Self-propelled front-mounted straw crushing and rear-mounted rotary tillage, ditching, fertilization and seeding combined operation equipment

A straw crushing and combined operation technology, which is applied in fertilizer and seeding equipment, digging/covering ditches, agriculture, etc., can solve the problem of straw environmental pollution, affecting farming quality and farming efficiency, affecting crop yield, etc. problems, to achieve the effect of eliminating air and water pollution, ensuring farming efficiency and quality, and realizing resource reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

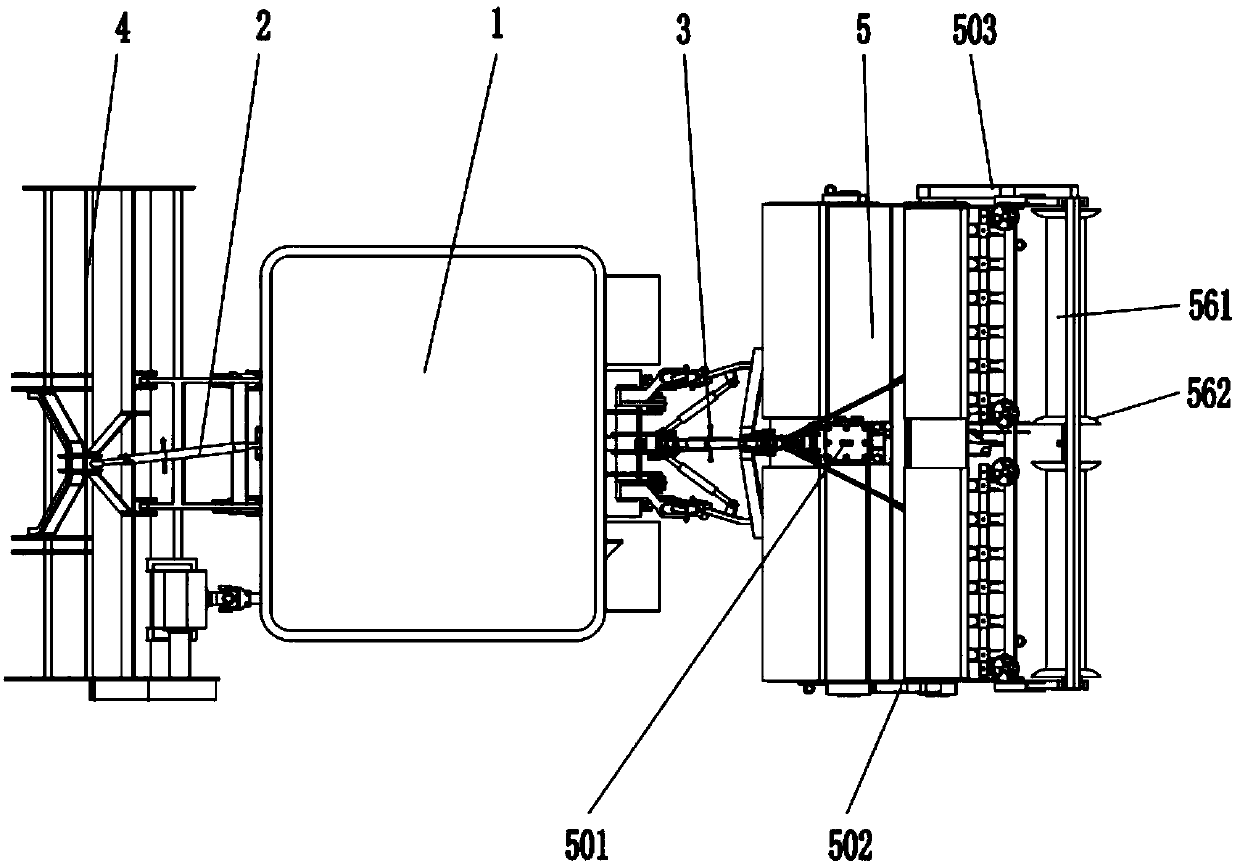

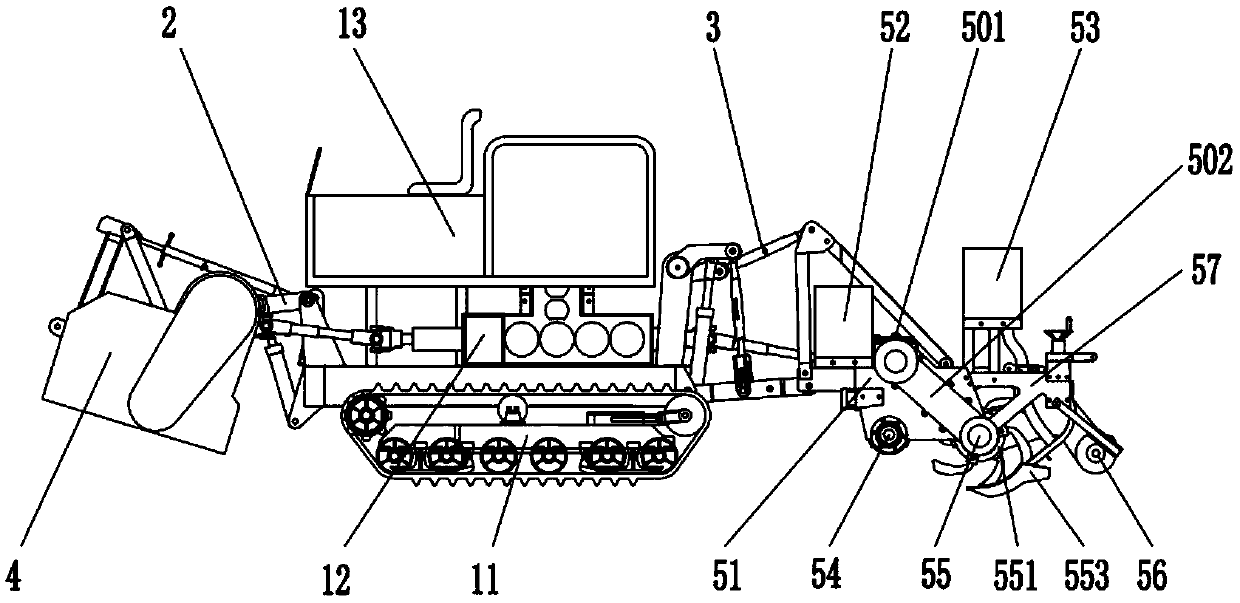

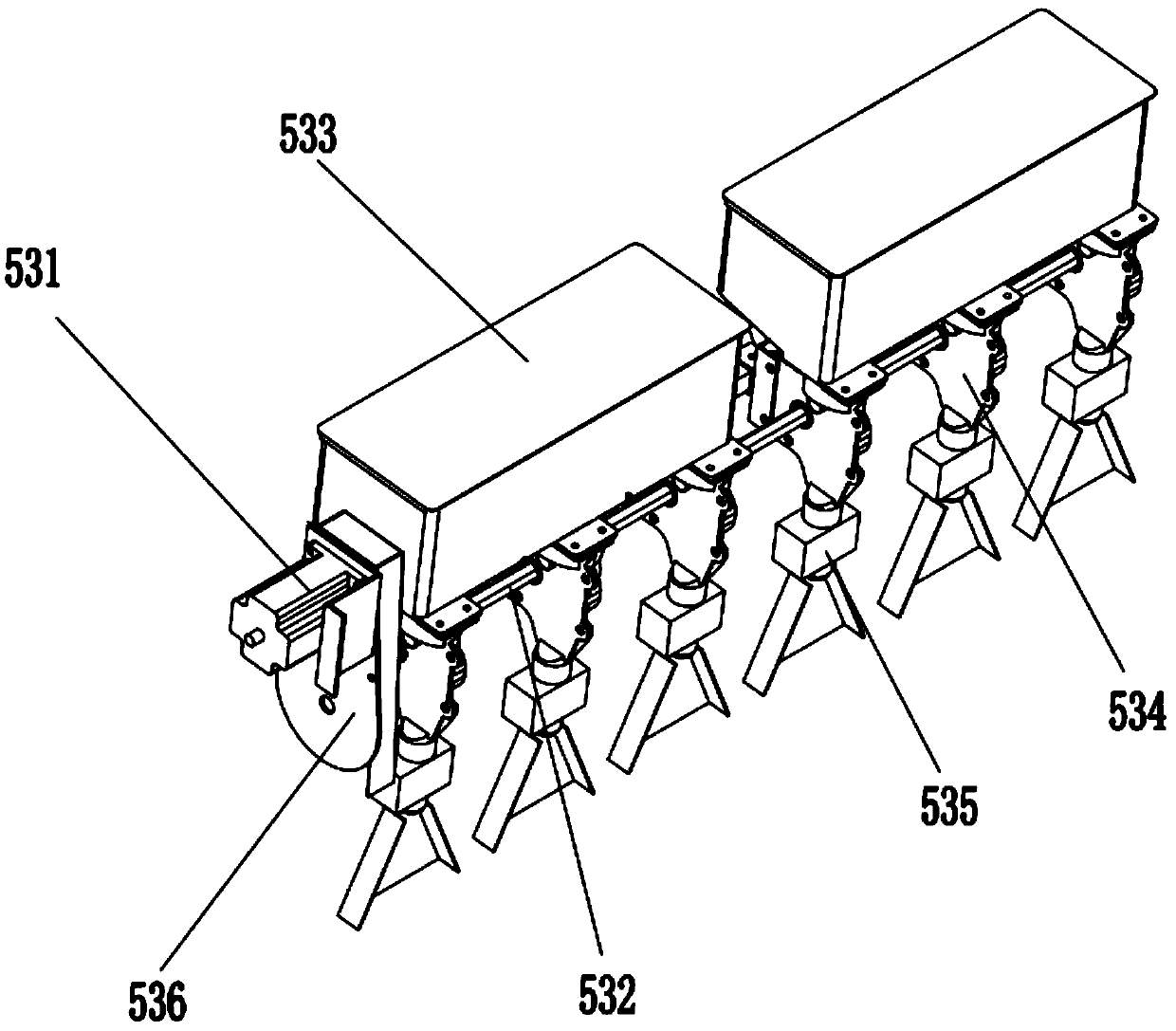

[0039] A self-propelled front-end straw crushing and rear-mounted rotary tillage, ditching, fertilization and seeding combined operation equipment described in the present invention, such as figure 1 , figure 2As shown, it includes a power chassis assembly 1, a front suspension frame 2, a rear suspension frame 3, a straw crushing device 4 and a finishing device 5; the straw crushing device 4 is arranged in front of the power chassis assembly 1 through the front suspension frame 2 The finishing device 5 is arranged behind the power chassis assembly 1 through the rear suspension frame 3; the power chassis assembly 1 includes a vehicle frame and a crawler-type running device 11 The transmission box 12 and the cab assembly 13; the finishing device 5 includes a frame 51, a fertilizing device 52, a seeding device 53, a rotary tiller 54 and a ditching device 55; the fertilizing device 52 and the seeding device 53 used to be Arriving at the top of the frame 51; the rotary tiller 54 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com