Non-counterweight elevator system

An elevator system without counterweight technology, which is applied to elevators, elevators, transportation and packaging in buildings, etc., can solve the problems of waste of resources, optimal cost, heavy counterweight, etc., to save materials, ensure traction capacity, The effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical contents and embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted that the drawings and embodiments of the present invention are not intended to limit the technical solution of the present invention.

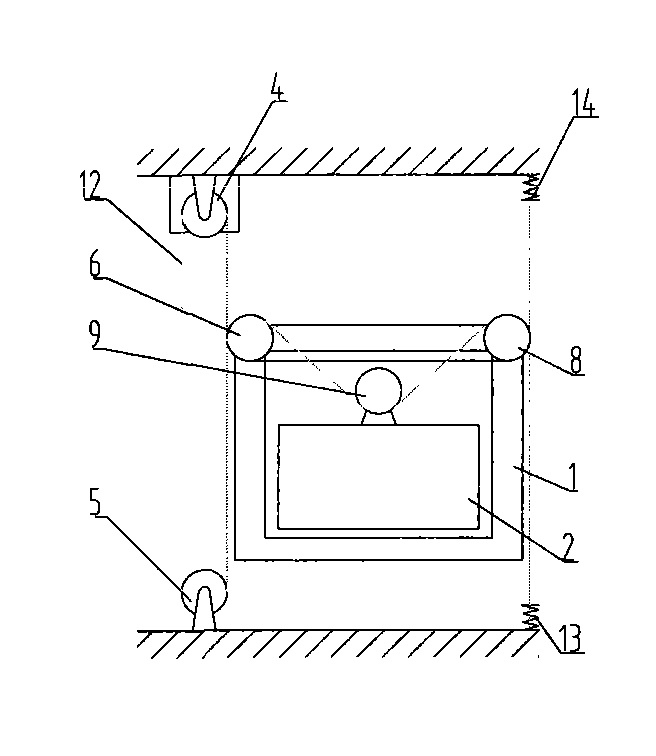

[0028] attached figure 1 A schematic diagram showing the structure of the prior art. See attached figure 1 You can clearly see the elevator system structure commonly used in the elevator industry at present, which includes: integral elevator car, car top wheel, pulley, traction rope and traction sheave, tensioning device and counterweight, etc., with structural It is complex, consumes a lot of energy, takes up a lot of space in the hoistway, and requires high man-hours and production costs.

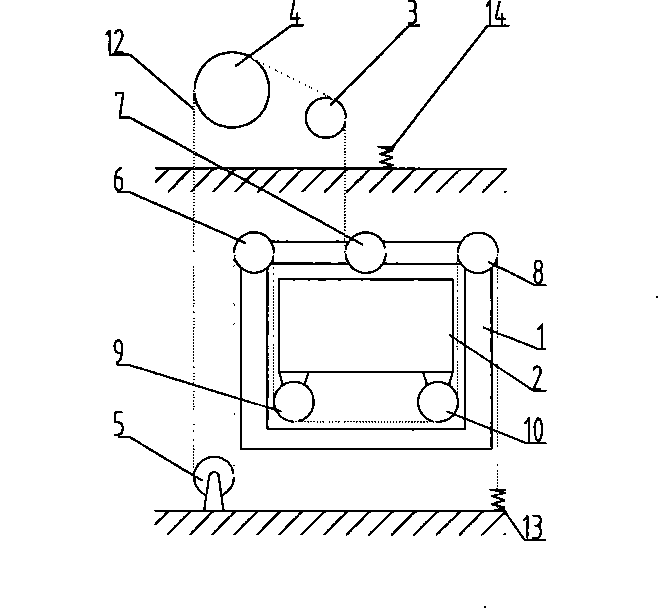

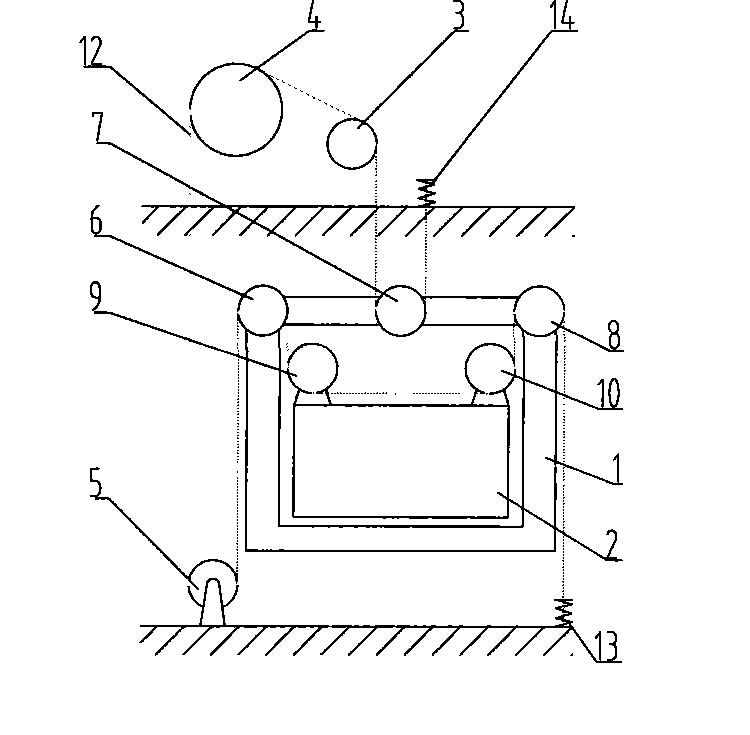

[0029] attached figure 2 Represent the structural representation of a preferred embodiment of the present invention, the non-counterweight elevator system of the present invention, com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com