning pin, the diameter of the belleville spring is increased by pressing the belleville spring by the aid of the pressing plate, accordingly, the belleville spring is expanded to fix the gear, the assembly and clamping are convenient and rapid, and besides, the clamp is simple in structure and low in manufacturing cost.

Owner:CHONGQING TAIJING PACKAGING PROD

A checking tool for testing the flatness of the windshield and the vehicle body

ActiveCN103363878BReduce misassemblyImprove detection efficiencyMechanical roughness/irregularity measurementsEmbedded systemWindshield

The invention discloses a detection device for detecting the coordination flatness of a windshield and a vehicle body. The detection device comprises a detection device body and detection blades, wherein the detection blades are in platy structures, a group of detection blades in different heights are uniformly distributed on the outer wall of the detection device body, and the bottom surfaces of one group of detection blades and the bottom surface of the detection device body are positioned on the same plane. The detection blades in corresponding heights are selected according to the detection standard of the coordination flatness of the windshield and the vehicle body of a vehicle model; the detection device is arranged on the metal plate plane of the vehicle body and translates to and is in contact with the edge of the windshield, whether the windshield is higher than the detection blades is observed, whether the coordination flatness of the windshield glass and the vehicle body meets requirements can be rapidly detected, the possibility that the windshield cannot be assembled in place is reduced, and the assembly quality is improved; and the detection device is simple in structure, convenient to operate and high in detection efficiency.

Owner:CHERY AUTOMOBILE CO LTD

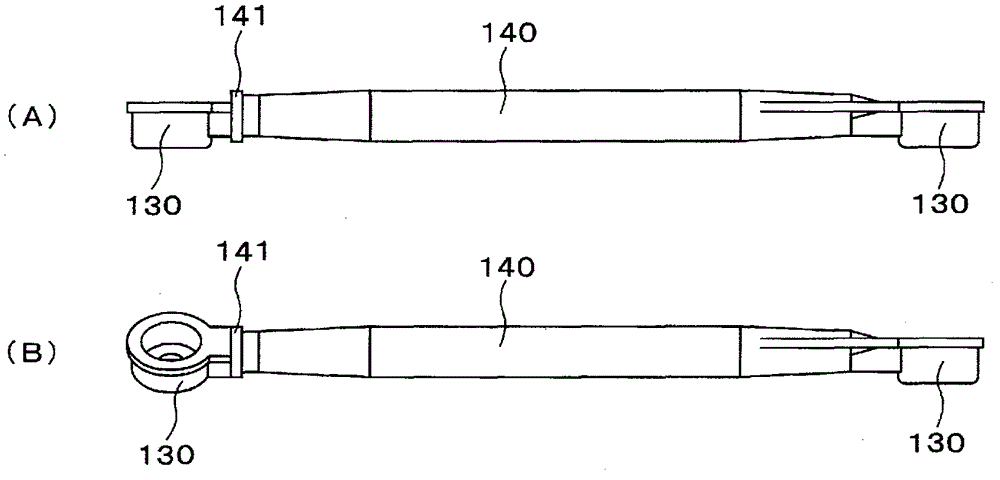

Stabilizer link and manufacturing method thereof

ActiveCN103608595BPrevent leakageSimple fixture structureInterconnection systemsPivotal connectionsFlange

