Intelligent oil sucking machine

A kind of pumping unit, intelligent technology, applied in the direction of mechanical equipment, machine/engine, liquid variable capacity machinery, etc., can solve the problems of fast wear of steel wire rope, high motor power requirement, inconvenient construction and operation of well site, etc., and achieve retractable speed Uniformity, reduced construction costs, and improved convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

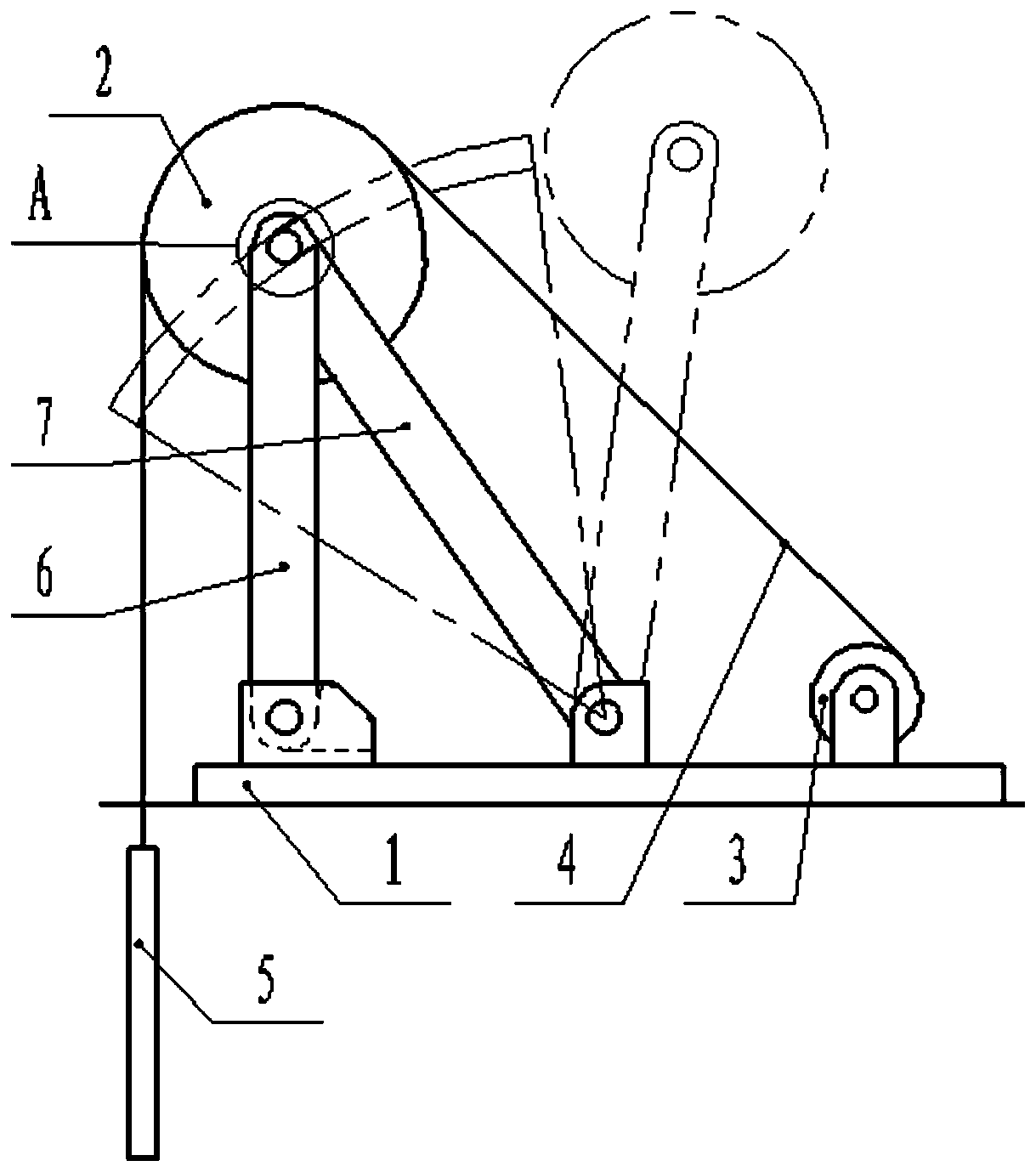

