Electromagnetic folding clamp for polycrystalline silicon wafer

A polycrystalline silicon wafer, electromagnetic technology, applied in the direction of conveyor objects, transportation and packaging, can solve problems such as complex structure, achieve the effect of simple fixture structure, save maintenance costs, and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

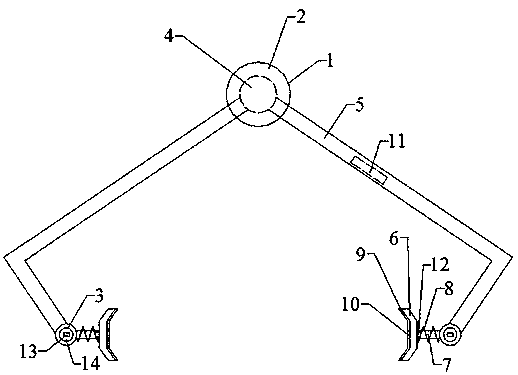

[0019] An electromagnetic folding fixture for polycrystalline silicon wafers, comprising: a folding support 1, the folding support 1 is composed of a folding device 2 and two rotating arms 5, and one end of the two rotating arms 5 is connected to the folding device 2 .

[0020] The folding motor 4 is installed on the rotating arm 5, and the folding motor 4 is embedded in the folding device 2. The folding motor 4 is used to adjust the angle of the two rotating arms 5, so as to achieve the purpose of clamping .

[0021] The bottom end of the rotating arm 5 is equipped with a fixed clip 6, the fixed clip 6 is installed on the rotating arm 5 through a slide bar 7, and the fixed clip 6 is sleeved on the slide bar 7 through a round hole. The fixing clip 6 is slidably connected to the sliding bar 7, so that the fixing clip 6 can slide on the sliding bar 7, thereby adapting to products of different sizes.

[0022] The slide bar 7 is covered with a spring 8, and the two ends of the s...

Embodiment 2

[0031] An electromagnetic folding fixture for polycrystalline silicon wafers, comprising: a folding support 1, the folding support 1 is composed of a folding device 2 and two rotating arms 5, and one end of the two rotating arms 5 is connected to the folding device 2 .

[0032] The folding motor 4 is installed on the rotating arm 5, and the folding motor 4 is embedded in the folding device 2. The folding motor 4 is used to adjust the angle of the two rotating arms 5, so as to achieve the purpose of clamping .

[0033] The bottom end of the rotating arm 5 is equipped with a fixed clip 6, the fixed clip 6 is installed on the rotating arm 5 through a slide bar 7, and the fixed clip 6 is sleeved on the slide bar 7 through a round hole. The fixing clip 6 is slidably connected to the sliding bar 7, so that the fixing clip 6 can slide on the sliding bar 7, thereby adapting to products of different sizes.

[0034] The slide bar 7 is covered with a spring 8, and the two ends of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com