Owner:NHK SPRING CO LTD

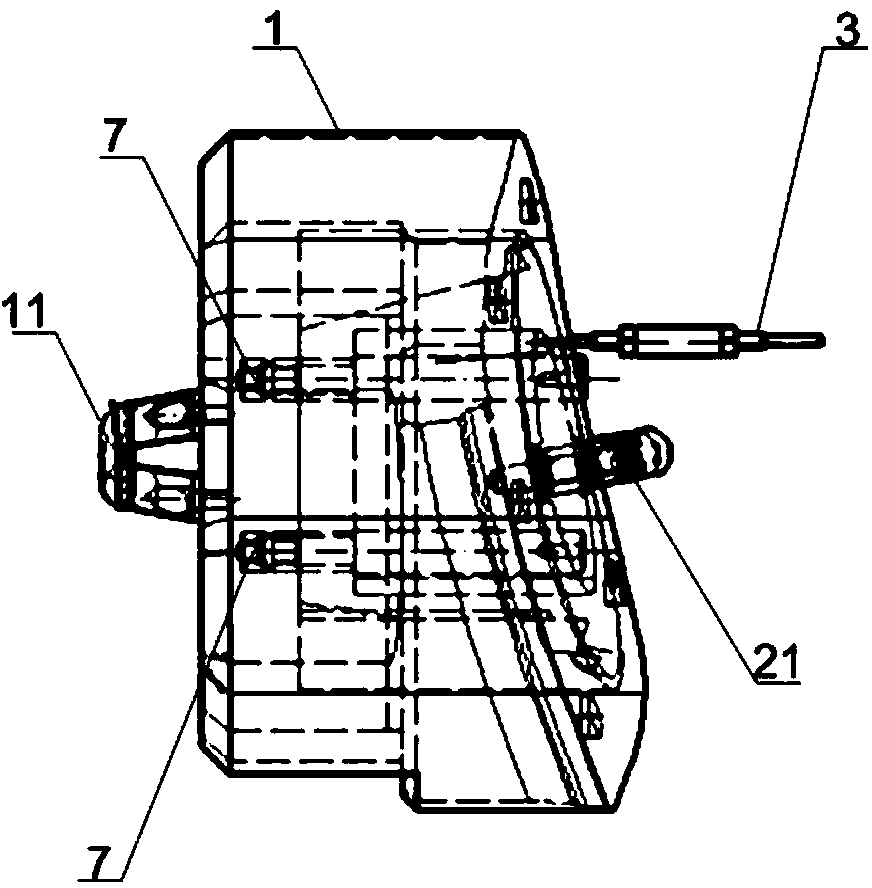

Hole-turning device for part with two parallel holes

ActiveCN102211282ASimple fixture structureEasy to manufactureAuxillary equipmentPositioning apparatusCentre of rotationEngineering

The invention relates to a hole-turning device for a part with two parallel holes. A jig plate is arranged on a flange plate of a lathe through an inner hole of the jig plate and fixed by an inner hexagon screw; a part mandrel is arranged on the jig plate; a counterweight mandrel is arranged in a corresponding hole of the jig plate, the axial lines of the part mandrel and the counterweight mandrel are in symmetrical positions of the jig plate rotation center; a counterweight member is arranged on the counterweight mandrel; a bracket is fixed on the counterweight member; a stud is arranged in a screw hole of the bracket and locked by using a nut; the part is arranged on the part mandrel through the inner holes of front and rear ends of the group of machined holes and by using a locating sleeve, a large retaining pad and a countersunk head screw; and the outer circles of middle sections of the other group of holes of the part are pressed on the bracket by using the stud, another nut anda pressure plate. By adopting the hole-turning device for the part with two parallel holes, one of two groups of mutually parallel holes in the part can be easily and quickly machined; moreover, the jig has the advantages of simple structure and convenience for manufacturing.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

