Detection tool for boss of ring piece and detection method and application of detection tool

A detection method and ring technology, applied in the detection field, can solve the problems of increasing workload, reducing work efficiency, prolonging detection working hours, etc., and achieve the effects of easy processing, saving labor costs and saving detection working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] In this embodiment, a method for measuring ring bosses 5 is provided. First, seven ring bosses 5 and a checker provided on the same ring are provided. Use the inspection tool to measure whether the seven ring bosses 5 are qualified, and then use a caliper to extract one of the ring bosses 5 to measure its size, and record the data.

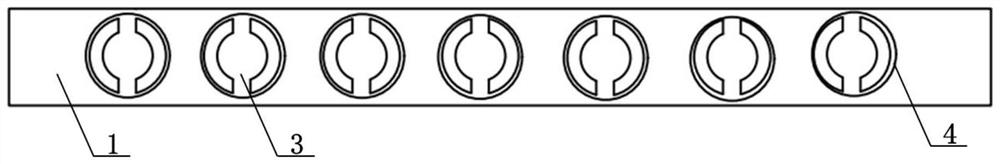

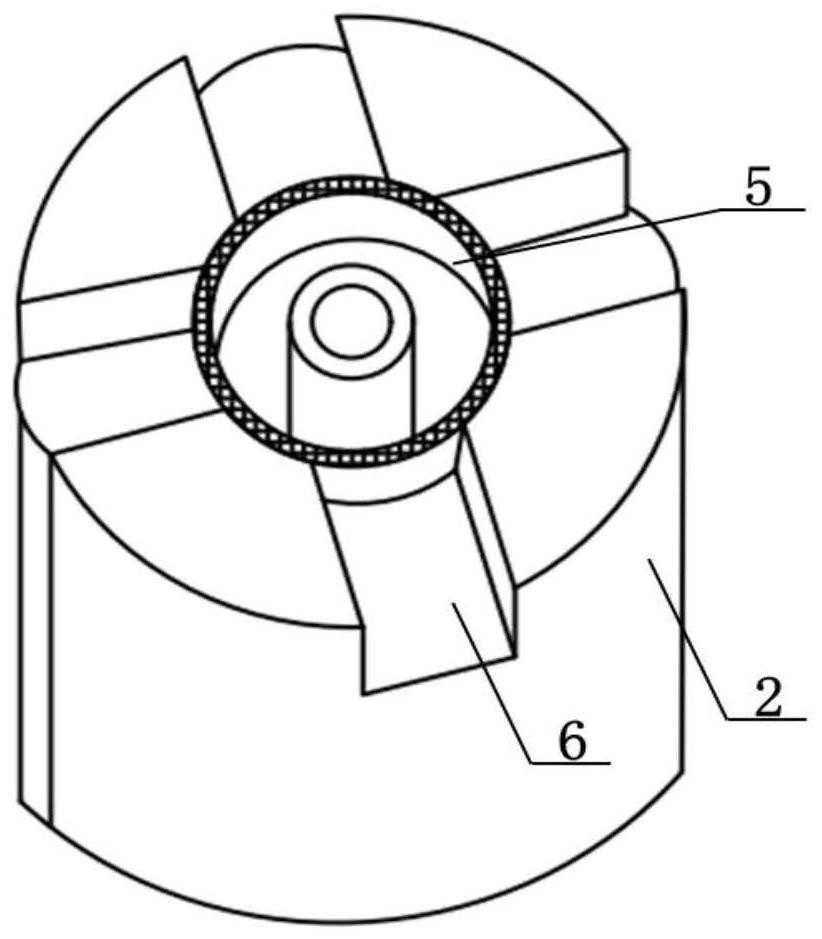

[0054] Wherein the inspection tool includes the base 1, such as figure 1 As shown, seven molds are arranged side by side on the surface of the base 1, the mold includes an upper mold assembly 2 and a lower mold assembly 3, the lower mold assembly 3 is fixed on the surface of the base 1, and the ring boss 5 is placed on the upper mold assembly 2 Inside, the upper mold assembly 2 and the lower mold assembly 3 are fastened together.

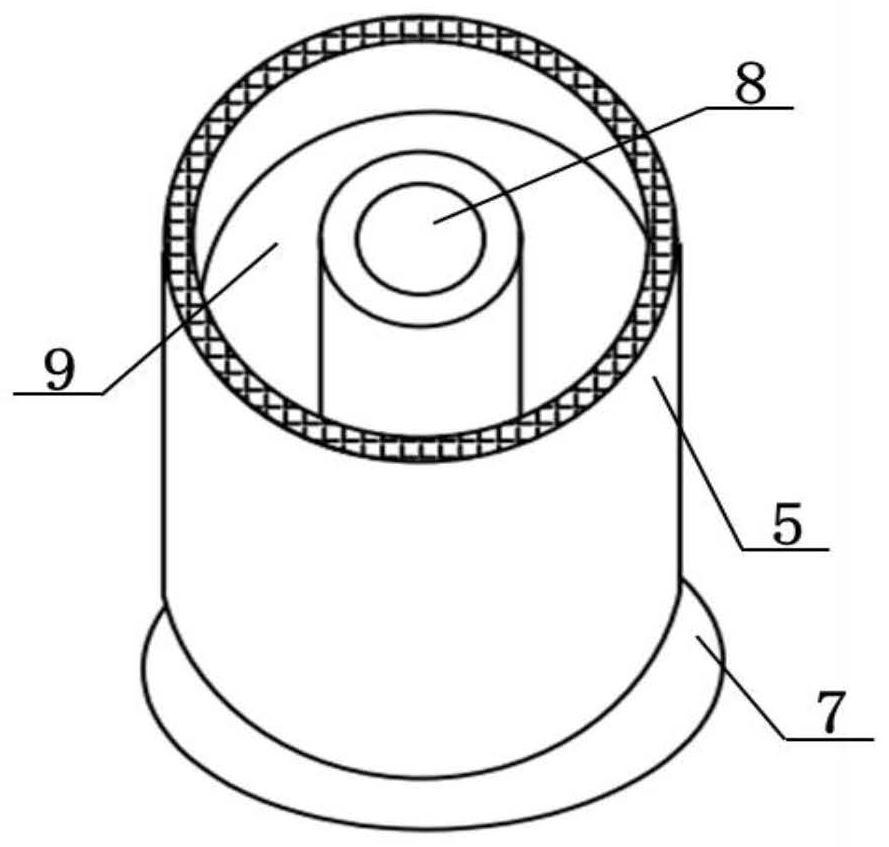

[0055] The lower mold assembly 3 is an annular boss structure, two symmetrical openings are arranged on the surface of the lower mold assembly 3, the width of the opening is smaller than the inner diameter of th...

Embodiment 2

[0065] In this embodiment, a method for measuring ring bosses 5 is provided. First, five ring bosses 5 and a checker provided on the same ring are provided. Check whether the five ring bosses 5 are qualified, extract one of the ring bosses 5 and measure its size with a caliper, and record the data.

[0066] The inspection tool includes a base 1, and five molds are arranged side by side on the surface of the base 1. The mold includes an upper mold assembly 2 and a lower mold assembly 3. The lower mold assembly 3 is fixed on the surface of the base 1, and the ring boss 5 is placed on the upper surface. In the mold assembly 2, the upper mold assembly 2 and the lower mold assembly 3 are fastened together.

[0067] The lower mold assembly 3 is an annular boss structure, two symmetrical openings are arranged on the surface of the lower mold assembly 3, the width of the opening is smaller than the inner diameter of the lower mold assembly 3, and a cushion is provided at the joint bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com