Stabilizer link and manufacturing method thereof

A manufacturing method and stabilizer technology, applied in the direction of connection, interconnection system, pivot connection, etc., can solve the problem of complicated structure of the fixture, and achieve the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] (1) Each manufacturing process

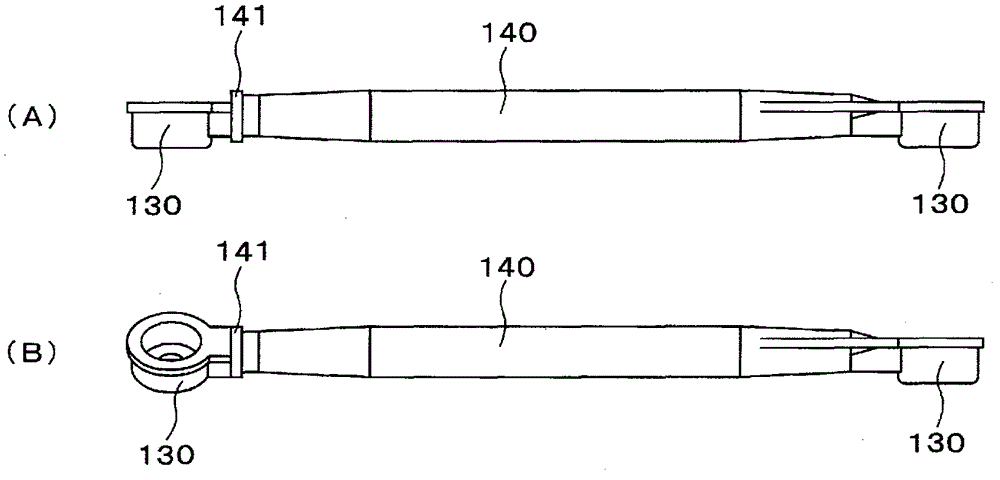

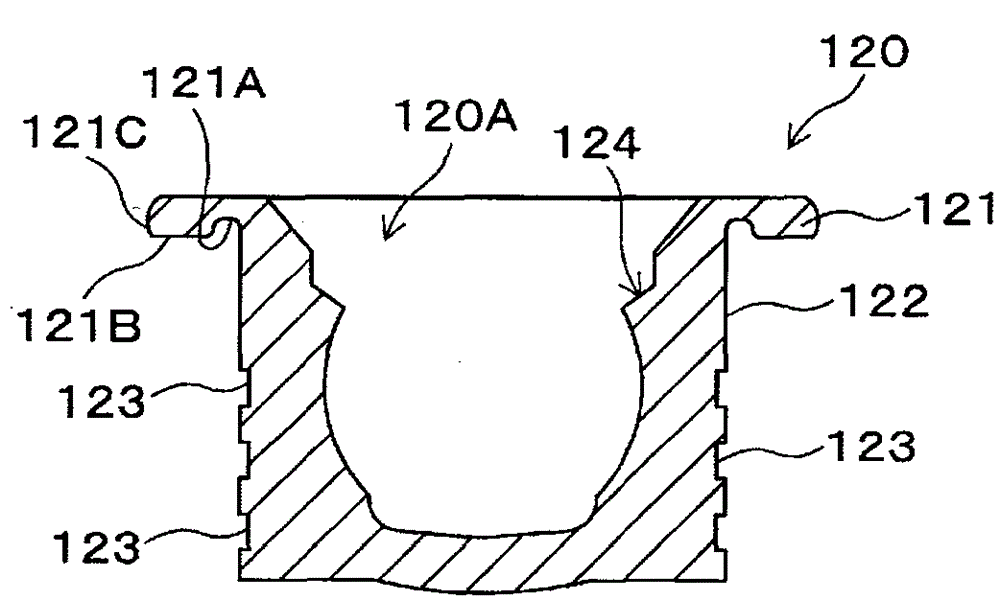

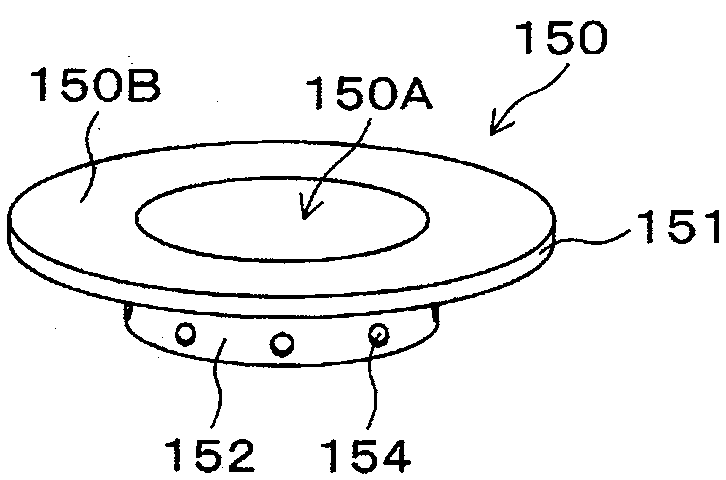

[0054] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. Figure 4 (A)~ Figure 4 (D) is a side sectional view showing a partial structure of each step of the method of manufacturing the stabilizer link 100 according to the embodiment of the present invention. Figure 6 is included Figure 4 (C) An enlarged side cross-sectional view of a part of the ring member 150 shown in insert molding. Figure 6 Make the up and down direction and Figure 4 (C) On the contrary. Figure 12 It is a side view showing a rough structure of the ball stud 101 used in the embodiment. Figure 13 It is a side cross-sectional view showing a schematic structure of the ball seat 120 used in the embodiment.

[0055] The manufacturing method of the stabilizer link 100 of this embodiment and image 3Compared with the manufacturing method of the shown stabilizer link 200, there is a big difference in that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com