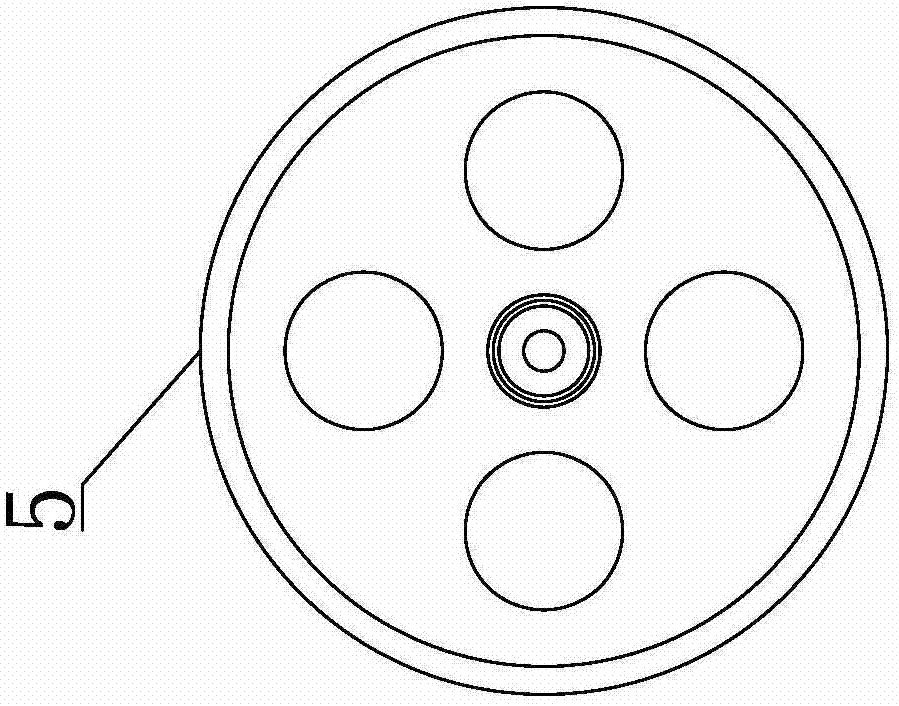

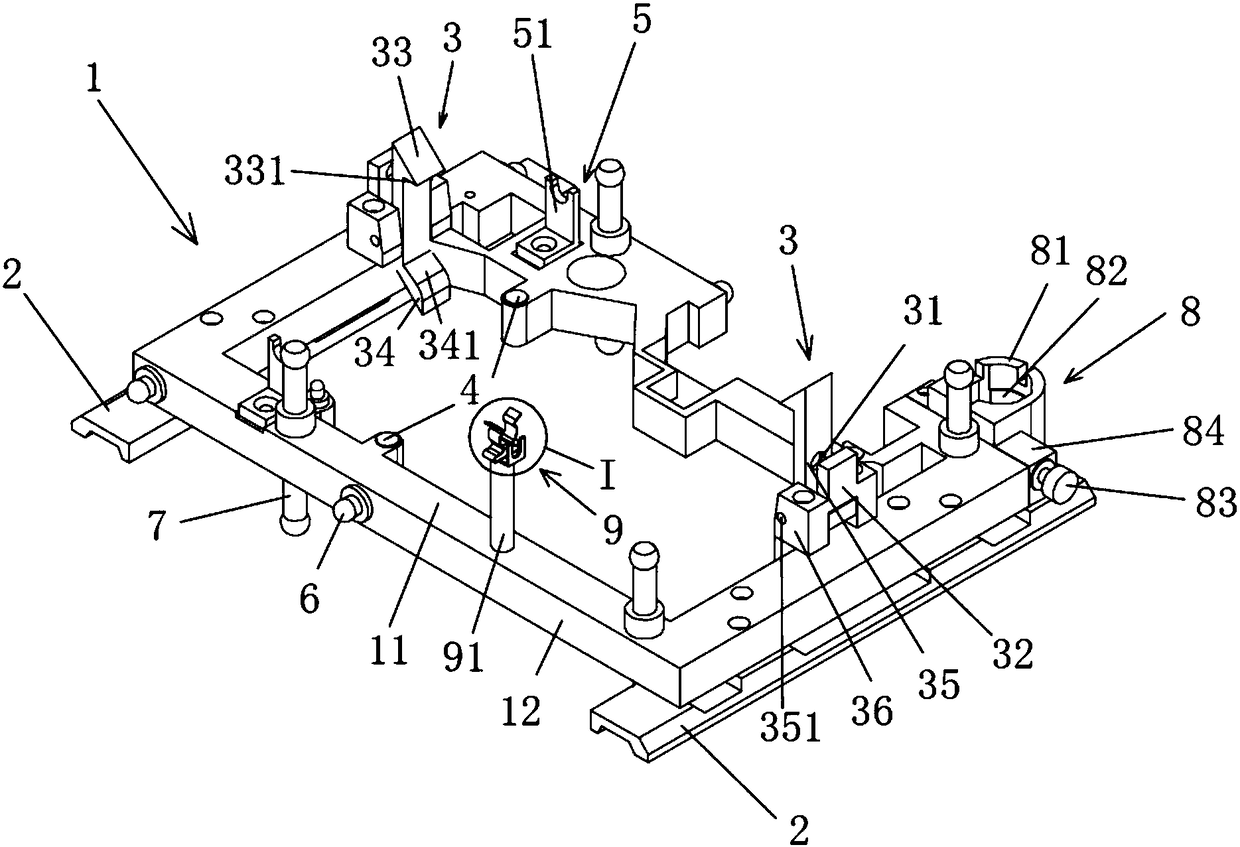

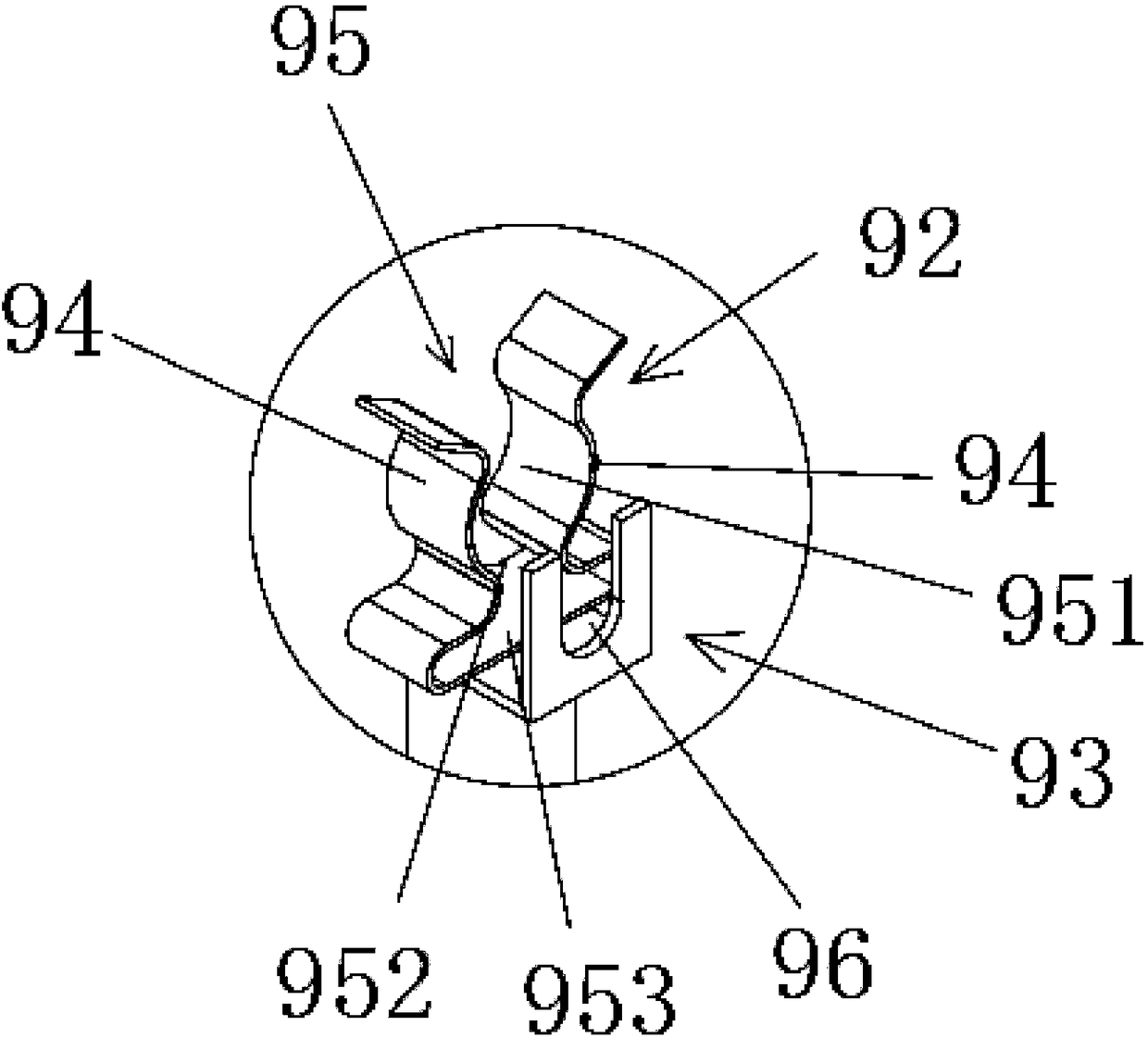

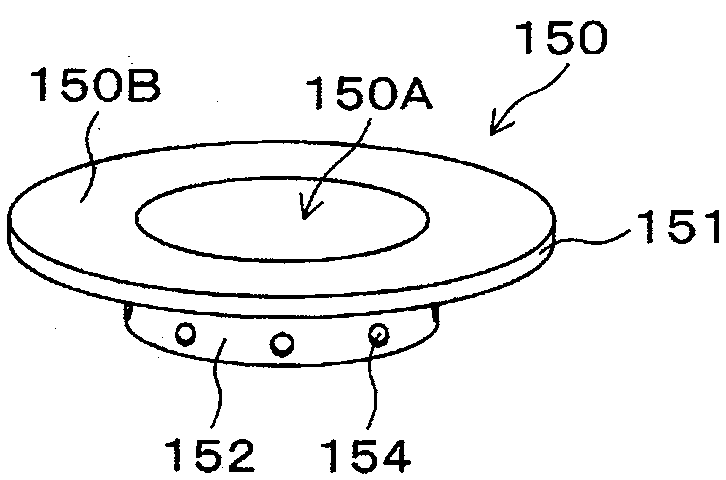

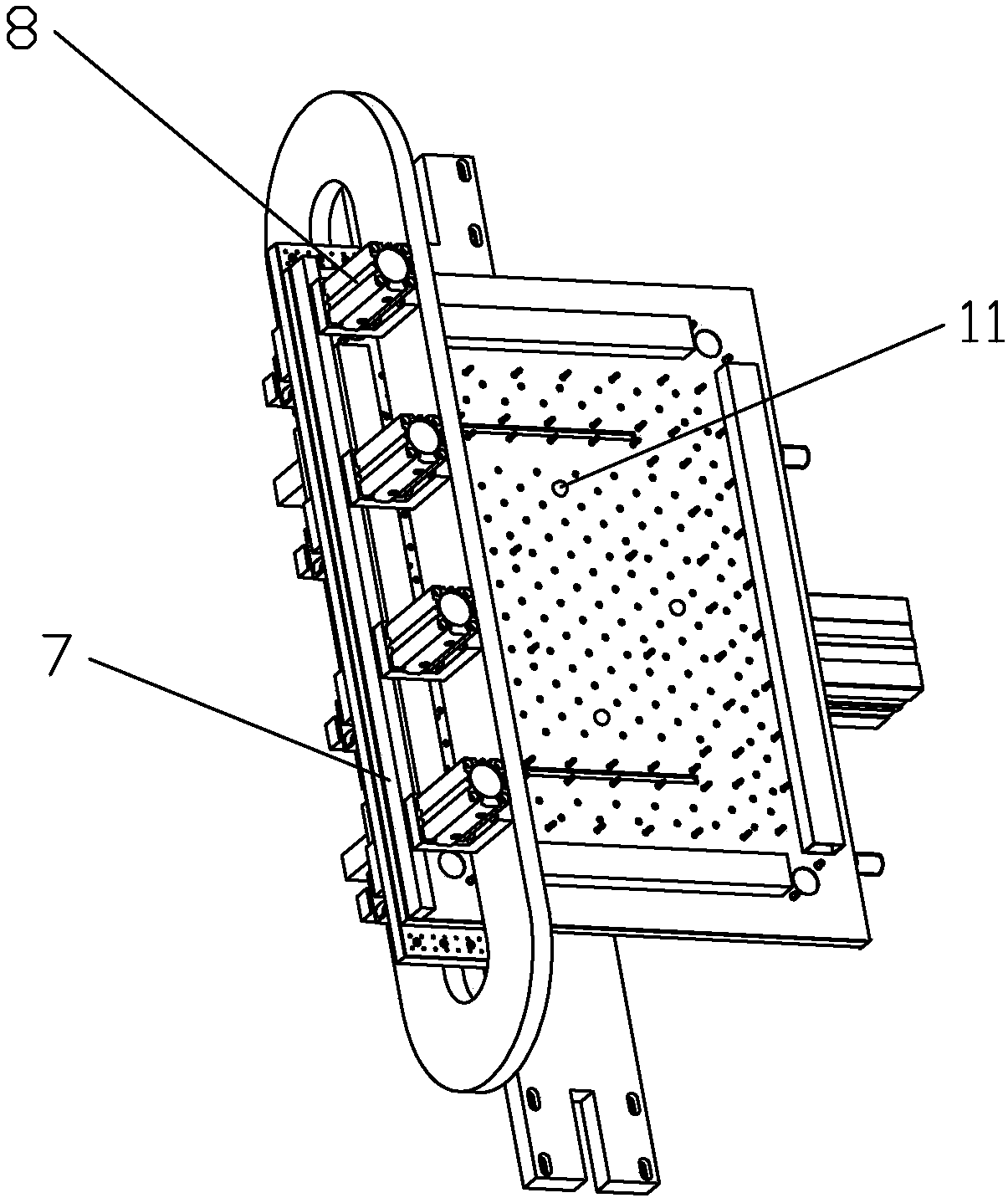

Fixture device of rotary-disc automatic welding machine for water outlet plate

InactiveCN107553051ASimple fixture structureEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCompression device

The invention discloses a fixture device of a rotary-disc automatic welding machine for a water outlet plate. The fixture device is installed on a rack main body, and comprises a welding rotary disc horizontally installed on the rack main body, wherein a compression device used for compressing the water outlet plate is arranged on the welding rotary