Rail system fuel tender

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

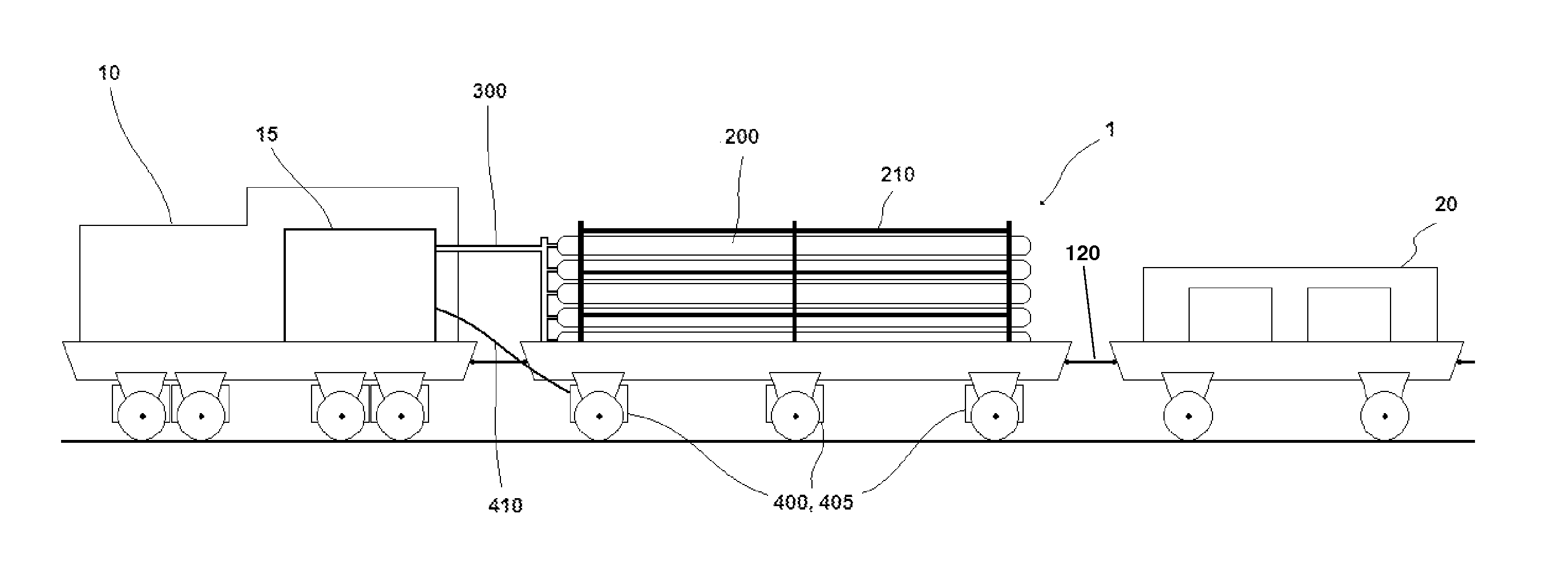

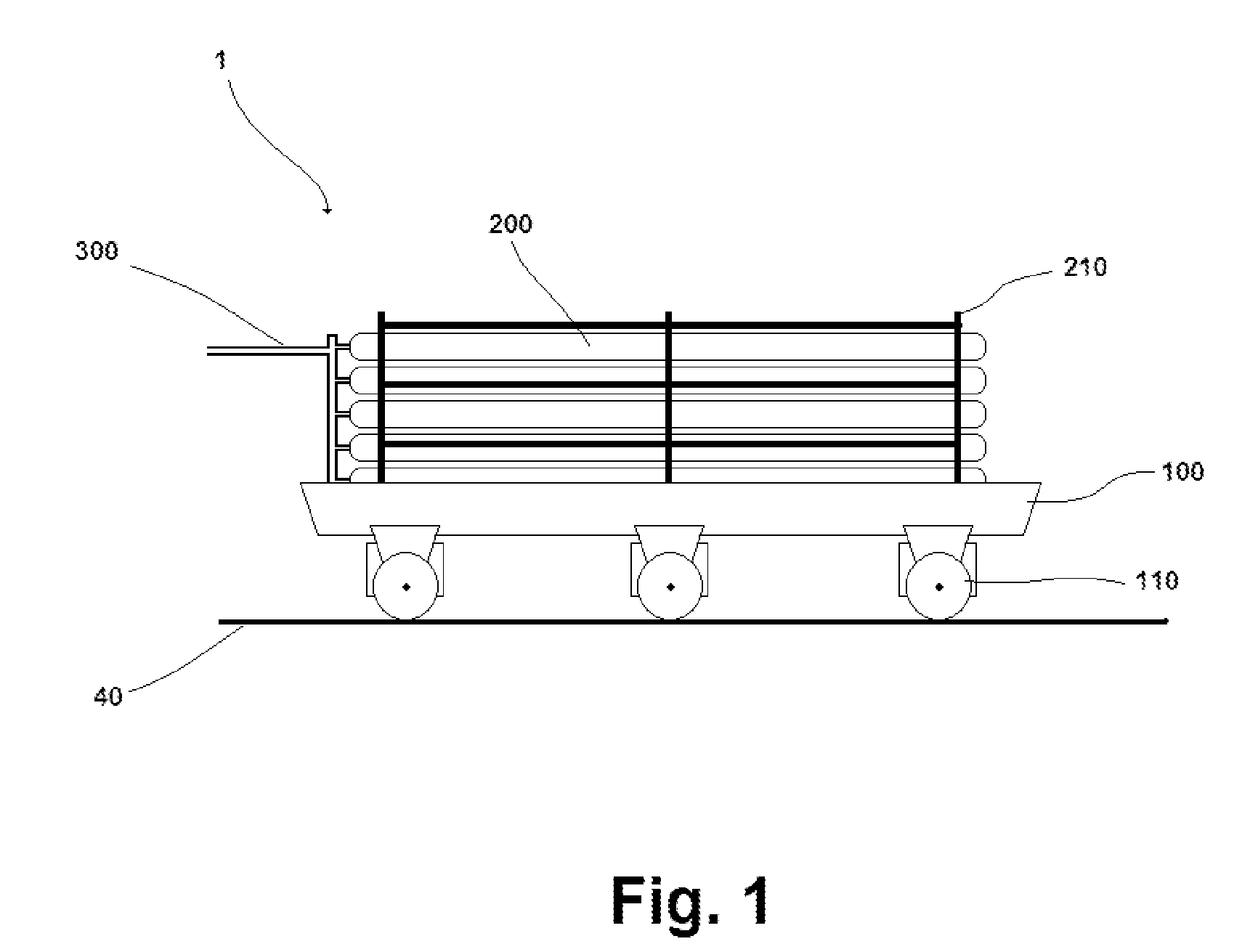

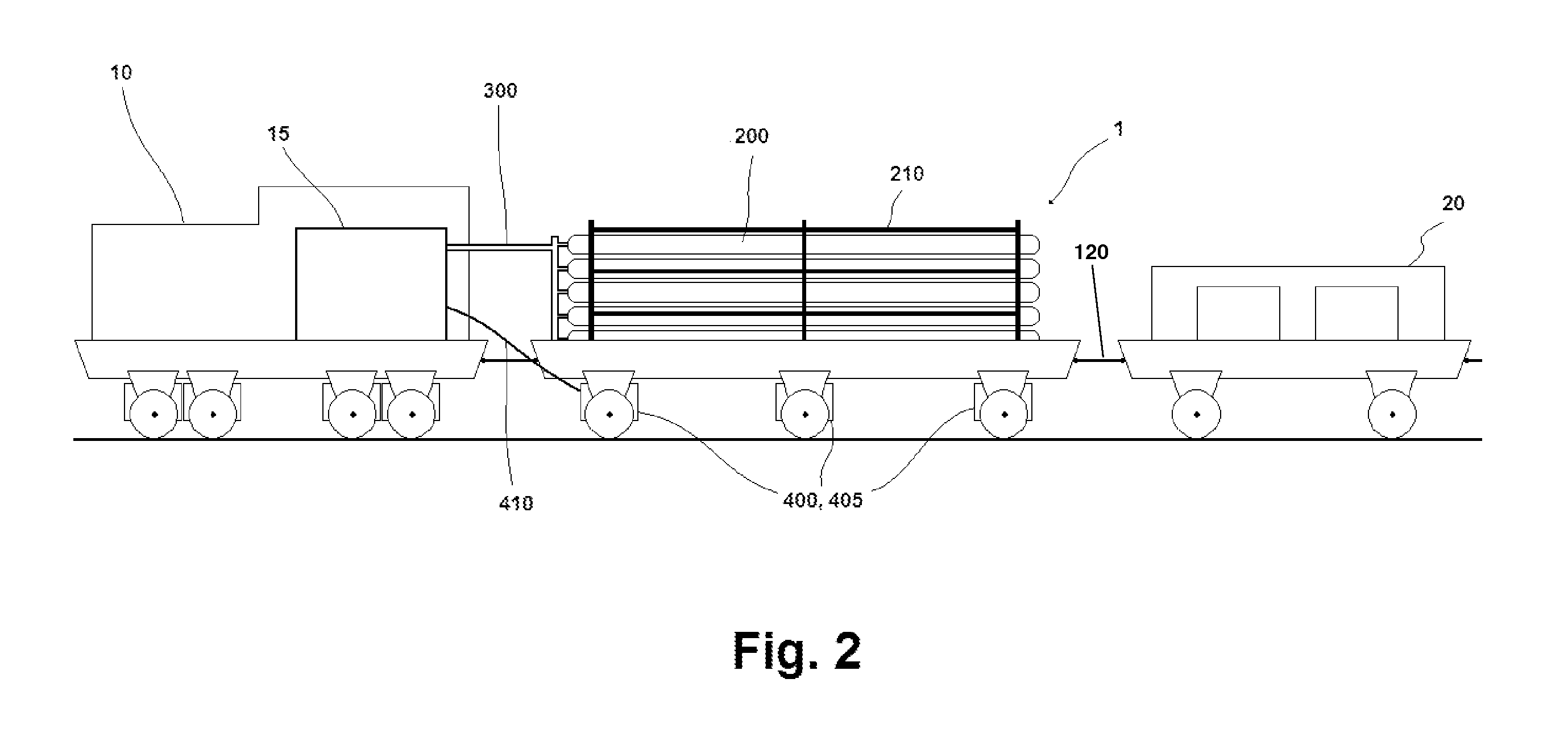

[0021]The present invention discloses an improved rail system fuel tender 1 for use with one or more railroad locomotives 10. See FIG. 1. The fuel tender 1 is a separate railroad vehicle from the one or more locomotives 10, and is intended to be used in connection with the one or more locomotives 10, see FIG. 2, the connection being either direct, e.g., the fuel tender 1 being coupled to a locomotive 10, or indirect, e.g., the fuel tender 1 being coupled to a railroad vehicle which is interposed between the fuel tender 1 and the locomotive 10. In the case of indirect coupling, the interposed railroad vehicle could be another locomotive 10 or another fuel tender 1. Thus, a single fuel tender 1 may be employed to fuel multiple locomotives 10, or multiple fuel tenders 1 may be employed to fuel multiple locomotives 10, as well as a single fuel tender 1 being employed to fuel a single locomotive 10.

[0022]The fuel tender 1 of the present invention comprises a chassis 100, and the chassis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com