Building construction cable continuous extrusion molding machine

An extrusion molding machine and construction technology, which is applied in the direction of insulating conductors/cables, etc., can solve the problems of too fast traction devices, too few insulating materials, and difficulty in adjusting the traction speed, so as to improve product quality, improve melting quality, The effect of improving traction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

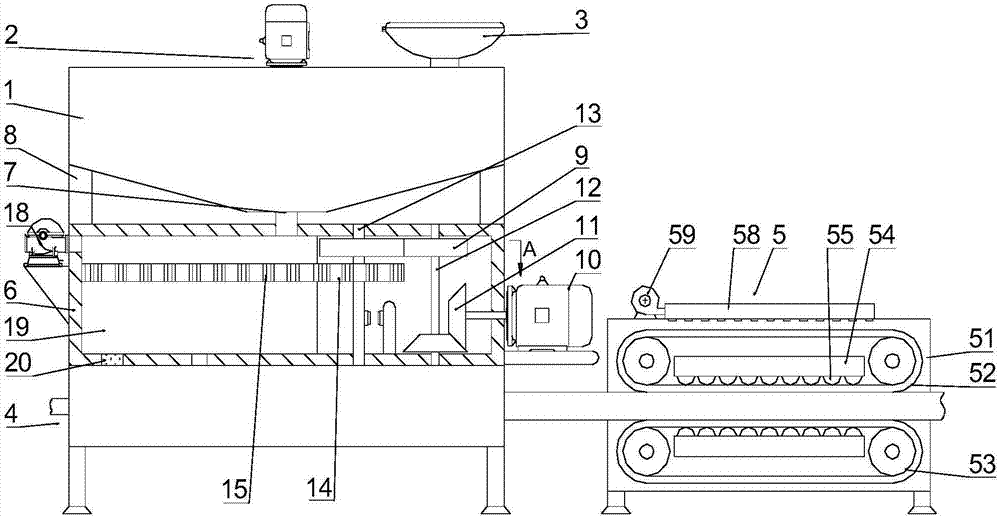

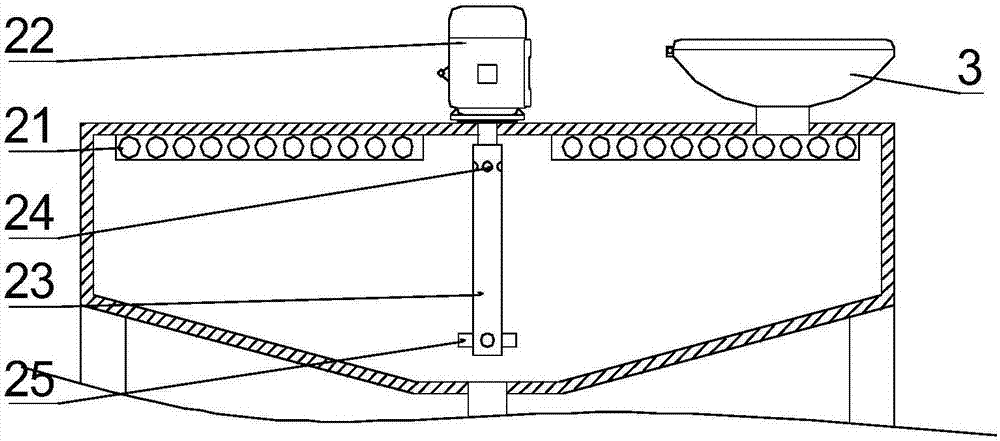

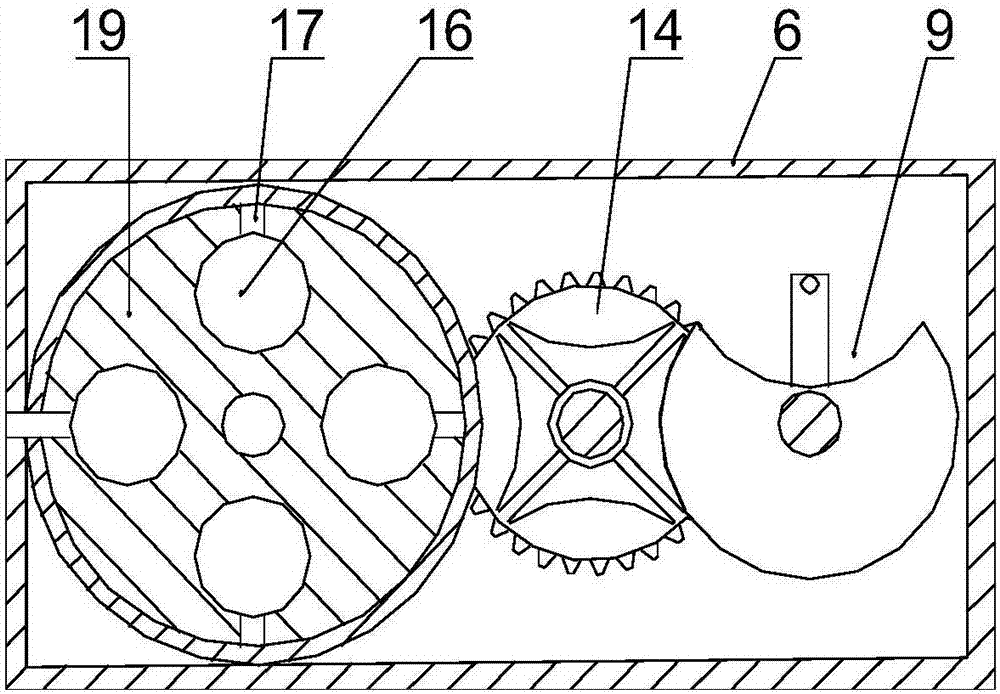

[0024] see Figure 1-6 , a continuous cable extrusion molding machine for building construction, comprising a melting tank 1, a heating device 2, a first outer sheave mechanism 9, a driving gear 14, a driven gear 15, a booster pump 18, a coating device 4 and Adjust the traction device 5, the inside of the melting box 1 is equipped with a heating device 2, the bottom of the melting box 1 is provided with a fixed box 6, the upper side wall of the fixed box 6 and the lower side wall of the melting box 1 pass through the discharge pipe The 7 phases are connected, and a pair of bevel gears 11 meshing with each other are arranged on the right side of the melting box 1. The right side wall of the melting box 1 is fixedly connected with a mounting frame, and a second motor 10 is installed on the mounting frame. The output end of the motor 10 is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com