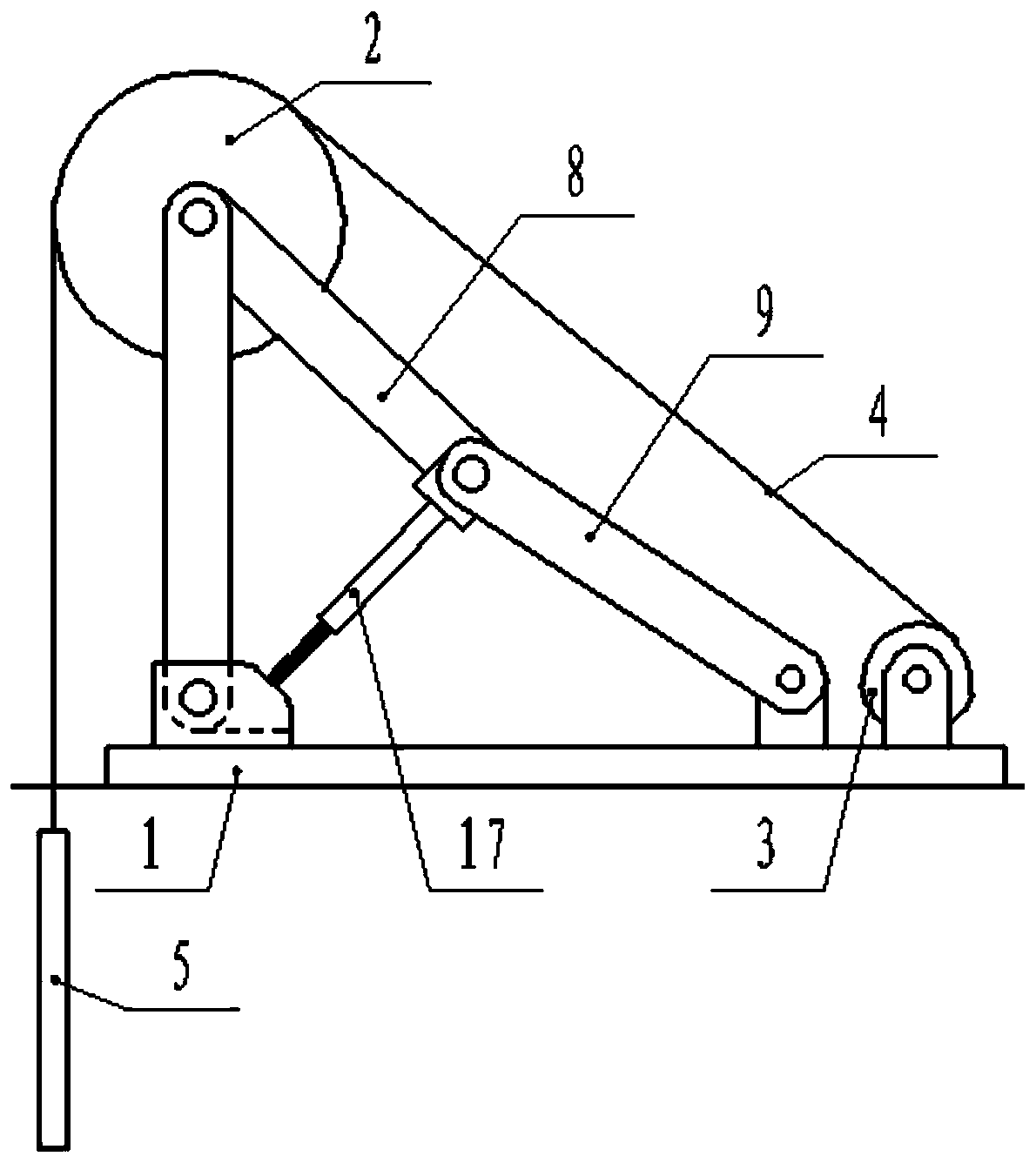

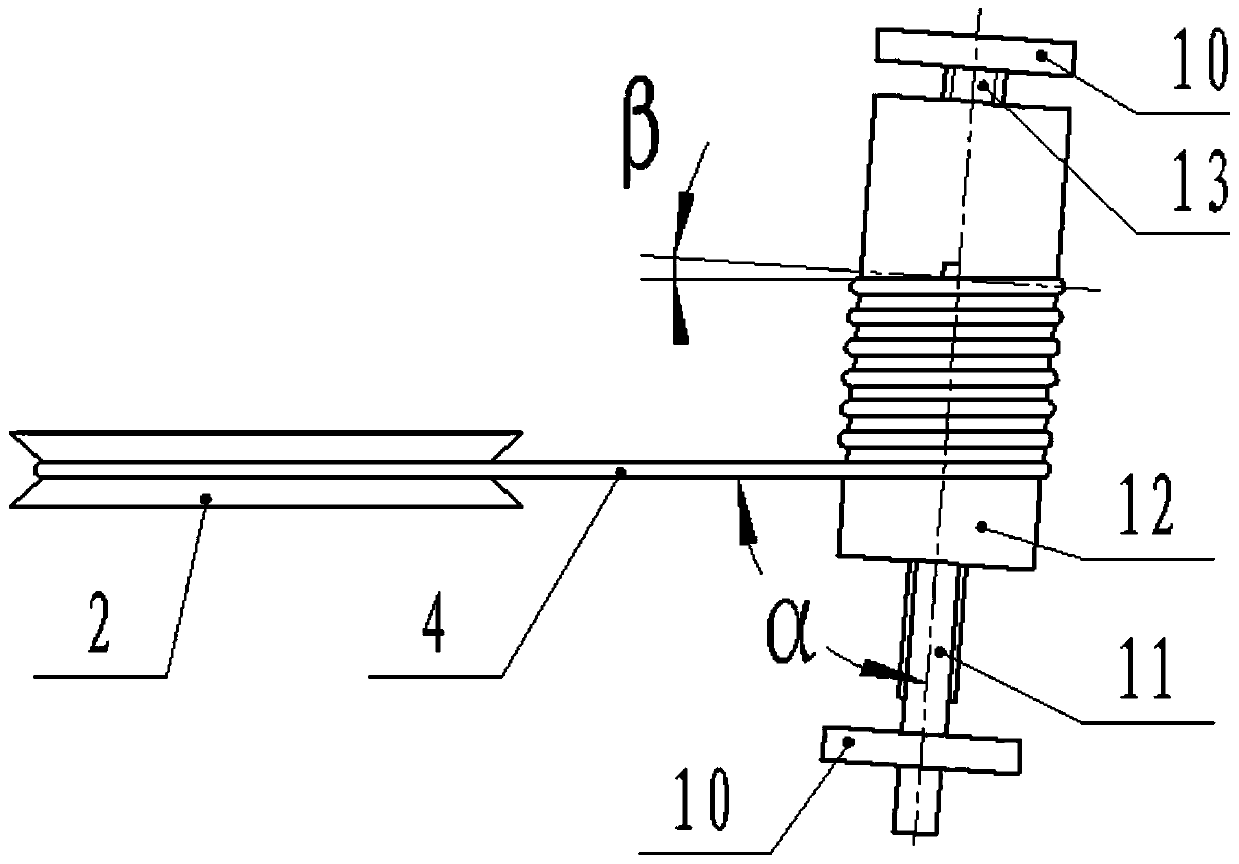

[0032] Such as figure 1 As shown, this embodiment includes a base 1, a support, a guide wheel 2, a reel 3, a wire rope 4, an oil well pump 5, a motor (not shown in the figure) and an intelligent variable frequency controller (not shown in the figure) for controlling the motor out), the bracket is fixedly installed on the base 1, the guide wheel 2 is installed on the top of the bracket, the reel 3 and the motor are fixedly installed on the base 1, the reel 3 rotates under the drive of the motor, and one end of the wire rope 4 is wound on the reel 3, the other end is connected with the oil pump 5 after bypassing the upper side of the guide wheel 2. The above is a common structure in the existing lifting type oil pumping unit, and will not be repeated here.

[0033] In the prior art, the wear of the wire rope 4 mainly occurs at the reel 3, and there are two specific reasons ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com