disc; and a drive mechanism connected with the welding rotary disc and driving the welding rotary disc to rotate is arranged on the rack main body. The fixture device of the rotary-disc automatic welding machine for the water outlet plate is simplein structure; and the welding rotary disc taking the centre thereof as a rotary shaft is adopted, and after welding for one side of a workpiece is completed, the welding rotary disc automatically rotates 90 degrees, then the other side can continue to be welded. The fixture device is simple to operate, and has no need to disassemble and assemble the workpiece for many times, thereby increasing the machining efficiency, and saving the labor cost.

Owner:江门市霈霖卫浴科技有限公司

Detection device for detecting coordination flatness of windshield and vehicle body

ActiveCN103363878AReduce misassemblyImprove detection efficiencyMechanical roughness/irregularity measurementsEngineeringWindshield

The invention discloses a detection device for detecting the coordination flatness of a windshield and a vehicle body. The detection device comprises a detection device body and detection blades, wherein the detection blades are in platy structures, a group of detection blades in different heights are uniformly distributed on the outer wall of the detection device body, and the bottom surfaces of one group of detection blades and the bottom surface of the detection device body are positioned on the same plane. The detection blades in corresponding heights are selected according to the detection standard of the coordination flatness of the windshield and the vehicle body of a vehicle model; the detection device is arranged on the metal plate plane of the vehicle body and translates to and is in contact with the edge of the windshield, whether the windshield is higher than the detection blades is observed, whether the coordination flatness of the windshield glass and the vehicle body meets requirements can be rapidly detected, the possibility that the windshield cannot be assembled in place is reduced, and the assembly quality is improved; and the detection device is simple in structure, convenient to operate and high in detection efficiency.

Owner:CHERY AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com