Novel walking chassis

A walking chassis and chassis technology, which is applied in the field of hybrid power system and new walking chassis, can solve the problems of low fault tolerance rate of equipment and difficult vehicle escape, and achieve high fault tolerance, mature and easy structure, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

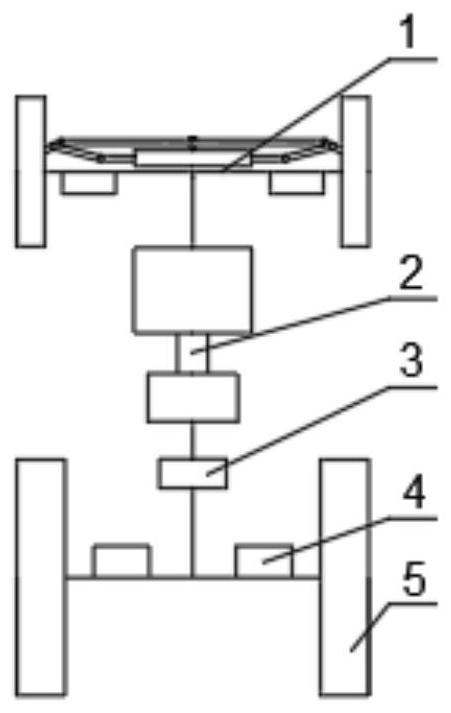

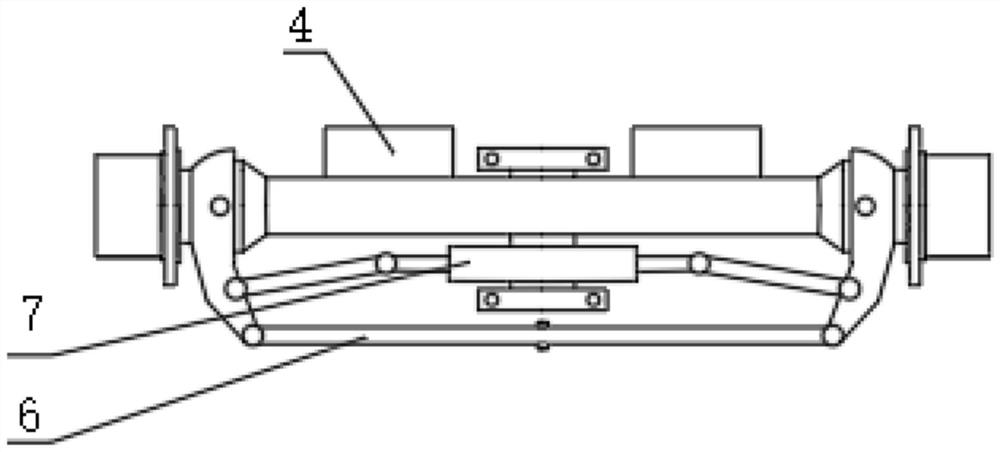

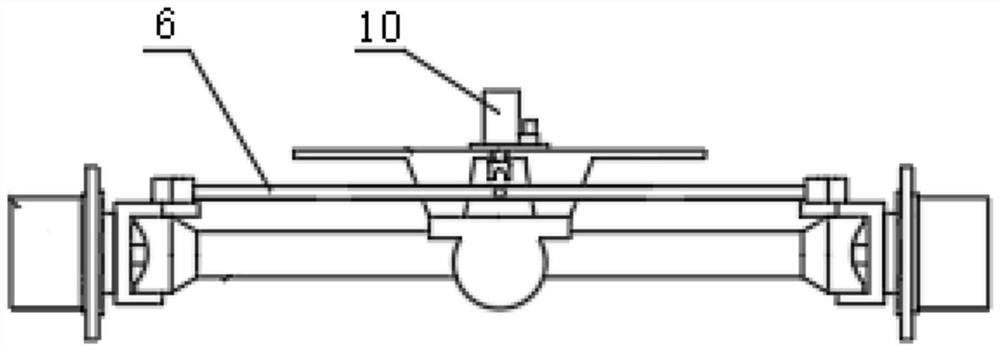

[0026] refer to Figure 1-4 As shown, a new type of walking chassis includes a chassis main body, which is provided with a front axle drive mechanism 1, a chassis power unit 2, a chassis system control unit 3, several groups of independent drive motors 4 and several groups of wheels 5, and the chassis system controls The unit 3 is connected with the front axle driving mechanism 1 , the chassis power unit 2 and the independent drive motor 4 , the chassis power unit 2 is connected with the independent drive motor 4 , and the independent drive motor 4 is connected with the wheels 5 .

[0027] The front axle driving mechanism 1 includes a fixed seat, a steering tie rod 6, a steering cylinder 7 and a steering center structure that can lock the front axle when the steering is at zero angle. The steering tie rod 6 is installed on the chassis body through the fixing seat, and the steering cylinder 7 Connect with steering rod 6.

[0028] The steering centering structure adopts the nut...

Embodiment 2

[0034] refer to Figure 1-4 As shown, a new type of walking chassis includes a chassis main body, which is provided with a front axle drive mechanism 1, a chassis power unit 2, a chassis system control unit 3, several groups of independent drive motors 4 and several groups of wheels 5, and the chassis system controls The unit 3 is connected with the front axle driving mechanism 1 , the chassis power unit 2 and the independent drive motor 4 , the chassis power unit 2 is connected with the independent drive motor 4 , and the independent drive motor 4 is connected with the wheels 5 .

[0035]The front axle driving mechanism 1 includes a fixed seat, a steering tie rod 6, a steering cylinder 7 and a steering center structure that can lock the front axle when the steering is at zero angle. The steering tie rod 6 is installed on the chassis body through the fixing seat, and the steering cylinder 7 Connect with steering rod 6.

[0036] The steering centering structure adopts the nut ...

Embodiment 3

[0043] refer to Figure 1-4 As shown, a new type of walking chassis includes a chassis main body, which is provided with a front axle drive mechanism 1, a chassis power unit 2, a chassis system control unit 3, several groups of independent drive motors 4 and several groups of wheels 5, and the chassis system controls The unit 3 is connected with the front axle driving mechanism 1 , the chassis power unit 2 and the independent drive motor 4 , the chassis power unit 2 is connected with the independent drive motor 4 , and the independent drive motor 4 is connected with the wheels 5 .

[0044] The front axle driving mechanism 1 includes a fixed seat, a steering tie rod 6, a steering cylinder 7 and a steering center structure that can lock the front axle when the steering is at zero angle. The steering tie rod 6 is installed on the chassis body through the fixing seat, and the steering cylinder 7 Connect with steering rod 6.

[0045] The steering centering structure adopts the nut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com