Strong-generality comprehensive experiment table for testing dynamic and static properties of spindle system

It is a kind of test bench and universal technology, which is applied in the direction of mechanical bearing test, mechanical component test, machine/structural component test, etc. It can solve the problem of large preload force, weak ability of main shaft to resist forced vibration and self-excited vibration , bearing temperature rise and other problems, to achieve the effect of ensuring the installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, device of the present invention is described in further detail:

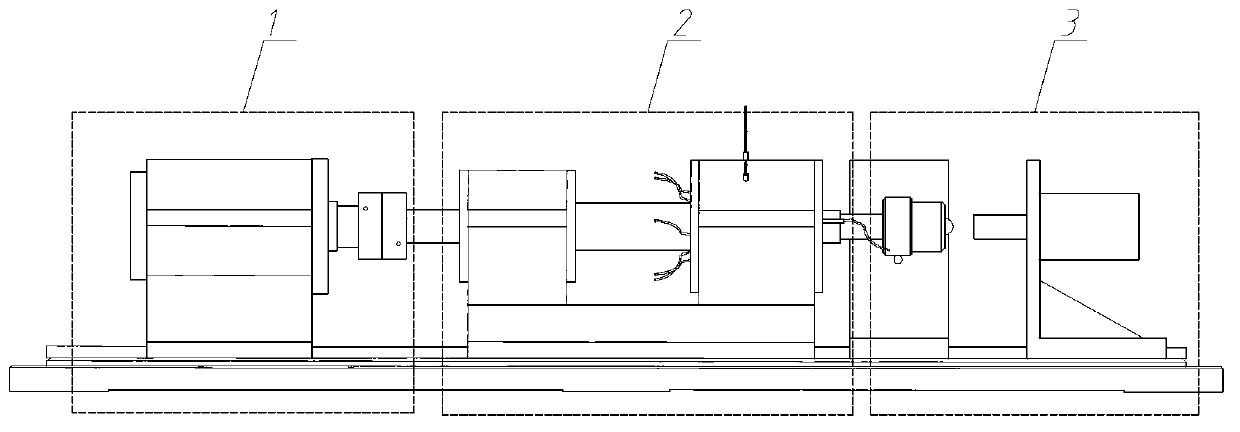

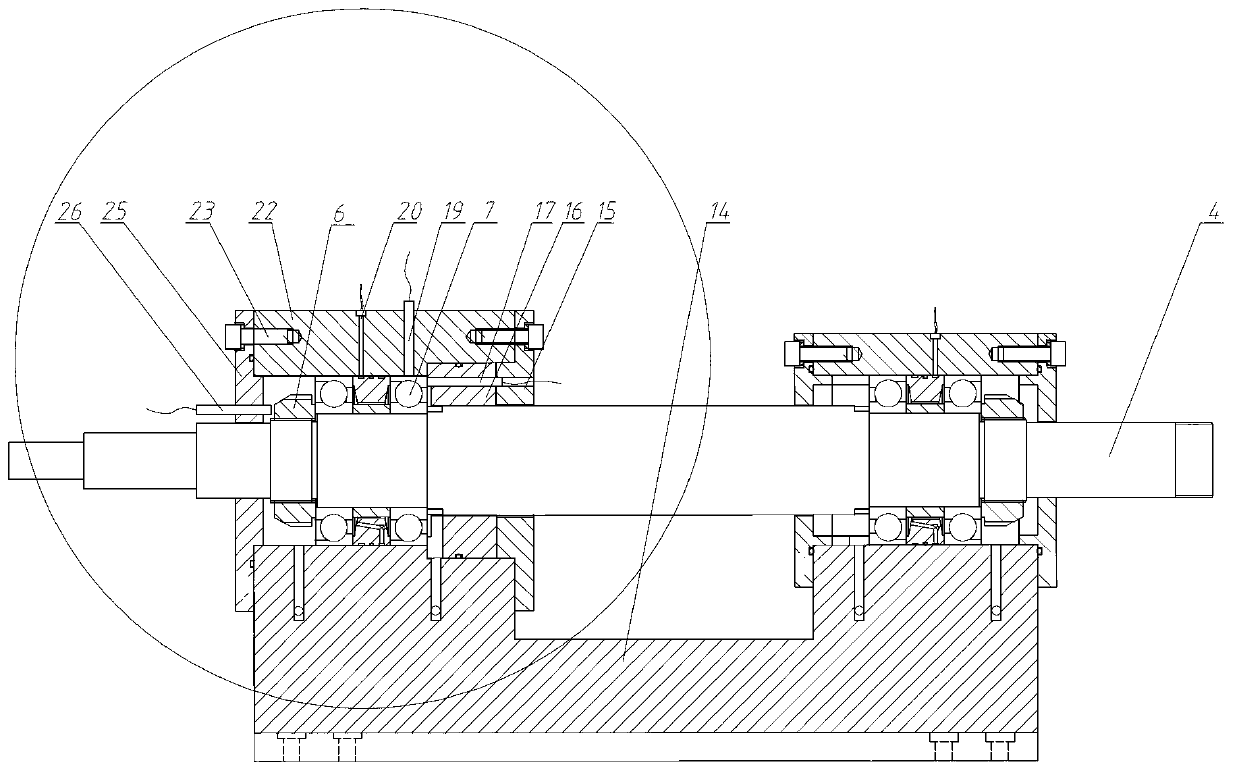

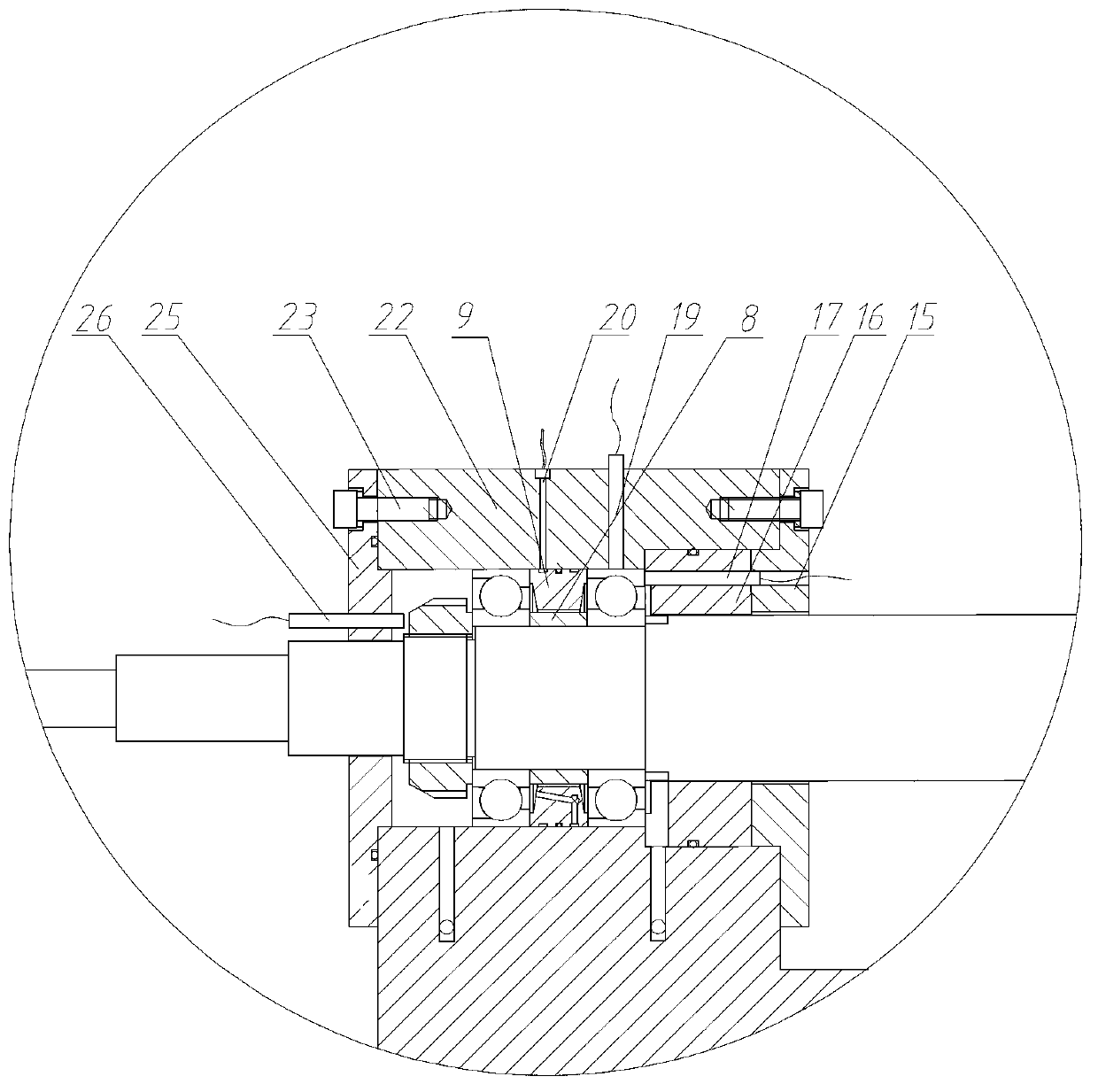

[0031] The invention provides a comprehensive experimental platform for testing the dynamic and static performance of the spindle system with strong versatility, and its structure refers to figure 1 , including: driving electric spindle module 1, mechanical spindle module 2, hydraulic loading module 3; the structure of mechanical spindle module 2 refers to figure 2 : The main shaft 4 is installed on the bearing seat 14, and the second stage of the main shaft is installed with angular contact ball bearings 7, inner rings 8, and lubricating oil rings 9 in sequence, and the two bearings are installed in series (there is a The lubricating oil ring is used to provide lubricating oil for the bearing), and is fastened on the main shaft 4 through the lock nut 6. Please see in particular image 3 As shown, specifically, the test bench includes a main shaft 4, a be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com