Elevator equipment

A technology of elevators and driving devices, which is applied in hoisting devices, transportation and packaging, elevators, etc., and can solve the problems that the car cannot stop smoothly and the traction force is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

[0015] [Embodiment 1]

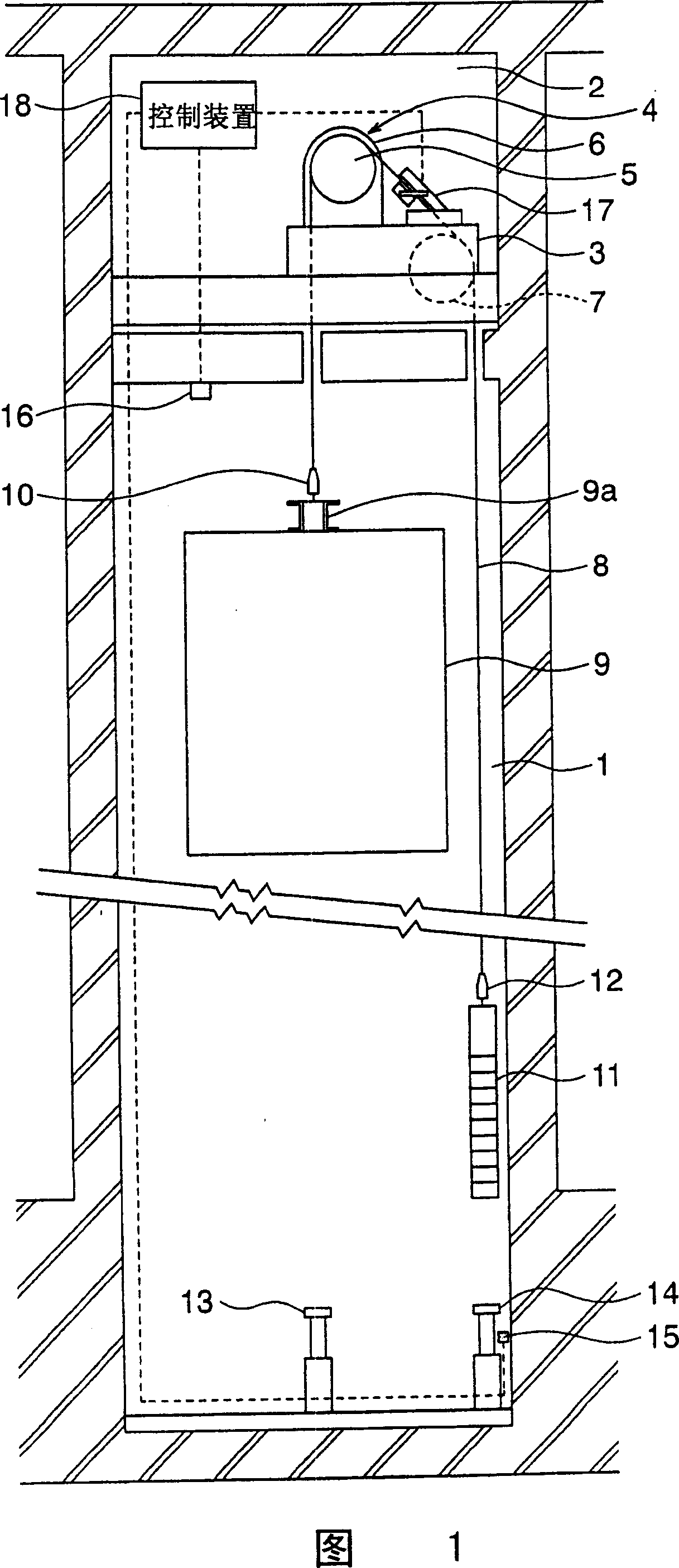

[0016] Figure 1 is a structural diagram showing an elevator apparatus according to Embodiment 1 of the present invention. In the figure, a machine room 2 is arranged above the hoistway 1. A machine table 3 is provided in the machine room 2. The driving device 4 is mounted on the machine table 3. The driving device 4 has a driving pulley 5 and a driving device body 6 that rotates the driving pulley 5. On the machine table 3, a deflection roller 7 that can rotate is mounted with a gap opposite to the drive pulley 5.

