Novel dry-wet combined water-saving cooling tower and using method thereof

A water-saving cooling tower technology, applied in the direction of water shower coolers, heat exchanger types, heat exchange equipment, etc., can solve the problems of large amount of finned tubes, low convective heat transfer coefficient, loss of metal resources, etc., to achieve Low spray stop temperature, reduced cooling water consumption, no evaporation loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

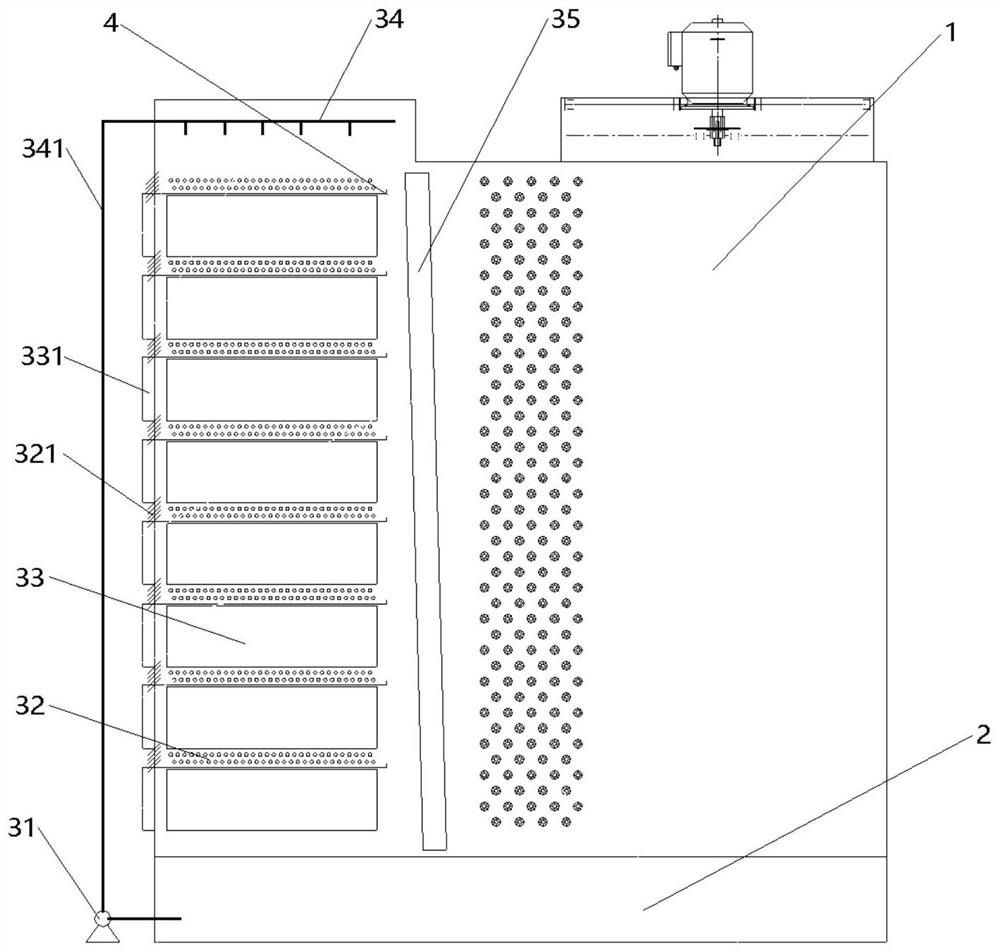

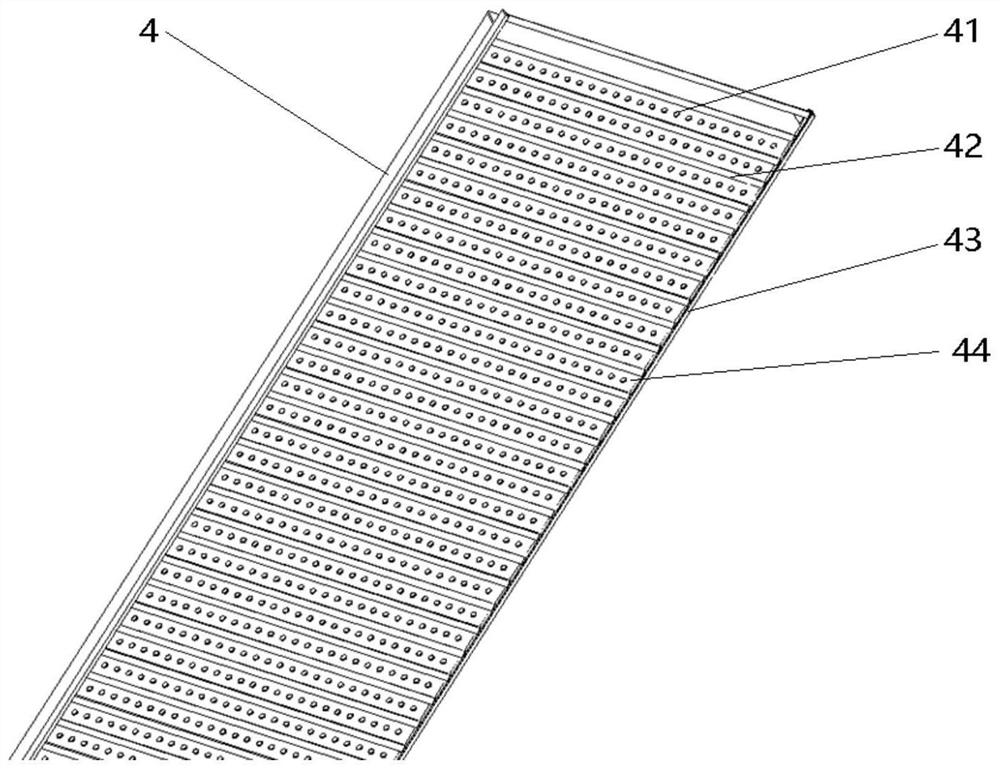

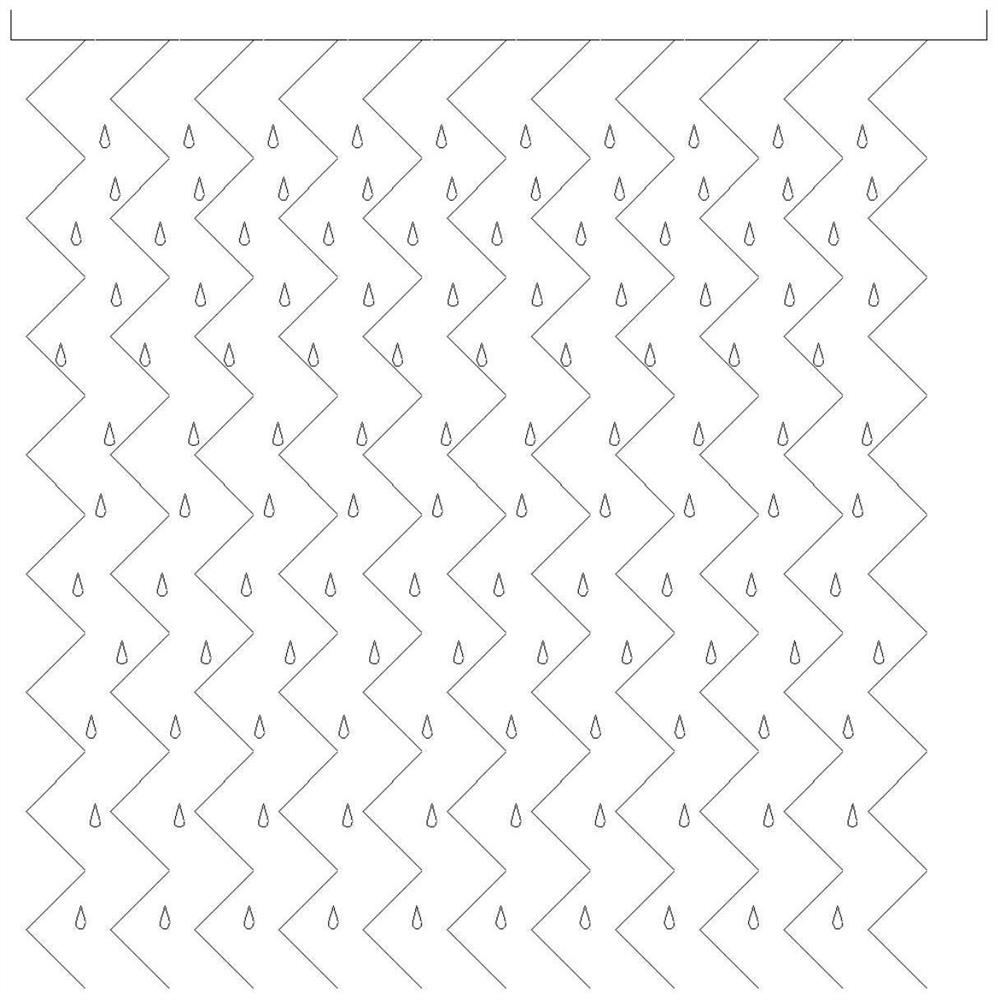

[0023] as attached Figure 1-4 : a new type of dry-wet combined water-saving cooling tower, comprising a wet-cooling section cooling module and a dry-cooling section cooling module 1, the wet-cooling section cooling module and the dry-cooling section cooling module 1 are arranged horizontally, and the air outlet end of the wet-cooling section cooling module Corresponding to the intake end of the dry cooling section cooling module 1, the wet cooling section cooling module and the dry cooling section cooling module 1 are provided with a sump 2 at the bottom; the wet cooling section cooling module includes a spray pump 31, a wet cooling section cooler 32, a filler 33. Nozzle 34 and water collecting structure 35; a plurality of said wet-cooling section coolers 32 are stacked in the height direction, and said filler 33 fills the gap between two adjacent wet-cooling section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com