500KV extra-high voltage power cable with real-time temperature detection function

A real-time temperature, power cable technology, applied to power cables with shielding/conductive layers, power cables, thermometers, etc., can solve the problems of long repair time, unpredictable consequences, and large losses

Inactive Publication Date: 2011-06-15

WUXI GREAT WALL ELECTRIC WIRE & CABLE

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since the cables are often laid in a centralized manner, once a fire occurs, it will have a wide range of influence, long repair time, and great losses

Especially for 500KV UHV power cables, once a fire occurs, the consequences are unpredictable

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

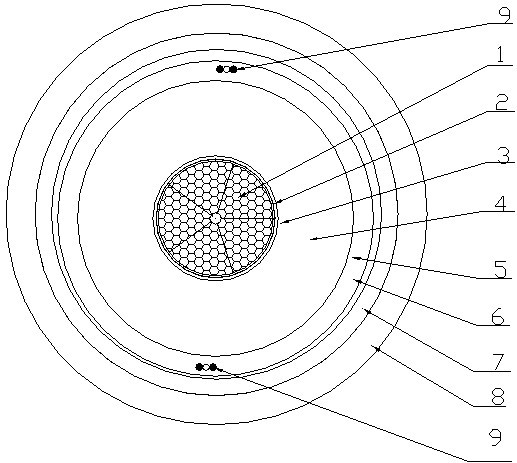

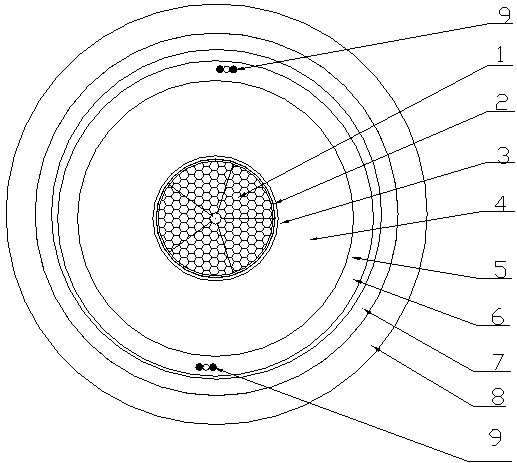

The invention discloses a 500KV extra-high voltage power cable with a real-time temperature detection function, which comprises a conductor positioned in the center of the cable. A semiconductive tape, a conductor shielding layer, an insulating layer, an insulating shielding layer, a semiconductive water-blocking expansion buffer layer, a corrugated aluminum sheath and a nonmetallic sheath are sequentially arranged outside the conductor. A temperature detection optical fiber is arranged in the insulating shielding layer along the axial direction of the cable, and is connected with a switch cabinet temperature monitoring and early warning system. The 500KV extra-high voltage power cable with the real-time temperature detection function can monitor the temperature variations of long-distance cables in real time and accurately monitor the temperature conditions of high voltage switch contacts so as to realize point and line combination and comprehensive monitoring, and simultaneously can timely transmit fire alarming information to a fire alarming controller to realize gang control.

Description

A 500KV UHV power cable with real-time temperature detection function technical field The invention relates to a power cable, especially a 500KV ultra-high voltage power cable. Background technique With the rapid development of my country's economy, new situations continue to emerge in terms of safety production. Some frequent accidents still occur from time to time, and some have become more and more prominent. Fire accidents and power outages caused by cables on fire Accidents account for a large proportion of them. A large number of power cables and control cables are laid in the power plant and connected to the high-voltage switchgear. These cables are distributed in cable tunnels, cable bridges, and cable interlayers, and are respectively connected to various electrical equipment and connected to the control room. After a cable fire accident, it is extremely harmful. Since the cables are often laid in a centralized manner, once a fire occurs, it will have a wide ra...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01B9/00H01B9/02G01K11/32

Inventor 张蕴皋王春朱向辉

Owner WUXI GREAT WALL ELECTRIC WIRE & CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com