Drive train for a mobile vehicle and method for controlling said drive train

A transmission line and vehicle technology, applied in the direction of transmission control, transmission, control devices, etc., can solve problems such as speed difficulties, and achieve the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

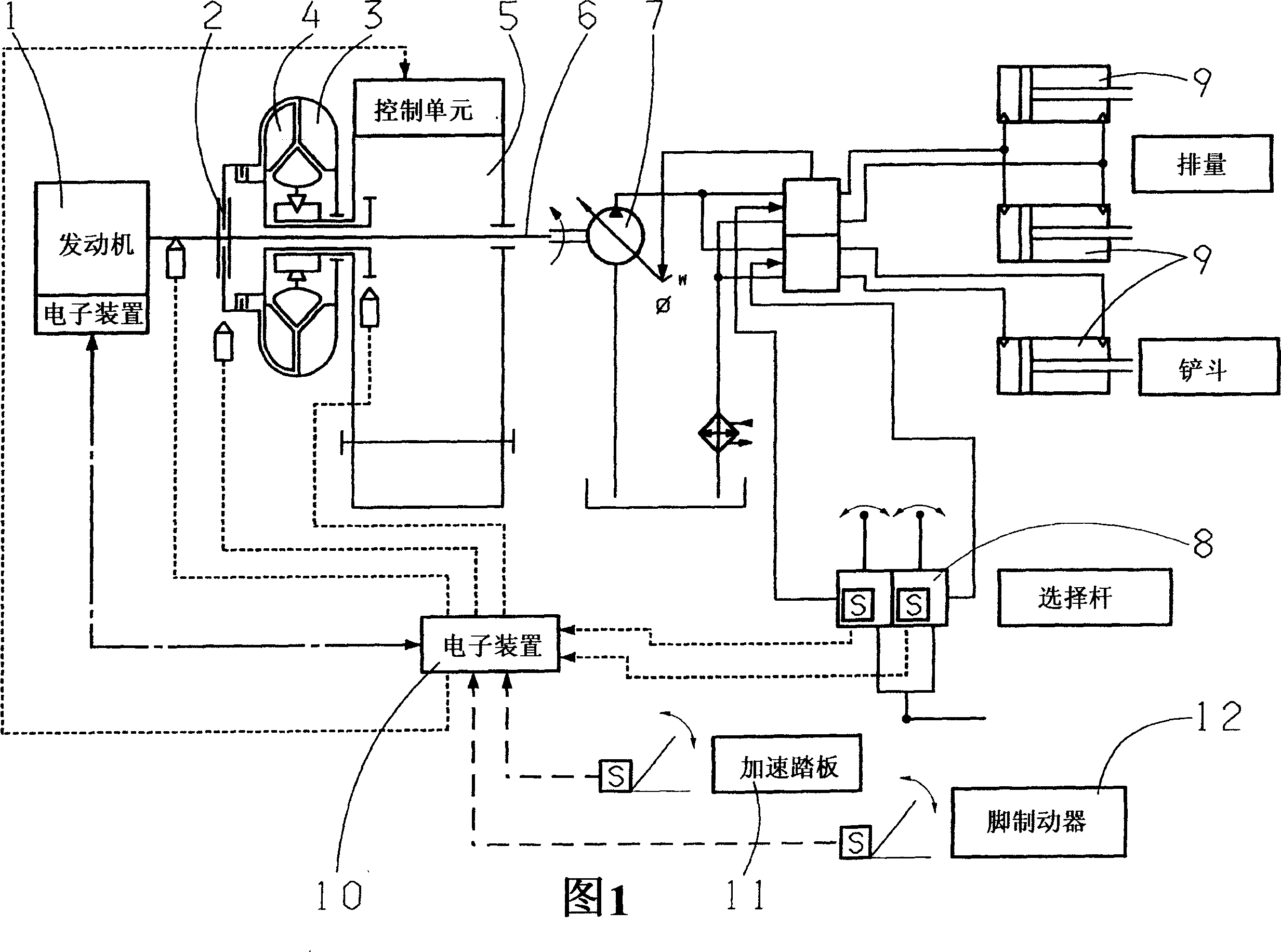

[0016] The single figure shows an engine 1 , which drives a pump impeller 3 of a hydrodynamic torque converter via a primary clutch 2 . The turbine 4 drives the load switching transmission 5 . The engine 1 also drives an auxiliary transmission 6 which drives a hydraulic pump 7 of the working hydraulic system. By actuating the selector lever 8 , the volume flow of the hydraulic pump 7 is delivered to a consumer 9 , for example a bucket of a wheel loader. The hydraulic pump 7 may be a load-sensing pump (Load-Sensing-Pump). The electronic control unit 10 receives signals from the selector lever 8 as well as the accelerator pedal 11 and the foot brake pedal 12 . The electronic control unit also receives sensor signals of engine 1 speed, clutch 2 operation and load switching transmission 5 speed. If the driving speed is adjusted with the accelerator pedal 11 and the selector lever 8 is actuated simultaneously, the electronic control unit 10 regulates the engine 1 to a minimum sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com