Method and jig for manufacturing equidistant coiled wires

A technology of equal spacing and winding, applied in the manufacture of extensible conductors/cables, etc., can solve the problems of affecting the telephone auscultation effect, the product quality is not ideal, the method is not reasonable enough, etc., to ensure the auscultation effect, the production method is reasonable, and the production convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

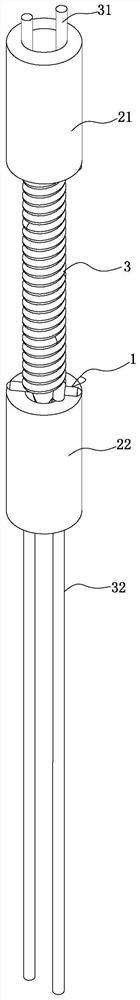

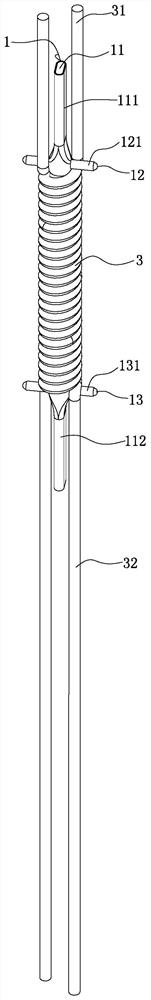

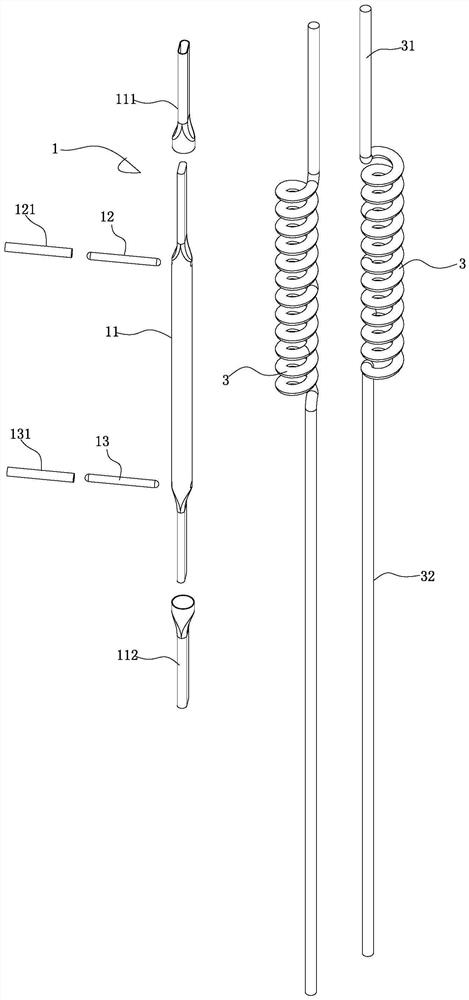

[0017] See Figure 1-3 As shown, it is a method of making equidistant coils, which includes the following steps:

[0018] S001: Prepare jig 1. The jig 1 includes a rolling rod 11 and an upper positioning pin 12 and a lower positioning pin 13 installed horizontally at the upper and lower ends of the rolling rod 11. The surface of the rolling rod 11 is sandblasted, and the roll The outer surfaces of the upper and lower ends of the rod 11 are respectively covered with a first protective sleeve 111 and a second protective sleeve 112; the outer surfaces of the upper positioning pin 12 and the lower positioning pin 13 are respectively sleeved with a third protective sleeve 121 and a second protective sleeve. Four protective sleeves 131;

[0019] S002: Prepare two wires with equal diameters;

[0020] S003: Coiling forming process: Press the ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com