Fixture of car gearbox valve body

A gearbox and valve body technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of not being able to be used as a fixture, achieve good wear resistance, simple fixture structure, and expand versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail and completely below in conjunction with the embodiments and the accompanying drawings.

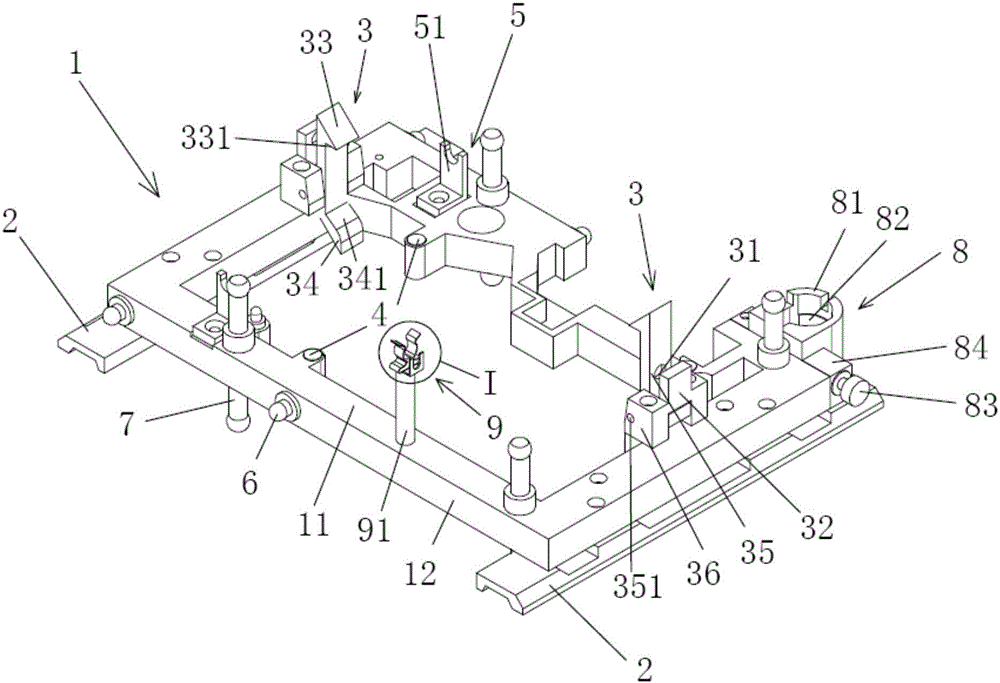

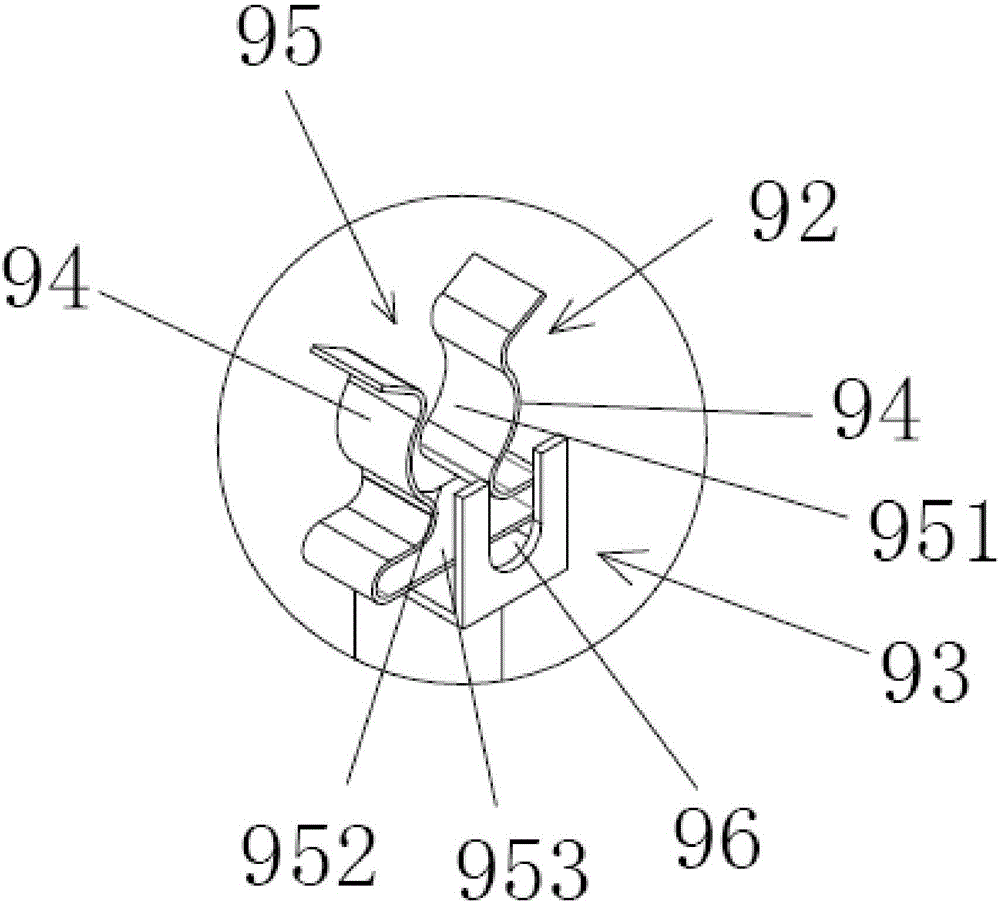

[0030] Such as Figure 1-2 As shown, the present invention provides a clamp for a vehicle gearbox valve body, which includes a pallet frame 1 for carrying the valve body, and a pair of opposite valve body fixing claws 3 are installed on the pallet frame 1. The valve body fixing claw 3 is also connected with a pressing device for bringing a pair of valve body fixing claws 3 closer to each other to generate a pre-tightening force, and the pallet frame 1 is also provided with a positioning surface 11 in contact with the valve body. The spacing direction of a pair of valve body fixing claws 3 is parallel to the positioning surface 11, and a valve body positioning pin 4 and a valve core baffle 5 are also arranged on the positioning surface 11, and the axis of the valve body positioning pin 4 is vertical On the positioning surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com