Method for measuring radial circular run-out quantity of iron core inner circle reference axes from stopping openings at two ends of stator

A reference axis and iron core technology, which is applied in the field of indirect measurement of the radial circular runout of the inner circle of the stator core to the common reference axis of the two ends of the spigot, can solve the problems of large irregularities, labor and materials, etc., and achieve the inspection tool The structure is simple, the measurement operation is convenient, and the test data is intuitive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

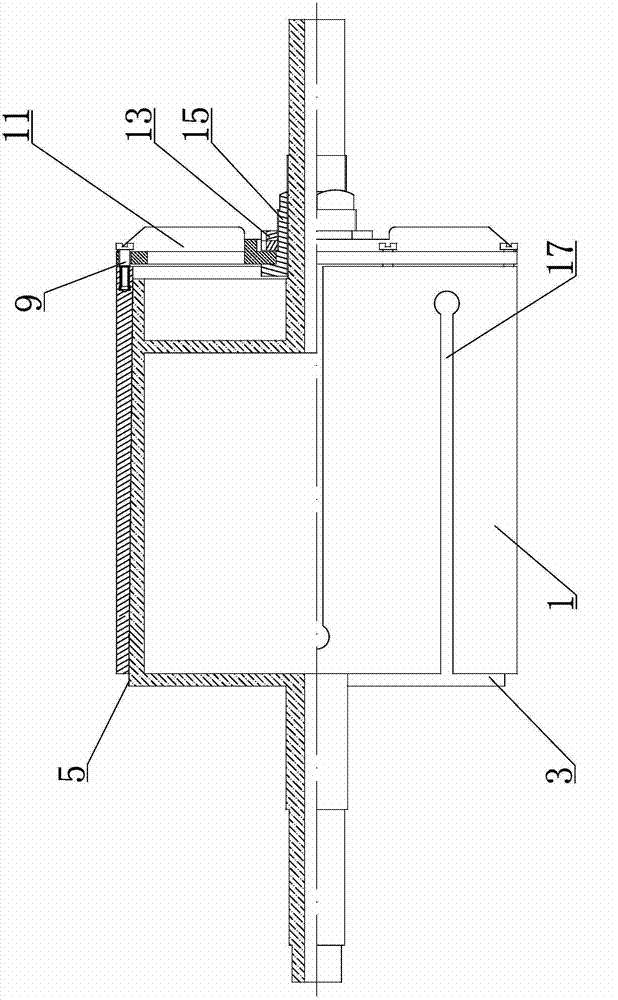

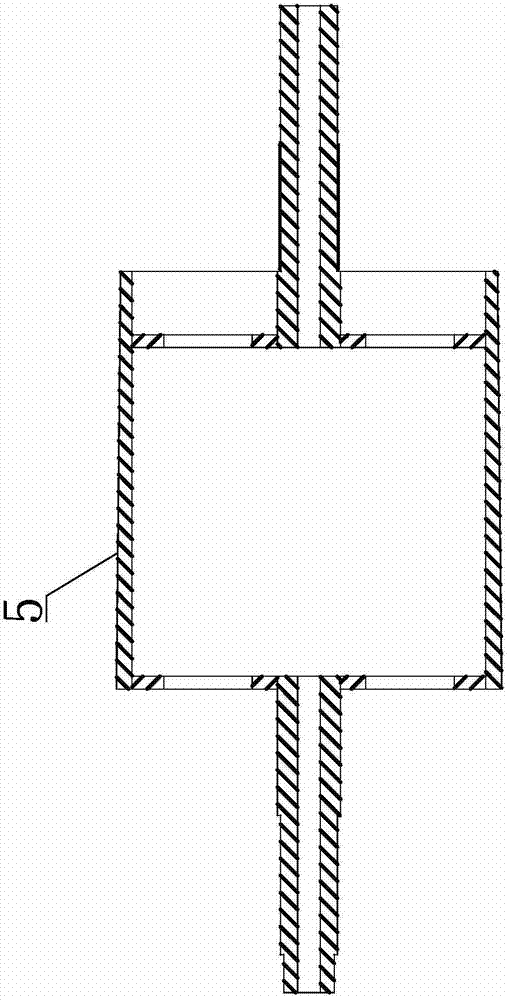

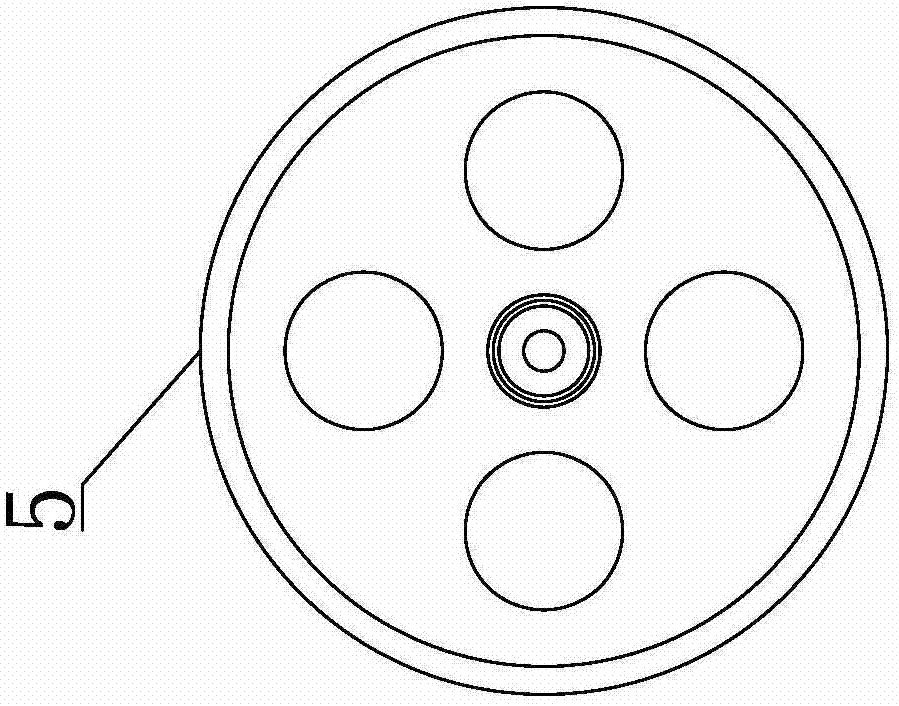

[0018] The present invention will be further described below in conjunction with the accompanying drawings. The method of measuring radial circular runout from the spigots at both ends of the stator to the reference axis of the inner circle of the iron core is characterized in that the inner cylindrical surface of the stator iron core is used to contain the inspection tool, so that the central axis of the two ends of the mandrel of the inspection tool is at the center of the inner cylindrical surface of the stator iron core Then routinely measure the radial circular runout of the two ends of the spigot to the central axis of the mandrel at both ends of the inspection tool; the inspection tool is composed of the mandrel (3), elastic sleeve (1), pressure ring (11), core The shaft nut (15) and the stepped screw (9) are composed; the central part of the mandrel (3) has an outer conical surface (5), and the inclination angle of the outer conical surface is 1 degree; the elastic slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com