Fixture for cylinder jacket rough boring

A cylinder liner and rough boring technology, applied in the direction of clamping, manufacturing tools, support, etc., can solve the problems of unstable cylinder sleeve clamping, slag holes, blisters, and uneven processing of cylinder liner blanks, so as to reduce the scrap rate. , Easy to maintain and use, easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

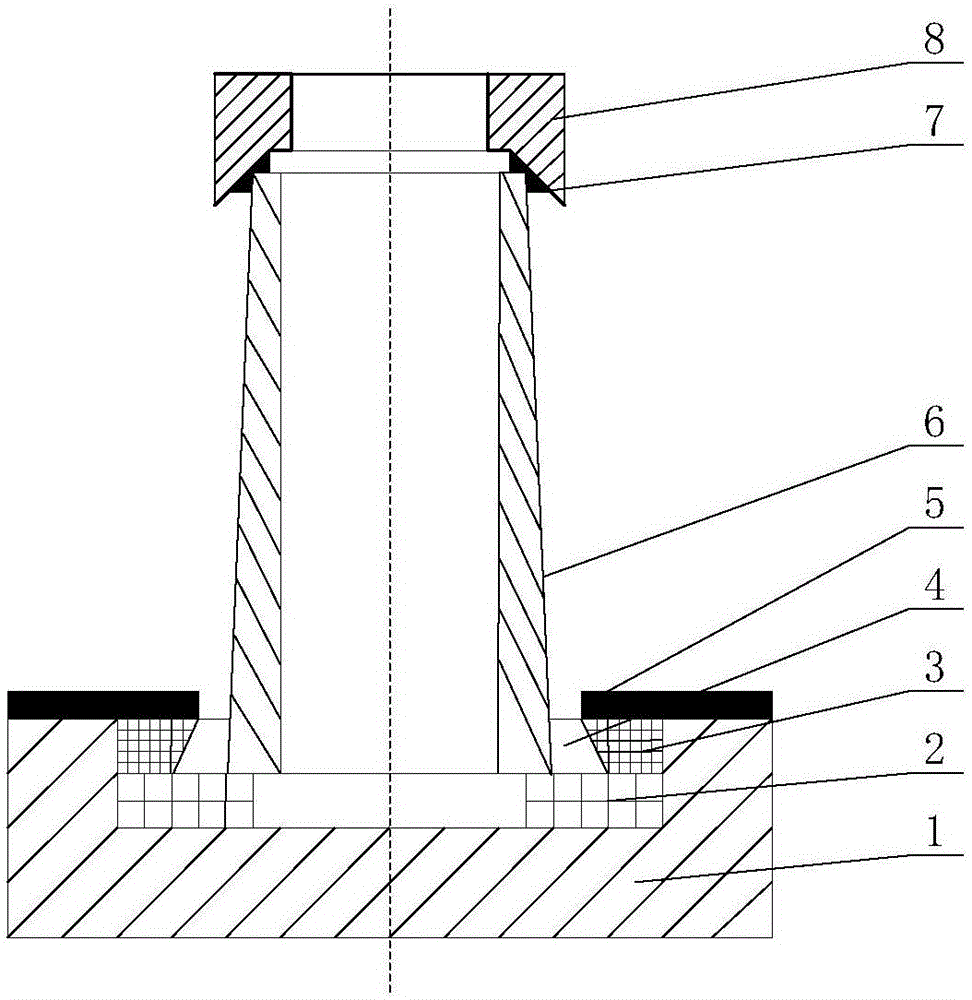

[0017] During specific implementation, combined with figure 1 , a jig for rough boring cylinder liners, including a base 1, tooth ring 2, rubber ring 3, positioning ring 4, cover plate 5, cylinder liner 6, sealing ring 7, pressure head 8. The base 1 is provided with a groove, and the tooth ring 2, the rubber ring 3 and the positioning ring 4 are installed in the groove of the base. The tooth ring 2 is installed at the bottom of the groove. The function of the tooth ring is to increase friction to prevent the cylinder liner blank from rotating. The inner and outer sides of the upper part of the tooth ring are respectively installed with a positioning ring 4 and an apron 3. A cylinder liner 6 is installed on the base 1. And link to each other wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com