Fixture device of rotary-disc automatic welding machine for water outlet plate

A technology of automatic welding machine and fixture device, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems of uneven welding seam, low processing efficiency, large processing error, etc., and achieve simple structure of the fixture device and save manpower. cost, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

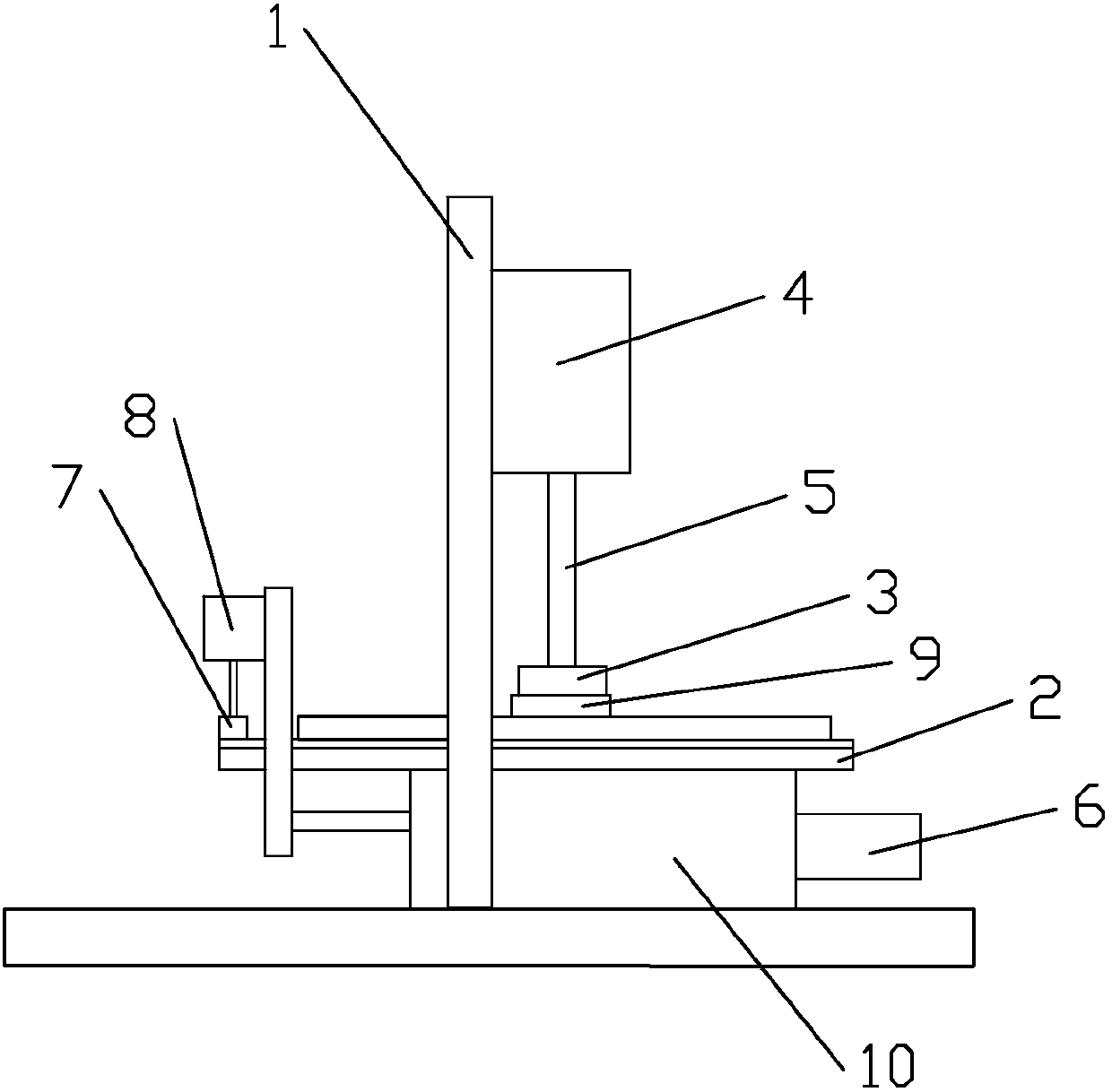

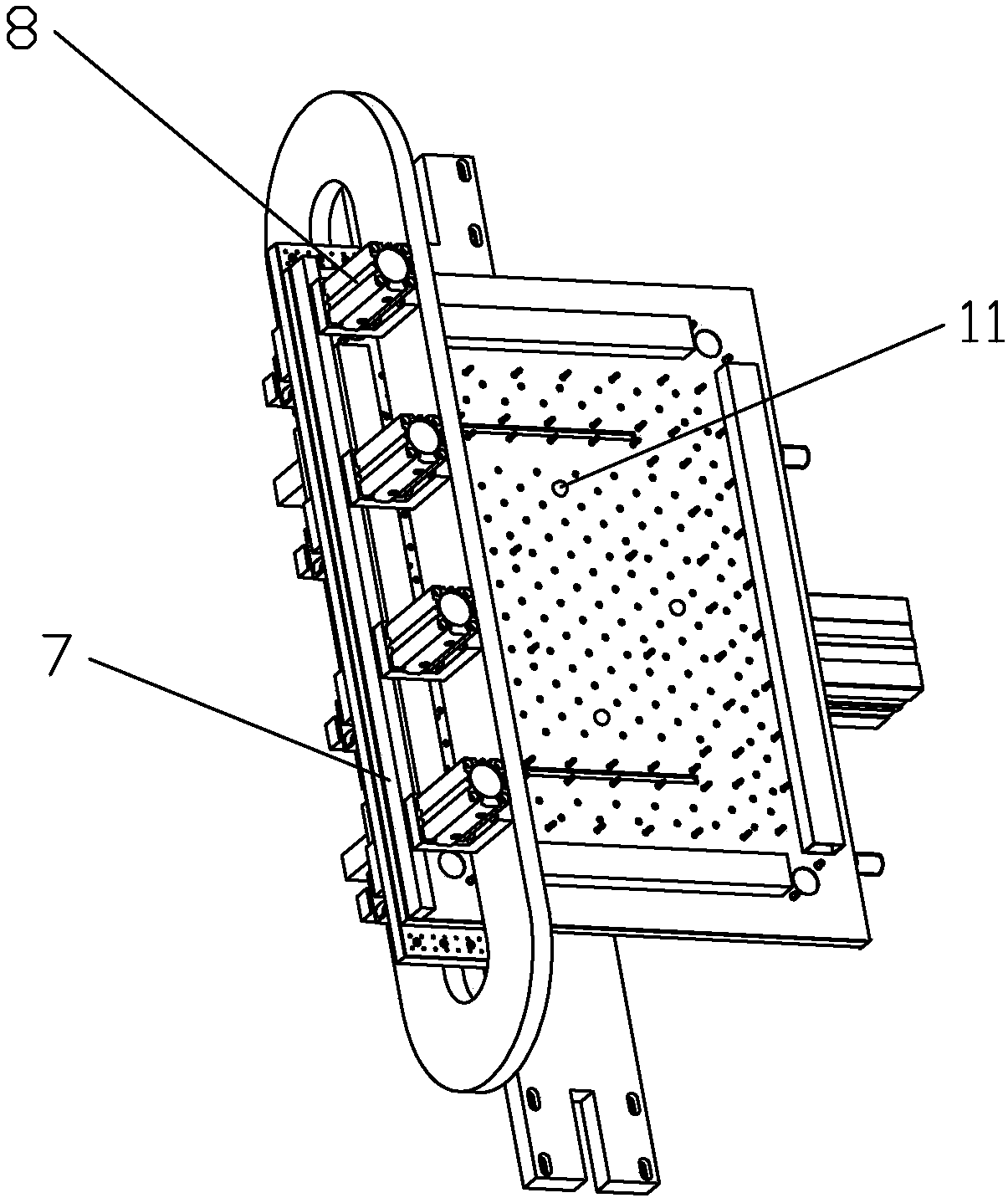

[0018] Such as figure 1 and figure 2 As shown, in one of the embodiments provided by the present invention, the fixture device of the water outlet plate turntable automatic welding machine is installed on the frame main body 1, and the fixture device includes a welding turntable 2 horizontally installed on the frame main body 1, so that The welding turntable 2 is provided with a pressing device 3 for pressing the outlet plate, and the frame main body 1 is provided with a driving mechanism 6 connected with the welding turntable 2 and driving the welding turntable 2 to rotate. Place the square workpiece on the welding turntable 2. After one side of the workpiece is welded, the welding turntable 2 automatically rotates 90 degrees with its center as the rotating shaft, and then the other side of the workpiece can be welded without multiple disassembly and assembly of the workpiece, which improves the processing efficiency and ensures welding. Precision, improve welding automatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com