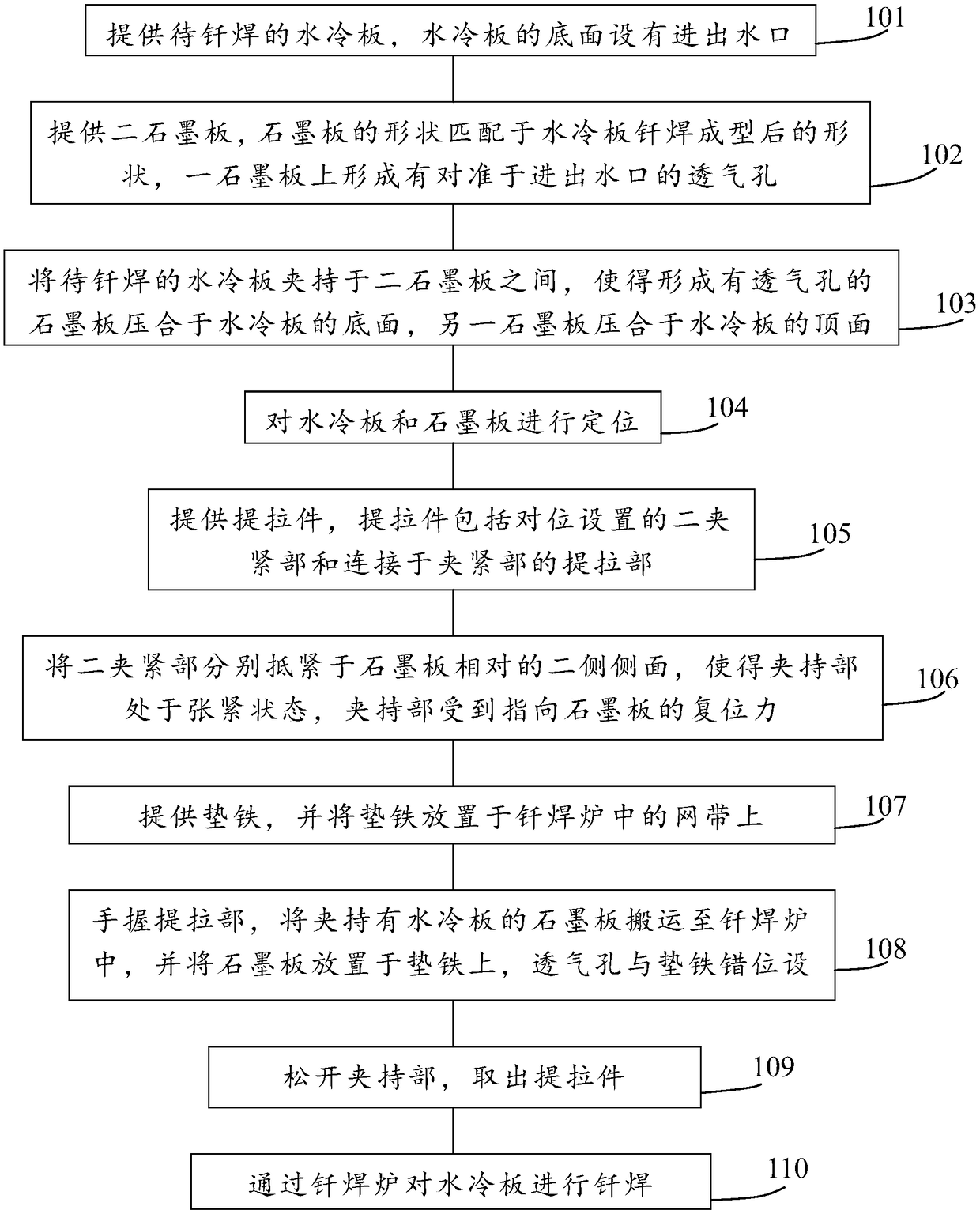

Brazing method for water-cooling plates

A brazing method and water-cooled plate technology, applied in welding equipment, auxiliary devices, metal processing equipment, etc., can solve the problems that the flatness of brazing fixtures cannot be guaranteed, affect the surface flatness of the water-cooled plate, and affect the surface finish of the water-cooled plate. Achieve the effects of shortening the time of clamping, facilitating clamping and positioning, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