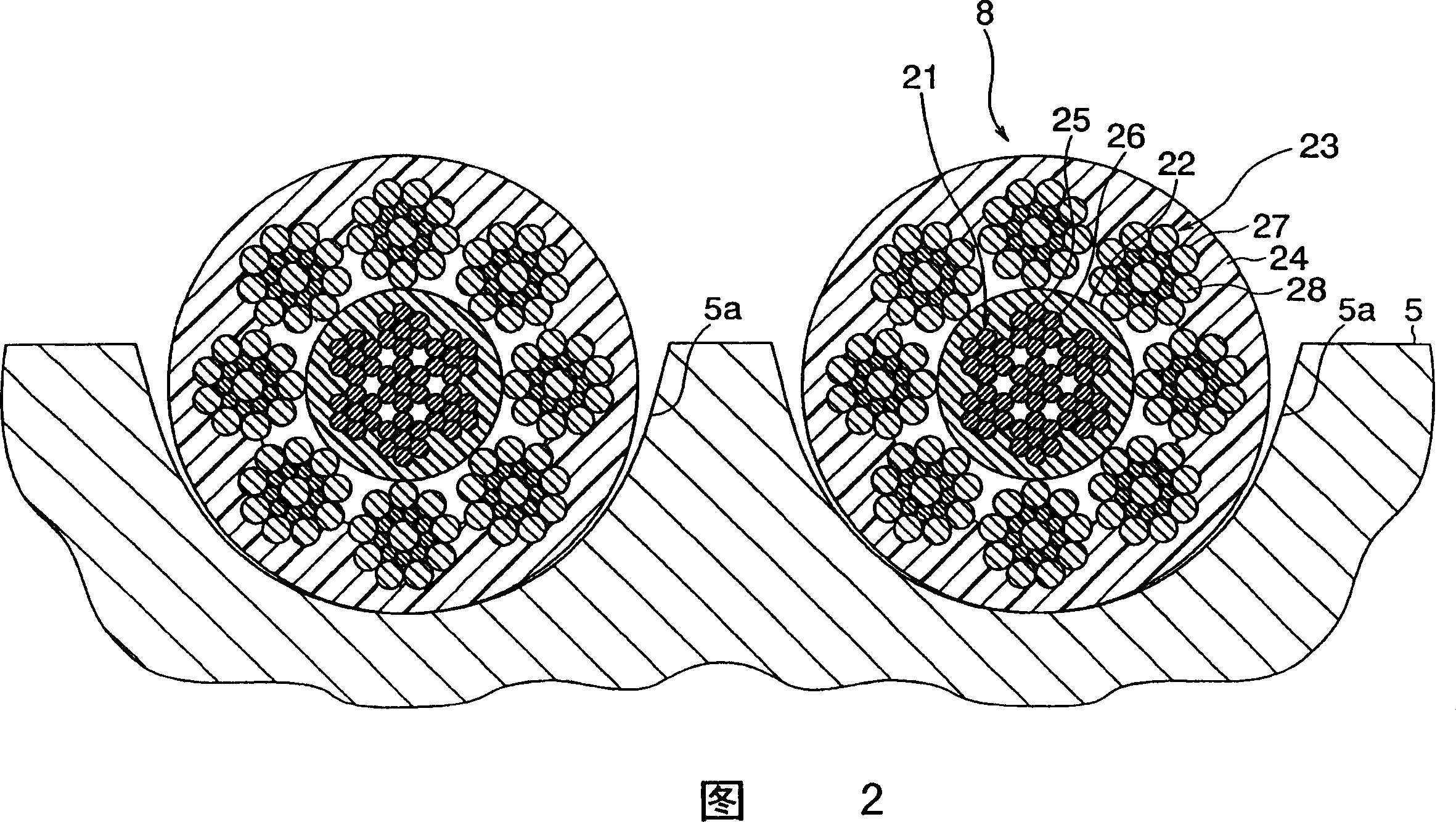

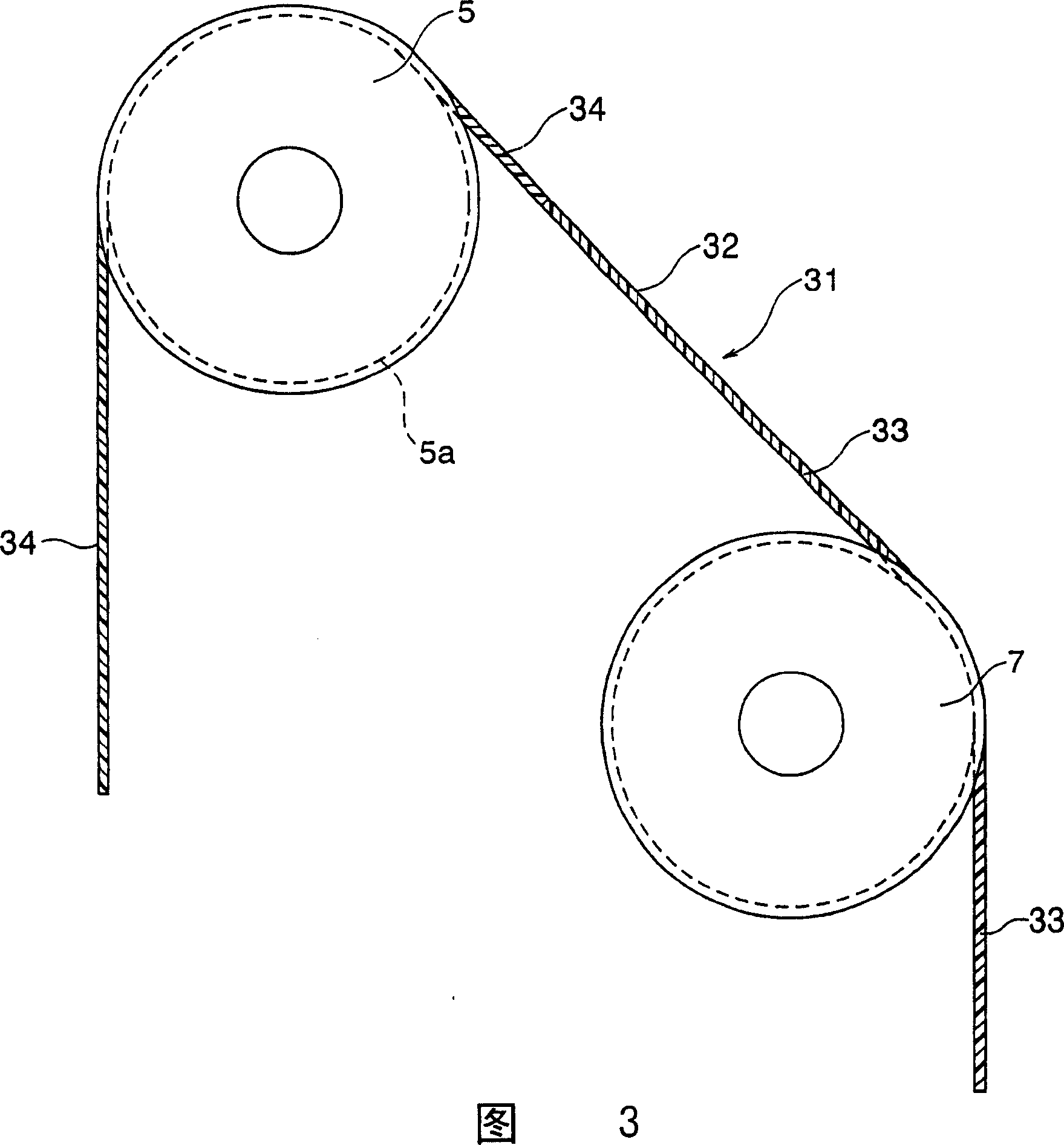

[0017] On the driving pulley 5 and the deflector pulley 7, a plurality of main ropes 8 (only one is shown in FIG. 1) are wound in a semi-hanging (semi-lap) manner. That is, the winding angles of the main rope 8 with respect to the driving pulley 5 and the deflector pulley 7 are respectively less than 180°.

[0018] The car 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com