Hub motor hydraulic hybrid system

A technology of hybrid power system and wheel hub motor, which is applied in the direction of fluid pressure actuation system components, power devices, servo motor components, etc., can solve problems such as inability to meet power requirements, achieve good adaptability to working conditions, and facilitate layout and installation , the effect of small structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

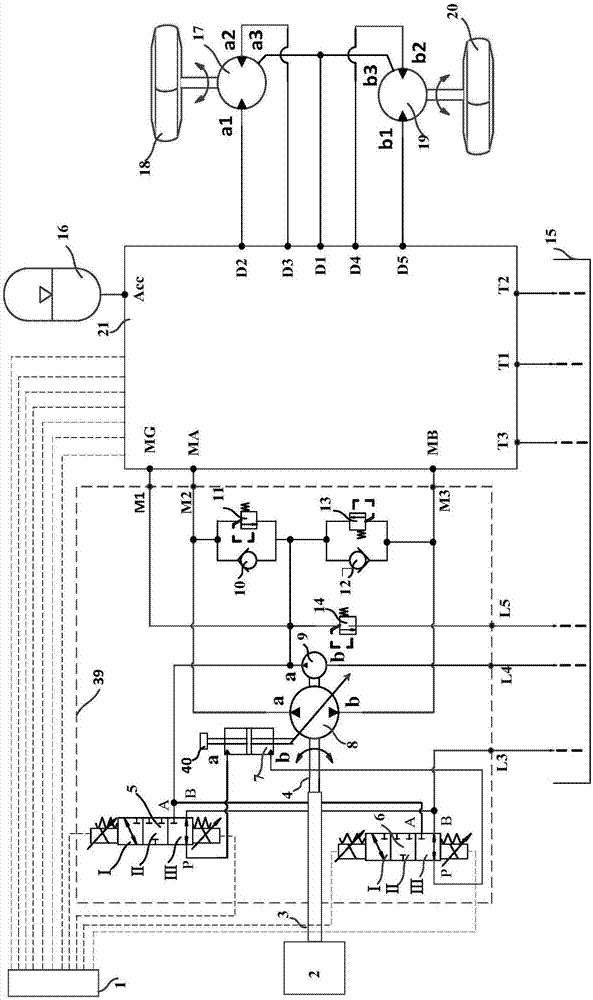

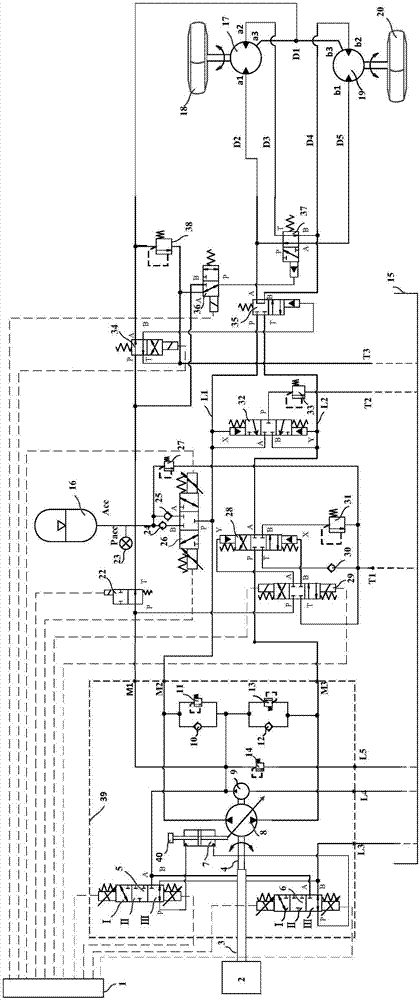

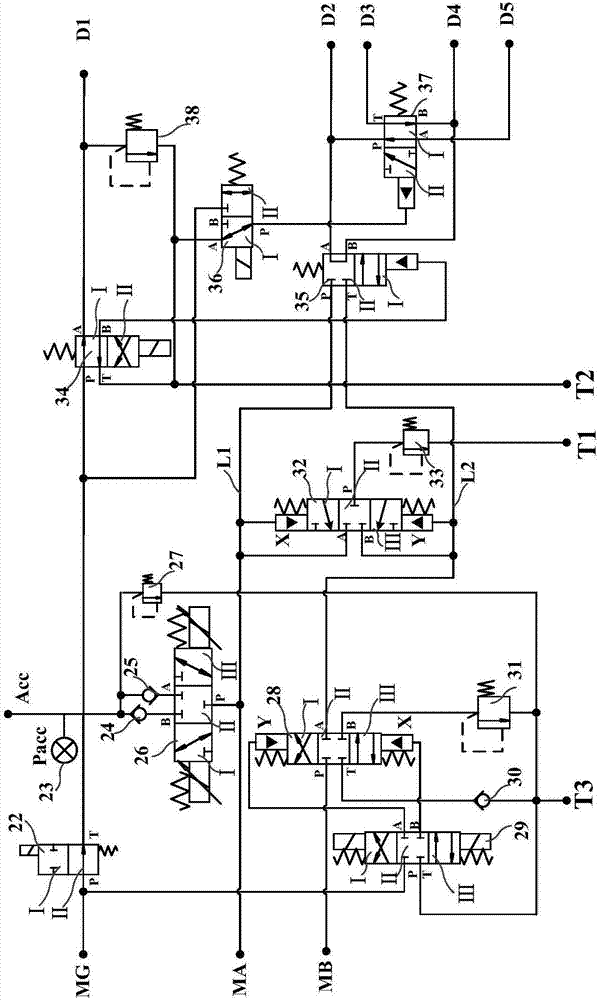

[0029] The hub motor hydraulic hybrid power system of the present invention includes a hydraulic pump assembly 39, a control valve group 21, a control unit 1, a power take-off device 2, a power transmission device 3, a left front wheel 18, a hub hydraulic motor 17, a right The front wheel 20, the second hub hydraulic motor 19, the oil storage tank 15, and the accumulator 16.

[0030] The power transmission device 3 is a universal joint drive shaft, the power take-off device 2 and the power transmission device 3 are flanged or splined, and the accumulator 16 is connected to the Acc port of the control valve group 21 through a hydraulic pipeline; The rotor shaft of the No. 1 hub hydraulic motor 17 and the left front wheel 18 are connected by a spline pair or both are coaxially connected. The rotor shaft of the No. 2 hub hydraulic motor 19 and the right front wheel 20 are connected by a spline pair or both Coaxial connection, the hydraulic pump assembly input shaft 4 and the power t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com