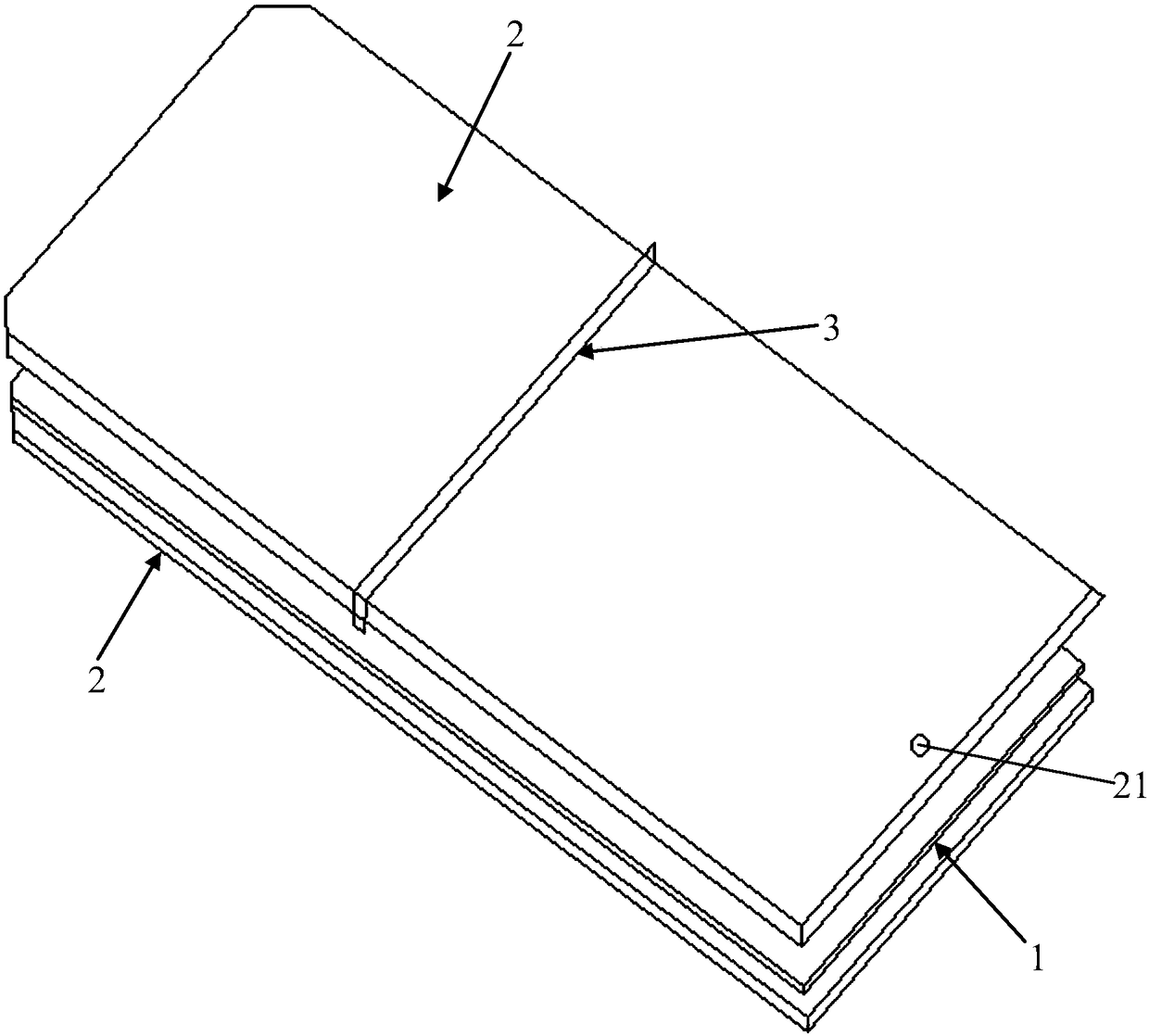

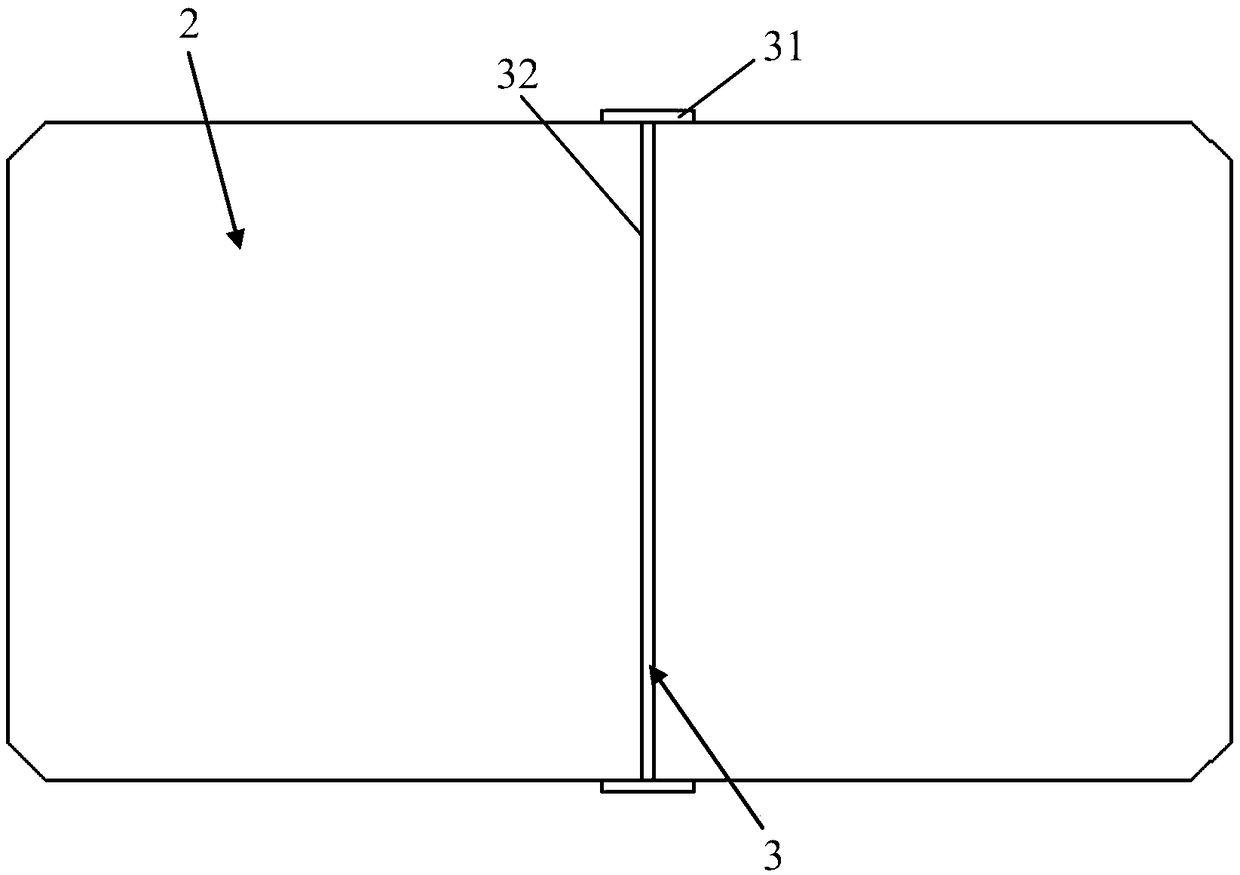

[0050] Embodiment 1: In the lifting member 3 , the clamping part 31 is a resilient member, and the lifting part 32 is a connecting rod welded to the resilient member. In this embodiment, by respectively supporting the two rebounding pieces against the opposite sides of the graphite plate 2, the resilient pieces are in a tensioned state, and the graphite plate 2 is clamped by utilizing the restoring force of the resilient pieces, and then using The lifting member 3 completes the transportation of the graphite plate 2 holding the water-cooled plate 1 . Specifically, (1) the resilient member is T-shaped; (2) the lifting member 3 is a component with a constant cross-section, and the diameter of the cross-section is 6 mm.

Embodiment 2

[0051] Embodiment 2: The clamping part 31 is a claw, and the lifting part 32 is a pull ring fixedly connected to the claw. The two claws are pivotally connected by a pivot, and a torsion spring is sleeved in the pivot connection. The first end of the torsion spring The second end of the torsion spring leans against or connects with the other claw. In this embodiment, the graphite plate 2 is clamped by using the restoring force of the torsion spring by supporting the two claws on the opposite sides of the graphite plate 2 respectively (the torsion spring is in a tensioned state and receives a reset force). , simple in structure and easy to operate.

[0052] In the present invention, the stainless steel brazing jig in the prior art is replaced by two graphite plates 2 , which simplifies the structure of the brazing jig, shortens the time for installing the brazing jig, and improves the production efficiency of the water-cooled plate 1 .

[0053] In the present invention, the le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flatness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com