Locking differential mechanism

A differential and locking technology, applied in the direction of differential transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of loss of traction function, the car cannot have enough traction, etc., to achieve the effect of high locking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

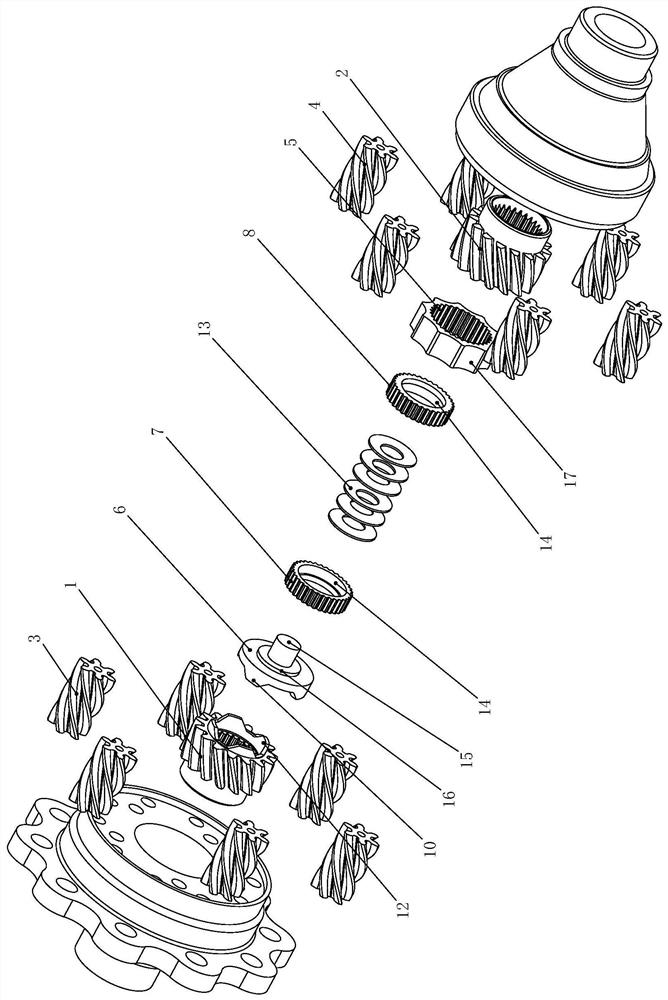

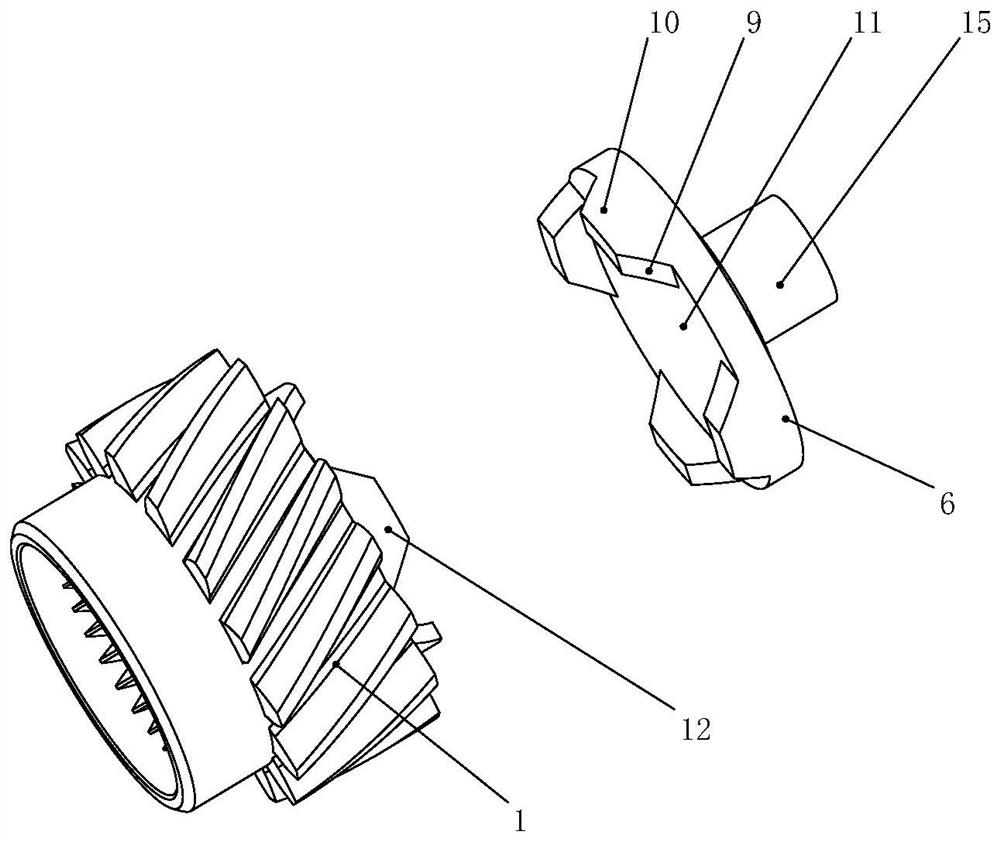

[0017] The present invention will be further described with reference to the specific embodiments. figure 1 -2:

[0018] Differential for a latch A locking differential, comprising a housing, the axle housing rotatably connected to the left helical teeth 1, 2 and right axle helical teeth, the helical teeth meshing with the left axle shaft 1 left planet gears 3, 4 and a right planetary gear, the planetary gear 3 and the left and right planetary gear 4 engaged circumferentially staggered and located between the left and the right axle half shaft 1 helical teeth meshing with the helical teeth of the helical teeth of the right axle 2 between the housing 2 equipped with a movable axially and circumferentially of the housing 5 rotate synchronously intermediate ring, the intermediate ring and the left axle shaft 5 is provided with a spiral movable axially between the teeth of a driving seat 6, the intermediate ring 5 on the inner hole of the right friction engagement with the gear 7 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com